fuel RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 8 of 204

13B-8V1 MR-376-X76-13B000$020.mif

DIESEL INJECTION

Fault finding – Cleanliness guidelines13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

II - INSTRUCTIONS TO BE FOLLOWED BEFORE CARRYING OUT ANY WORK

Ensure that you have plugs for the unions to be opened (set of plugs available from the Parts Department). Plugs

are to be used only once. They must be discarded after use (once used they are soiled and cleaning is not sufficient

to make them reusable). Unused plugs must be thrown away.

Ensure that you have hermetically resealable plastic bags for storing removed parts. Parts stored in this way will be

less susceptible to the risk of contamination. The bags are to be used once only, and discarded after use.

Use lint-free cleaning cloths (cloth part reference 77 11 211 707). The use of ordinary cloth or paper is not permitted.

They are not lint-free and could contaminate the fuel circuit. A lint-free cloth should only be used once.

Use fresh cleaning agent for each operation (used cleaning agent is contaminated). Pour it into a clean receptacle.

For each operation, use a clean brush in good condition (the brush must not shed its bristles).

Use a brush and cleaning agent to clean the unions to be opened.

Blow compressed air over the cleaned parts (tools, workbench, the parts, unions and injection system zones).

Check that no bristles are left.

Wash your hands before and during the operation if necessary.

When wearing leather protective gloves cover them with latex gloves to prevent contamination.IMPORTANT

Before carrying out any work on the high pressure injection system, protect:

– the accessories belts,

– the electrical accessories, (starter, alternator, electric power-assisted steering pump),

– the flywheel surface, to prevent any diesel from running onto the clutch friction plate.

– timing chain

Page 10 of 204

13B-10V1 MR-376-X76-13B000$030.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

System outline

The DCM 1.2 injection system used on the K9K engine is an electronically-managed high pressure injection system.

The fuel is compressed by a high pressure pump then stored in a rail that feeds the injectors. Injection takes place

when a current pulse is applied to the injector holders.

The amount injected is proportional to the rail pressure and the applied pulse length, and the start of injection is

synchronised with the start of the pulse.

The system includes two subsystems, which have different fuel pressure levels:

– the low pressure circuit contains the tank, the diesel fuel filter, the transfer pump and the injector holder return pipes,

– the high pressure circuit contains the high pressure pump, the rail, the injector holders and the high pressure pipes.

The injection system contains a number of sensors and actuators for controlling and monitoring the entire system.

Functions provided

Function: Fuel supply management (timing, flow and pressure).

Quantity of fuel injected and injection timing setting

The injection checking parameters are the quantities to be injected and their respective timing.

These are calculated by the computer using signals from the following sensors:

– Engine speed (Crankshaft +Cam for synchronisation).

– Accelerator pedal.

– Turbocharging pressure and air temperature (Turbocharger pressure).

– Coolant temperature.

– Air temperature.

– Air charge (Flow and Pressure).

– Pressure in the rail.

The quantities to be injected and their respective timing are converted into:

– a reference tooth,

– the time between this tooth and the start of the pulse,

– the time for which the supply to the injector holder is on.

Each injector holder is controlled by an electrical current which is sent according to previously calculated data. The

system makes one or two injections (one pilot injection, one main injection).

The general principle is to calculate an overall injected flow, which is then divided into the main injection flow and a

pilot injection flow to promote correct combustion and help reduce pollutant emissions.

DIESEL INJECTION

Fault finding – System operation

Page 11 of 204

13B-11V1 MR-376-X76-13B000$030.mif

DIESEL INJECTION

Fault finding – System operation13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

An accelerometer is used to monitor some of the fuel injection deviation. This has several roles:

– Protecting the engine by detecting injection leaks (disabled on the basic version).

– Checking the pilot quantity by measuring deviation and dispersion.

By changing both the injection duration and advance, the quantity of fuel injected and the mixture's moment of

ignition can be readjusted.

Rail pressure check

The quality of combustion is influenced by the size of the atomised droplets in the cylinder.

In the combustion chamber, smaller fuel droplets will have time to burn fully, and will not produce smoke or

unburned particles. To meet emission control requirements, the droplet size, and therefore the size of the injection

holes, must be reduced.

With smaller holes, less fuel will be able to be introduced at a given pressure, which limits the power. To offset this

disadvantage, the quantity of fuel injected must be increased, which means increased pressure (and more holes in

the injector nozzles).

For the DCM 1.2 injection system, the pressure reaches 1400 bar - 1600 bar in the rail and must be constantly

regulated. The measuring circuit comprises an active pressure sensor on the rail connected to an analogue port on

the computer.

The high pressure pump is supplied at low pressure (5bar) by a built-in transfer pump. This pump supplies the rail.

The rail filling pressure is controlled by the fuel flow actuator (IMV) and the discharge pressure is controlled by the

injector valves. This compensates for pressure drops. The flow actuator enables the high pressure pump to supply

the exact quantity of diesel fuel required to maintain the rail pressure. This mechanism minimises the heat generated

and improves engine output.

In order to discharge the rail using the injector valves, the valves are actuated by short electrical pulses which are:

– short enough in amplitude not to open the injector (and pass through the return circuit from the injectors),

– long enough in time to open the valves and discharge the rail.

The fuel surplus is sent back to the fuel filter or the tank, according to its flow. If there is no fuel flow actuator control,

the rail pressure is limited by a discharge valve fitted on the pump.

New pump chamber filling procedure (pump boosting)

The pump lubrication goes through a booster cycle during which the pump is filled and pressurised before

"transferring" the diesel fuel to the rail.

This lubrication goes through programming called "filling the new pump chamber", which prohibits starting for

approximately 10 seconds (the time required to fill the pump and to start if the key is released before the end of this

"first starting" phase). Power latch is not necessary before attempting to start the vehicle again.

This procedure runs when a computer is replaced if the parameters relating to the rail pressure have not been

copied into the new computer, or otherwise, after reprogramming of the injection computer.

Page 12 of 204

13B-12V1 MR-376-X76-13B000$030.mif

DIESEL INJECTION

Fault finding – System operation13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

Idling speed regulation

The computer handles the calculation of idling speed. This has to take account of the instantaneous power level to

be supplied, according to the following factors:

– engine coolant temperature,

– gear ratio engaged,

– battery charge,

– electrical consumers (Additional heating, Air conditioning, Fan Unit, electric windows, etc.) active or inactive,

– system faults detected.

Individual injector correction (C2I)

The DCM 1.2 system injectors must be calibrated with correction values so that their flow may be adjusted precisely.

Each injector is calibrated for different pressures on a test bench, and its specifications are shown on a label

attached to the body of the injector holders. These individual correction values are then entered into the computer

EEPROM, which can then control the injectors, taking their manufacturing variations into account.

Measuring the angular position (Cylinder reference sensor)

The angular position is measured using a magneto-inductive sensor triggered by machined teeth on the shaft

flywheel. This flywheel has sixty teeth separated by six degrees minus two missing teeth, that form a notch.

A second sensor (Hall effect) triggered by a machined tooth on the high pressure pump drive pulley (synchronised

with the camshaft), which rotates at half the engine speed, supplies an injection cycle running signal. By comparing

the signals from these two sensors, the computer's APS module (Angular Position Subsystem) is able to supply the

synchronisation components to the system assembly, namely:

– the angular position of the flywheel

– the speed and number of the active injector

– the injection cycle progress.

This module also supplies the system with the engine speed signal.

Flow capacity function (VLC)

Because of the combination of several parameters such as the diesel fuel temperature, part wear, clogging of the

diesel filter etc., the system limit may be reached during its service life. If this happens, the rail pressure cannot be

maintained because the pump lacks the necessary capacity. If the pump lacks the necessary capacity, this

programming will therefore reduce the requested flow to a value that will enable the pressure monitoring system to

control the pressure again.

The customer may have noticed a loss of vehicle performance when this program is activated (confirmed by status

Flow capacity function). This is part of normal operation.

Page 13 of 204

13B-13V1 MR-376-X76-13B000$030.mif

DIESEL INJECTION

Fault finding – System operation13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

Function: Air flow management

EGR valve control

The EGR system (Exhaust gas recirculation) comprises a proportional EGR valve, with a built-in valve position

feedback potentiometer. The EGR valve position is controlled by the potentiometer in a closed loop and/or by

changes in the estimated air flow.

Special feature of the K9K796 Euro 2 engine (Indonesia): The EGR solenoid valve is present on the vehicle, but not

used. It always remains closed. It must not be replaced on this vehicle (unless there is a mechanical fault).

Calculating the air flow

K9K 790 and 794 engines are not fitted with an air flowmeter. Instead, the amount of fresh inlet air is evaluated

based on the values supplied by the surrounding systems.

The (theoretical) air load is calculated using a model with various calculation parameters, which are:

– the inlet air temperature measured by a sensor located after the turbocharger and/or after the exchanger (if fitted),

– the turbocharging pressure,

– the atmospheric pressure (external air),

– the EGR valve position,

– the fuel flow,

– the engine speed.

The atmospheric pressure sensor is optional. If fitted, it sends back a signal relating to the atmospheric pressure to

an analogue port on the micro-controller. If not, atmospheric pressure is recovered based on the turbocharger

pressure and the engine field.

For K9K 792 and 796 engines, the flow of fresh air entering the engine is measured by a hot-wire ratiometric sensor.

This flowmeter is used to manage the amount of exhaust gas to be recirculated to ensure optimum recirculation

rates. A fresh air temperature sensor is integrated into the flowmeter. Air flow measurement allows closed-loop

control via the EGR valve.

Turbocharger control

K9K 796 engine:

The turbocharging system is made up of a solenoid valve which is used to control the wastegate to adjust the

absolute pressure of the inlet circuit.

K9K 790, 792, 794 engines:

The turbocharger system is controlled by the inlet pressure and does not need to be controlled by the computer.

Pre-postheating actuation

Pre-postheating actuation consists of controlling the heater plugs and the preheating warning light on the instrument

panel. The heater plugs are activated by a preheating unit (controlled by the injection computer), and the power is

supplied by the battery. After the ignition is switched on a preheating delay is activated. The indicator light comes on

for the activation period which is dependent on the battery voltage, atmospheric pressure and coolant temperature.

If the temperature is below a certain threshold, a postheating function can be used to improve the combustion

stability, and consequently engine operation (reducing unburnt particles and pollutant emissions).

Page 14 of 204

13B-14V1 MR-376-X76-13B000$030.mif

DIESEL INJECTION

Fault finding – System operation13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

Functions included

Air conditioning management assistance

On models with air conditioning, the DCM 1.2 system allows the air conditioning to be deactivated under certain

operating conditions:

– when requested by the driver,

– when starting the engine,

– if the engine overheats (in order to reduce the power the engine has to supply),

– when the engine speed is kept at a very high level (to protect the compressor),

– during transition phases (eg. high acceleration demand for overtaking, anti-stalling and moving off). These

conditions are only taken into account if they do not occur repeatedly, so as to prevent system instabilities (erratic

deactivation),

– when certain faults appear.

Cold loop air conditioning management

The air conditioning system is a cold loop system and is managed by the injection computer which is responsible for:

– managing the cooling request according to passenger compartment controls and the refrigerant fluid pressure

value,

– calculating the power absorbed by the compressor from the refrigerant pressure,

– determining the fan unit commands according to the vehicle speed and the refrigerant fluid pressure.

The driver requests the air conditioning to be switched on by means of the ventilation selector coupled to a switch.

This cooling request may or may not be authorised depending on the refrigerant fluid pressure measured. If this

pressure is outside the operating limits, the cold loop program is not activated.

Thermal regulation of the passenger compartment heating circuit

Engines with direct injection systems are characterised by the direct injection of fuel into the combustion chamber.

This leads to heat being lost through the upper part of the engine and consequently, the cylinder head cooling

system is smaller in size.

The effect of this is that the temperature of the coolant which flows through this circuit rises more slowly. This

coolant is also used by the passenger compartment heating system. In very cold conditions, it is therefore difficult to

achieve a comfortable passenger compartment temperature quickly.

To reduce the time taken to warm up the system, air heating resistors, called passenger compartment heating

resistors, are fitted in the passenger compartment heating circuit. The DCM 1.2 injection computer determines

whether it is necessary to physically control the passenger compartment heating resistors. The injection computer

determines, on the one hand, limitation of the passenger compartment heating resistor power control depending on

the alternator charge, and on the other hand, the inhibition of the passenger compartment heating resistors

according to the engine speed, load and vehicle speed.Note:

Fan unit control requests are made from the injection computer.

These requests depend on the air conditioning, but also on the engine coolant temperature and vehicle speed.

Page 15 of 204

13B-15V1 MR-376-X76-13B000$030.mif

DIESEL INJECTION

Fault finding – System operation13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

Instrument panel display

The computer manages the data display on the instrument panel relating to engine operation.

There are six functions concerned:

–the On board diagnostics MIL (Malfunction Indicator Lamp),

– pre-postheating,

– the coolant temperature,

– engine problems; Level 1 (non-critical fault) and Level 2 (emergency stop).

– detection of water in the fuel (depending on instrument panel).

These six functions are represented using four indicator lights.

Pre-postheating and electronic fault warning light (Level 1)

This light is used to indicate that the heater plugs are preheating and as a system fault indicator light:

– Continuously illuminated during + after ignition feed: indicates preheating of the heater plugs.

– Flashing after preheating and an automatic 3-second stop indicates a Level 1 fault (the function is not working

optimally and safety levels are reduced). The user must carry out repairs as soon as possible).

Engine coolant temperature warning light (Level 2)

This indicator light is used both as an in-operation indicator light and as a system fault warning light. It illuminates for

3 seconds when the power is switched on (automatic test procedure).

Continuously illuminated during + after ignition feed: indicates engine overheating or a Level 2 fault.

OBD warning light

This warning light is used to alert the driver of any injection faults that could lead to excessive pollution, or if the OBD

system has been deactivated.

The injection computer requests illumination of the OBD warning light for a present fault only after three successive

driving cycles.

The 3 second visual inspection when the ignition is switched on (automatic test procedure managed by the

instrument panel) is carried out by the injection computer.

Page 16 of 204

13B-16V1 MR-376-X76-13B000$030.mif

DIESEL INJECTION

Fault finding – System operation13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

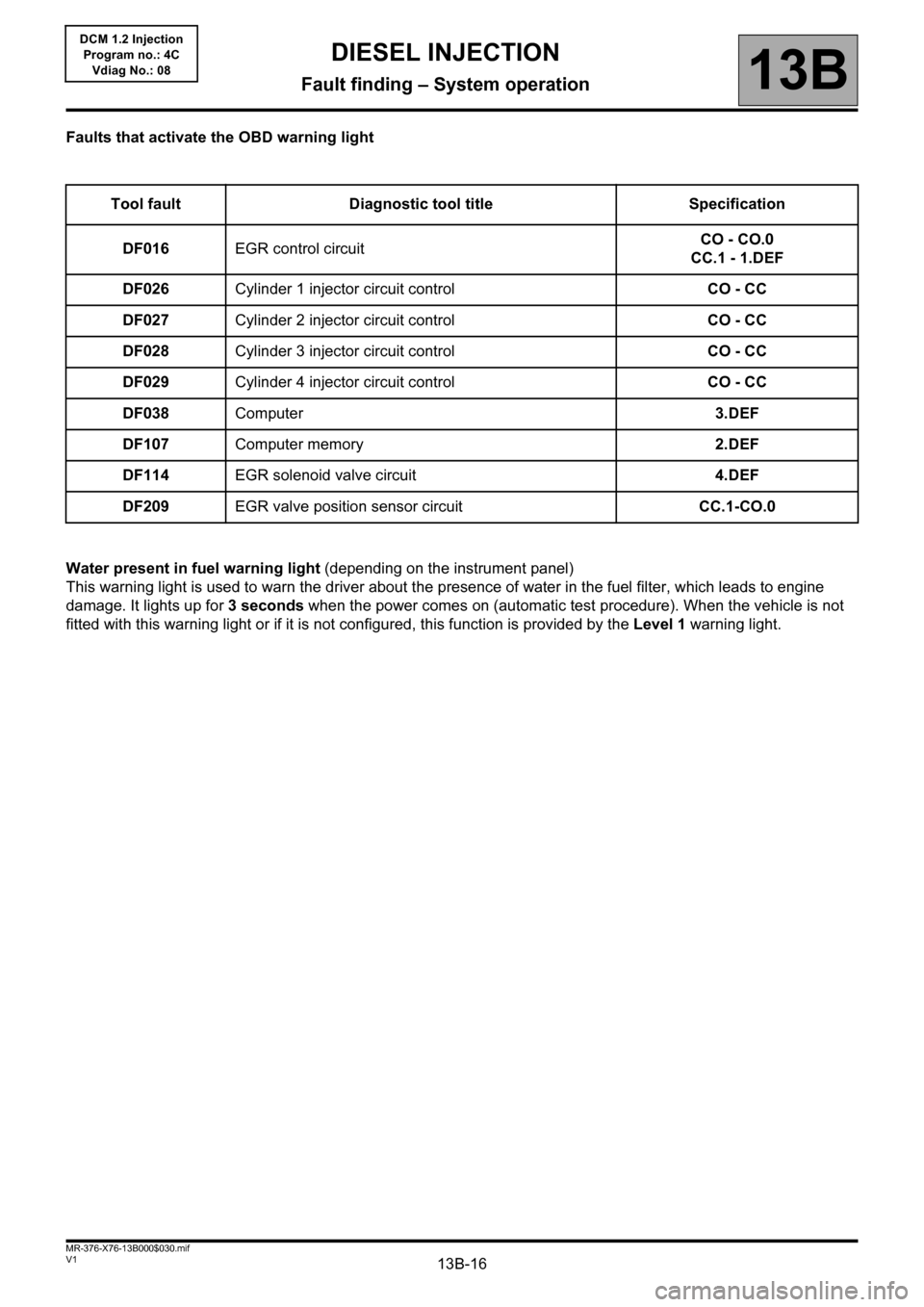

Faults that activate the OBD warning light

Water present in fuel warning light (depending on the instrument panel)

This warning light is used to warn the driver about the presence of water in the fuel filter, which leads to engine

damage. It lights up for 3 seconds when the power comes on (automatic test procedure). When the vehicle is not

fitted with this warning light or if it is not configured, this function is provided by the Level 1 warning light. Tool fault Diagnostic tool title Specification

DF016EGR control circuitCO - CO.0

CC.1 - 1.DEF

DF026Cylinder 1 injector circuit controlCO - CC

DF027Cylinder 2 injector circuit controlCO - CC

DF028Cylinder 3 injector circuit controlCO - CC

DF029Cylinder 4 injector circuit controlCO - CC

DF038Computer3.DEF

DF107Computer memory2.DEF

DF114EGR solenoid valve circuit4.DEF

DF209EGR valve position sensor circuitCC.1-CO.0

Page 18 of 204

13B-18V1 MR-376-X76-13B000$040.mif

DIESEL INJECTION

Fault finding – Replacement of components13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

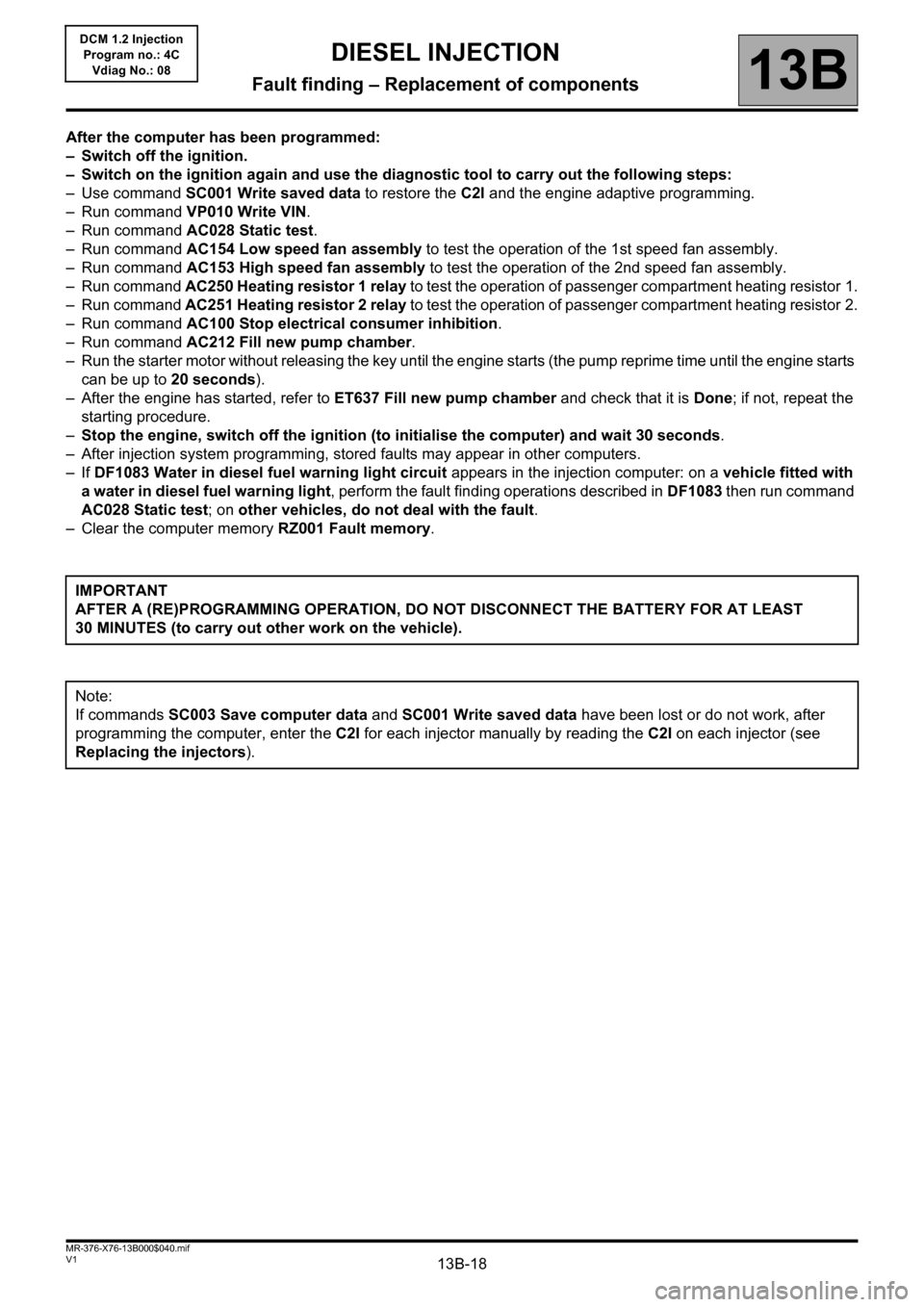

After the computer has been programmed:

– Switch off the ignition.

– Switch on the ignition again and use the diagnostic tool to carry out the following steps:

– Use command SC001 Write saved data to restore the C2I and the engine adaptive programming.

– Run command VP010 Write VIN.

– Run command AC028 Static test.

– Run command AC154 Low speed fan assembly to test the operation of the 1st speed fan assembly.

– Run command AC153 High speed fan assembly to test the operation of the 2nd speed fan assembly.

– Run command AC250 Heating resistor 1 relay to test the operation of passenger compartment heating resistor 1.

– Run command AC251 Heating resistor 2 relay to test the operation of passenger compartment heating resistor 2.

– Run command AC100 Stop electrical consumer inhibition.

– Run command AC212 Fill new pump chamber.

– Run the starter motor without releasing the key until the engine starts (the pump reprime time until the engine starts

can be up to 20 seconds).

– After the engine has started, refer to ET637 Fill new pump chamber and check that it is Done; if not, repeat the

starting procedure.

–Stop the engine, switch off the ignition (to initialise the computer) and wait 30 seconds.

– After injection system programming, stored faults may appear in other computers.

– If DF1083 Water in diesel fuel warning light circuit appears in the injection computer: on a vehicle fitted with

a water in diesel fuel warning light, perform the fault finding operations described in DF1083 then run command

AC028 Static test; on other vehicles, do not deal with the fault.

– Clear the computer memory RZ001 Fault memory.

IMPORTANT

AFTER A (RE)PROGRAMMING OPERATION, DO NOT DISCONNECT THE BATTERY FOR AT LEAST

30 MINUTES (to carry out other work on the vehicle).

Note:

If commands SC003 Save computer data and SC001 Write saved data have been lost or do not work, after

programming the computer, enter the C2I for each injector manually by reading the C2I on each injector (see

Replacing the injectors).

Page 23 of 204

13B-23V1 MR-376-X76-13B000$060.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

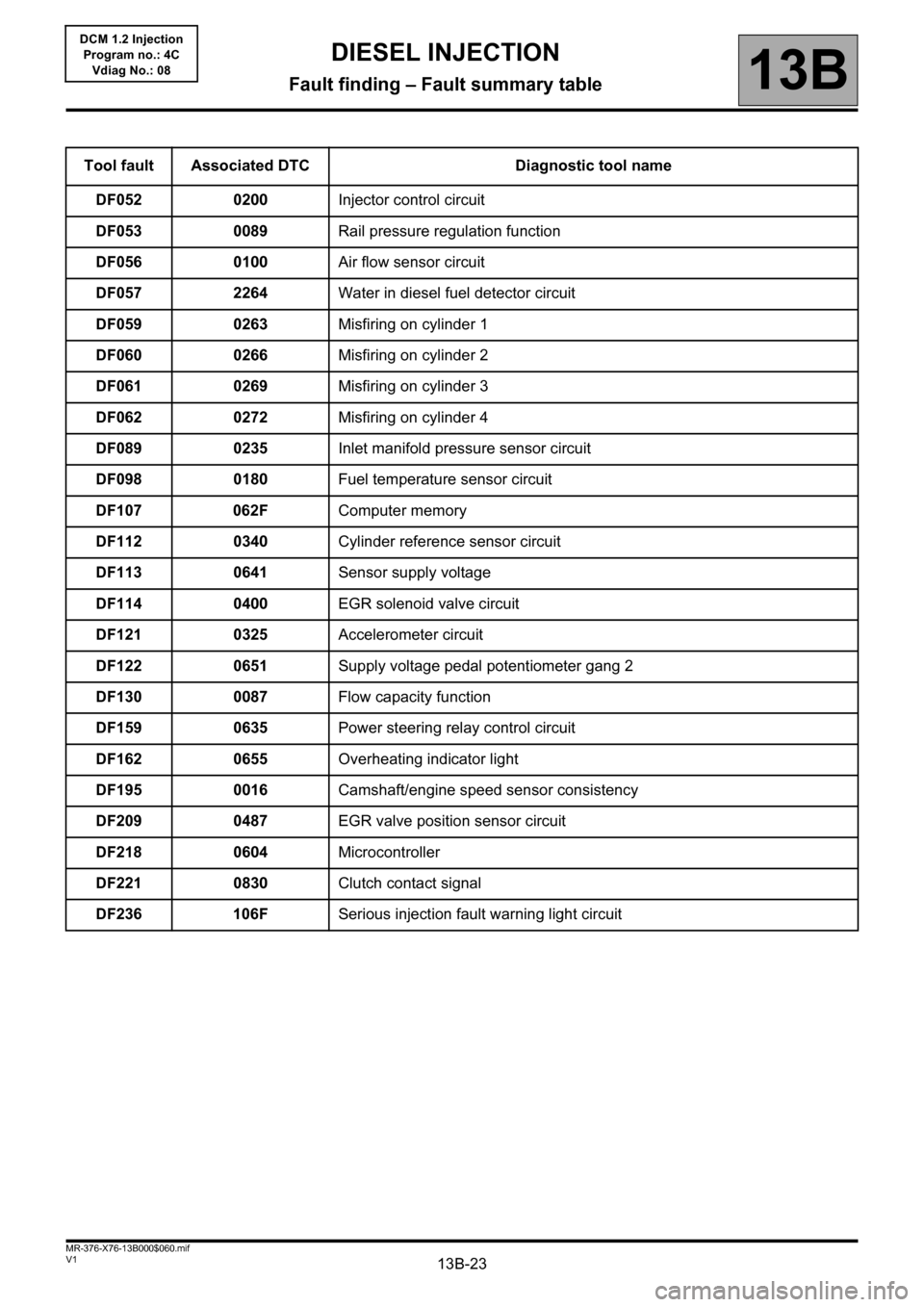

Tool fault Associated DTC Diagnostic tool name

DF052 0200Injector control circuit

DF053 0089Rail pressure regulation function

DF056 0100Air flow sensor circuit

DF057 2264Water in diesel fuel detector circuit

DF059 0263Misfiring on cylinder 1

DF060 0266Misfiring on cylinder 2

DF061 0269Misfiring on cylinder 3

DF062 0272Misfiring on cylinder 4

DF089 0235Inlet manifold pressure sensor circuit

DF098 0180Fuel temperature sensor circuit

DF107 062FComputer memory

DF112 0340Cylinder reference sensor circuit

DF113 0641Sensor supply voltage

DF114 0400EGR solenoid valve circuit

DF121 0325Accelerometer circuit

DF122 0651Supply voltage pedal potentiometer gang 2

DF130 0087Flow capacity function

DF159 0635Power steering relay control circuit

DF162 0655Overheating indicator light

DF195 0016Camshaft/engine speed sensor consistency

DF209 0487EGR valve position sensor circuit

DF218 0604Microcontroller

DF221 0830Clutch contact signal

DF236 106FSerious injection fault warning light circuit