RENAULT KANGOO 1997 KC / 1.G General Information Workshop Manual

KANGOO 1997 KC / 1.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1733/w960_1733-0.png

RENAULT KANGOO 1997 KC / 1.G General Information Workshop Manual

Page 3 of 37

TOWING

All types

Contents

SPECIFICATIONS

Engine - Clutch - Gearbox

Vehicle identification

01-1

01-2

LIFTING

Trolley jack - Axle stands

Underbody lifts

Page

01

02

03

General

vehicle

02-1

02-2

03-1

LUBRICANTS CONSUMABLES

Packaging

04-1

DRAINING FILLING

Engine

Gearbox

Power assisted steering

04

05

05-1

05-3

05-4

VALUES AND SETTINGS

Dimensions

Capacity - Grades

Belt tension

Accessories belt tension

Timing belt tension

Tightening the cylinder head

Tyres and wheels

Brakes

Brake limiter

Underbody heights

Values for checking the front axle

geometry

Values for checking the rear axle

geometry07

07-1

07-2

07-5

07-7

07-11

07-12

07-14

07-15

07-16

07-17

07-20

07-21

Page

Page 5 of 37

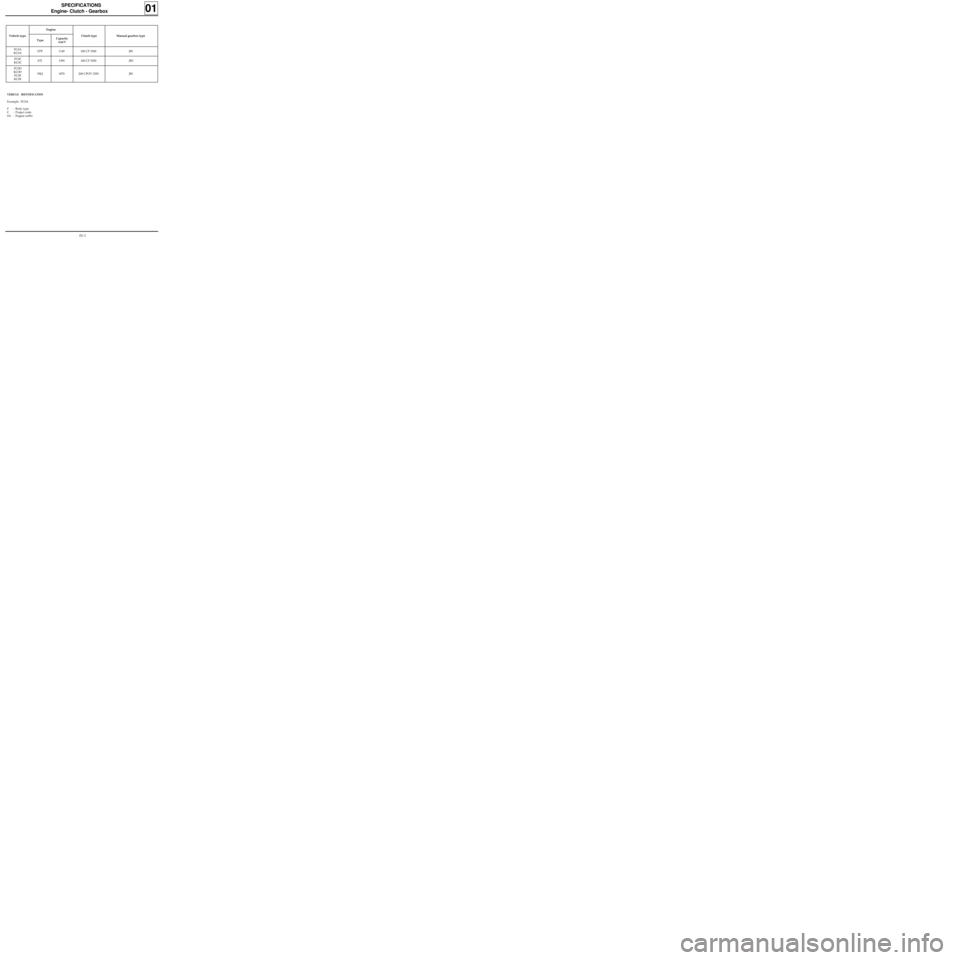

SPECIFICATIONS

Engine- Clutch - Gearbox

01

Vehicle typeEngine

TypeCapacity

(cm

3)Clutch type Manual gearbox type

FC0A

KC0AD7F 1149 180 CP 3300 JB1

FC0C

KC0CE7J 1390 180 CP 3300 JB3

FC0D

KC0D

FC0E

KC0EF8Q 1870 200 CPOV 3250 JB1

VEHICLE IDENTIFICATION

Example : FC0A

F : Body type

C : Project code

0A : Engine suffix

01-1

Page 8 of 37

LIFTING

Underbody lifts

02

SAFETY INSTRUCTIONS

Various cases have to be considered:

