clutch RENAULT KANGOO 1997 KC / 1.G Transmission Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 22, PDF Size: 0.17 MB

Page 1 of 22

Transmission

CLUTCH

MANUAL GEARBOX

DRIVESHAFTS

Renault 1997

77 11 194 244JULY 1997Edition Anglaise

"The repair methods given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The methods may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories

from which his vehicles are constructed."All copyrights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault

C

FC0A - FC0C - FC0D - FC0E - KC0A - KC0C - KC0D - KC0E

Page 3 of 22

21-1

21-2

21-3

21-4

21-4

21-5

Contents

Page

Transmission

CLUTCH

Mechanism- Disc

Flywheel20

20-1

20-4

ENSEMBLE MOTEUR ET BAS

Identification

Ratios

Capacities-Lubricants

Consumables

Parts to be systematically replaced

Gearbox (Removal-Refitting)MANUAL GEARBOX21

29-1

29-2General

Front driveshaft

DRIVESHAFTS29

Page 4 of 22

CLUTCH

Mechanism - Disc

20

Cable-controlled dry-operating single disc clutch.

Constant pressure clutch thrust bearing.

Vehicle

TypeEngine

TypeMechanism Disc

F/K C0A

F/K C0CD7F

E7J

180 CP330026 splinesGA : Grey Silver

D = 181.5 mm VR : Violet Red

E = 6.7 mm

F/K C0D

F/K C0EF8Q

200 CPOV 325026 splinesRR : Red Ruby

D = 242 mm GB : Grey Blue

E = 6.8 mm

85873S

76906R

85873S

76906R 90693R9 90693R8

20-1

Page 5 of 22

CLUTCH

Mechanism - Disc

REFITTING

Clean the splines of the clutch shaft and refit the

assembly without lubricant.

Fit the disc (with the offset on the hub on the

gearbox side).

Centre using the tool supplied in the kit.

20

REMOVAL

Fit the locking sector tool Mot. 582 or

Mot. 582-01.

Remove the mounting bolts from the mechanism

and remove the friction plate.

Check and replace any faulty parts.

99055R

SPECIAL TOOLING REQUIRED

Mot. 582

or Locking tool

Mot. 582-01

Mechanism mounting bolt 2

TIGHTENING TORQUES (in daN.m)

REPLACEMENT (after removal of the gearbox)

95414S

Tighten progressively in a star pattern, then tigh-

tenthe mounting bolts to the correct torque.

Remove the locking sector tool Mot. 582 or

Mot. 582-01.

Coat with

MOLYKOTE BR2 grease:

- the guide tube,

- the fork pads.

20-2

Page 6 of 22

CLUTCH

Mechanism - Disc

20

After refitting the gearbox, place the cable onto

the clutch fork, reset the notched sector and

check that the play compensation is in working or-

der.

Check the travel of the clutch.

The travel of the fork must be:

X = 27.4 to 30.7 mm

97758-1R

NOTE : in the case of any intervention not requi-

ring the removal of the gearbox or after the fit-

ting of the gearbox,

DO NOT LIFT the fork, as it

would risk releasing itself from the slot (A) of the

clutch thrust bearing.

99054R

20-3

Page 7 of 22

CLUTCH

Flywheel

20

REMOVAL

After removing the friction plate, remove the

mounting bolts of the flywheel (must not be

re-used).

Regrinding of the friction face is not permitted.

REFITTING

Clean the threads of the mounting bolts of the fly-

wheel on the crankshaft.

Remove the grease from the bearing face of the

flywheel on the crankshaft.

Refit the flywheel by immobilising it with tool

Mot. 582 or Mot. 582-01.

NOTE: the flywheel mounting bolts are to be sys-

tematically replaced.

SPECIAL TOOLING REQUIRED

Mot. 582

or Locking tool

Mot. 582-01

Flywheel bolt 2 + 60°

TIGHTENING TORQUES (In daN.m)

