wheel RENAULT MASTER 2017 X62 / 2.G Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2017, Model line: MASTER, Model: RENAULT MASTER 2017 X62 / 2.GPages: 286, PDF Size: 6.97 MB

Page 155 of 286

2.41

The self-locking differential controls the

torque transmitted to each rear wheel.

Depending on the grip conditions on

the road surface, and at low speeds

(under 20 mph / 30 kph), this device en-

ables wheel torque to move automati-

cally, thereby providing increased grip.

This enables the grip potential of each

wheel to be used to the fullest possi-

ble extent, thereby enabling the vehicle

to run over areas with decreased grip

(e.g.: work sites, muddy ground, etc.).

Once the rear wheels return to surfaces

with normal grip (eg: return to paved

roads), the self-locking differential

device will be deactivated, sometimes

accompanied by a noise (with no con-

sequence to vehicle behaviour). You

have the option of turning this device

off yourself, once normal grip condi-

tions have resumed, by briefly releas-

ing the accelerator

SELF-LOCKING DIFFERENTIAL

This function is an addi-

tional driving aid.

However, it does not in-

crease the vehicle’s limits

and should not encourage you to

drive more quickly.

It cannot, therefore, under any cir-

cumstances replace the vigilance or

the responsibility of the driver.

Page 161 of 286

2.47

SEQUENTIAL GEARBOX (6/6)Bleep

– If you hold the vehicle on a slope for too long without applying the

brakes or handbrake, you will strain

the system (risk of overheating the

clutch).

In this case, an intermittent beep-

ing sound will remind you that you

should put your foot on the brake

pedal or apply the handbrake.

– Never leave the vehicle with the engine running when in gear. For

safety reasons you will hear an in-

termittent beeping sound when you

open the door if you have not shifted

into neutral or you have not switched

off the ignition or depressed the

brake pedal.

Operating faults

i

If this warning light comes on

when the vehicle is in motion , it

indicates a fault in the system. In most

cases, you may still drive the vehicle,

although it will not function perfectly.

Contact an approved dealer as soon as

possible.

Towing a vehicle with a sequential

gearbox

If the gearbox is stuck in a gear:

– switch on the ignition;

– select neutral with the brake pedal

depressed;

– check that the gearbox is in neutral (by pushing the vehicle, for exam-

ple).

If you cannot find neutral you must tow

the vehicle with the front wheels raised.

The vehicle should always be towed

with the ignition switched off.

Accelerating and overtaking

– Slowly depress the accelerator pedal to accelerate gradually;

– to obtain maximum vehicle per-

formance regardless of the mode

selected (automatic or manual),

quickly depress the accelerator

pedal beyond the kickdown point.

The speed with which you depress the

pedal will allow you to downshift ac-

cording to the vehicle’s capabilities.

Parking

It is possible to park in gear (for exam-

ple, on a slope):

– with the ignition on, select a gear with your foot on the brake ;

– check that a gear other than N is dis- played on the instrument panel, then

remove the ignition key;

– apply the handbrake.

To disengage the gear, switch on the

ignition without starting the engine and

shift the selector lever to neutral with

the brake pedal depressed . Check

that N is displayed on the instrument

panel.

Page 192 of 286

3.30

TRANSPORTING OBJECTS (2/2)

