run flat Ram ProMaster 2020 Owner's Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2020, Model line: ProMaster, Model: Ram ProMaster 2020Pages: 264, PDF Size: 10.11 MB

Page 52 of 264

50GETTING TO KNOW YOUR INSTRUMENT PANEL

Yellow Warning Lights

Immobilizer Fail / VPS Electrical Alarm Indicator

Light

This telltale will illuminate when the

vehicle security alarm system has

detected an attempt to break into the

vehicle.

NOTE:

After cycling the ignition to the ON/RUN posi -

tion, the Vehicle Security Warning Light could

illuminate if a problem with the system is

detected. This condition will result in the engine

being shut off after two seconds.

Tire Pressure Monitoring System (TPMS) Warning

Light

The warning light switches on and a

message is displayed to indicate that

the tire pressure is lower than the

recommended value and/or that slow

pressure loss is occurring. In these cases,

optimal tire duration and fuel consumption may

not be guaranteed.

Should one or more tires be in the condition

mentioned above, the display will show the indi -

cations corresponding to each tire. Each tire, including the spare (if provided),

should be checked monthly when cold and

inflated to the inflation pressure recommended

by the vehicle manufacturer on the vehicle

placard or tire inflation pressure label. If your

vehicle has tires of a different size than the size

indicated on the vehicle placard or tire inflation

pressure label, you should determine the

proper tire inflation pressure for those tires.

As an added safety feature, your vehicle has

been equipped with a Tire Pressure Monitoring

System (TPMS) that illuminates a low tire pres

-

sure telltale when one or more of your tires is

significantly under-inflated. Accordingly, when

the low tire pressure telltale illuminates, you

should stop and check your tires as soon as possible, and inflate them to the proper pres

-

sure. Driving on a significantly under-inflated

tire causes the tire to overheat and can lead to

tire failure. Under-inflation also reduces fuel

efficiency and tire tread life, and may affect the

vehicle’s handling and stopping ability.

Please note that the TPMS is not a substitute for

proper tire maintenance, and it is the driver’s

responsibility to maintain correct tire pressure,

even if under-inflation has not reached the level

to trigger illumination of the TPMS low tire pres -

sure telltale.

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate when

the system is not operating properly. The TPMS

malfunction indicator is combined with the low

tire pressure telltale. When the system detects

a malfunction, the telltale will flash for approxi -

mately one minute and then remain continu -

ously illuminated. This sequence will continue

upon subsequent vehicle start-ups as long as

the malfunction exists. When the malfunction

indicator is illuminated, the system may not be

able to detect or signal low tire pressure as

intended. TPMS malfunctions may occur for a

variety of reasons, including the installation of

CAUTION!

Do not continue driving with one or more flat

tires as handling may be compromised. Stop

the vehicle, avoiding sharp braking and

steering. If a tire puncture occurs, repair

immediately using the dedicated tire repair

kit and contact an authorized dealer as soon

as possible.

20_VF_OM_EN_US_t.book Page 50

Page 68 of 264

66SAFETY

Seat Belt Systems

Buckle up even though you are an excellent

driver, even on short trips. Someone on the road

may be a poor driver and could cause a collision

that includes you. This can happen far away

from home or on your own street.

Research has shown that seat belts save lives,

and they can reduce the seriousness of injuries

in a collision. Some of the worst injuries happen

when people are thrown from the vehicle. Seat

belts reduce the possibility of ejection and the

risk of injury caused by striking the inside of the

vehicle. Everyone in a motor vehicle should be

belted at all times.

Enhanced Seat Belt Use Reminder System

(BeltAlert)

Driver and Passenger BeltAlert — If Equipped

BeltAlert is a feature intended to remind

the driver and outboard front seat passenger

(if equipped with outboard front passenger

seat BeltAlert) to buckle their seat belts. The

BeltAlert feature is active whenever the igni -

tion switch is in the AVV/START or MAR/RUN

position. Initial Indication

If the driver is unbuckled when the ignition

switch is first in the AVV/START or MAR/RUN

position, a chime will signal for a few seconds. If

the driver or outboard front seat passenger (if

equipped with outboard front passenger seat

BeltAlert) is unbuckled when the ignition switch

is first in the AVV/START or MAR/RUN position

the Seat Belt Reminder Light will turn on and

remain on until both outboard front seat belts

are buckled. The outboard front passenger seat

BeltAlert is not active when an outboard front

passenger seat is unoccupied.

