steering RENAULT KANGOO 1997 KC / 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 105

Page 1 of 105

Chassis

GENERAL

FRONT AXLE

REAR AXLE

WHEELS AND TYRES

STEERING ASSEMBLY

MECHANICAL ELEMENT CONTROLS

ELECTRONICALLY CONTROLLED SYSTEMS

Renault 1997

77 11 194 253JULY 1997Edition Anglaise

"The repair methods given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The methods may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories

from which his vehicles are constructed."All copyrights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault.

C

FC0A - FC0C - FC0D - FC0E - KC0A - KC0C - KC0D - KC0E

Page 4 of 105

Master cylinder

Brake servo

Air filter - Brake servo non-return

valve

Vacuum pump

Handbrake control lever

Handbrake control

Brake pipes

Braking compensator

Clutch control cable

Clutch automatic wear take-up

system

External gear control37-1

37-3

37-5

37-6

37-7

37-8

37-10

37-11

37-22

37-23

37-24

Contents

Page

MECHANICAL ELEMENT CONTROLS37

38-1

38-2

38-3

38-4

38-5

38-6

38-7

38-8

38-9

BOSCH ABS

Presentation of BOSCH ABS 5.3

Location of components

Presentation of the hydraulic

regulation assembly

Wiring diagram

Wiring diagram key

31 track connector

Diagnostic socket

Hydraulic assembly

Hydraulic braking test

ELECTRONICALLY CONTROLLED

HYDRAULIC SYSTEMS38STEERING ASSEMBLY

Axial ball joint

Manual steering rack

Power assisted steering rack

Gaiter

Steering rack pinion

Manual steering assistance pump

Steering column

36-1

36-3

36-4

36-6

36-7

36-8

36-12

36

Page 25 of 105

FRONT AXLE

Engine sub-frame

Remove:

- the two nuts for the steering rack heat shield,

- the mounting nuts for the steering rack and

attach it to the exhaust manifold.

31

12988R

SPECIAL TOOLING REQUIRED

Mot. 1040 -01 Dummy sub-frame for removing/refitting engine/transmission assembly

T. Av. 476 Ball joint extractor

REMOVAL

Disconnect the battery.

Put the vehicle on a two post lift.

Remove the wheels.

Disconnect the track rod ends using tool T. Av.

476.

Remove the key on the stub axle carrier.

Release but do not remove the mudguards to

reach the upper bolt on the sub-frame - side mem-

ber tie rod and remove it.

Remove:

- the exhaust downpipe and attach the catalytic

converter,

- the bolt (engine side) for the engine tie bar.

- the gear control by removing the two bolts at

the ends of the control. To do this, the cataly-

tic converter heat shield must be removed and

the gaiter on the gearbox side must also be re-

moved.

TIGHTENING TORQUES (in daN.m)

Wheel bolts 9

Track rod end nut 3.7

Steering universal joint bolt 2.5

Sub-frame mounting bolt front Ø10 6

rear Ø 12 10.5

Sub-frame - side member tie rod nut 3

Key nut on stub axle carrier 5.5

Engine tie bar 6.5

Steering box mounting bolt 5

Fit tool Mot. 1040-01 under the engine sub-frame.