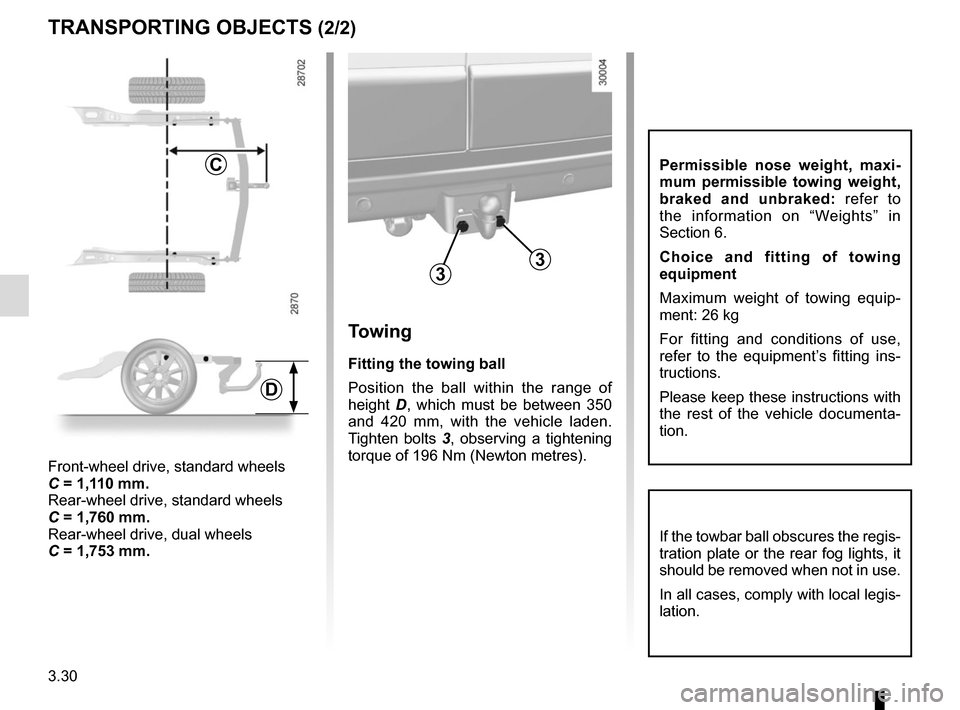

Towing

Fitting the towing ball

Position the ball within the range of

height D, which must be between 350

and 420 mm, with the vehicle laden.

Tighten bolts 3, observing a tightening

torque of 196 Nm (Newton metres).

33

C

Front-wheel drive, standard wheels

C = 1,110 mm.

Rear-wheel drive, standard wheels

C = 1,760 mm.

Rear-wheel drive, dual wheels

C = 1,753 mm.

D

If the towbar ball obscures the regis-

tration plate or the rear fog lights, it

should be removed when not in use.

In all cases, comply with local legis-

lation.

Permissible nose weight, maxi-

mum permissible towing weight,

braked and unbraked: refer to

the information on “Weights” in

Section 6.

Choice and fitting of towing

equipment

Maximum weight of towing equip-

ment: 26 kg

For fitting and conditions of use,

refer to the equipment’s fitting ins-

tructions.

Please keep these instructions with

the rest of the vehicle documenta-

tion.

Page 204 of 286

4.12

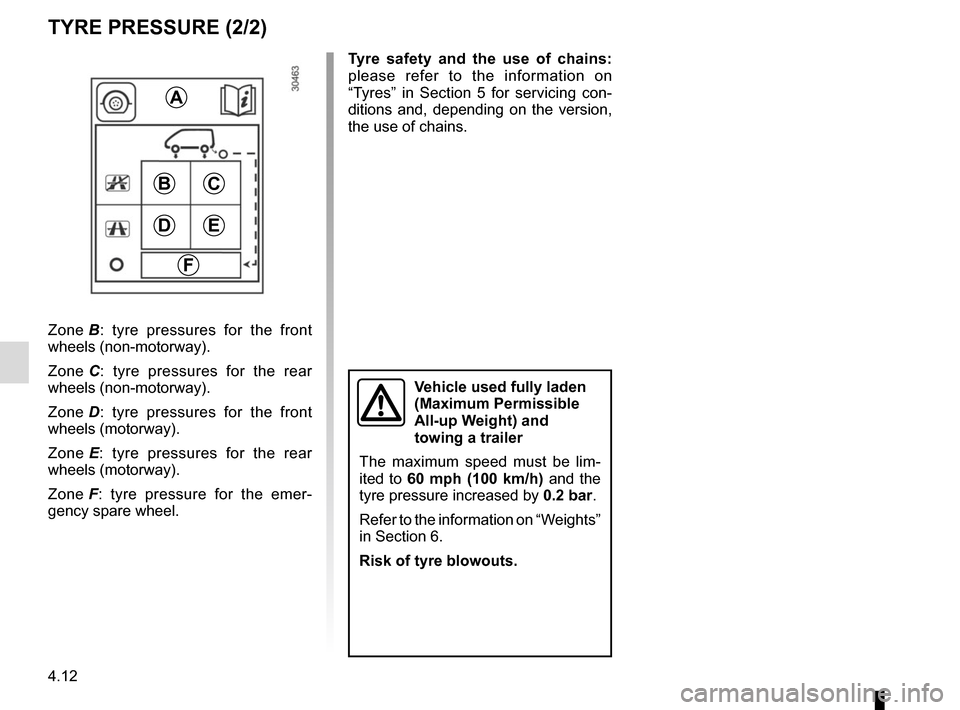

BC

ED

F

A

Zone B: tyre pressures for the front

wheels (non-motorway).

