RENAULT KANGOO 2013 X61 / 2.G Petrol V42 Injection User Guide

Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 279, PDF Size: 1.29 MB

Page 11 of 279

17B-11V2 MR-376-X76-17B050$050.mif

PETROL INJECTION

Fault finding – Features17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

Engine temperature management

The engine is cooled by a 2-speed fan assembly.

To cool the engine, the first speed of the fan assembly is activated if the coolant temperature exceeds 99°C or 94°C

(F4R400/402/403 engines), then the second speed is activated if the temperature exceeds the 102°C or 97°C

(F4R400/402/403 engines). A "very high temperature" warning light illuminates on the instrument panel if the

temperature exceeds 118°C or 113°C (F4R400/402/403 engines).

Page 12 of 279

17B-12V2 MR-376-X76-17B050$060.mif

17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

OPERATIONS FOR REPLACING OR REPROGRAMMING THE COMPUTER

Procedure to be applied before replacement

This procedure must be applied before replacing or reprogramming the injection computer (see MR 388 (Logan and

Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6), or MR 374 (Kangoo VLL),

Mechanical, 17B, Petrol injection, Petrol injection computer: Removal - Refitting).

– Connect the diagnostic tool (mains or cigarette lighter supply).

– Save the data by running command: SC003 Save computer data. In the event of a fault, contact the Techline.

– In the event of a replacement, note the vehicle VIN code using command ID008 VIN code.

– Switch on vehicle + after ignition feed and wait until the coolant temperature is less than 70°C and the air

temperature is less than 50°C. Consult parameter PR064 Coolant temperature and PR059 Air temperature.

– Apply the programming or reprogramming operations described in Technical Note 3585A Computer

(re)programming procedure.

Procedure to be applied after repair:

This procedure must be applied after replacing or reprogramming the computer.

Entering the saved data

– enter the saved data by running command SC001 Write saved data.

Programming the VIN code

– Display the identifier ID008

If the VIN is not entered, enter the VIN. using command VP010 Enter VIN. IMPORTANT:

– The computer permanently stores the immobilisation function code. It is forbidden to perform tests with

computers borrowed from the Parts Department or from another vehicle.

– Connect a battery charger and switch on the vehicle + after ignition feed.

– Switch off all the electrical consumers (lights, interior lighting, air conditioning, radio, etc.).

IMPORTANT:

It is necessary to respect these temperature values in order to carry out the computer programming or

reprogramming operations.

IMPORTANT:

After (re)programming the computer, switch off the + after ignition feed and wait for the loss of communication

message to appear on the diagnostic tool, if the message does not appear, wait for 9 minutes.

Failure to follow this procedure may cause the computer data to be corrupted.

PETROL INJECTION

Fault finding – Replacement of components

Page 13 of 279

17B-13V2 MR-376-X76-17B050$060.mif

PETROL INJECTION

Fault finding – Replacement of components17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

Programming the alcohol level

– Put the vehicle under + after ignition and wait for the value of parameter PR064 Coolant temperature to be greater

than or equal to 80°C.

– There must be no present or stored faults.

– With the ignition on and engine stopped, note the value of PR743 Estimated alcohol level in the tank.

– Carry out resetting using command RZ064 Programming the alcohol level.

– Start the engine and allow the engine to idle for 5 minutes.

– Check the correct programming using parameter PR743; its value must have changed.

– If programming was not performed correctly, repeat the operation from the start.

– If the fault is still present, contact the Techline.

Injection computer initialisation

Start and stop the engine to initialise the computer and wait for the loss of communication message to appear on the

diagnostic tool. If the message does not appear, wait for 9 minutes.

The computer is automatically configured according to the sensors and options present on the vehicle.

If the data were not saved before the operation, carry out the following operations:

– Programming the VIN code

– Enter the V.I.N. using command VP010 Enter VIN.

– Injector programming

Program the injectors by accessing the sub-section entitled Injector replacement operations.

– Programming the TDC sensor

Program the TDC sensor by accessing the sub-section entitled TDC (Top Dead Centre) sensor replacement

operations.

– Programming the motorised throttle

Program the motorised throttle by accessing the sub-section entitled Throttle valve replacement operations.

– Injection computer initialisation

Start and stop the engine to initialise the computer and wait for the loss of communication message to appear on the

diagnostic tool, if the message does not appear, wait for 9 minutes.

The computer is automatically configured according to the sensors and options present on the vehicle.

Page 14 of 279

17B-14V2 MR-376-X76-17B050$060.mif

PETROL INJECTION

Fault finding – Replacement of components17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

THROTTLE VALVE REPLACEMENT OPERATIONS

– When replacing the inlet throttle valve, switch on the vehicle + after ignition feed, after replacing the part.

