RENAULT KANGOO 1997 KC / 1.G General Information Workshop Manual

Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 37

Page 1 of 37

77 11 194 217JULY 1997Edition anglaise

General

SPECIFICATIONS

LIFTING

TOWING

LUBRICANTS CONSUMABLES

DRAINING FILLING

FC0A - FC0C - FC0D - FC0E - KC0A - KC0C - KC0D - KC0E

VALUES AND SETTINGS

Renault 1997

"The repair methods given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The methods may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories

from which his vehicles are constructed."All copyrights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault.

C

Page 2 of 37

SECTION VIEW

PRO00.1

Page 3 of 37

TOWING

All types

Contents

SPECIFICATIONS

Engine - Clutch - Gearbox

Vehicle identification

01-1

01-2

LIFTING

Trolley jack - Axle stands

Underbody lifts

Page

01

02

03

General

vehicle

02-1

02-2

03-1

LUBRICANTS CONSUMABLES

Packaging

04-1

DRAINING FILLING

Engine

Gearbox

Power assisted steering

04

05

05-1

05-3

05-4

VALUES AND SETTINGS

Dimensions

Capacity - Grades

Belt tension

Accessories belt tension

Timing belt tension

Tightening the cylinder head

Tyres and wheels

Brakes

Brake limiter

Underbody heights

Values for checking the front axle

geometry

Values for checking the rear axle

geometry07

07-1

07-2

07-5

07-7

07-11

07-12

07-14

07-15

07-16

07-17

07-20

07-21

Page

Page 4 of 37

The KANGOO Workshop Repair Manual has been prepared by specialists in repair methods

and diagnostics.

The document covers the methods and the diagnostic operations needed in order to obtain

high quality repairs for this vehicle.

However, if a removal - refitting operation involves no particular features, difficulties or

special tools, the method is not described in this manual, being considered very simple for

a vehicle repair specialist.

The labour times are the result of time and motion studies carried out in our workshops,

even though certain methods have not been described in the Workshop Repair Manual.

UNITS OF MEASUREMENT

• All dimensions are expressed in millimetres (mm) unless otherwise indicated.

• Tightening torques are expressed in decaNewton.metres (

daN.m).

• Pressure are given in

bars (reminder: 1 bar = 100 000 Pa).

• Electrical resistance values are in Ohms (Ω).

• Voltages are expressed in Volts (

V).

TOLERANCES

Tightening torques given without a tolerance must be accurate to within:

• In

degrees : ± 3°.

• In

daN.m : ± 10 %.