12993-1R1

31-12

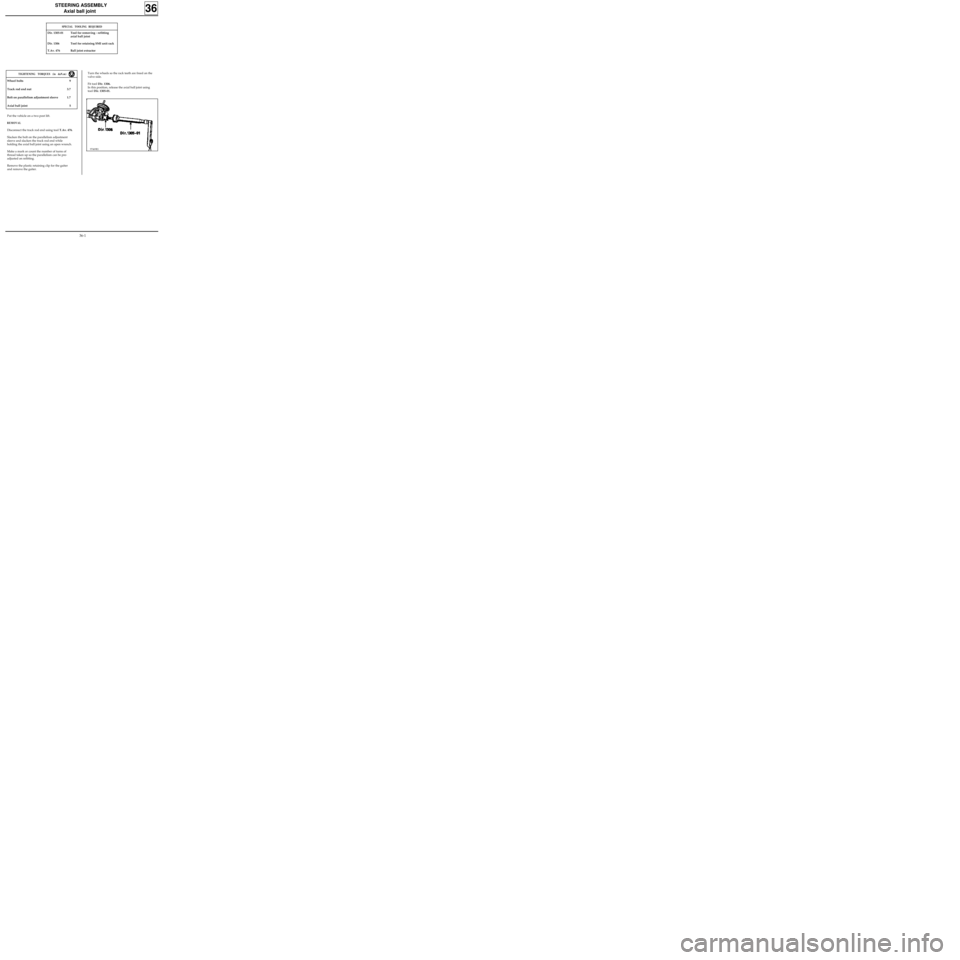

Page 53 of 105

STEERING ASSEMBLY

Axial ball joint

36

Put the vehicle on a two post lift.

REMOVAL

Disconnect the track rod end using tool T.Av. 476.

Slacken the bolt on the parallelism adjustment

sleeve and slacken the track rod end while

holding the axial ball joint using an open wrench.

Make a mark or count the number of turns of

thread taken up so the parallelism can be pre-

adjusted on refitting.

Remove the plastic retaining clip for the gaiter

and remove the gaiter.

SPECIAL TOOLING REQUIRED

Wheel bolts 9

Track rod end nut 3.7

Bolt on parallelism adjustment sleeve 1.7

Axial ball joint 5

Dir. 1305-01 Tool for removing - refitting

axial ball joint

Dir. 1306 Tool for retaining SMI unit rack

T.Av. 476 Ball joint extractor

TIGHTENING TORQUES (in daN.m)Turn the wheels so the rack teeth are freed on the

valve side.

Fit tool Dir. 1306.

In this position, release the axial ball joint using

tool Dir. 1305-01.

97469R1

36-1

Page 54 of 105

STEERING ASSEMBLY

Axial ball joint

36

REFITTING

Assembly (2) MUST be renewed systematically.

83510-1R3

Refit to the rack (3) :

- the stop washer assembled with the locking

ring (2),

- the new axial ball joint (1) having lightly coated

the threads with

LOCTITE FREN-BLOC, ensuring

that the air evacuation opening is not blocked.

Before finally tightening the axial ball joint using

tool Dir. 1305-01, check that the tabs on the

locking ring (2) align with the flats (B) on the rack.

Tighten the axial ball joint to the recommended

torque.

Centre the steering to equalise the air in the

gaiters.

Fit a new gaiter and secure it with a new clip

(after greasing the gaiter bearing surface on the

axial ball joint).

Checking

Gently press on the gaiter to check the other

gaiter inflates which indicates the air is circulating

correctly.

36-2

Page 55 of 105

STEERING ASSEMBLY

Manual steering rack

36

Put the vehicle on a two post lift.

REMOVAL

Remove the front wheels.

Cut the rubber gaiter retaining clip and push the

gaiter back towards the bulkhead.

Disconnect the ball joints using tool T.Av. 476.

Remove:

- the universal joint eccentric bolt,

- the steering rack mounting bolts on the sub-

frame.

Remove the steering rack.