1-

REMOVING COMPONENTS

As a general rule, never use a 2 post lift whenever

a four post lift can be used.

If this is not possible, place the lifting pads

beneath the underbody flange at the level of the

tool kit jack supports.

98703S

FRONT

98704S

REAR

These must be positioned level with the tool kit

jack supports. They must slot into the openings in

the underbody flanges.

2-

REMOVING - REFITTING THE ENGINE AND

TRANSMISSION ASSEMBLY

In this particular case, the vehicle body must be

secured to the arms of the 2 post lift using special

pads.

Company FOG

Part Number FOG 449 8111 - 449 8411

or

Company CHEMICO

Part Number 39 2550 0001

or

Company SCHENCH

Part Number 776 684

02-2

Page 13 of 37

DRAINING - FILLING

Engine

E7J ENGINE

05

D7F ENGINE

TOOLING REQUIRED

Engine drain plug spanner

DRAINING: plug (1)

13367R

FILLING: plug(2)

13369R12560R

13357R

05-1

Page 14 of 37

DRAINING - FILLING

Engine

05

F8Q ENGINE

DRAINING: plug (1)FILLING: plug (2)

13368R13358R

05-2

Page 15 of 37

DRAINING - FILLING

Gearbox

05

DRAINING: plug (1)

FILLING: plug (2)

D7F ENGINE

13369R1

E7J ENGINE

13367R1

F8Q ENGINE

13368R1

05-3

Page 16 of 37

DRAINING - FILLING

Power assisted steering

05

CHECKING THE LEVEL

POWER ASSISTED STEERING PUMP LEVEL

For topping up or filling, use ELF RENAULTMATIC

D2 or MOBIL ATF 220 oil

.

The level, when correct, should be visible between

the

MIN and MAX marks on the reservoir (1).