REPLACEMENT of the flywheel

20-4

Page 11 of 22

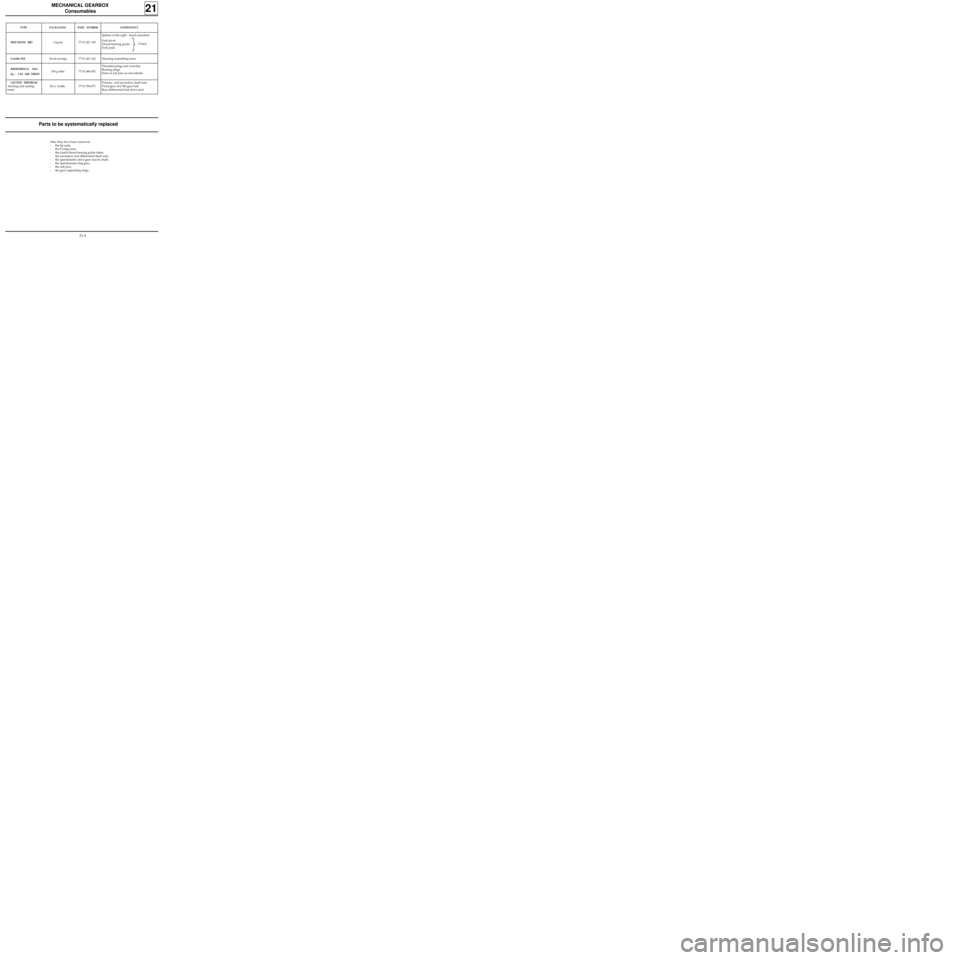

MECHANICAL GEARBOX

Consumables

21

TYPEPACKAGING

Loctite 518

LOCTITE FRENBLOC

(locking and sealing

resin)

24 ml syringe

100 g tube

24 cc bottle

PART NUMBER

77 01 404 452

77 01 394 071

COMPONENT

77 01 421 162Housing assembling faces

Threaded plugs and switches

Bearing plugs

Ends of roll pins on driveshafts

Primary and secondary shaft nuts

Fixed gear and 5th gear hub

Rear differential lock drive stud

Splines of the right - hand sunwheel

Fork pivot

Thrust bearing guide

Fork pads

MOLYKOTE BR277 01 421 1451 kg tinClutch

Parts to be systematically replaced

After they have been removed :

- the lip seals,

- the O-ring seals,

- the clutch thrust bearing guide tubes,

- the secondary and differential shaft nuts,

- the speedometer drive gear and its shaft,

- the speedometer ring gear,

- the roll pins,

- the gear supporting rings.

RHODORSEAL 5661

Eg : CAF 4/60 THIXO

21-4

Page 13 of 22

MANUAL GEARBOX

Gearbox (Removal - Refitting)

21

Remove :

- the two mounting bolts (B),

13119R

Disconnect the clutch cable.

Remove :

- the upper bolts at the gearbox edge and on

the starter motor (slacken the bolt (D) as far

as possible)

- the earth strap bolts on the gearbox,

- the two bolts of the

TDC sensor.

13097-2R

- the front wheels,

- the oil collector under the gearbox.

On the right-hand side of the vehicle, remove the

driveshaft pins using tool B. Vi. 31-01.

91755-1R2

Remove on both sides :

- the brake callipers and attach them together

- the mudguards,

- the track rod ends (T. Av. 476),

- the shock absorber base bolts,

- the sub-frame side member tie-rods (A),

- the stub axle carrier-driveshaft by disconnec-

ting it from the lower ball joint

99070R1

21-6

Page 16 of 22

MANUAL GEARBOX

Gearbox (Removal - Refitting)

21

REFITTING

Coat the walls of the guide tube and the fork pads

with

MOLIKOTE BR2 grease.

Place the fork onto the slots of the clutch thrust

bearing.

Assemble the gearbox on the engine taking care

not to alter the height of the engine.

Ensure the presence and correct positioning of

the engine- gearbox centering rings .

The presence of the stud (C) aids assembly.

86308R2

Refit:

- the engine sub-frame,

- the steering,

- the exhaust downpipe,

- the engine tie-bar.

SPECIAL NOTE FOR THE E7J ENGINE

Refit the exhaust downpipe before the right-

hand driveshaft.

Refit the other components by proceeding in the

reverse order to removal.

21-9