BeltAlert Warning Sequence

The BeltAlert warning sequence is activated

when the vehicle is moving above a specified

vehicle speed range and the driver or outboard

front seat passenger is unbuckled (if equipped

with outboard front passenger seat BeltAlert)

(the outboard front passenger seat BeltAlert is

not active when the outboard front passenger

seat is unoccupied). The BeltAlert warning

sequence starts by blinking the Seat Belt

Reminder Light and sounding an intermittent

chime. Once the BeltAlert warning sequence

has completed, the Seat Belt Reminder Light will remain on until the seat belts are buckled.

The BeltAlert warning sequence may repeat

based on vehicle speed until the driver and

occupied outboard front seat passenger seat

belts are buckled. The driver should instruct all

occupants to buckle their seat belts.

Change of Status

If the driver or outboard front seat passenger (if

equipped with outboard front passenger seat

BeltAlert) unbuckles their seat belt while the

vehicle is traveling, the BeltAlert warning

sequence will begin until the seat belts are

buckled again.

The outboard front passenger seat BeltAlert is

not active when the outboard front passenger

seat is unoccupied. BeltAlert may be triggered

when an animal or other items are placed on

the outboard front passenger seat or when the

seat is folded flat (if equipped). It is recom

-

mended that pets be restrained in the rear seat

(if equipped) in pet harnesses or pet carriers

that are secured by seat belts, and cargo is

properly stowed.

BeltAlert can be activated or deactivated by an

authorized dealer. FCA US LLC does not recom -

mend deactivating BeltAlert.

20_VF_OM_EN_US_t.book Page 66

Page 75 of 264

SAFETY73

(Continued)

How To Engage The Automatic Locking Mode

1. Buckle the combination lap and shoulder

belt.

2. Grasp the shoulder portion and pull down -

ward until the entire seat belt is extracted.

3. Allow the seat belt to retract. As the seat belt retracts, you will hear a clicking sound.

This indicates the seat belt is now in the

Automatic Locking Mode.

How To Disengage The Automatic Locking Mode

Unbuckle the combination lap/shoulder belt

and allow it to retract completely to disengage

the Automatic Locking Mode and activate the

vehicle sensitive (emergency) locking mode.

Supplemental Restraint Systems (SRS)

Some of the safety features described in this

section may be standard equipment on some

models, or may be optional equipment on

others. If you are not sure, ask an authorized

dealer.

The air bag system must be ready to protect you

in a collision. The Occupant Restraint Controller

(ORC) monitors the internal circuits and inter -

connecting wiring associated with the electrical

Air Bag System Components. Your vehicle may

be equipped with the following Air Bag System

Components:

Air Bag System Components

Occupant Restraint Controller (ORC)

Air Bag Warning Light

Steering Wheel and Column

Instrument Panel

Driver and Front Passenger Air Bags

Seat Belt Buckle Switch

Supplemental Side Air Bags

Front and Side Impact Sensors

Seat Belt Pretensioners

Air Bag Warning Light

The Occupant Restraint Controller

(ORC) monitors the readiness of the

electronic parts of the air bag system

whenever the ignition switch is in the

AVV/START or MAR/ACC/ON/RUN position. If

the ignition switch is in the STOP/OFF/LOCK

position the air bag system is not on and the air

bags will not inflate.WARNING!

The seat belt assembly must be replaced if

the switchable Automatic Locking Retractor

(ALR) feature or any other seat belt function

is not working properly when checked

according to the procedures in the Service

Manual.

Failure to replace the seat belt assembly

could increase the risk of injury in colli -

sions.

Do not use the Automatic Locking Mode to

restrain occupants who are wearing the

seat belt or children who are using booster

seats. The locked mode is only used to

install rear-facing or forward-facing child

restraints that have a harness for

restraining the child.

WARNING!

