air RENAULT CAPTUR 2018 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2018, Model line: CAPTUR, Model: RENAULT CAPTUR 2018Pages: 258, PDF Size: 7.15 MB

Page 197 of 258

5.7

Jack 2Fold it correctly before refitting it in its

housing (ensure that the wheelbrace is

correctly positioned).

Hubcap tool 3

This tool is used to remove the wheel

trims.

Wheel bolt guide 4To finish loosening or starting to tighten

the wheel bolts.

Tow eye 5Please see “Towing: breakdown recov-

ery” in Section 5.

Lever 6This tightens or releases the tow eye 5.

Wheelbrace 1Locks or unlocks the wheel bolts and

tow eye 5.

Depending on the vehicle, tools are lo-

cated:

– in a bag in the luggage compart-

ment, or

– in the tool kit A located in the tray

under the luggage compartment

carpet. Lift the cover, then remove it.

Wheel bolt bag

TOOLS

A

Do not leave the tools unsecured inside the vehicle as they may come loo\

se under braking. After use, check that all the

tools are correctly clipped into the tool kit, then position it correctl\

y in its housing: there is a risk of injury.

If wheel bolts are supplied in the tool kit, only use these bolts for th\

e emergency spare wheel: refer to the label affixed

to the emergency spare wheel.

The jack is designed for wheel changing purposes only. Under no circumstances should it be used for carrying out repairs un-

derneath the vehicle or to gain access to the underside of the vehicle.

2

1

3

5

4

6

Page 200 of 258

5.10

If you have a puncture, re-

place the wheel as soon as

possible.

A tyre which has been punc-

tured should always be inspected

(and repaired, where possible) by a

specialist.

CHANGING A WHEEL (2/2)

Undo the bolts and take off the wheel.

Fit the emergency spare wheel on the

central hub and turn it to locate the

mounting holes in the wheel and the

hub.

Tighten the bolts, checking that the

wheel is correctly positioned on its hub.

Lower the jack.

With the wheel on the ground, tighten

the bolts fully and have the tightness of

the bolts checked and the emergency

spare wheel pressure checked as soon

as possible.

Do not leave the tools un-

secured inside the vehicle

as they may come loose

under braking. After use,

check that all the tools are correctly

clipped into the tool kit, then posi-

tion it correctly in its housing: risk of

injury.

If wheel bolts are supplied in the

tool kit, only use these bolts for the

emergency spare wheel: refer to the

label affixed to the emergency spare

wheel.

The jack is designed for wheel

changing purposes only. Under no

circumstances should it be used for

carrying out repairs underneath the

vehicle or to gain access to the un-

derside of the vehicle.

Vehicle fitted with a tyre pressure

loss warning system

If under-inflated (puncture, low pres-

sure, etc.), the warning light

on

the instrument panel comes on. See

“Tyre pressure loss warning” in

Section 2.

Page 202 of 258

5.12

Pressures should be checked when the

tyres are cold; ignore higher pressures

which may be reached in hot weather

or following a fast journey.

If tyre pressures cannot be checked

when the tyres are cold, assume an in-

crease of 0.2 to 0.3 bar (or 3 PSI).

Never deflate a hot tyre.

TYRES (2/3)

Please be aware that a

poorly tightened or miss-

ing valve cap can make the

tyres less airtight and lead

to pressure loss.

Always use valve caps identical to

those fitted originally and tighten

them fully.

Incorrect tyre pressures

lead to abnormal tyre wear

and unusually hot running.

These are factors which

may seriously affect safety and lead

to:

– poor road holding,

– risk of bursting or tread separa- tion.

The pressure depends on the load

and the speed of use. Adjust the

pressure according to the condi-

tions of use (refer to the label affixed

to the edge of the driver’s door).

Tyre pressures

Adhere to the tyre pressures (including

the emergency spare wheel). The tyre

pressures should be checked at least

once a month and additionally before

any long journey (refer to the label af-

fixed to the edge of the driver’s door). Vehicle fitted with a tyre pressure

loss warning system

If under-inflated (puncture, low pres-

sure etc.), the warning light

on

the instrument panel comes on. See

“Tyre pressure loss warning” in

Section 2.

Emergency spare wheel

Refer to the information on the

“Emergency spare wheel” and in-

structions on “Changing a wheel” in

Section 5.

Changing wheels around

This practice is not recommended.

