wheel RAM PROMASTER CITY 2021 Workshop Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: PROMASTER CITY, Model: RAM PROMASTER CITY 2021Pages: 280, PDF Size: 15.78 MB

Page 200 of 280

198IN CASE OF EMERGENCY

1. Loosen (but do not remove) the wheel lug

bolts with the wrench handle by turning

them to the left one turn while the wheel is

still on the ground.

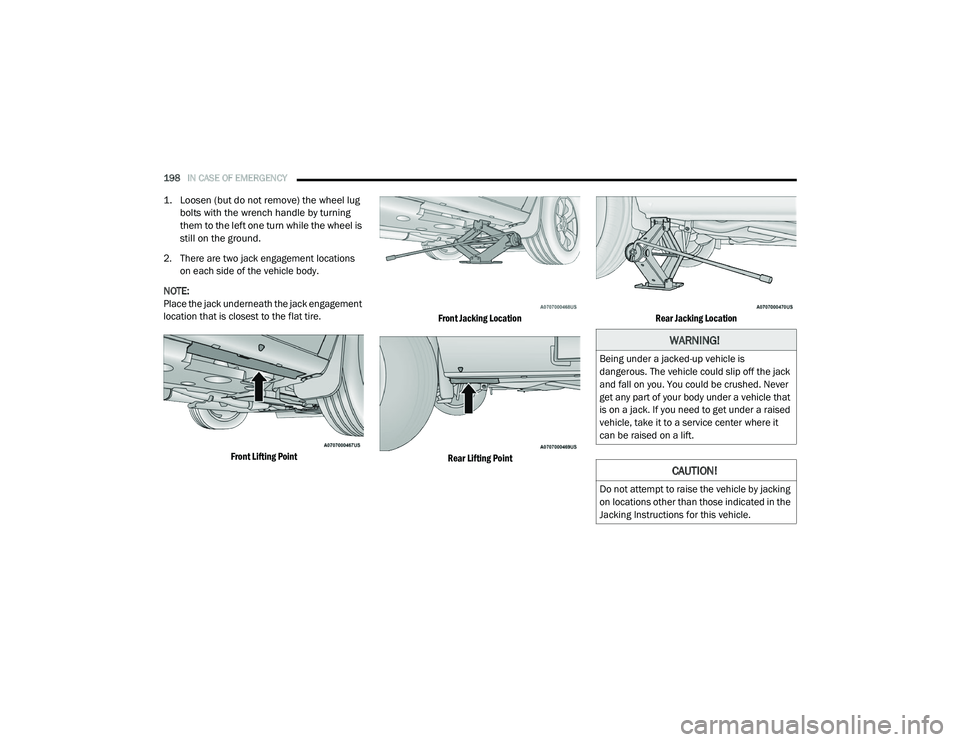

2. There are two jack engagement locations on each side of the vehicle body.

NOTE:

Place the jack underneath the jack engagement

location that is closest to the flat tire.

Front Lifting Point Front Jacking Location

Rear Lifting Point Rear Jacking Location

WARNING!

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the jack

and fall on you. You could be crushed. Never

get any part of your body under a vehicle that

is on a jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

21_VM_OM_EN_USC_t.book Page 198

Page 201 of 280

IN CASE OF EMERGENCY199

3. Turn the handle on the jack screw to the

right until the jack head is properly engaged

in the described location. Do not raise the

vehicle until you are sure the jack is

securely engaged.

4. Raise the vehicle by turning the jack screw to the right until the tire just clears the

surface and enough clearance is obtained

to install the spare tire. Minimum tire lift

provides maximum stability.

5. Remove the wheel lug bolts. For vehicles with wheel covers, remove the cover from

the wheel by hand. Do not pry the wheel

cover off. Then pull the wheel off the hub. 6. Install the spare tire. Lightly tighten the

wheel lug bolts using the bolt install wrench.

Mounting Spare Tire Installing Spare Tire

7. Lower the vehicle by turning the jack screw to the left Ú page 255.

8. Lower the jack to its fully-closed position.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not fully tighten the wheel bolts until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted

incorrectly.