(Continued)

4

20_VF_OM_EN_US_t.book Page 73

Page 76 of 264

74SAFETY

The ORC contains a backup power supply

system that may deploy the air bag system even

if the battery loses power or it becomes discon -

nected prior to deployment.

The ORC turns on the Air Bag Warning Light in

the instrument panel for approximately four to

eight seconds for a self-check when the ignition

switch is in the MAR/ACC/ON/RUN position.

After the self-check, the Air Bag Warning Light

will turn off. If the ORC detects a malfunction in

any part of the system, it turns on the Air Bag

Warning Light, either momentarily or continu -

ously. A single chime will sound to alert you if

the light comes on again after initial startup.

The ORC also includes diagnostics that will illu-

minate the instrument panel Air Bag Warning

Light if a malfunction is detected that could

affect the air bag system. The diagnostics also

record the nature of the malfunction. While the

air bag system is designed to be maintenance

free, if any of the following occurs, have an

authorized dealer service the air bag system

immediately.The Air Bag Warning Light does not come on

during the four to eight seconds when the

ignition switch is first in the MAR/ACC/ON/

RUN position.

The Air Bag Warning Light remains on after

the four to eight-second interval.

The Air Bag Warning Light comes on intermit -

tently or remains on while driving.

NOTE:

If the speedometer, tachometer, or any engine

related gauges are not working, the Occupant

Restraint Controller (ORC) may also be

disabled. In this condition the air bags may not

be ready to inflate for your protection. Have an

authorized dealer service the air bag system

immediately.

Front Air Bags

This vehicle has front air bags and lap/shoulder

belts for both the driver and front passenger.

The front air bags are a supplement to the seat

belt restraint systems. The driver front air bag is

mounted in the center of the steering wheel.

The passenger front air bag is mounted in the

instrument panel, above the glove compart -

ment. The words “SRS AIRBAG” or “AIRBAG” are

embossed on the air bag covers.

Front Air Bag Locations

WARNING!

Ignoring the Air Bag Warning Light in your

instrument panel could mean you won’t have

the air bag system to protect you in a

collision. If the light does not come on as a

bulb check when the ignition is first turned

on, stays on after you start the vehicle, or if it

comes on as you drive, have an authorized

dealer service the air bag system

immediately.

1 — Driver Front Air Bag

2 — Passenger Front Air Bag

20_VF_OM_EN_US_t.book Page 74

Page 93 of 264

SAFETY91

(Continued)

Periodic Safety Checks You Should Make

Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones, nails,

glass, or other objects lodged in the tread or

sidewall. Inspect the tread for cuts and cracks.

Inspect sidewalls for cuts, cracks, and bulges.

Check the wheel bolts for tightness. Check the

tires (including spare) for proper cold inflation

pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam indi -

cator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under the vehicle after overnight

parking for fuel, coolant, oil, or other fluid leaks.

Also, if gasoline fumes are detected or if fuel, or

brake fluid leaks are suspected, the cause

should be located and corrected immediately.

ONLY install floor mats designed to fit your

vehicle. NEVER install a floor mat that

cannot be properly attached and secured to

your vehicle. If a floor mat needs to be

replaced, only use a FCA approved floor

mat for the specific make, model, and year

of your vehicle.

ONLY use the driver’s side floor mat on the

driver’s side floor area. To check for inter -

ference, with the vehicle properly parked

with the engine off, fully depress the accel -

erator, the brake, and the clutch pedal (if

present) to check for interference. If your

floor mat interferes with the operation of

any pedal, or is not secure to the floor,

remove the floor mat from the vehicle and

place the floor mat in your trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

WARNING!

(Continued)

ALWAYS make sure objects cannot fall or

slide into the driver’s side floor area when

the vehicle is moving. Objects can become

trapped under accelerator, brake, or clutch

pedals and could cause a loss of vehicle

control.

NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These objects

could change the position of the floor mat

and may cause interference with the accel -

erator, brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet

to the floor and check the floor mat

fasteners are secure to the vehicle carpet.

Fully depress each pedal to check for inter -

ference with the accelerator, brake, or

clutch pedals then re-install the floor mats.

It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat has

been properly installed and is secured to

your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING!