Page 5 of 37

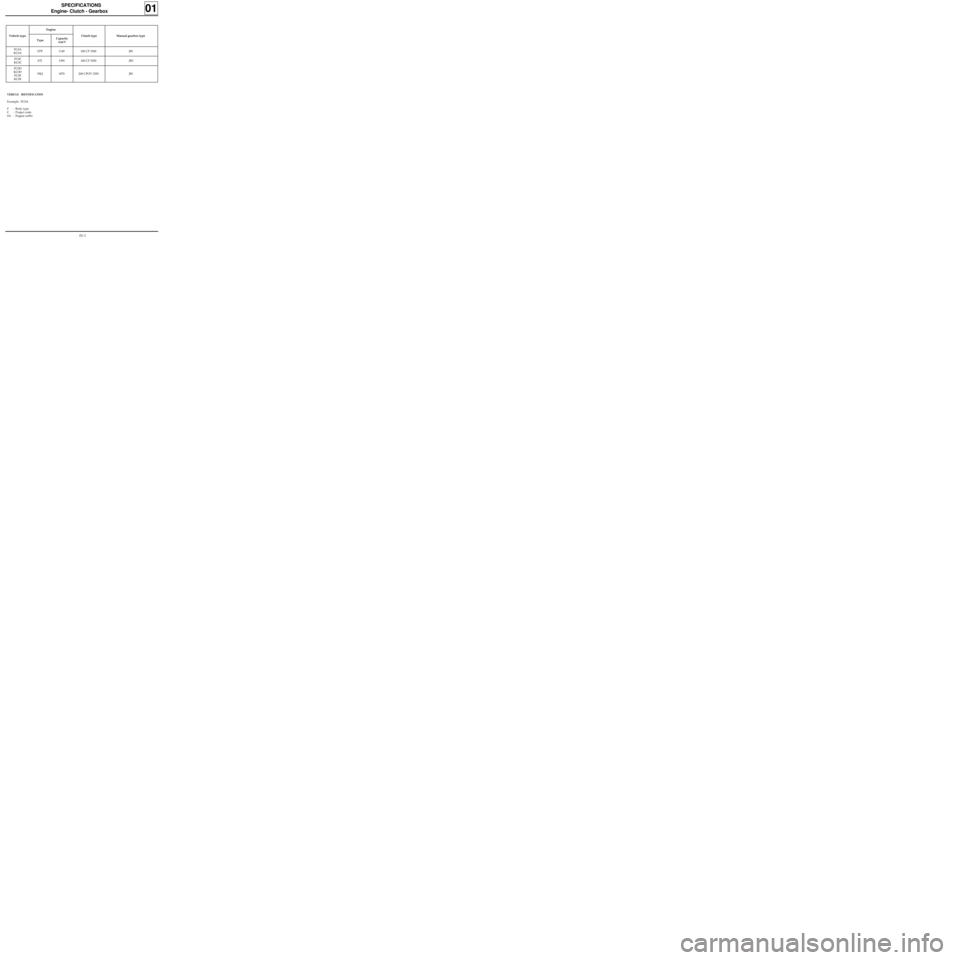

SPECIFICATIONS

Engine- Clutch - Gearbox

01

Vehicle typeEngine

TypeCapacity

(cm

3)Clutch type Manual gearbox type

FC0A

KC0AD7F 1149 180 CP 3300 JB1

FC0C

KC0CE7J 1390 180 CP 3300 JB3

FC0D

KC0D

FC0E

KC0EF8Q 1870 200 CPOV 3250 JB1

VEHICLE IDENTIFICATION

Example : FC0A

F : Body type

C : Project code

0A : Engine suffix

01-1

Page 6 of 37

SPECIFICATIONS

Vehicle identification

01

LOCATION OF VEHICLE IDENTIFICATION PLATE

e0-00/00-0000-000-000-00

VF000000000000000

0000 kg

0000 kg

1

- 0000 kg

2

- 0000 kg

000000000000000

RENAULT S.A.

1

2

3

4

5

8 7

6

9

10

13

12 11

1 Type mines of the vehicle and chassis number

2 PTMA [total all up weight of the vehicle]

3 PTR [maximum permitted total train weight -

vehicle loaded with trailer]

4 Maximum permitted weight on the front axle

(P.T.M.A. front axle)

5 Maximum permitted weight on the rear axle

(P.T.M.A. rear axle)6 Technical specifications of the vehicle

7 Paint reference

8 Equipment level

9 Vehicle type

10 Trim code

11 Additional factory optional equipment

12 Fabrication number

13 Interior matching trim code

13187R

01-2

Page 7 of 37

LIFTING

Trolley jack - Axle stands

AXLE STANDS

When putting the vehicle on axle stands, they

must be positioned:

_ either under the reinforcements provided for

lifting the vehicle with the tool kit jack,

- or under the studs located behind the

reinforcements.

Positioning of axle stands at the rear is carried out

by lifting the vehicle at the sides.

02

Safety symbol (special precautions to be taken when carrying out operations).

SPECIAL TOOLING REQUIRED

Cha. 280 -02 Adaptable cross piece for trolley jack

Cha. 408 -01

or Adaptable socket for trolley jack

Cha. 408 -02

If a trolley jack is used, appropriate axle

stands must always be used.

It is forbidden to lift the vehicle by supporting its

weight under the front suspension arms or under

the "V" member of the rear axle.

Depending on the type of trolley jack, use sockets

Cha. 408-01 or Cha. 408-02 for positioning the

cross piece Cha. 280-02.

To lift at the front or the rear of the vehicle, take

the weight under the side jacking points.

TROLLEY JACK AT THE SIDE

Use cross piece Cha. 280-02.

Take the weight under the valance at the level of

the front door.

Position the flange correctly in the groove of the

cross piece.

12333-2G

12274-1R

85679-1G15

02-1

Page 8 of 37

LIFTING

Underbody lifts

02

SAFETY INSTRUCTIONS

Various cases have to be considered:

1-

REMOVING COMPONENTS

As a general rule, never use a 2 post lift whenever

a four post lift can be used.

If this is not possible, place the lifting pads

beneath the underbody flange at the level of the

tool kit jack supports.

98703S

FRONT

98704S

REAR

These must be positioned level with the tool kit

jack supports. They must slot into the openings in

the underbody flanges.

2-

REMOVING - REFITTING THE ENGINE AND

TRANSMISSION ASSEMBLY

In this particular case, the vehicle body must be

secured to the arms of the 2 post lift using special

pads.

Company FOG

Part Number FOG 449 8111 - 449 8411

or

Company CHEMICO

Part Number 39 2550 0001

or

Company SCHENCH

Part Number 776 684

02-2

Page 9 of 37

TOWING

All types

FRONT

03

OBSERVE THE LEGAL TOWING REQUIREMENTS OF THE COUNTRY YOU ARE IN.

NEVER USE THE DRIVESHAFTS AS ATTACHMENT POINTS.