7

21_VM_OM_EN_USC_t.book Page 199

Page 202 of 280

200IN CASE OF EMERGENCY

9. Stow the cable and wheel spacer before

driving the vehicle Ú page 200.

10. Stow the jack and tools under the driver’s seat.

11. Check the spare tire pressure as soon as possible. Correct the tire pressure, as

required.

12. When you place the spare tire back on the winch or if you carry the tire in need of repair

on the winch, always check that the tire is

properly secured under the vehicle by

pushing on the stowed tire under the rear

fascia/bumper at the back of the vehicle. If

the tire has motion when pushed, use the

tools to re-tighten the winch until a loud

click is heard.

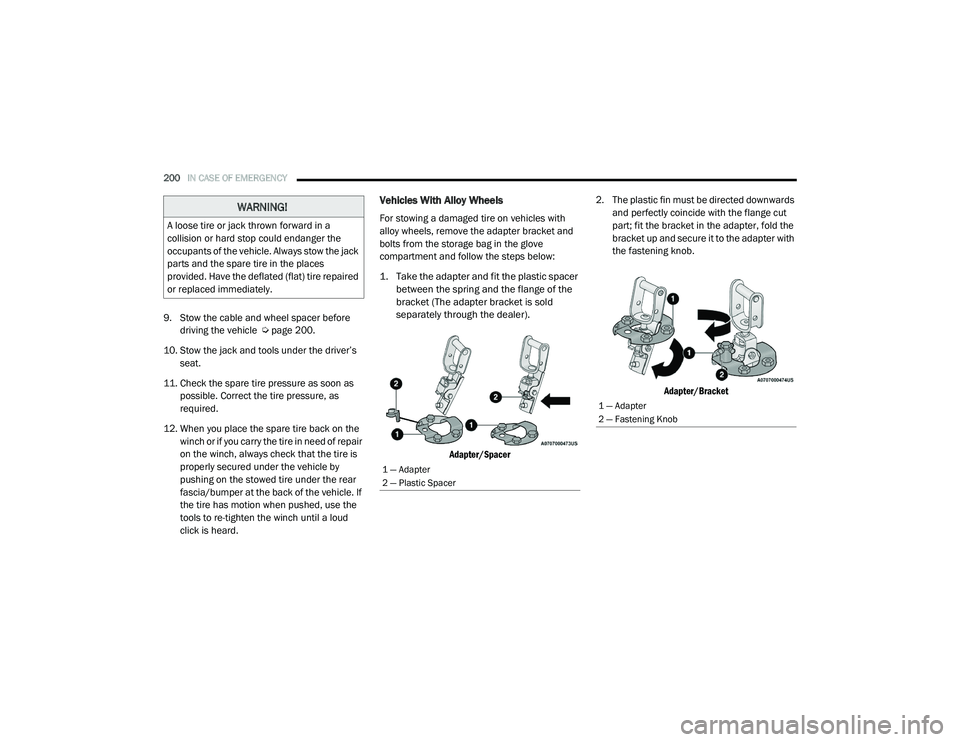

Vehicles With Alloy Wheels

For stowing a damaged tire on vehicles with

alloy wheels, remove the adapter bracket and

bolts from the storage bag in the glove

compartment and follow the steps below:

1. Take the adapter and fit the plastic spacer between the spring and the flange of the

bracket (The adapter bracket is sold

separately through the dealer).

Adapter/Spacer

2. The plastic fin must be directed downwards

and perfectly coincide with the flange cut

part; fit the bracket in the adapter, fold the

bracket up and secure it to the adapter with

the fastening knob.

Adapter/Bracket

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

1 — Adapter

2 — Plastic Spacer

1 — Adapter

2 — Fastening Knob

21_VM_OM_EN_USC_t.book Page 200

Page 203 of 280

IN CASE OF EMERGENCY201

3. Position the tire vertically and lay the

mounted adapter on the inner part of the

rim, using the supplied bolts fasten the

wheel to the adapter using the bolt install

wrench.