– Carry out resetting using command RZ031 Throttle stop programming.

– Switch off the ignition. The inlet valve will run a new programming procedure whilst maintaining the supply (power

latch) due to the reinitialisation phase.

– Check that the programming is correct using status ET051 Throttle stop programming, it must be at 1.

If programming was not performed correctly, repeat the operation from the start.

– If the fault is still present, contact the Techline.

OPERATIONS FOR REPLACING THE BRAKE PEDAL SWITCH

– When replacing the brake pedal switch, switch on the vehicle + after ignition feed, after replacing the part.

– Check that the switch statuses change as follows, when the brake pedal is activated:

–ET039 Brake pedal = 1 and ET799 Brake Wire Contact = 1 when the brake pedal is released

–ET039 Brake pedal = 2 and ET799 Brake Wire Contact = 2 when the brake pedal is depressed

OPERATIONS FOR REPLACING THE TDC (TOP DEAD CENTRE) SENSOR

– Switch on the vehicle + after ignition feed,

– Carry out resetting using command RZ037 Flywheel target programming.

Operation for Programming

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator and clutch pedals) between 3500 and

3000 rpm, in 3rd gear for a BVM* for at least 3 seconds.

– Decelerate a second time with injection cut-off (i.e. feet off the brake, accelerator and clutch pedals) between 2400

and 2000 rpm, in 3rd gear for a BVM* for at least 14 seconds (K4M, K7M engine) or 3 seconds (D4D, F4R, K4M

engine of Duster).

*BVM: Manual gearbox

The programming was successful when status ET089 Flywheel target programming has the value1.

Page 15 of 279

17B-15V2 MR-376-X76-17B050$060.mif

PETROL INJECTION

Fault finding – Replacement of components17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