(Continued)

4

20_VF_OM_EN_US_t.book Page 91

Page 123 of 264

STARTING AND OPERATING121

DRIVING TIPS

Driving On Slippery Surfaces

Acceleration

Rapid acceleration on snow covered, wet, or

other slippery surfaces may cause the driving

wheels to pull erratically to the right or left. This

phenomenon occurs when there is a difference

in the surface traction under the front (driving)

wheels.

Traction

When driving on wet or slushy roads, it is

possible for a wedge of water to build up

between the tire and road surface. This is hydro -

planing and may cause partial or complete loss

of vehicle control and stopping ability. To

reduce this possibility, the following precau -

tions should be observed:

Slow down during rainstorms or when the

roads are slushy.

Slow down if the road has standing water or

puddles.

Replace the tires when tread wear indicators

first become visible.

Keep tires properly inflated.

Maintain sufficient distance between your

vehicle and the vehicle in front of you to avoid

a collision in a sudden stop.

Driving Through Water

Driving through water more than a few inches/

centimeters deep will require extra caution to

ensure safety and prevent damage to your

vehicle.

Flowing/Rising Water

WARNING!

Rapid acceleration on slippery surfaces is

dangerous. Unequal traction can cause

sudden pulling of the front wheels. You could

lose control of the vehicle and possibly have a

collision. Accelerate slowly and carefully

whenever there is likely to be poor traction

(ice, snow, wet, mud, loose sand, etc.).

WARNING!

Do not drive on or across a road or path

where water is flowing and/or rising (as in

storm run-off). Flowing water can wear away

the road or path's surface and cause your

vehicle to sink into deeper water.

Furthermore, flowing and/or rising water can

carry your vehicle away swiftly. Failure to

follow this warning may result in injuries that

are serious or fatal to you, your passengers,

and others around you.

5

20_VF_OM_EN_US_t.book Page 121

Page 138 of 264

136IN CASE OF EMERGENCY

(Continued)

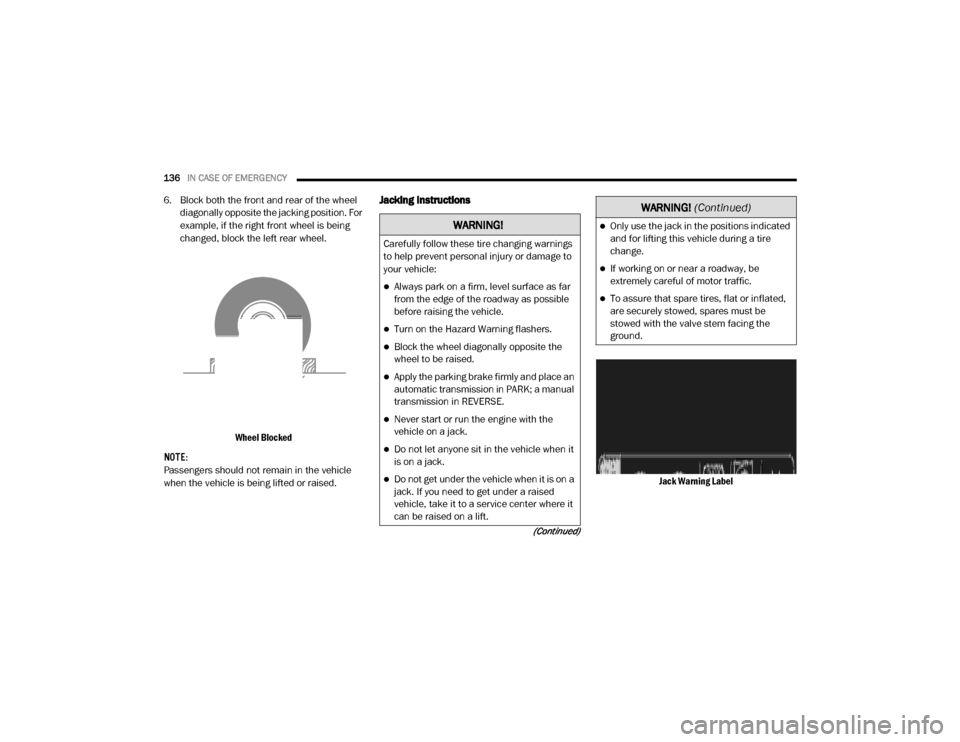

6. Block both the front and rear of the wheel

diagonally opposite the jacking position. For

example, if the right front wheel is being

changed, block the left rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being lifted or raised.Jacking Instructions

Jack Warning Label

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning flashers.

