Ram ProMaster City 2020 Owner's Manual

Manufacturer: RAM, Model Year: 2020, Model line: ProMaster City, Model: Ram ProMaster City 2020Pages: 350, PDF Size: 13.27 MB

Page 261 of 350

258 SERVICING AND MAINTENANCE

The image on the coolant system pressure cap is a

reminder that the radiator contains hot engine

coolant under pressure.

Disposal Of Used Coolant

Used ethylene glycol-based coolant (antifreeze) is a regu-

lated substance requiring proper disposal. Check with your

local authorities to determine the disposal rules for your

community. To prevent ingestion by animals or children, do

not store ethylene glycol-based coolant in open containers or

allow it to remain in puddles on the ground. If ingested by a

child or pet, seek emergency assistance immediately. Clean

up any ground spills immediately. Coolant Level

The coolant expansion bottle provides a quick visual method

for determining that the coolant level is adequate. With the

engine OFF and cold, the level of the engine coolant (anti

-

freeze) in the bottle should be between the “MIN” and

“MAX” marks.

The radiator normally remains completely full, so there is no

need to remove the radiator/coolant pressure cap unless

checking for engine coolant (antifreeze) freeze point or

replacing coolant. Advise your service attendant of this. As

long as the engine operating temperature is satisfactory, the

coolant bottle need only be checked once a month.

When additional engine coolant (antifreeze) is needed to

maintain the proper level, only OAT coolant that meets the

requirements of FCA Material Standard MS.90032 should be

added to the coolant bottle. Do not overfill.

WARNING!

• Do not open hot engine cooling system. Never add engine coolant (antifreeze) when the engine is over -

heated. Do not loosen or remove the cap to cool an over -

heated engine. Heat causes pressure to build up in the

cooling system. To prevent scalding or injury, do not

remove the pressure cap while the system is hot or

under pressure.

• Do not use a pressure cap other than the one specified for your vehicle. Personal injury or engine damage may

result.

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 258

Page 262 of 350

SERVICING AND MAINTENANCE 259

Points To Remember

NOTE:

When the vehicle is stopped after a few miles/kilometers of

operation, you may observe vapor coming from the front of

the engine compartment. This is normally a result of mois-

ture from rain, snow, or high humidity accumulating on the

radiator and being vaporized when the thermostat opens,

allowing hot engine coolant (antifreeze) to enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be safely

driven. The vapor will soon dissipate.

• Do not overfill the coolant expansion bottle.

• Check the coolant freeze point in the radiator and in the coolant expansion bottle. If engine coolant (antifreeze)

needs to be added, the contents of the coolant expansion

bottle must also be protected against freezing.

• If frequent engine coolant (antifreeze) additions are required, the cooling system should be pressure tested for

leaks. • Maintain engine coolant (antifreeze) concentration at a

minimum of 50% OAT coolant (conforming to MS.90032)

and distilled water for proper corrosion protection of your

engine which contains aluminum components.

• Make sure that the coolant expansion bottle overflow hoses are not kinked or obstructed.

• Keep the front of the radiator clean. If your vehicle is equipped with air conditioning, keep the front of the

condenser clean.

• Do not change the thermostat for Summer or Winter oper -

ation. If replacement is ever necessary, install ONLY the

correct type thermostat. Other designs may result in unsat -

isfactory engine coolant (antifreeze) performance, poor

gas mileage, and increased emissions.

7

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 259

Page 263 of 350

260 SERVICING AND MAINTENANCE

(Continued)

Brake System

In order to ensure brake system performance, all brake

system components should be inspected periodically. Refer

to the “Maintenance Plan” in this section for the proper

maintenance intervals.

Brake Master Cylinder

The fluid in the master cylinder should be checked when

performing under hood services or immediately if the

“Brake Warning Light” is illuminated.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the fluid

level up to the requirements described on the brake fluid

reservoir. With disc brakes, fluid level can be expected to fallas the brake pads wear. Brake fluid level should be checked

when pads are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.

Use only manufacturer's recommended brake fluid. Refer to

“Fluids And Lubricants” in “Technical Specifications” for

further information.

WARNING!

Riding the brakes can lead to brake failure and possibly

a collision. Driving with your foot resting or riding on

the brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible brake

damage. You would not have your full braking capacity

in an emergency.

WARNING!