SPECIAL TOOLING REQUIRED

Wheel bolts 9

Track rod end nut 3.7

Steering rack mounting bolts 5.5

Universal joint eccentric bolt 2.5

T.Av. 476 Ball joint extractor

TIGHTENING TORQUES (in daN.m)REFITTING

Refitting is the reverse of removal. Observe the

recommended tightening torques.

If a new steering rack is being fitted, fit the track

rod ends in the position noted on removal.

To do this, slacken the bolt on the parallelism

adjustment sleeve and slacken the track rod end

while holding the axial ball joint using an open

wrench.

Make a mark or count the number of turns of

thread taken up so the parallelism can be pre-

adjusted on refitting.

Check the parallelism.

NOTE : the markings on the track rod ends MUST

BE OBSERVED

(one mark on right hand joint, two

marks on left hand joint).

36-3

Page 56 of 105

STEERING ASSEMBLY

Power assisted steering rack

36

SPECIAL TOOLING REQUIRED

Mot. 453-01 Hose clamp pliers

T.Av. 476 Ball joint extractor

Wheel bolts 9

Track rod end nut 3.7

Steering rack mounting bolt 5

Universal joint eccentric bolt 2.5

Engine tie bar bolt 6.5

TIGHTENING TORQUES (in daN.m)

Put the vehicle on a two post lift.

REMOVAL

Remove the front wheels.

Fit a clamp Mot. 453-01 to each of the pipes from

the oil reservoir.

NOTE :never clamp the high pressure pipes.

Cut the rubber gaiter retaining clip and push the

gaiter back towards the bulkhead.

Disconnect the ball joints using tool T.Av. 476.

Remove the universal joint eccentric bolt.

Disconnect the oxygen sensor.

Remove the exhaust downpipe.

Remove the bolt (engine side) from the engine tie

bar and pivot the engine and transmission

assembly forwards.

Insert a retaining block.

Special notes for F8Q engine

Remove (from above) :

- the battery,

- the battery mounting,

- the high and low pressure pipes from the

steering valve.

13120S

36-4

Page 57 of 105

STEERING ASSEMBLY

Power assisted steering rack

36

Disconnect the high and low pressure pipes on the

steering rack (take precautions to catch the oil)

and the nut on the pipe retaining bracket.

Remove:

- the two nuts on the heat shield for the right

hand steering rack bearing,

- the steering rack mounting nuts and remove it

from the timing side.

NOTE :

- do not remove the pipes between the valve

and cylinder,

- fit plugs to the steering rack openings to

prevent the introduction of impurities.

12997R

REFITTING

Refitting is the reverse of removal. Observe the

recommended tightening torques.

Fill the circuit with oil.

Turn the wheels from left to right (engine not

running) to distribute the oil in the circuit.

Repeat the operation with the engine running

then top up the level.

If a new steering rack is being fitted, fit the track

rod ends in the position noted on removal.

To do this, slacken the bolt on the parallelism

adjustment sleeve and slacken the track rod end

while holding the axial ball joint using an open

wrench.

Make a mark or count the number of turns of

thread taken up so the parallelism can be pre-

adjusted on refitting.

Check the parallelism.

36-5

Page 58 of 105

STEERING ASSEMBLY

Gaiter

36

The gaiter MUST be renewed with a new gaiter

whenever an axial ball joint is removed.

Fitting the gaiter

Use an ogive on the axial ball joint to prevent

damage to the gaiter during fitting.

Coat the gaiter bearing face on the axial ball joint

with grease to prevent the gaiter twisting.

Secure the gaiter with a new clip (supplied with

the gaiter).

NOTE : the steering MUST be at the centre point

to equalise the air.

36-6

Page 59 of 105

STEERING ASSEMBLY

Steering pushrod

36

1. Determining the source of the noise

Hold the steering rack on the pinion side and

check for transverse play (up and down).

Movement followed by a click is caused by the

pinion.

2. Adjusting for SMI steering racks

Release the adjusting nut (1) by straightening the

bent over edges (A) on the nut collar.

Check when driving that the steering returns to

the centre point.

Maximum adjustment allowed : 1 notch.

Lock the nut again in the two lugs opposite the

housing by bending over the nut collar.

ADJUSTMENT

If the steering rack pinion is noisy, before considering replacing the steering rack, check that the pinion is

correctly adjusted.

83920R

36-7