Block the wheel diagonally opposite the

wheel to be raised.

Apply the parking brake firmly and place an

automatic transmission in PARK; a manual

transmission in REVERSE.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when it

is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.

WARNING!

(Continued)

20_VF_OM_EN_US_t.book Page 136

Page 144 of 264

142IN CASE OF EMERGENCY

Sealing A Tire With Tire Service Kit

(A) Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the

vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near

to the ground. This will allow the Tire Service

Kit Hoses (3) and (5) to reach the valve

stem and keep the Tire Service Kit flat on

the ground. This will provide the best posi -

tioning of the kit when injecting the sealant

into the deflated tire and running the air

pump. Move the vehicle as necessary to

place the valve stem in this position before

proceeding.

3. Place the transmission in PARK (P) (auto transmission) or in Gear (manual transmis -

sion) and place the ignition in the OFF posi -

tion.

4. Apply the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob (2) and turn to the Sealant Mode position. 2. Uncoil the Sealant Hose (3) and then

remove the cap from the fitting at the end of

the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose (3) onto the valve stem.

5. Uncoil the Power Plug (7) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:

Do not remove foreign objects (e.g., screws or

nails) from the tire.

(C) Injecting Tire Service Kit Sealant Into The

Deflated Tire:

Always start the engine before turning ON the

Tire Service Kit.

NOTE:

Manual transmission vehicles must have the

parking brake engaged and the gear selector in

NEUTRAL.

After pushing the Power Button (1), the

sealant (white fluid) will flow from the Sealant

Bottle (4) through the Sealant Hose (3) and

into the tire. NOTE:

Sealant may leak out through the puncture in

the tire.

If the sealant (white fluid) does not flow within 0

– 10 seconds through the Sealant Hose (3):

1. Push the Power Button (1) to turn Off the

Tire Service Kit. Disconnect the Sealant

Hose (3) from the valve stem. Make sure

the valve stem is free of debris. Reconnect

the Sealant Hose (3) to the valve stem.

Check that the Mode Select Knob (2) is in

the Sealant Mode position and not Air

Mode. Push the Power Button (1) to turn On

the Tire Service Kit.

2. Connect the Power Plug (7) to a different 12 Volt power outlet in your vehicle or another

vehicle, if available. Make sure the engine is

running before turning ON the Tire Service

Kit.

3. The Sealant Bottle (4) may be empty due to previous use. Call for assistance.

NOTE:

If the Mode Select Knob (2) is on Air Mode and

the pump is operating, air will dispense from the

Air Pump Hose (5) only, not the Sealant Hose

(3).

20_VF_OM_EN_US_t.book Page 142

Page 152 of 264

150IN CASE OF EMERGENCY

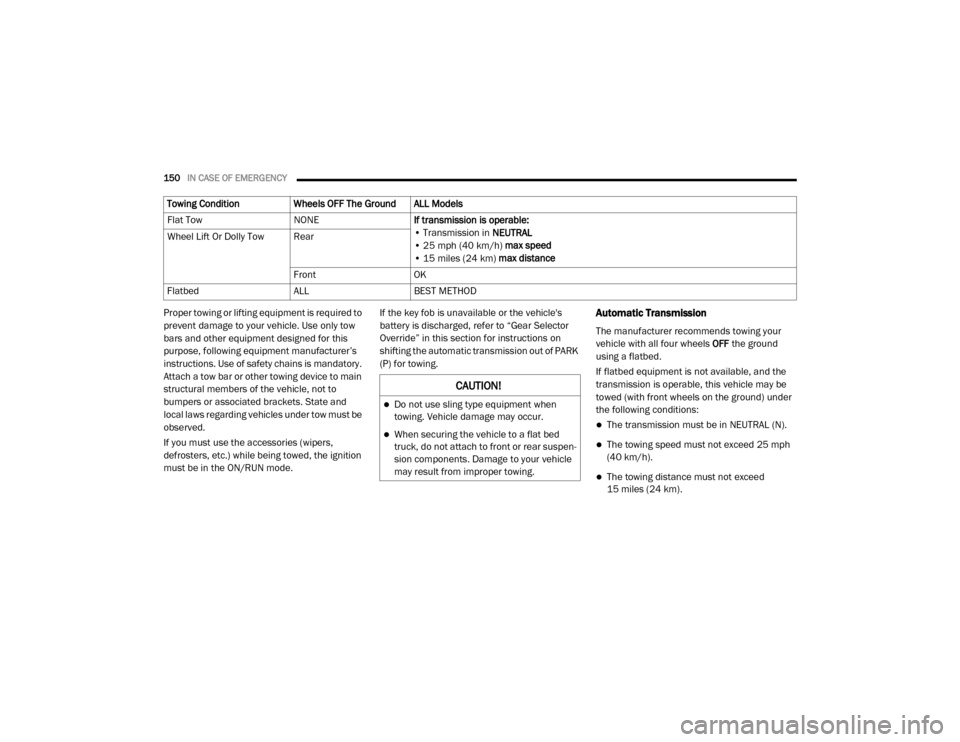

Proper towing or lifting equipment is required to

prevent damage to your vehicle. Use only tow

bars and other equipment designed for this

purpose, following equipment manufacturer’s

instructions. Use of safety chains is mandatory.

Attach a tow bar or other towing device to main

structural members of the vehicle, not to

bumpers or associated brackets. State and

local laws regarding vehicles under tow must be

observed.

If you must use the accessories (wipers,

defrosters, etc.) while being towed, the ignition

must be in the ON/RUN mode. If the key fob is unavailable or the vehicle's

battery is discharged, refer to “Gear Selector

Override” in this section for instructions on

shifting the automatic transmission out of PARK

(P) for towing.Automatic Transmission

The manufacturer recommends towing your

vehicle with all four wheels

OFF the ground

using a flatbed.

If flatbed equipment is not available, and the

transmission is operable, this vehicle may be

towed (with front wheels on the ground) under

the following conditions:

The transmission must be in NEUTRAL (N).

The towing speed must not exceed 25 mph

(40 km/h).

The towing distance must not exceed

15 miles (24 km).

Towing Condition

Wheels OFF The Ground ALL Models

Flat Tow NONEIf transmission is operable:

• Transmission in NEUTRAL

• 25 mph (40 km/h) max speed

• 15 miles (24 km) max distance

Wheel Lift Or Dolly Tow Rear

FrontOK

Flatbed ALLBEST METHOD

CAUTION!

Do not use sling type equipment when

towing. Vehicle damage may occur.

When securing the vehicle to a flat bed

truck, do not attach to front or rear suspen -

sion components. Damage to your vehicle

may result from improper towing.

20_VF_OM_EN_US_t.book Page 150

Page 154 of 264

152

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indi-

cator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate in the

instrument cluster. This means that service is

required for your vehicle. Operating conditions

such as frequent short-trips, trailer tow, and

extremely hot or cold ambient temperatures will

influence when the “Oil Change Required”

message is displayed. Severe Operating Condi-

tions can cause the change oil message to illu -

minate as early as 3,500 miles (5,600 km)

since last reset. Have the vehicle serviced as

soon as possible, within the next 500 miles

(805 km). An authorized dealer will reset the oil change

indicator message after completing the sched

-

uled oil change. If a scheduled oil change is

performed by someone other than an autho -

rized dealer, the message can be reset by refer -

ring to the steps described under “Instrument

Cluster Display” in “Getting To Know Your

Instrument Panel” for further information.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominately at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty. Once A Month Or Before A Long Trip:Check engine oil level

Check windshield washer fluid level

Check the tire inflation pressures and look

for unusual wear or damage. Rotate at the

first sign of irregular wear, even if it occurs

before the oil indicator system turns on

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering

and fill as needed

Check function of all interior and exterior

lights

Maintenance Plan

Required Maintenance Intervals

Refer to the maintenance plan on the following

pages for the required maintenance intervals.

20_VF_OM_EN_US_t.book Page 152