Alloy Wheel Mounting

4. Tighten the bolts with the wrench handle.

5. Rotate the winch mechanism clockwise until the wheel is properly stowed under the

vehicle and until the wench makes three

audible noises. 6. Reach underneath and shake tire by hand

to confirm that it is secure. The tire should

not move. If the tire is still loose and/or

three audible noises are not heard, place

and secure damaged wheel into the vehicle

and seek dealer assistance for the winch

mechanism.

This is for temporary use only.

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two wheel

bolts on the wheel. Install the wheel bolts

with the threaded end of the bolt toward the

wheel. Lightly tighten the wheel bolts.

Tire And Wheel Cover Or Center Cap

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install the

cover by hand, snapping the cover over the

two wheel bolts. Do not use a hammer or

excessive force to install the cover.1 — Valve Stem

2 — Valve Notch

3 — Wheel Bolt

4 — Wheel Cover

5 — Road Wheel

7

21_VM_OM_EN_USC_t.book Page 201

Page 204 of 280

202IN CASE OF EMERGENCY

4. Install the remaining wheel bolts with the

threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the wheel bolts. Push down on the wrench while holding at the

end of the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice Ú page 255.

7. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that

all wheel bolts are properly seated against

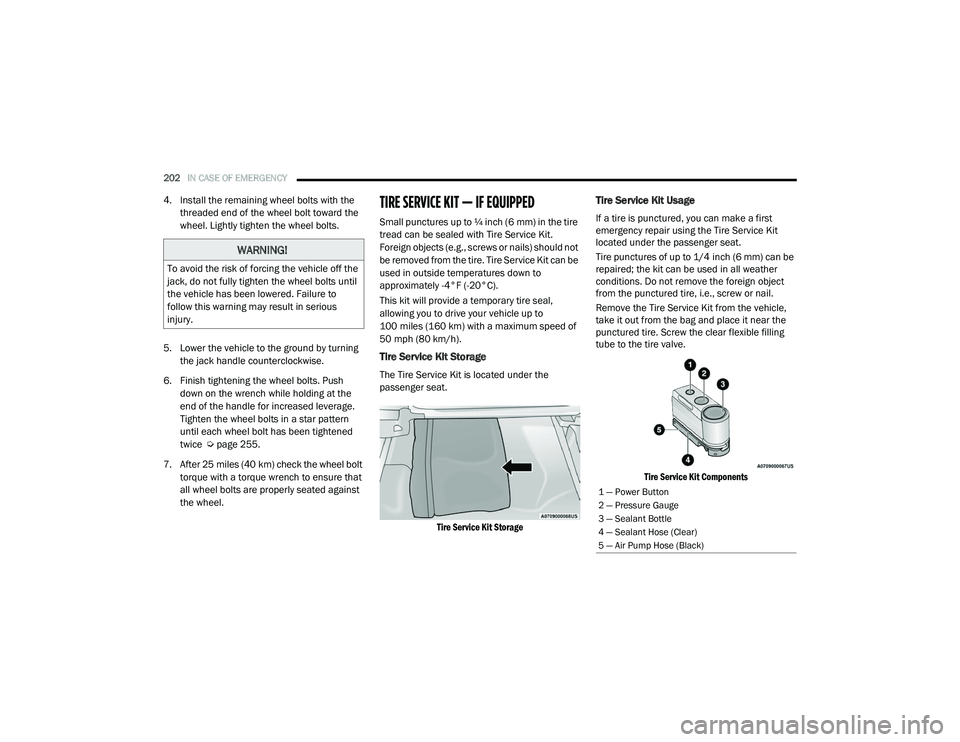

the wheel.TIRE SERVICE KIT — IF EQUIPPED

Small punctures up to ¼ inch (6 mm) in the tire

tread can be sealed with Tire Service Kit.

Foreign objects (e.g., screws or nails) should not

be removed from the tire. Tire Service Kit can be

used in outside temperatures down to

approximately -4°F (-20°C).

This kit will provide a temporary tire seal,

allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of 50 mph (80 km/h).

