sensor RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 144 of 204

13B-144

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$120.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

PR064COOLANT TEMPERATURE

NOTESSpecial notes:

Only apply the checks if the parameter is inconsistent.

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Check the condition of the coolant temperature sensor connections, component code 244.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A (Renault) or Technical Note

9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise replace

the wiring.

If necessary, replace the sensor.

Measure the resistance between connections 3C and 3JK of the coolant temperature sensor, component code

244:

If the resistance of the coolant temperature sensor is not:

(theoretical values)

11.5 < X < 13.5 at – 10°C,

2140 < X < 2364 at 25°C,

773 < X < 851 at 50°C,

275 < X < 291 at 80°C,

112 < X < 118 at 110°C,

Replace the coolant temperature sensor (see MR 388 (Logan/Sandero), MR 451 (Duster), MR 423 (Thalia 2/

Symbol 2) or MR 374 (Kangoo VLL), Mechanical, 19A Cooling, Coolant temperature sensor: Removal –

Refitting).

DCM1.2_V08_PR064

Page 153 of 204

13B-153

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

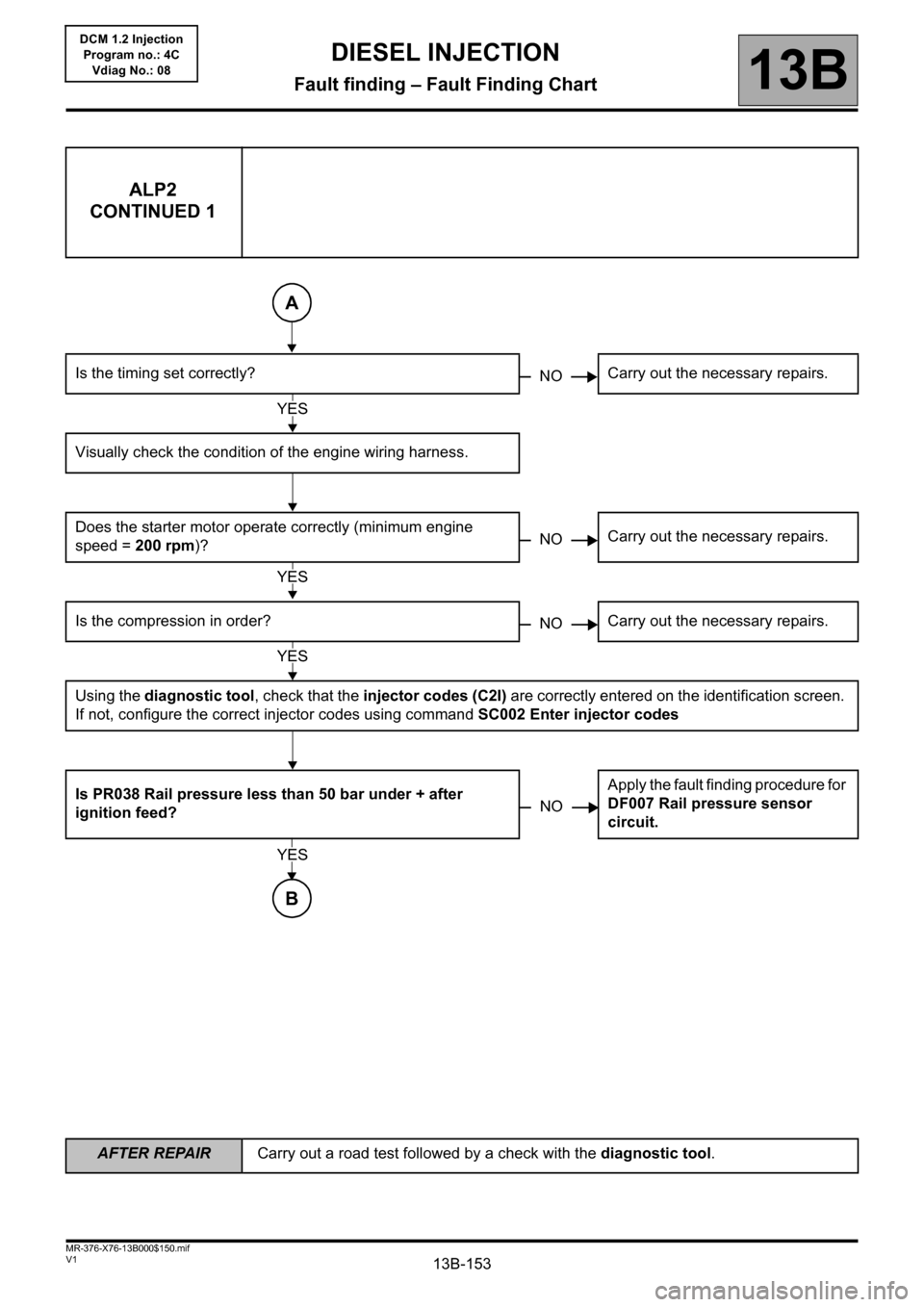

ALP2

CONTINUED 1

Is the timing set correctly? Carry out the necessary repairs.

Visually check the condition of the engine wiring harness.

Does the starter motor operate correctly (minimum engine

speed = 200 rpm)?Carry out the necessary repairs.

Is the compression in order? Carry out the necessary repairs.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen.

If not, configure the correct injector codes using command SC002 Enter injector codes

Is PR038 Rail pressure less than 50 bar under + after

ignition feed?Apply the fault finding procedure for

DF007 Rail pressure sensor

circuit.

A

NO

YES

NO

YES

NO

YES

NO

B

YES

Page 175 of 204

13B-175

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

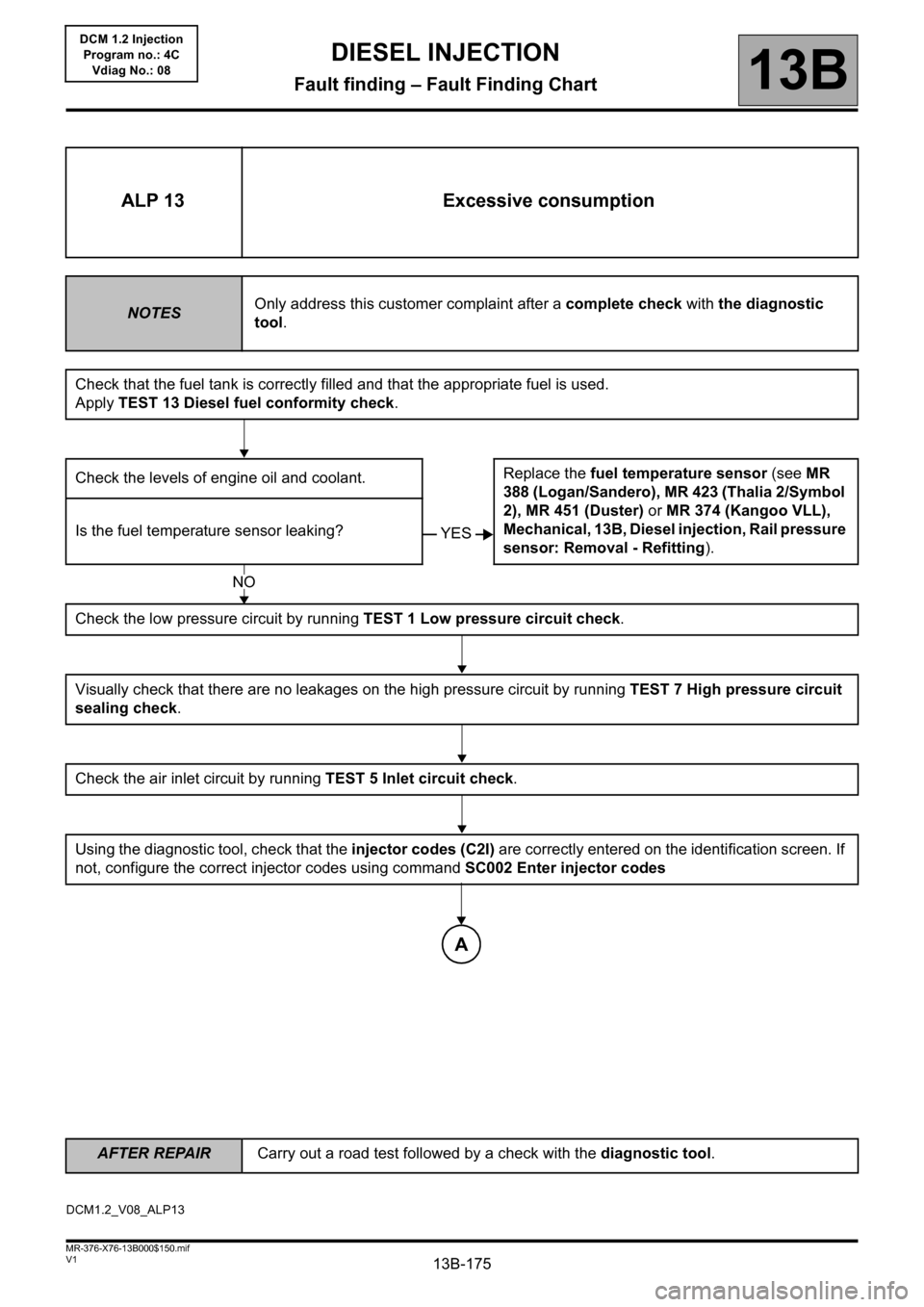

ALP 13 Excessive consumption

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Check that the fuel tank is correctly filled and that the appropriate fuel is used.

Apply TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.Replace the fuel temperature sensor (see MR

388 (Logan/Sandero), MR 423 (Thalia 2/Symbol

2), MR 451 (Duster) or MR 374 (Kangoo VLL),

Mechanical, 13B, Diesel injection, Rail pressure

sensor: Removal - Refitting). Is the fuel temperature sensor leaking?

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Visually check that there are no leakages on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

Check the air inlet circuit by running TEST 5 Inlet circuit check.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes

YES

NO

A

DCM1.2_V08_ALP13

Page 201 of 204

13B-201V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

TEST 11

CONTINUED

High pressure circuit check

Note:

Depending on the vehicle type, the best visual access will be either

from above or from below.

Visually inspect the condition of the following components:

– the compressor outlet pipe to the turbocharging air cooler (the

turbocharging air cooler does not exist for all engines),

– outlet pipe of the turbocharging air cooler to the inlet manifold,

– inlet manifold,

– temperature and pressure sensors.

Is one of these components incorrect (disconnected, cut, bent,

pierced or kinked pipes)?Replace the faulty parts

(see MR 388 (Logan/

Sandero), MR 451

(Duster), MR 423 (Thalia

2/Symbol 2) or MR 374

(Kangoo VLL),

Mechanical, 12B,

Turbocharging). Exhaust system check

– Visually inspect the condition of the following engine sections:

– from the exhaust manifold circuit to the turbocharger turbine,

– from the turbine outlet pipe to the end of the exhaust pipe,

– from the inlet manifold to the EGR valve

– check that the temperature and pressure sensors are connected.

Do some of these components have black or white marks on

them?

Run TEST 10 Turbocharger solenoid valve check.

A

YES

NO

YES

NO