• Use only manufacturer's recommended brake fluid. Refer to “Fluids And Lubricants” in “Technical Speci -

fications” for further information. Using the wrong

type of brake fluid can severely damage your brake

system and/or impair its performance. The proper type

of brake fluid for your vehicle is also identified on the

original factory installed hydraulic master cylinder

reservoir.

• To avoid contamination from foreign matter or mois -

ture, use only new brake fluid or fluid that has been in

a tightly closed container. Keep the master cylinder

reservoir cap secured at all times. Brake fluid in a open

container absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil unexpect -

edly during hard or prolonged braking, resulting in

sudden brake failure. This could result in a collision.

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 260

Page 264 of 350

SERVICING AND MAINTENANCE 261

Power Steering Fluid

Check the fluid level with the vehicle on flat ground and

engine cold. Fluid should be between MIN and MAX refer-

ences on the reservoir body.

The level may go over the MAX line when oil is hot.

If topping off is required, make sure the oil you use is

approved. Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information. NOTE:

Power steering fluid consumption is very low. If you need to

top off your fluid often and multiple times, have your system

inspected by an authorized dealer.

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission fluid to ensure

optimum transmission performance and life. Use only the

manufacturer's specified transmission fluid. Refer to “Fluids

And Lubricants” in “Technical Specifications” for fluid spec

-

ifications. It is important to maintain the transmission fluid

at the correct level using the recommended fluid.

NOTE:

No chemical flushes should be used in any transmission;

only the approved lubricant should be used.

• Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

• Do not allow petroleum based fluid to contaminate the brake fluid. Brake seal components could be damaged,

causing partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)WARNING!

Because it is flammable, do not allow the power steering

fluid to come into contact with hot engine parts

7

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 261

Page 265 of 350

262 SERVICING AND MAINTENANCE

Special Additives

The manufacturer strongly recommends against using any

special additives in the transmission. Automatic Transmis-

sion Fluid (ATF) is an engineered product and its perfor -

mance may be impaired by supplemental additives.

Therefore, do not add any fluid additives to the transmis -

sion. Avoid using transmission sealers as they may

adversely affect seals. Fluid Level Check

The fluid level is preset at the factory and does not require

adjustment under normal operating conditions. Routine

fluid level checks are not required; therefore the transmis

-

sion has no dipstick. An authorized dealer can check your

transmission fluid level using special service tools. If you

notice fluid leakage or transmission malfunction, visit an

authorized dealer immediately to have the transmission

fluid level checked. Operating the vehicle with an improper

fluid level can cause severe transmission damage.

CAUTION!

Using a transmission fluid other than the manufacturer’s

recommended fluid may cause deterioration in

transmission shift quality and/or torque converter

shudder. Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

CAUTION!

Do not use chemical flushes in your transmission as the

chemicals can damage your transmission components.

Such damage is not covered by the New Vehicle Limited

Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an authorized

dealer immediately. Severe transmission damage may

occur. An authorized dealer has the proper tools to adjust

the fluid level accurately.

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 262

Page 266 of 350

SERVICING AND MAINTENANCE 263

Fluid And Filter Changes

Under normal operating conditions, the fluid installed at the

factory will provide satisfactory lubrication for the life of the

vehicle.