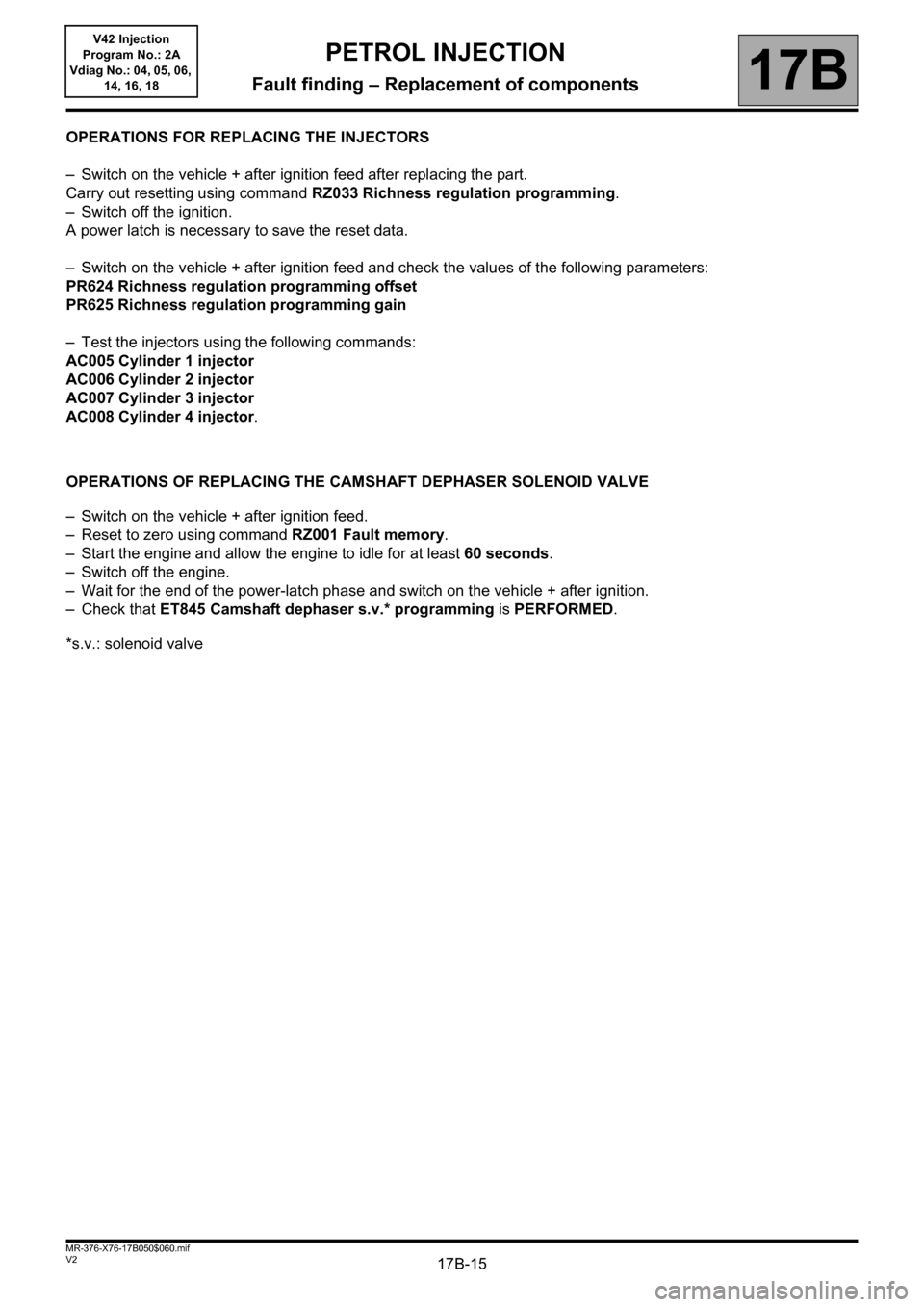

OPERATIONS FOR REPLACING THE INJECTORS

– Switch on the vehicle + after ignition feed after replacing the part.

Carry out resetting using command RZ033 Richness regulation programming.

– Switch off the ignition.

A power latch is necessary to save the reset data.

– Switch on the vehicle + after ignition feed and check the values of the following parameters:

PR624 Richness regulation programming offset

PR625 Richness regulation programming gain

– Test the injectors using the following commands:

AC005 Cylinder 1 injector

AC006 Cylinder 2 injector

AC007 Cylinder 3 injector

AC008 Cylinder 4 injector.

OPERATIONS OF REPLACING THE CAMSHAFT DEPHASER SOLENOID VALVE

– Switch on the vehicle + after ignition feed.

– Reset to zero using command RZ001 Fault memory.

– Start the engine and allow the engine to idle for at least 60 seconds.

– Switch off the engine.

– Wait for the end of the power-latch phase and switch on the vehicle + after ignition.

– Check that ET845 Camshaft dephaser s.v.* programming is PERFORMED.

*s.v.: solenoid valve

Page 16 of 279

17B-16V2 MR-376-X76-17B050$070.mif

17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

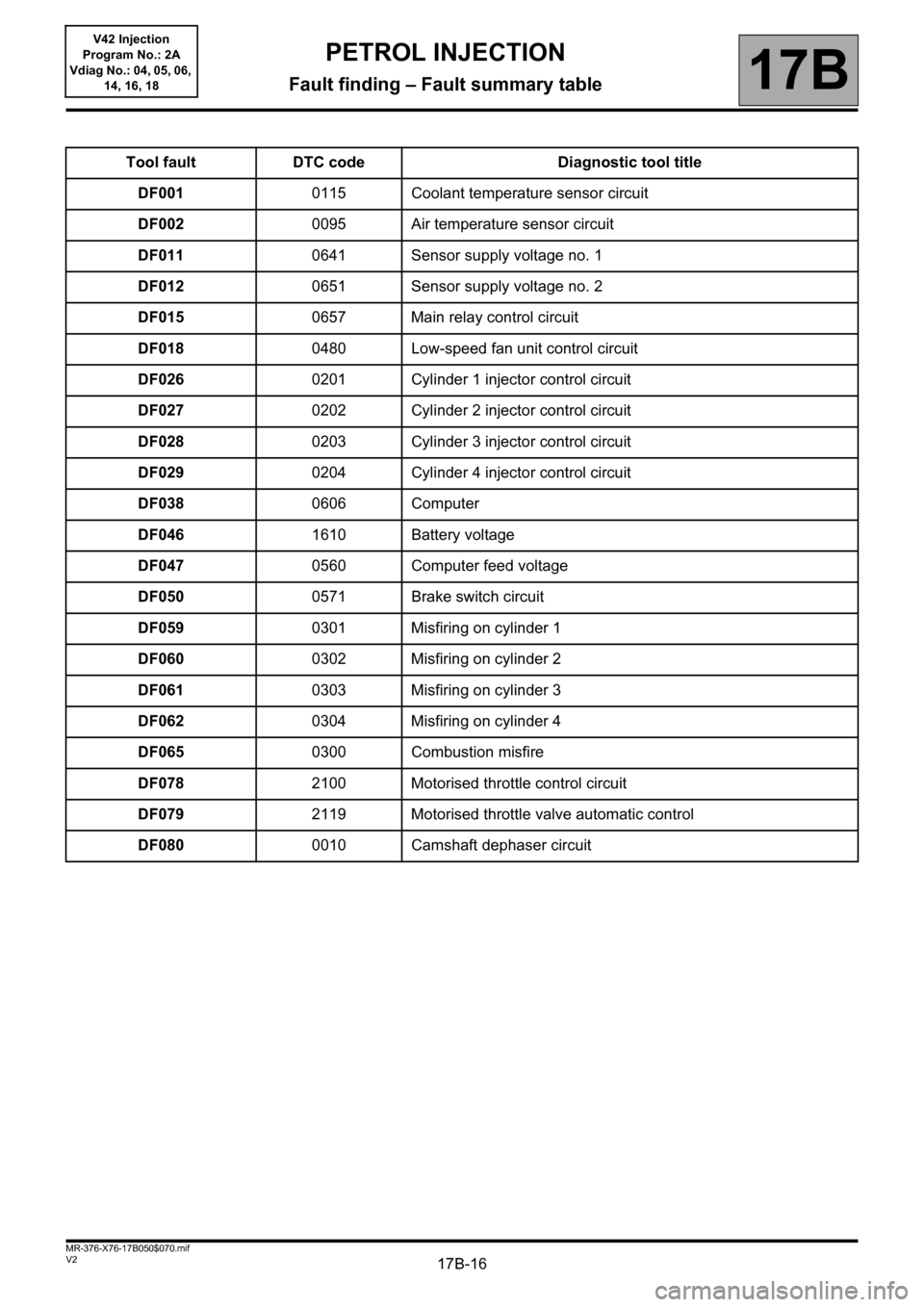

Tool fault DTC code Diagnostic tool title

DF0010115 Coolant temperature sensor circuit

DF0020095 Air temperature sensor circuit

DF0110641 Sensor supply voltage no. 1

DF0120651 Sensor supply voltage no. 2

DF0150657 Main relay control circuit

DF0180480 Low-speed fan unit control circuit

DF0260201 Cylinder 1 injector control circuit

DF0270202 Cylinder 2 injector control circuit

DF0280203 Cylinder 3 injector control circuit

DF0290204 Cylinder 4 injector control circuit

DF0380606 Computer

DF0461610 Battery voltage

DF0470560 Computer feed voltage

DF0500571 Brake switch circuit

DF0590301 Misfiring on cylinder 1

DF0600302 Misfiring on cylinder 2

DF0610303 Misfiring on cylinder 3

DF0620304 Misfiring on cylinder 4

DF0650300 Combustion misfire

DF0782100 Motorised throttle control circuit

DF0792119 Motorised throttle valve automatic control

DF0800010 Camshaft dephaser circuit

PETROL INJECTION

Fault finding – Fault summary table

Page 17 of 279

17B-17V2 MR-376-X76-17B050$070.mif

PETROL INJECTION

Fault finding – Fault summary table17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

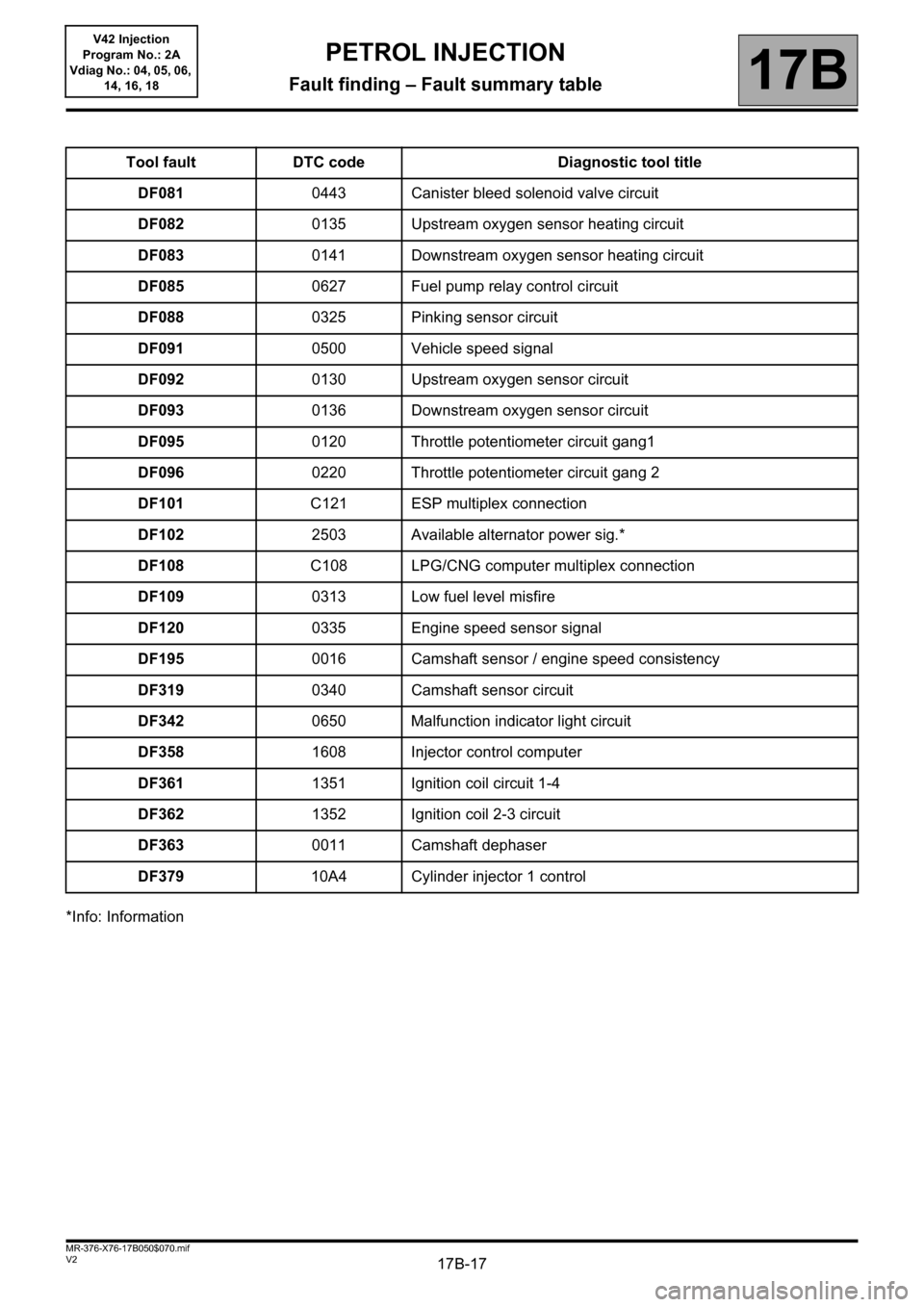

*Info: InformationTool fault DTC code Diagnostic tool title

DF0810443 Canister bleed solenoid valve circuit

DF0820135 Upstream oxygen sensor heating circuit

DF0830141 Downstream oxygen sensor heating circuit

DF0850627 Fuel pump relay control circuit

DF0880325 Pinking sensor circuit

DF0910500 Vehicle speed signal

DF0920130 Upstream oxygen sensor circuit

DF0930136 Downstream oxygen sensor circuit

DF0950120 Throttle potentiometer circuit gang1

DF0960220 Throttle potentiometer circuit gang 2

DF101C121 ESP multiplex connection

DF1022503 Available alternator power sig.*

DF108C108 LPG/CNG computer multiplex connection

DF1090313 Low fuel level misfire

DF1200335 Engine speed sensor signal

DF1950016 Camshaft sensor / engine speed consistency

DF3190340 Camshaft sensor circuit

DF3420650 Malfunction indicator light circuit

DF3581608 Injector control computer

DF3611351 Ignition coil circuit 1-4

DF3621352 Ignition coil 2-3 circuit

DF3630011 Camshaft dephaser

DF37910A4 Cylinder injector 1 control

Page 18 of 279

17B-18V2 MR-376-X76-17B050$070.mif

PETROL INJECTION

Fault finding – Fault summary table17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

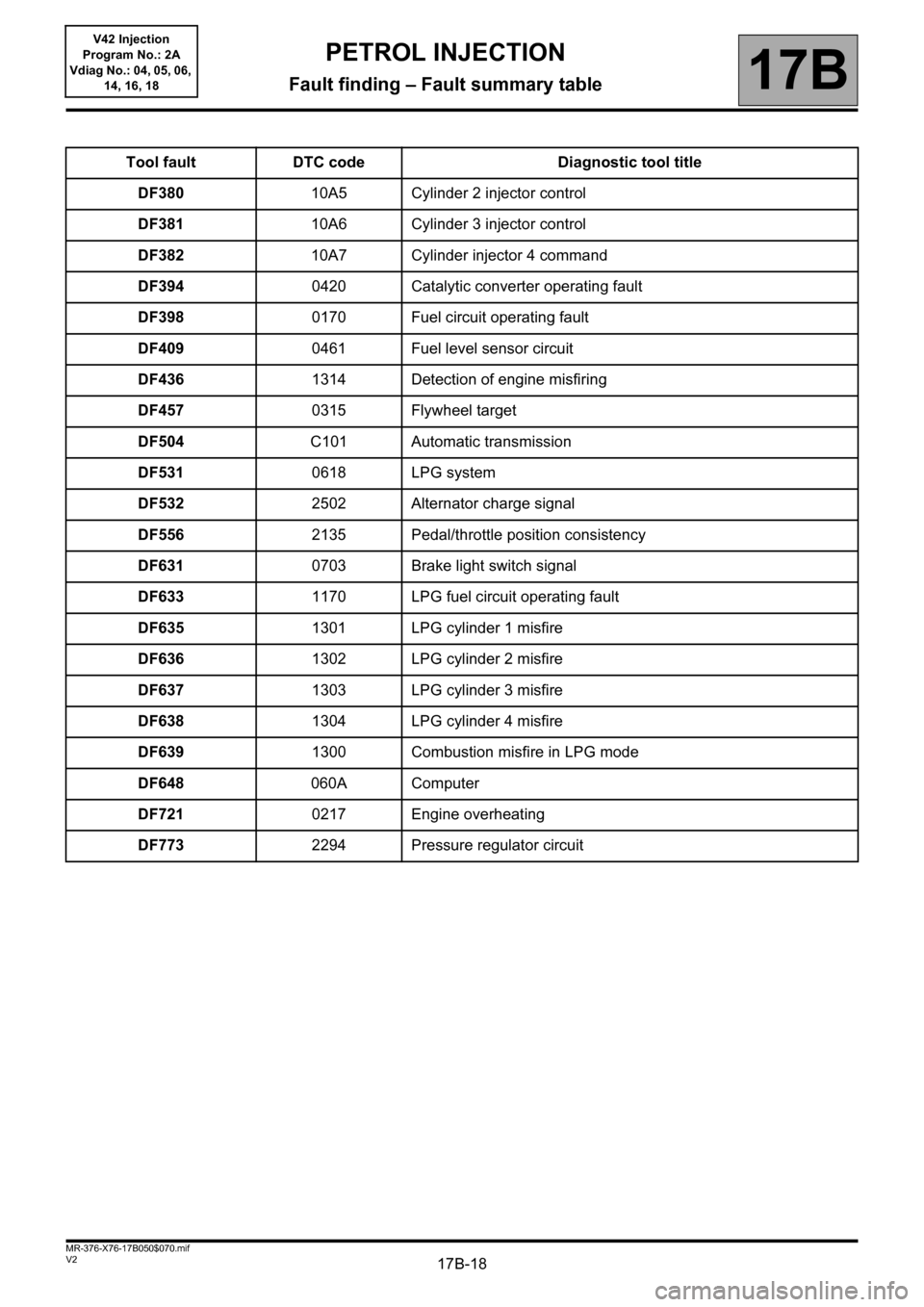

Tool fault DTC code Diagnostic tool title

DF38010A5 Cylinder 2 injector control

DF38110A6 Cylinder 3 injector control

DF38210A7 Cylinder injector 4 command

DF3940420 Catalytic converter operating fault

DF3980170 Fuel circuit operating fault

DF4090461 Fuel level sensor circuit

DF4361314 Detection of engine misfiring

DF4570315 Flywheel target

DF504C101 Automatic transmission

DF5310618 LPG system

DF5322502 Alternator charge signal

DF5562135 Pedal/throttle position consistency

DF6310703 Brake light switch signal

DF6331170 LPG fuel circuit operating fault

DF6351301 LPG cylinder 1 misfire

DF6361302 LPG cylinder 2 misfire

DF6371303 LPG cylinder 3 misfire

DF6381304 LPG cylinder 4 misfire

DF6391300 Combustion misfire in LPG mode

DF648060A Computer

DF7210217 Engine overheating

DF7732294 Pressure regulator circuit

Page 19 of 279

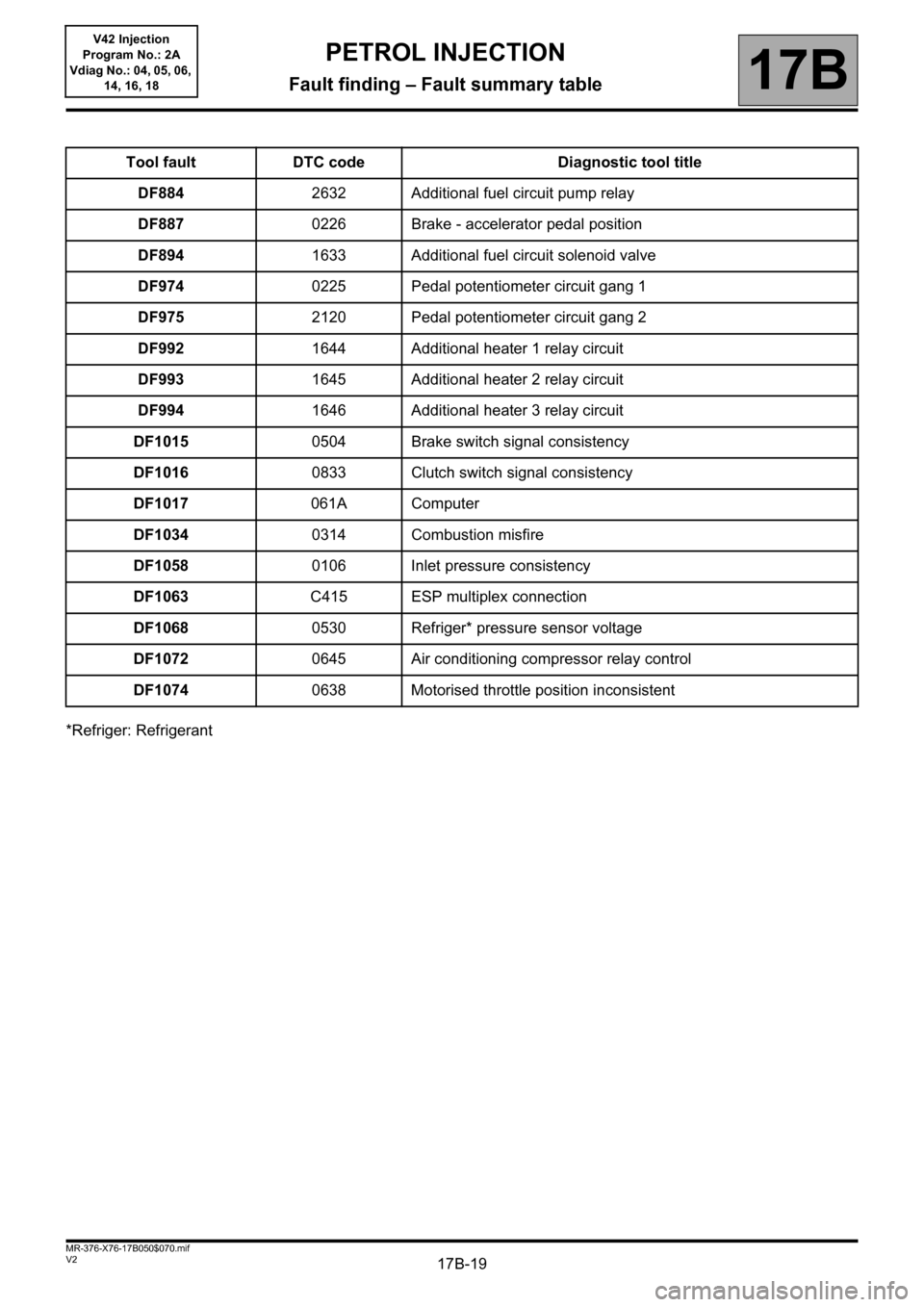

17B-19V2 MR-376-X76-17B050$070.mif

PETROL INJECTION

Fault finding – Fault summary table17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

*Refriger: RefrigerantTool fault DTC code Diagnostic tool title

DF8842632 Additional fuel circuit pump relay

DF8870226 Brake - accelerator pedal position

DF8941633 Additional fuel circuit solenoid valve

DF9740225 Pedal potentiometer circuit gang 1

DF9752120 Pedal potentiometer circuit gang 2

DF9921644 Additional heater 1 relay circuit

DF9931645 Additional heater 2 relay circuit

DF9941646 Additional heater 3 relay circuit

DF10150504 Brake switch signal consistency

DF10160833 Clutch switch signal consistency

DF1017061A Computer

DF10340314 Combustion misfire

DF10580106 Inlet pressure consistency

DF1063C415 ESP multiplex connection

DF10680530 Refriger* pressure sensor voltage

DF10720645 Air conditioning compressor relay control

DF10740638 Motorised throttle position inconsistent

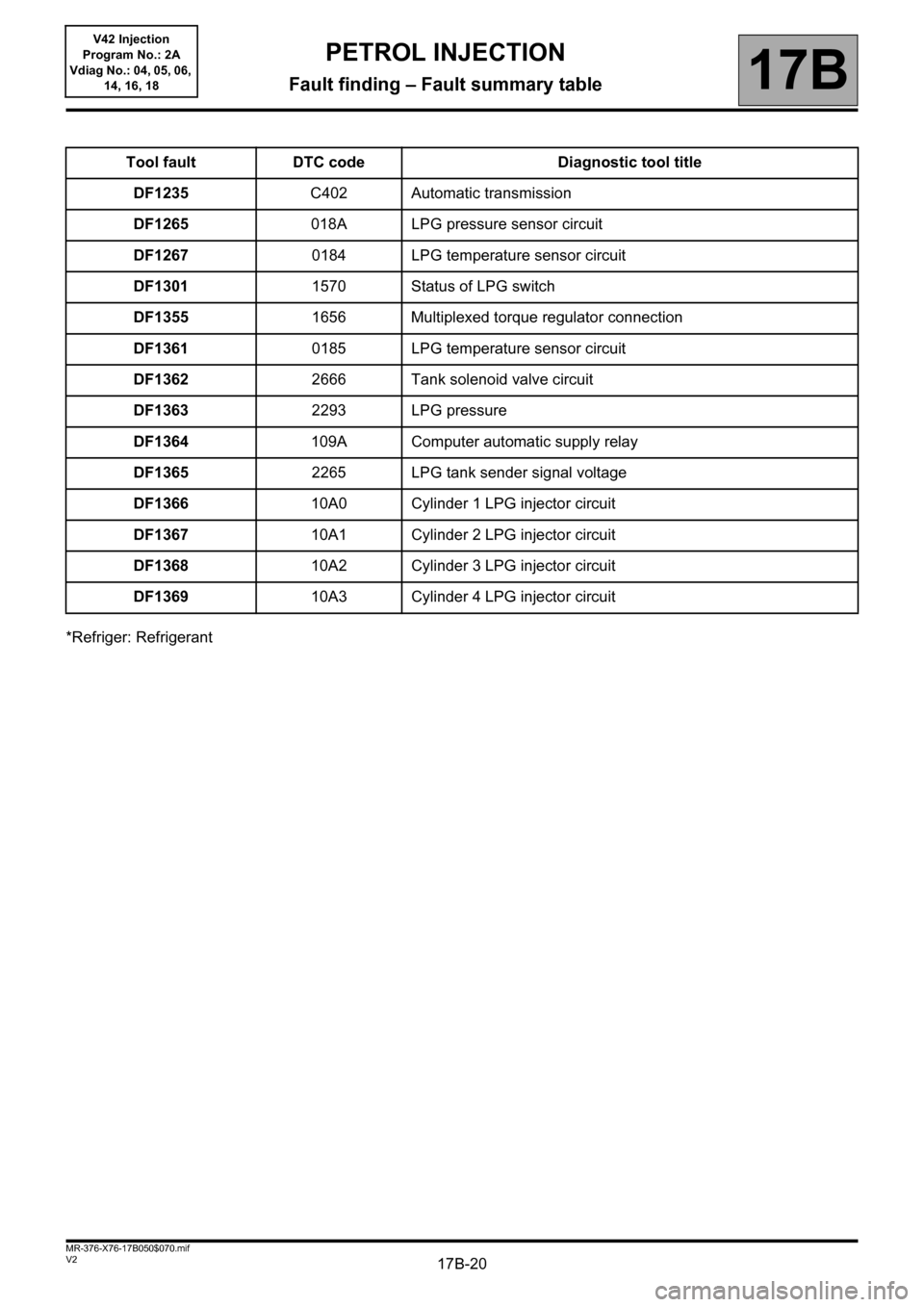

Page 20 of 279

17B-20V2 MR-376-X76-17B050$070.mif

PETROL INJECTION

Fault finding – Fault summary table17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

*Refriger: RefrigerantTool fault DTC code Diagnostic tool title

DF1235C402 Automatic transmission

DF1265018A LPG pressure sensor circuit

DF12670184 LPG temperature sensor circuit

DF13011570 Status of LPG switch

DF13551656 Multiplexed torque regulator connection

DF13610185 LPG temperature sensor circuit

DF13622666 Tank solenoid valve circuit

DF13632293 LPG pressure

DF1364109A Computer automatic supply relay

DF13652265 LPG tank sender signal voltage

DF136610A0 Cylinder 1 LPG injector circuit

DF136710A1 Cylinder 2 LPG injector circuit

DF136810A2 Cylinder 3 LPG injector circuit

DF136910A3 Cylinder 4 LPG injector circuit