Page 215 of 258

5.25

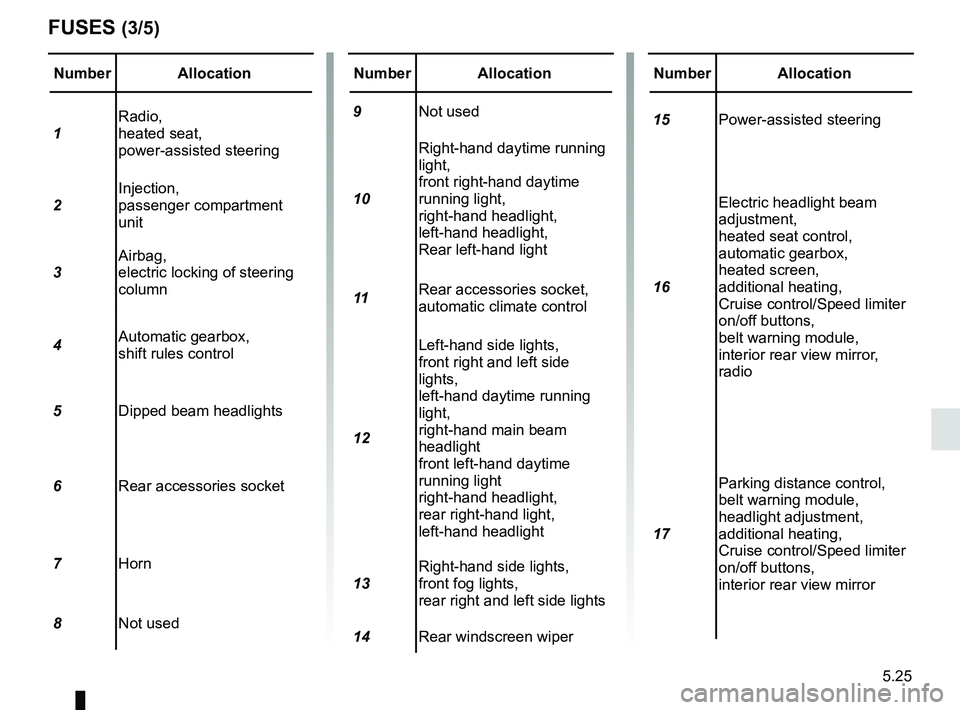

Number Allocation

1 Radio,

heated seat,

power-assisted steering

2 Injection,

passenger compartment

unit

3 Airbag,

electric locking of steering

column

4 Automatic gearbox,

shift rules control

5 Dipped beam headlights

6 Rear accessories socket

7 Horn

8 Not used

FUSES (3/5)