Tire Service Kit Storage

The Tire Service Kit is located under the

passenger seat.

Tire Service Kit Storage

Tire Service Kit Usage

If a tire is punctured, you can make a first

emergency repair using the Tire Service Kit

located under the passenger seat.

Tire punctures of up to 1/4 inch (6 mm) can be

repaired; the kit can be used in all weather

conditions. Do not remove the foreign object

from the punctured tire, i.e., screw or nail.

Remove the Tire Service Kit from the vehicle,

take it out from the bag and place it near the

punctured tire. Screw the clear flexible filling

tube to the tire valve.

Tire Service Kit Components

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not fully tighten the wheel bolts until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

1 — Power Button

2 — Pressure Gauge

3 — Sealant Bottle

4 — Sealant Hose (Clear)

5 — Air Pump Hose (Black)

21_VM_OM_EN_USC_t.book Page 202

Page 205 of 280

IN CASE OF EMERGENCY203

(Continued)

Insert the power plug into the vehicle power

outlet socket. Start the vehicle engine.

Push the Tire Service Kit power button on. The

electric compressor will be turned on, sealant

and air will inflate the tire.

Minimum 26 psi (1.8 bar) of pressure should be

reached within 20 minutes. If the pressure has

not been reached, turn off and remove the Tire

Service Kit, drive the vehicle 30 feet

(10 meters) back and forth, to better distribute

the sealant inside the tire.

Attach the clear flexible filling tube of the

compressor directly to the tire valve and repeat

the inflation process.

When the correct pressure has been reached,

start driving the vehicle to uniformly distribute

the sealant inside the tire. After 10 minutes,

stop and check the tire pressure. If the pressure

is below 19 psi (1.3 bar), do not drive the

vehicle, as the tire is too damaged, contact the

nearest authorized dealer.WARNING!

Do not attempt to seal a tire on the side of

the vehicle closest to traffic. Pull far enough

off the road to avoid the danger of being hit

when using the Tire Service Kit.

Do not use Tire Service Kit or drive the

vehicle under the following circumstances:

If the puncture in the tire tread is

approximately 1/4 inch (6 mm) or

larger.

If the tire has any sidewall damage.

If the tire has any damage from driving

with extremely low tire pressure.

If the tire has any damage from driving

on a flat tire.

If the wheel has any damage.

If you are unsure of the condition of the

tire or the wheel.

Keep Tire Service Kit away from open

flames or heat source.

A loose Tire Service Kit thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

Tire Service Kit in the place provided.

Failure to follow these warnings can result

in injuries that are serious or fatal to you,

your passengers, and others around you.

Take care not to allow the contents of Tire

Service Kit to come in contact with hair,

eyes, or clothing. Tire Service Kit sealant is

harmful if inhaled, swallowed, or absorbed

through the skin. It causes skin, eye, and

respiratory irritation. Flush immediately

with plenty of water if there is any contact

with eyes or skin. Change clothing as soon

as possible, if there is any contact with

clothing.

Tire Service Kit Sealant solution contains

latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep Tire

Service Kit out of reach of children. If swal -

lowed, rinse mouth immediately with plenty

of water and drink plenty of water. Do not

induce vomiting! Consult a physician imme -

diately.

WARNING! (Continued)

7

21_VM_OM_EN_USC_t.book Page 203

Page 210 of 280

208IN CASE OF EMERGENCY

IGNITION KEY REMOVAL OVERRIDE

This vehicle is equipped with a Key Ignition Park

Interlock which requires the transmission to be

in PARK (P) before the ignition switch can be

turned to the OFF/LOCK (key removal) position.

To remove the key manually, proceed as

follows:

1. Firmly apply the parking brake.

2. Remove the Allen Key located in the rear

cargo area, in the tool bag (if equipped) or

on the left side in the cargo box.

3. Unlock the steering column, pull the tilt/ telescoping control handle down. 4. Pull the steering wheel outward until it is in

the end of the travel position, then lock the

steering column in position, push the

control handle up until fully engaged.

5. Using the Allen Key, undo the lower steering column cover screws, and remove the lower

cover.