Routine fluid and filter changes are not required. However,

change the fluid and filter if the fluid becomes contaminated

(with water, etc.), or if the transmission is disassembled for

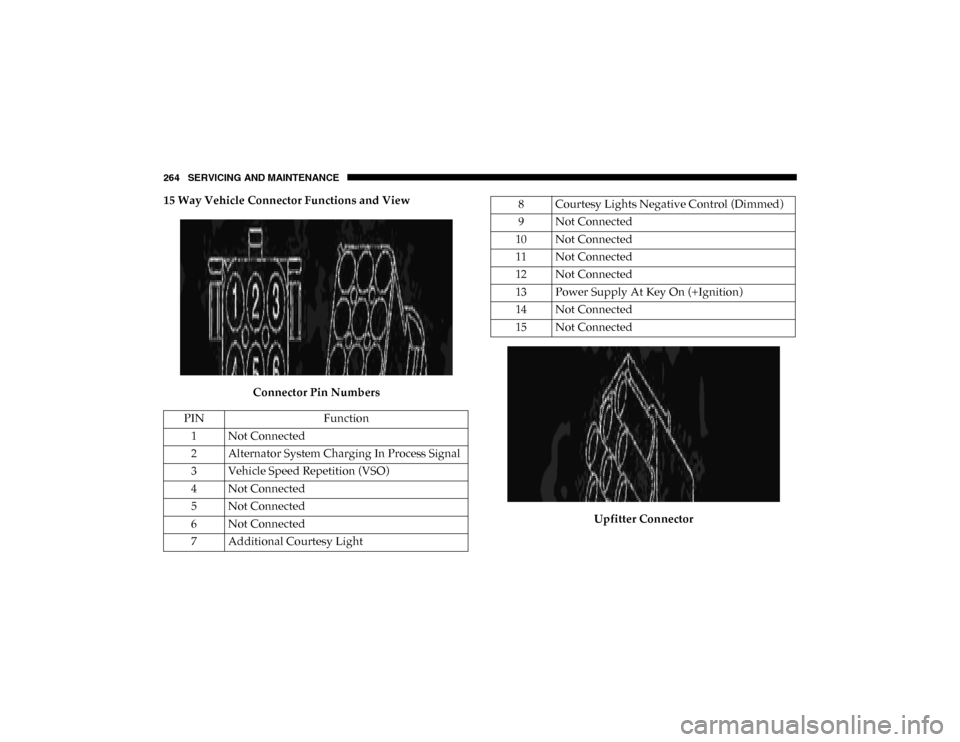

any reason.Upfitter Connectors — If Equipped

The preparation connectors are to be only used by upfitters .

This connector is located under the dashConnector Location

7

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 263

Page 267 of 350

264 SERVICING AND MAINTENANCE

15 Way Vehicle Connector Functions and ViewConnector Pin Numbers Upfitter Connector

PIN

Function

1 Not Connected

2 Alternator System Charging In Process Signal

3 Vehicle Speed Repetition (VSO) 4 Not Connected

5 Not Connected

6 Not Connected

7 Additional Courtesy Light8 Courtesy Lights Negative Control (Dimmed)

9 Not Connected

10 Not Connected

11 Not Connected

12 Not Connected

13 Power Supply At Key On (+Ignition) 14 Not Connected

15 Not Connected

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 264

Page 268 of 350

SERVICING AND MAINTENANCE 265

This connector is supplied to the upfitter when the vehicle is

ordered with the applicable package.

2 Way Vehicle Connector Functions and ViewConnector Pins Upfitter Connector

This connector is supplied to the upfitter when the vehicle is

ordered with the applicable package.

For additional questions about these connectors as well as

general technical questions about upfitting your Ram

product, refer to https://www.ramtrucks.com/

ram-commercial/body-builders-guide.html/ or call 1

(866)-205-4102.

PIN

Function

A Power Supply B GND

CAUTION!

The maximum current load allowed is 15 amps for

continuous use.

7

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 265

Page 269 of 350

266 SERVICING AND MAINTENANCE

RAISING THE VEHICLE

In the case where it is necessary to raise the vehicle, go to an

authorized dealer or service station.

TIRES

Tire Safety Information

Tire safety information will cover aspects of the following

information: Tire Markings, Tire Identification Numbers,

Tire Terminology and Definitions, Tire Pressures, and Tire

Loading.Tire Markings

Tire Markings

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Temperature Grades

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 266

Page 270 of 350

SERVICING AND MAINTENANCE 267

NOTE:

• P (Passenger) — Metric tire sizing is based on US designstandards. P-Metric tires have the letter “P” molded into

the sidewall preceding the size designation. Example:

P215/65R15 95H.

• European — Metric tire sizing is based on European design standards. Tires designed to this standard have the

tire size molded into the sidewall beginning with the

section width. The letter "P" is absent from this tire size

designation. Example: 215/65R15 96H.

• LT (Light Truck) — Metric tire sizing is based on US design standards. The size designation for LT-Metric tires is the

same as for P-Metric tires except for the letters “LT” that

are molded into the sidewall preceding the size designa -

tion. Example: LT235/85R16. • Temporary spare tires are designed for temporary emer

-

gency use only. Temporary high pressure compact spare

tires have the letter “T” or “S” molded into the sidewall

preceding the size designation. Example: T145/80D18

103M.

• High flotation tire sizing is based on US design standards and it begins with the tire diameter molded into the side -

wall. Example: 31x10.5 R15 LT.

7

2020_RAM_PROMASTER_CITY_OM_USA=GUID-7B6A7FCA-79B0-423F-95C5-ED2A949C3D13=1=en=.book Page 267