D7F - E7J - F8Q ENGINES

12422R1

05-4

Page 18 of 37

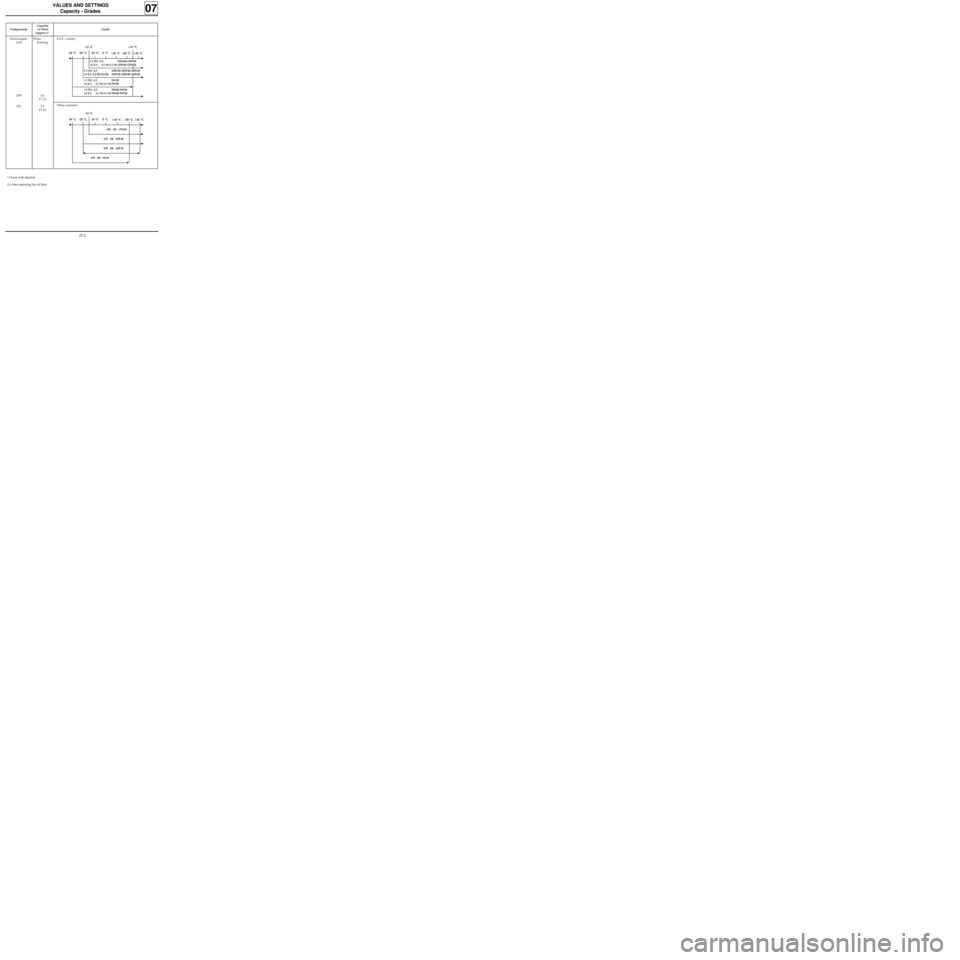

VALUES AND SETTINGS

Capacity - Grades

07

Components

When

draining

3,5

3.7 (1)

2.7

2.9 (1)E.E.C. country

Other countries

Capacity

in litres

(approx.)*

Grade

Petrol engine

(oil)

D7F

E7J

0 °C+30 °C-30 °C

+10 °C+20 °C-20 °C-10 °C

-15 °C+25 °C

CCMC-G415W40-15W50

ACEA A2-96/A3-9615W40-15W50

CCMC-G510W30-10W40-10W50

ACEA A2-96/A3-96 10W30-10W40-10W50

CCMC-G55W30

ACEA A2-96/A3-965W30

CCMC-G55W40-5W50

ACEA A2-96/A3-965W40-5W50

API SH 10W40

API SH 10W30

0 °C+30 °C-30 °C+10 °C+20 °C-20 °C-10 °C

-15 °C

API SH 5W30

API SH 15W40

* Check with dipstick

(1) After replacing the oil filter

07-2

Page 19 of 37

VALUES AND SETTINGS

Capacity - Grades

07

When

draining

4.7

5.2 (1)E.E.C. country

Other countries

Diesel engine

(oil)

F8Q

0 °C+30 °C-30 °C

+10 °C+20 °C-20 °C-10 °C

-15 °C+25 °C

CCMC-PD215W40

ACEA B2-96/B3-9615W40

CCMC-PD210W40

ACEA B2-96/B3-9610W40

CCMC-PD25W30

ACEA B2-96/B3-965W30

CCMC-PD25W40

ACEA B2-96/B3-965W40

API CF 10W30

0 °C+30 °C-30 °C+10 °C+20 °C-20 °C-10 °C

-15 °C+15 °C

API CF 15W40

API CF 10W40

* Check with dipstick

(1) After replacing the oil filter

Components

Capacity

in litres

(approx.)*

Grade

07-3

Page 23 of 37

VALUES AND SETTINGS

Accessories belt tension

07

RIBBED BELT

Tensioning process

Engine cold (ambient temperature).

Fit the new belt.

Position the sensor of Mot. 1273.

Turn the wheel of the sensor until it disengages (three "CLICKS").

Tension the belt until the recommended fitting value is displayed on Mot. 1273 .

Lock the tensioner, check it, adjust the value.

Turn the crankshaft over three times.

Check that the tension value is within the fitting tension tolerance, otherwise readjust it.

NOTE :

Never refit a belt which has been removed.

Replace the belt if the tension is below the minimum operating tension.

Small cuts or cracks do not mean that the belt has to be replaced.

07-7