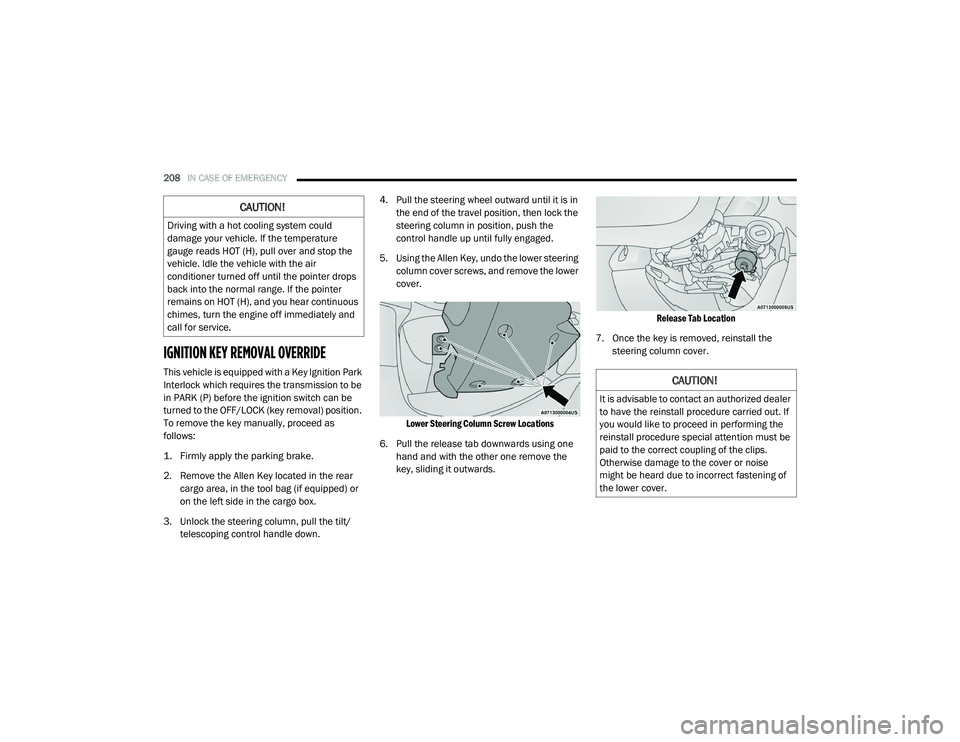

Lower Steering Column Screw Locations

6. Pull the release tab downwards using one hand and with the other one remove the

key, sliding it outwards.

Release Tab Location

7. Once the key is removed, reinstall the steering column cover.

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop the

vehicle. Idle the vehicle with the air

conditioner turned off until the pointer drops

back into the normal range. If the pointer

remains on HOT (H), and you hear continuous

chimes, turn the engine off immediately and

call for service.

CAUTION!

It is advisable to contact an authorized dealer

to have the reinstall procedure carried out. If

you would like to proceed in performing the

reinstall procedure special attention must be

paid to the correct coupling of the clips.

Otherwise damage to the cover or noise

might be heard due to incorrect fastening of

the lower cover.

21_VM_OM_EN_USC_t.book Page 208

Page 211 of 280

IN CASE OF EMERGENCY209

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector

cannot be moved out of the PARK (P) position,

you can use the following procedure to

temporarily move the gear selector:

1. Turn the engine OFF.

2. Firmly apply the parking brake.

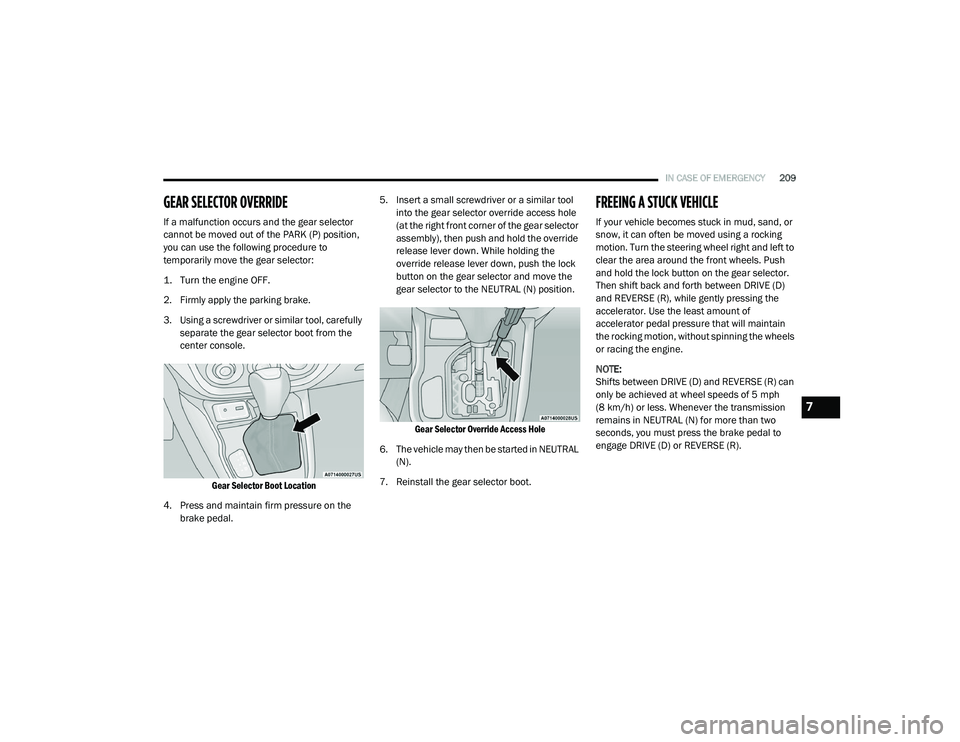

3. Using a screwdriver or similar tool, carefully

separate the gear selector boot from the

center console.

Gear Selector Boot Location

4. Press and maintain firm pressure on the brake pedal. 5. Insert a small screwdriver or a similar tool

into the gear selector override access hole

(at the right front corner of the gear selector

assembly), then push and hold the override

release lever down. While holding the

override release lever down, push the lock

button on the gear selector and move the

gear selector to the NEUTRAL (N) position.

Gear Selector Override Access Hole

6. The vehicle may then be started in NEUTRAL (N).

7. Reinstall the gear selector boot.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left to

clear the area around the front wheels. Push

and hold the lock button on the gear selector.

Then shift back and forth between DRIVE (D)

and REVERSE (R), while gently pressing the

accelerator. Use the least amount of

accelerator pedal pressure that will maintain

the rocking motion, without spinning the wheels

or racing the engine.

NOTE:

Shifts between DRIVE (D) and REVERSE (R) can

only be achieved at wheel speeds of 5 mph

(8 km/h) or less. Whenever the transmission

remains in NEUTRAL (N) for more than two

seconds, you must press the brake pedal to

engage DRIVE (D) or REVERSE (R).

7

21_VM_OM_EN_USC_t.book Page 209

Page 212 of 280

210IN CASE OF EMERGENCY

NOTE:

Push the ESC OFF switch, to place the Electronic

Stability Control (ESC) system in Partial Off

mode, before rocking the vehicle Ú page 146.

Once the vehicle has been freed, push the ESC

OFF switch again to restore ESC On mode.

WARNING!

Fast spinning tires can be dangerous. Forces

generated by excessive wheel speeds may

cause damage, or even failure, of the axle

and tires. A tire could explode and injure

someone. Do not spin your vehicle's wheels

faster than 30 mph (48 km/h) or for longer than 30 seconds continuously without

stopping when you are stuck and do not let

anyone near a spinning wheel, no matter

what the speed.

CAUTION!

Racing the engine or spinning the wheels may

lead to transmission overheating and failure.

Allow the engine to idle with the transmission

in NEUTRAL for at least one minute after

every five rocking-motion cycles. This will

minimize overheating and reduce the risk of

transmission failure during prolonged efforts

to free a stuck vehicle.

CAUTION!