Number Allocation

9 Not used

10 Right-hand daytime running

light,

front right-hand daytime

running light,

right-hand headlight,

left-hand headlight,

Rear left-hand light

11 Rear accessories socket,

automatic climate control

12 Left-hand side lights,

front right and left side

lights,

left-hand daytime running

light,

right-hand main beam

headlight

front left-hand daytime

running light

right-hand headlight,

rear right-hand light,

left-hand headlight

13 Right-hand side lights,

front fog lights,

rear right and left side lights

14 Rear windscreen wiperNumber Allocation

15 Power-assisted steering

16 Electric headlight beam

adjustment,

heated seat control,

automatic gearbox,

heated screen,

additional heating,

Cruise control/Speed limiter

on/off buttons,

belt warning module,

interior rear view mirror,

radio

17 Parking distance control,

belt warning module,

headlight adjustment,

additional heating,

Cruise control/Speed limiter

on/off buttons,

interior rear view mirror

Page 217 of 258

5.27

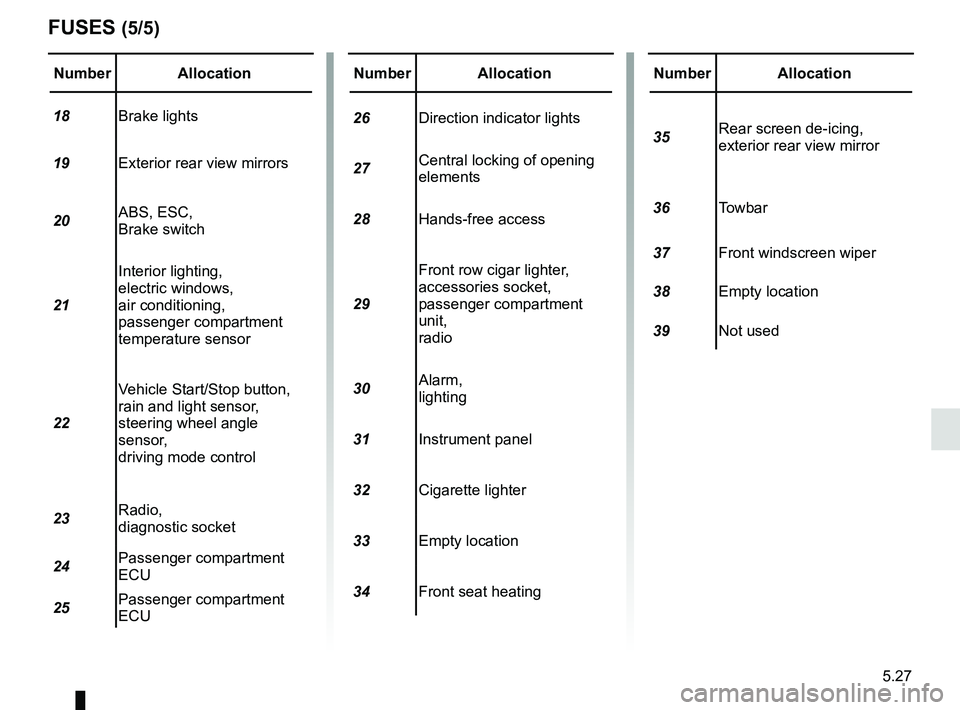

Number Allocation

18 Brake lights

19 Exterior rear view mirrors

20 ABS, ESC,

Brake switch

21 Interior lighting,

electric windows,

air conditioning,

passenger compartment

temperature sensor

22 Vehicle Start/Stop button,

rain and light sensor,

steering wheel angle

sensor,

driving mode control

23 Radio,

diagnostic socket

24 Passenger compartment

ECU

25 Passenger compartment

ECU

FUSES (5/5)

Number Allocation

26 Direction indicator lights

27 Central locking of opening

elements

28 Hands-free access

29 Front row cigar lighter,

accessories socket,

passenger compartment

unit,

radio

30 Alarm,

lighting

31 Instrument panel

32 Cigarette lighter

33 Empty location

34 Front seat heatingNumber Allocation

35 Rear screen de-icing,

exterior rear view mirror

36 Towbar

37 Front windscreen wiper

38 Empty location

39 Not used

Page 233 of 258

6.1

Section 6: Technical specifications

Vehicle identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . 6.2

Engine identification plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . 6.3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

Engine specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . 6.5

Towing weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6

Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6

Replacement parts and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . 6.7

Service sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.8

Anticorrosion check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . 6.14

Page 239 of 258

6.7

Original parts are based on strict specifications and are subject to hig\

hly-specialised tests. Therefore, they are of at least the same

level of quality as the parts fitted originally.

If you always fit genuine replacement parts to your vehicle, you will en\

sure that it performs well. Furthermore, repairs carried out

within the manufacturer’s Network using original parts are guaranteed according to the condition\

s set out on the reverse of the

repair order.

REPLACEMENT PARTS AND REPAIRS

Page 246 of 258

6.14

ANTICORROSION CHECK (1/5)

If the continuation of the warranty is subject to repair, it is indicated below.

VIN: ..........................................................

Corrosion repair operation to be carried

out:

Stamp

Date of repair:

Repair to be carried out:

Stamp

Date of repair:

Repair to be carried out:

Stamp

Date of repair:

Page 247 of 258

6.15

ANTICORROSION CHECK (2/5)

If the continuation of the warranty is subject to repair, it is indicated below.

VIN: ..........................................................

Corrosion repair operation to be carried

out:

Stamp

Date of repair:

Repair to be carried out:

Stamp

Date of repair:

Repair to be carried out:

Stamp

Date of repair:

Page 248 of 258

6.16

ANTICORROSION CHECK (3/5)

If the continuation of the warranty is subject to repair, it is indicated below.

VIN: ..........................................................

Corrosion repair operation to be carried

out:

Stamp

Date of repair:

Repair to be carried out:

Stamp

Date of repair:

Repair to be carried out:

Stamp

Date of repair: