air conditioning RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 12 of 204

13B-12V1 MR-376-X76-13B000$030.mif

DIESEL INJECTION

Fault finding – System operation13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

Idling speed regulation

The computer handles the calculation of idling speed. This has to take account of the instantaneous power level to

be supplied, according to the following factors:

– engine coolant temperature,

– gear ratio engaged,

– battery charge,

– electrical consumers (Additional heating, Air conditioning, Fan Unit, electric windows, etc.) active or inactive,

– system faults detected.

Individual injector correction (C2I)

The DCM 1.2 system injectors must be calibrated with correction values so that their flow may be adjusted precisely.

Each injector is calibrated for different pressures on a test bench, and its specifications are shown on a label

attached to the body of the injector holders. These individual correction values are then entered into the computer

EEPROM, which can then control the injectors, taking their manufacturing variations into account.

Measuring the angular position (Cylinder reference sensor)

The angular position is measured using a magneto-inductive sensor triggered by machined teeth on the shaft

flywheel. This flywheel has sixty teeth separated by six degrees minus two missing teeth, that form a notch.

A second sensor (Hall effect) triggered by a machined tooth on the high pressure pump drive pulley (synchronised

with the camshaft), which rotates at half the engine speed, supplies an injection cycle running signal. By comparing

the signals from these two sensors, the computer's APS module (Angular Position Subsystem) is able to supply the

synchronisation components to the system assembly, namely:

– the angular position of the flywheel

– the speed and number of the active injector

– the injection cycle progress.

This module also supplies the system with the engine speed signal.

Flow capacity function (VLC)

Because of the combination of several parameters such as the diesel fuel temperature, part wear, clogging of the

diesel filter etc., the system limit may be reached during its service life. If this happens, the rail pressure cannot be

maintained because the pump lacks the necessary capacity. If the pump lacks the necessary capacity, this

programming will therefore reduce the requested flow to a value that will enable the pressure monitoring system to

control the pressure again.

The customer may have noticed a loss of vehicle performance when this program is activated (confirmed by status

Flow capacity function). This is part of normal operation.

Page 14 of 204

13B-14V1 MR-376-X76-13B000$030.mif

DIESEL INJECTION

Fault finding – System operation13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

Functions included

Air conditioning management assistance

On models with air conditioning, the DCM 1.2 system allows the air conditioning to be deactivated under certain

operating conditions:

– when requested by the driver,

– when starting the engine,

– if the engine overheats (in order to reduce the power the engine has to supply),

– when the engine speed is kept at a very high level (to protect the compressor),

– during transition phases (eg. high acceleration demand for overtaking, anti-stalling and moving off). These

conditions are only taken into account if they do not occur repeatedly, so as to prevent system instabilities (erratic

deactivation),

– when certain faults appear.

Cold loop air conditioning management

The air conditioning system is a cold loop system and is managed by the injection computer which is responsible for:

– managing the cooling request according to passenger compartment controls and the refrigerant fluid pressure

value,

– calculating the power absorbed by the compressor from the refrigerant pressure,

– determining the fan unit commands according to the vehicle speed and the refrigerant fluid pressure.

The driver requests the air conditioning to be switched on by means of the ventilation selector coupled to a switch.

This cooling request may or may not be authorised depending on the refrigerant fluid pressure measured. If this

pressure is outside the operating limits, the cold loop program is not activated.

Thermal regulation of the passenger compartment heating circuit

Engines with direct injection systems are characterised by the direct injection of fuel into the combustion chamber.

This leads to heat being lost through the upper part of the engine and consequently, the cylinder head cooling

system is smaller in size.

The effect of this is that the temperature of the coolant which flows through this circuit rises more slowly. This

coolant is also used by the passenger compartment heating system. In very cold conditions, it is therefore difficult to

achieve a comfortable passenger compartment temperature quickly.

To reduce the time taken to warm up the system, air heating resistors, called passenger compartment heating

resistors, are fitted in the passenger compartment heating circuit. The DCM 1.2 injection computer determines

whether it is necessary to physically control the passenger compartment heating resistors. The injection computer

determines, on the one hand, limitation of the passenger compartment heating resistor power control depending on

the alternator charge, and on the other hand, the inhibition of the passenger compartment heating resistors

according to the engine speed, load and vehicle speed.Note:

Fan unit control requests are made from the injection computer.

These requests depend on the air conditioning, but also on the engine coolant temperature and vehicle speed.

Page 17 of 204

13B-17V1 MR-376-X76-13B000$040.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

COMPUTER REPLACEMENT, PROGRAMMING AND REPROGRAMMING OPERATIONS

The system can be programmed via the diagnostic socket using the diagnostic tool (see Technical Note 3585A

Computer programming and reprogramming procedure and Technical Note 9869A Computer programming

and reprogramming procedure and following the instructions provided by the diagnostic tool).

Before removing the computer in After-Sales, save the computer data using the diagnostic tool by running

command SC003 Save computer data. This command saves the following information:

–C2I parameters (individual injector correction) and engine parameters,

–Measuring system information,

–Injection system reset data. IMPORTANT

– Switch on the diagnostic tool (mains or cigarette lighter supply).

– Connect a battery charger.

– Switch off all electrical consumers (lights, interior lights, air conditioning, radio/CD, etc.).

– Wait for the engine to cool (engine coolant temperature below 60°C and air temperature below 50°C).

IMPORTANT

It is not possible to try an injection computer coming from the Parts Department because it will no longer be

possible to use it on another vehicle.

DIESEL INJECTION

Fault finding – Replacement of components

Page 24 of 204

13B-24V1 MR-376-X76-13B000$060.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

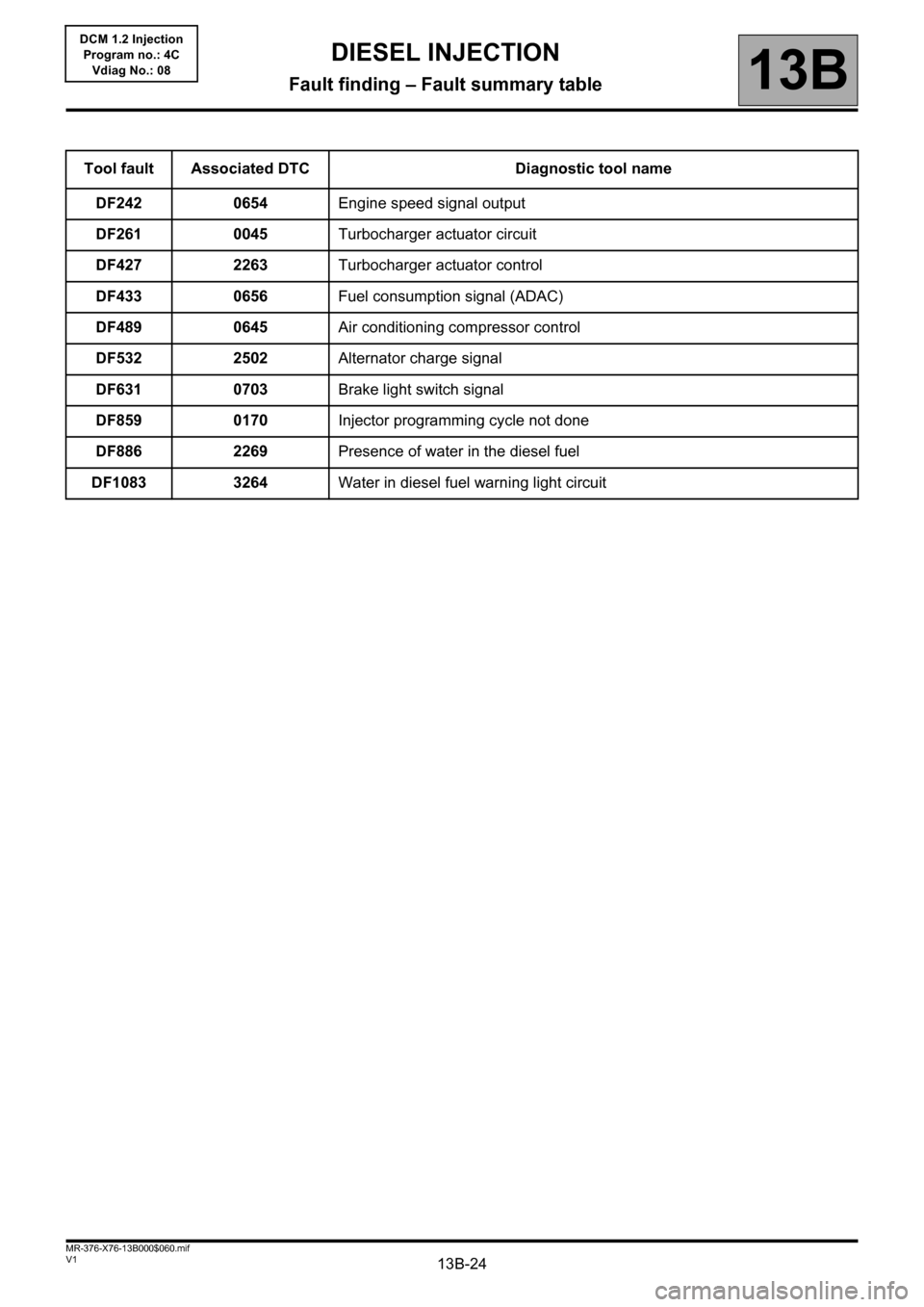

Tool fault Associated DTC Diagnostic tool name

DF242 0654Engine speed signal output

DF261 0045Turbocharger actuator circuit

DF427 2263Turbocharger actuator control

DF433 0656Fuel consumption signal (ADAC)

DF489 0645Air conditioning compressor control

DF532 2502Alternator charge signal

DF631 0703Brake light switch signal

DF859 0170Injector programming cycle not done

DF886 2269Presence of water in the diesel fuel

DF1083 3264Water in diesel fuel warning light circuit

Page 25 of 204

13B-25

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$071.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

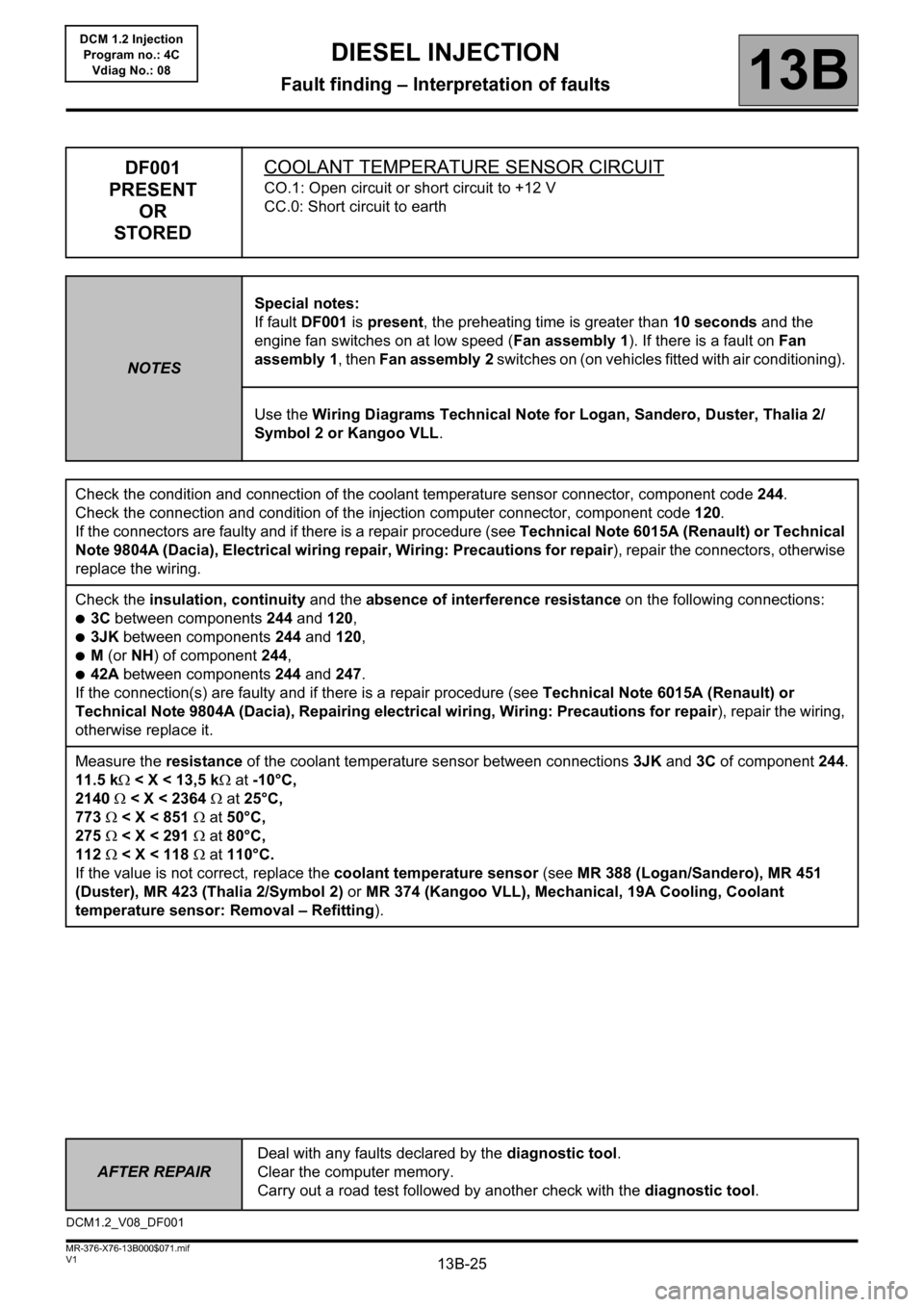

DF001

PRESENT

OR

STOREDCOOLANT TEMPERATURE SENSOR CIRCUIT

CO.1: Open circuit or short circuit to +12 V

CC.0: Short circuit to earth

NOTESSpecial notes:

If fault DF001 is present, the preheating time is greater than 10 seconds and the

engine fan switches on at low speed (Fan assembly 1). If there is a fault on Fan

assembly 1, then Fan assembly 2 switches on (on vehicles fitted with air conditioning).

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Check the condition and connection of the coolant temperature sensor connector, component code 244.

Check the connection and condition of the injection computer connector, component code 120.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connectors, otherwise

replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connections:

●3C between components 244 and 120,

●3JK between components 244 and 120,

●M (or NH) of component 244,

●42A between components 244 and 247.

If the connection(s) are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or

Technical Note 9804A (Dacia), Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

Measure the resistance of the coolant temperature sensor between connections 3JK and 3C of component 244.

11.5 k < X < 13,5 k at -10°C,

2140 < X < 2364 at 25°C,

773 < X < 851 at 50°C,

275 < X < 291 at 80°C,

112 < X < 118 at 110°C.

If the value is not correct, replace the coolant temperature sensor (see MR 388 (Logan/Sandero), MR 451

(Duster), MR 423 (Thalia 2/Symbol 2) or MR 374 (Kangoo VLL), Mechanical, 19A Cooling, Coolant

temperature sensor: Removal – Refitting).

DCM1.2_V08_DF001

DIESEL INJECTION

Fault finding – Interpretation of faults

Page 71 of 204

13B-71

AFTER

REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

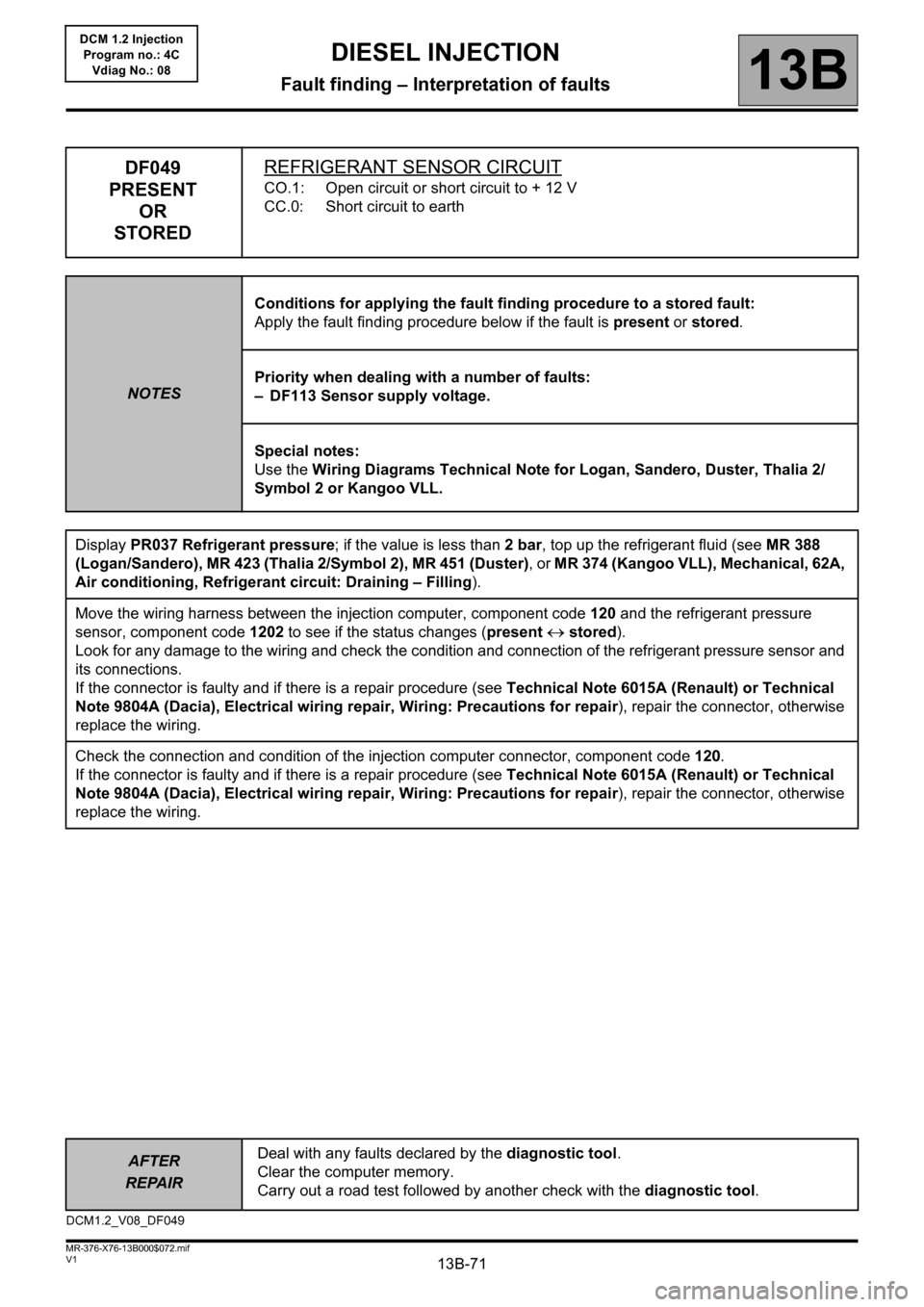

DF049

PRESENT

OR

STOREDREFRIGERANT SENSOR CIRCUIT

CO.1: Open circuit or short circuit to + 12 V

CC.0: Short circuit to earth

NOTESConditions for applying the fault finding procedure to a stored fault:

Apply the fault finding procedure below if the fault is present or stored.

Priority when dealing with a number of faults:

– DF113 Sensor supply voltage.

Special notes:

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Display PR037 Refrigerant pressure; if the value is less than 2 bar, top up the refrigerant fluid (see MR 388

(Logan/Sandero), MR 423 (Thalia 2/Symbol 2), MR 451 (Duster), or MR 374 (Kangoo VLL), Mechanical, 62A,

Air conditioning, Refrigerant circuit: Draining – Filling).

Move the wiring harness between the injection computer, component code 120 and the refrigerant pressure

sensor, component code 1202 to see if the status changes (present

stored).

Look for any damage to the wiring and check the condition and connection of the refrigerant pressure sensor and

its connections.

If the connector is faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise

replace the wiring.

Check the connection and condition of the injection computer connector, component code 120.

If the connector is faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise

replace the wiring.

DCM1.2_V08_DF049

Page 112 of 204

13B-112

AFTER

REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

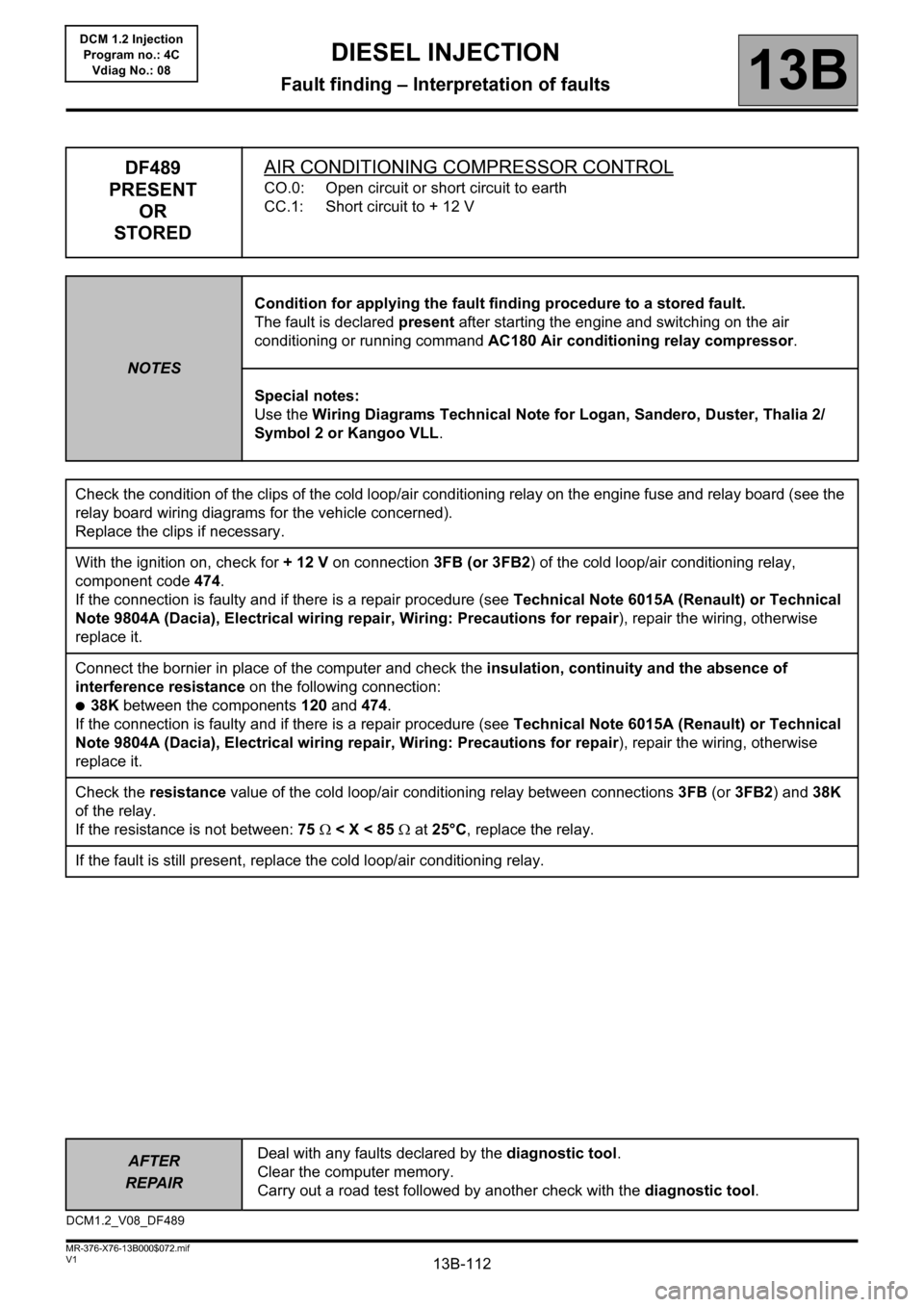

DF489

PRESENT

OR

STOREDAIR CONDITIONING COMPRESSOR CONTROL

CO.0: Open circuit or short circuit to earth

CC.1: Short circuit to + 12 V

NOTESCondition for applying the fault finding procedure to a stored fault.

The fault is declared present after starting the engine and switching on the air

conditioning or running command AC180 Air conditioning relay compressor.

Special notes:

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Check the condition of the clips of the cold loop/air conditioning relay on the engine fuse and relay board (see the

relay board wiring diagrams for the vehicle concerned).

Replace the clips if necessary.

With the ignition on, check for + 12 V on connection 3FB (or 3FB2) of the cold loop/air conditioning relay,

component code 474.

If the connection is faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise

replace it.

Connect the bornier in place of the computer and check the insulation, continuity and the absence of

interference resistance on the following connection:

●38K between the components 120 and 474.

If the connection is faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise

replace it.

Check the resistance value of the cold loop/air conditioning relay between connections 3FB (or 3FB2) and 38K

of the relay.

If the resistance is not between: 75 < X < 85 at 25°C, replace the relay.

If the fault is still present, replace the cold loop/air conditioning relay.

DCM1.2_V08_DF489

Page 119 of 204

13B-119V1 MR-376-X76-13B000$080.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

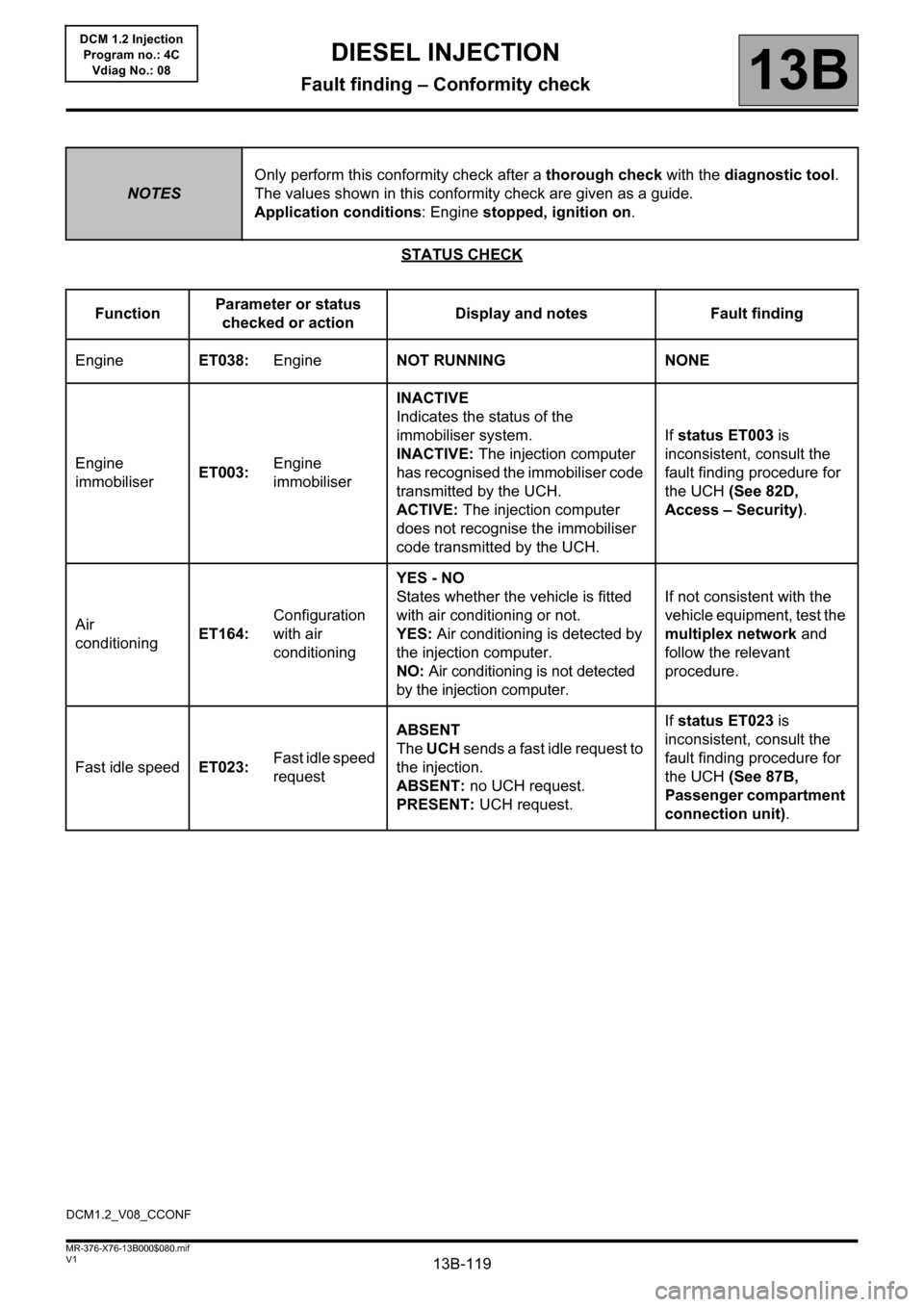

STATUS CHECK

NOTESOnly perform this conformity check after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine stopped, ignition on.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

EngineET038:EngineNOT RUNNING NONE

Engine

immobiliserET003:Engine

immobiliserINACTIVE

Indicates the status of the

immobiliser system.

INACTIVE: The injection computer

has recognised the immobiliser code

transmitted by the UCH.

ACTIVE: The injection computer

does not recognise the immobiliser

code transmitted by the UCH.If status ET003 is

inconsistent, consult the

fault finding procedure for

the UCH (See 82D,

Access – Security).

Air

conditioningET164:Configuration

with air

conditioningYES - NO

States whether the vehicle is fitted

with air conditioning or not.

YES: Air conditioning is detected by

the injection computer.

NO: Air conditioning is not detected

by the injection computer.If not consistent with the

vehicle equipment, test the

multiplex network and

follow the relevant

procedure.

Fast idle speedET023:Fast idle speed

requestABSENT

The UCH sends a fast idle request to

the injection.

ABSENT: no UCH request.

PRESENT: UCH request.If status ET023 is

inconsistent, consult the

fault finding procedure for

the UCH (See 87B,

Passenger compartment

connection unit).

DCM1.2_V08_CCONF

DIESEL INJECTION

Fault finding – Conformity check

Page 120 of 204

13B-120V1 MR-376-X76-13B000$080.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

STATUS CHECK (CONTINUED 1)

NOTESOnly perform this conformity check after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine stopped, ignition on.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

Air

conditioningET116:Climate control

authorisationNO

YES: The UCH should send an

activation request to the injection.

The coolant pressure sensor must

not be defective. Satisfactory engine

operating conditions (coolant

temperature, engine load etc.).

NO: One of the above conditions has

not been fulfilled.NONE

EGRET008:EGR solenoid

valve controlINACTIVE

Shows the condition of the EGR

valve control.

INACTIVE: The valve is not

controlled by the computer.

ACTIVE: The valve is controlled by

the computer.NONE

PreheatingET007:Pre-

postheating

controlACTIVE/INACTIVE

Shows the status of the preheating

unit control.In the event of a fault,

consult the interpretation

of fault DF017 Preheating

unit control circuit.