When “rocking” a stuck vehicle by shifting

between DRIVE and REVERSE, do not spin

the wheels faster than 15 mph (24 km/h), or drivetrain damage may result.

Revving the engine or spinning the wheels

too fast may lead to transmission over -

heating and failure. It can also damage the

tires. Do not spin the wheels above 30 mph

(48 km/h) while in gear (no transmission

shifting occurring).

21_VM_OM_EN_USC_t.book Page 210

Page 213 of 280

IN CASE OF EMERGENCY211

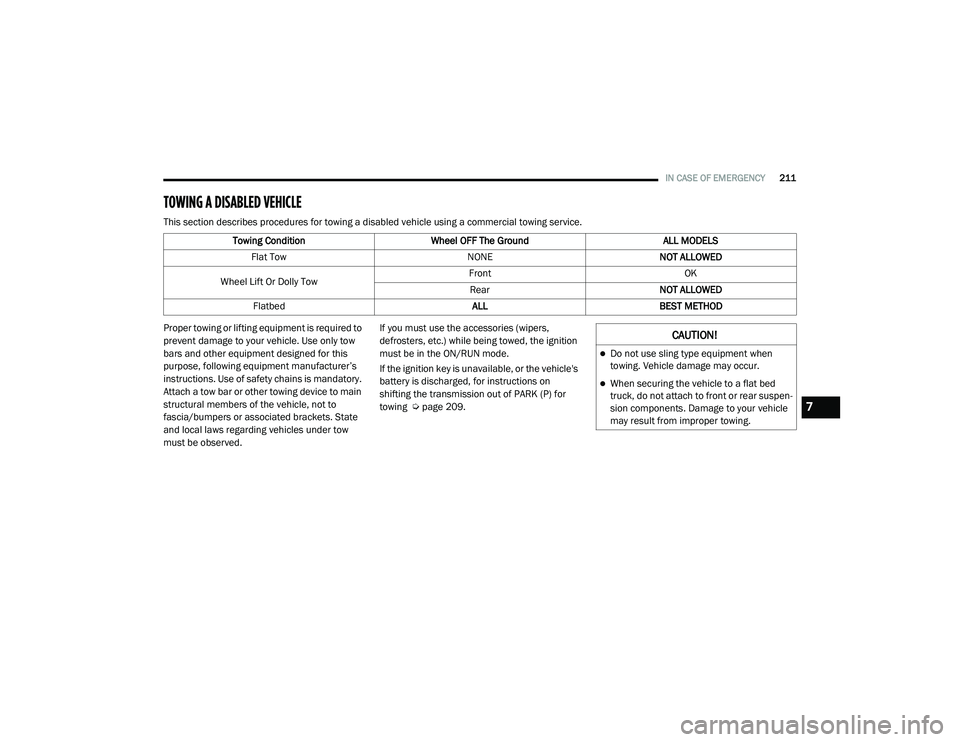

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing service.

Proper towing or lifting equipment is required to

prevent damage to your vehicle. Use only tow

bars and other equipment designed for this

purpose, following equipment manufacturer’s

instructions. Use of safety chains is mandatory.

Attach a tow bar or other towing device to main

structural members of the vehicle, not to

fascia/bumpers or associated brackets. State

and local laws regarding vehicles under tow

must be observed. If you must use the accessories (wipers,

defrosters, etc.) while being towed, the ignition

must be in the ON/RUN mode.

If the ignition key is unavailable, or the vehicle's

battery is discharged, for instructions on

shifting the transmission out of PARK (P) for

towing Ú

page 209.

Towing Condition

Wheel OFF The Ground ALL MODELS

Flat Tow NONENOT ALLOWED

Wheel Lift Or Dolly Tow Front

OK

Rear NOT ALLOWED

Flatbed ALLBEST METHOD

CAUTION!

Do not use sling type equipment when

towing. Vehicle damage may occur.

When securing the vehicle to a flat bed

truck, do not attach to front or rear suspen-

sion components. Damage to your vehicle

may result from improper towing.

7

21_VM_OM_EN_USC_t.book Page 211