The towing points may only be used for towing the vehicle on the road. They should never be used for remo-

ving the vehicle from a ditch or for any other similar breakdown operation or to lift the vehicle, either direct-

ly or indirectly.

REAR

13366S13189S

03-1

Page 10 of 37

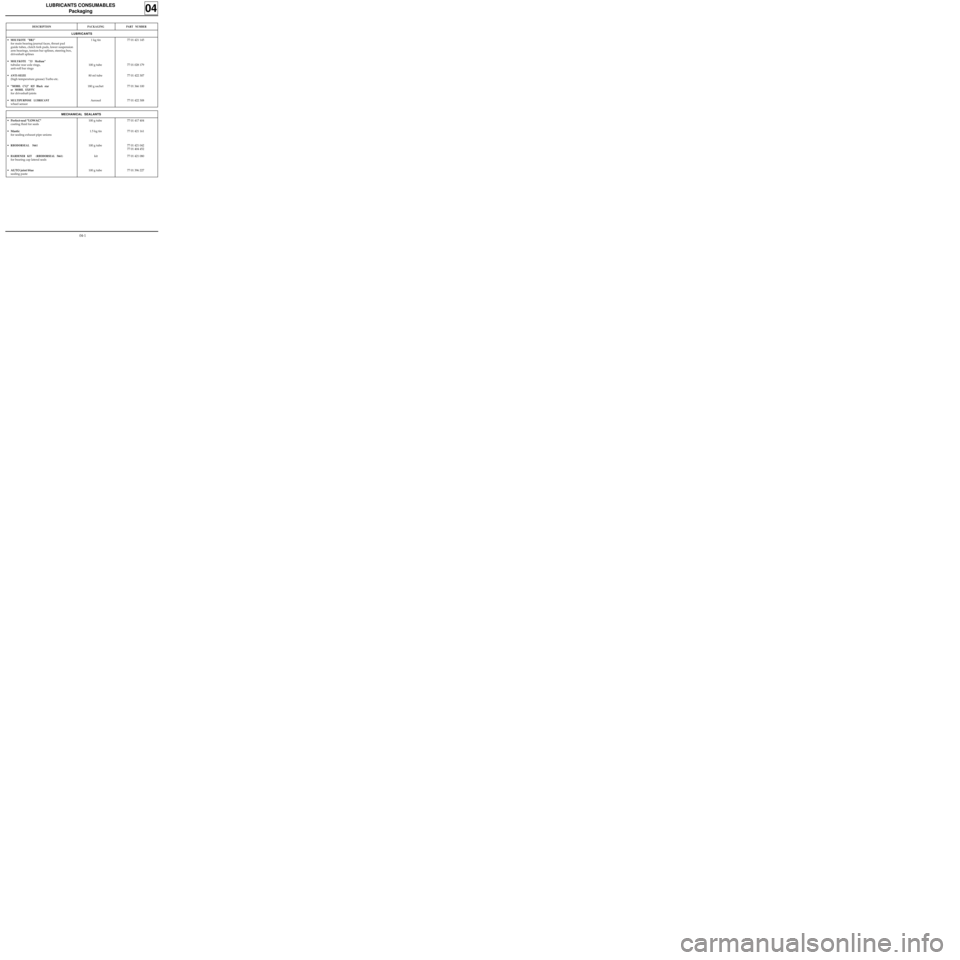

DESCRIPTIONPACKAGINGPART NUMBER

1 kg tin

100 g tube

80 ml tube

180 g sachet

Aerosol77 01 421 145

77 01 028 179

77 01 422 307

77 01 366 100

77 01 422 308

LUBRICANTS

LUBRICANTS CONSUMABLES

Packaging

04

•MOLYKOTE "BR2"

for main bearing journal faces, thrust pad

guide tubes, clutch fork pads, lower suspension

arm bearings, torsion bar splines, steering box,

driveshaft splines

•

MOLYKOTE "33 Medium"

tubular rear axle rings,

anti-roll bar rings

•

ANTI-SEIZE

(high temperature grease) Turbo etc.

•

"MOBIL CVJ" 825 Black star

or MOBIL EXF57C

for driveshaft joints

•

MULTIPURPOSE LUBRICANT

wheel sensor

• Perfect-seal "LOWAC"

coating fluid for seals

• Mastic

for sealing exhaust pipe unions

•

RHODORSEAL 5661

•HARDENER KIT (RHODORSEAL 5661)

for bearing cap lateral seals

• AUTO joint blue

sealing paste

100 g tube

1.5 kg tin

100 g tube

kit

100 g tube77 01 417 404

77 01 421 161

77 01 421 042

77 01 404 452

77 01 421 080

77 01 396 227

MECHANICAL SEALANTS

04-1