Page 127 of 204

13B-127V1 MR-376-X76-13B000$080.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

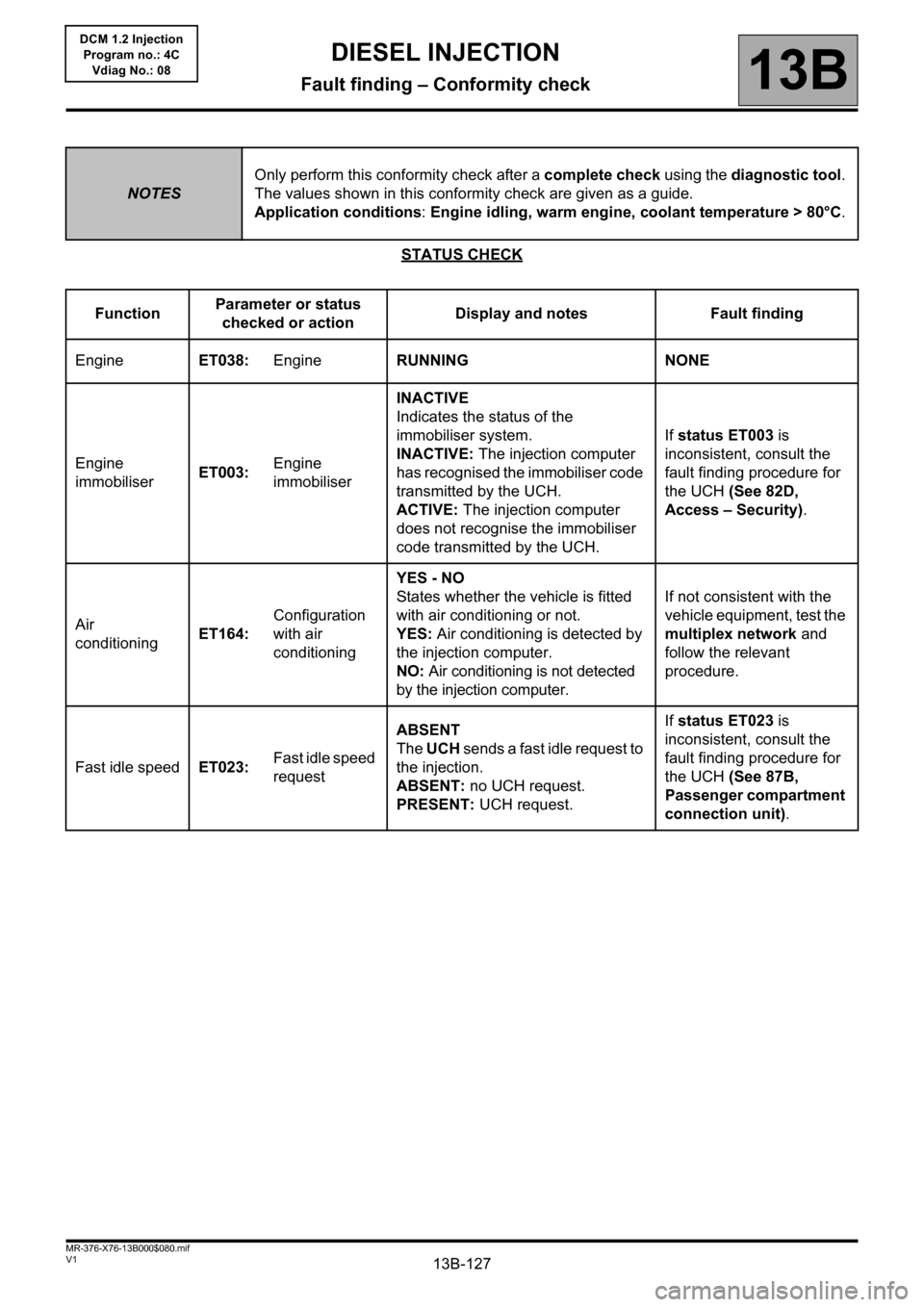

STATUS CHECK

NOTESOnly perform this conformity check after a complete check using the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine idling, warm engine, coolant temperature > 80°C.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

EngineET038:EngineRUNNING NONE

Engine

immobiliserET003:Engine

immobiliserINACTIVE

Indicates the status of the

immobiliser system.

INACTIVE: The injection computer

has recognised the immobiliser code

transmitted by the UCH.

ACTIVE: The injection computer

does not recognise the immobiliser

code transmitted by the UCH.If status ET003 is

inconsistent, consult the

fault finding procedure for

the UCH (See 82D,

Access – Security).

Air

conditioningET164:Configuration

with air

conditioningYES - NO

States whether the vehicle is fitted

with air conditioning or not.

YES: Air conditioning is detected by

the injection computer.

NO: Air conditioning is not detected

by the injection computer.If not consistent with the

vehicle equipment, test the

multiplex network and

follow the relevant

procedure.

Fast idle speedET023:Fast idle speed

requestABSENT

The UCH sends a fast idle request to

the injection.

ABSENT: no UCH request.

PRESENT: UCH request.If status ET023 is

inconsistent, consult the

fault finding procedure for

the UCH (See 87B,

Passenger compartment

connection unit).