Zone C : tyre pressures for the rear

wheels (non-motorway).

Zone D : tyre pressures for the front

wheels (motorway).

Zone E : tyre pressures for the rear

wheels (motorway).

Zone F : tyre pressure for the emer-

gency spare wheel.

TYRE PRESSURE (2/2)

Tyre safety and the use of chains:

please refer to the information on

“Tyres” in Section 5 for servicing con-

ditions and, depending on the version,

the use of chains.

Vehicle used fully laden

(Maximum Permissible

All-up Weight) and

towing a trailer

The maximum speed must be lim-

ited to 60 mph (100 km/h) and the

tyre pressure increased by 0.2 bar.

Refer to the information on “Weights”

in Section 6.

Risk of tyre blowouts.

Page 206 of 286

4.14

BODYWORK MAINTENANCE (1/2)

You should

Wash your car frequently, with the

engine off, with cleaning products rec-

ommended by the manufacturer (never

use abrasive products). Rinse thor-

oughly beforehand with a jet:

– spots of tree resin and industrial

grime;

– mud in the wheel arches and under-

neath the body which forms damp

patches;

– bird droppings , which cause a

chemical reaction with the paint that

rapidly discolours paintwork and

may even cause the paint to peel

off;

wash the vehicle immediately to

remove these marks since it is im-

possible to remove them by polish-

ing;

– salt, particularly in the wheel arches

and underneath the body after driv-

ing in areas where the roads have

been gritted.

What you should not doDo not degrease or clean mechani-

cal components (e.g. the engine com-

partment), underneath the body, parts

with hinges (e.g. inside the doors) and

painted plastic external fittings (e.g.

bumpers) using high-pressure clean-

ing equipment or by spraying on prod-

ucts not approved by our Technical

Department. Doing this could give rise

to corrosion or operational faults.

Wash the vehicle in bright sunlight or

freezing temperatures.

Do not scrape off mud or dirt without

pre-wetting.

Allow dirt to accumulate on the exterior.

Allow rust to form following minor im-

pacts.

Do not use solvents not approved by

our Technical Department to remove

stains as this could damage the paint-

work.

Do not drive in snow or muddy condi-

tions without washing the vehicle, par-

ticularly under the wheel arches and

body.

A well-maintained vehicle will last

longer. It is therefore recommended to

maintain the exterior of the vehicle reg-

ularly.

Your vehicle has been treated with very

effective anti-corrosion products. It is

nevertheless subject to various outside

influences.

Corrosive agents in the atmosphere

–

atmospheric pollution (built-up and

industrial areas),

– saline atmospheres (near the sea,

particularly in hot weather),

– seasonal and damp weather condi-

tions (e.g. road salt in winter, water

from road cleaners, etc.).

Minor impacts

Abrasive action

Dust and sand in the air, mud, road grit

thrown up by other vehicles, etc.

You should take a number of minor pre-

cautions in order to safeguard your ve-

hicle against such risks.

Page 211 of 286

5.1

Section 5: Practical advice

Puncture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2

Emergency spare wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . 5.2

Tool kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.4

Tyre inflation kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5

Wheel trims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.11

Changing a wheel: hydraulic jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . 5.13

Changing a wheel: jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . 5.16

Tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.18

Headlights (changing bulbs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . 5.21front fog lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . 5.23

Side lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.24

Rear lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . . . . 5.25

Interior lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . . . 5.27

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.28

Battery: troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . 5.33

Key, radio frequency remote control: battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . 5.35

Hands-free access transmitter/receiver: battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . 5.36

Replacing wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . 5.37

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.38

Fitting a radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.40

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.41

Operating faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.42

Page 212 of 286

5.2

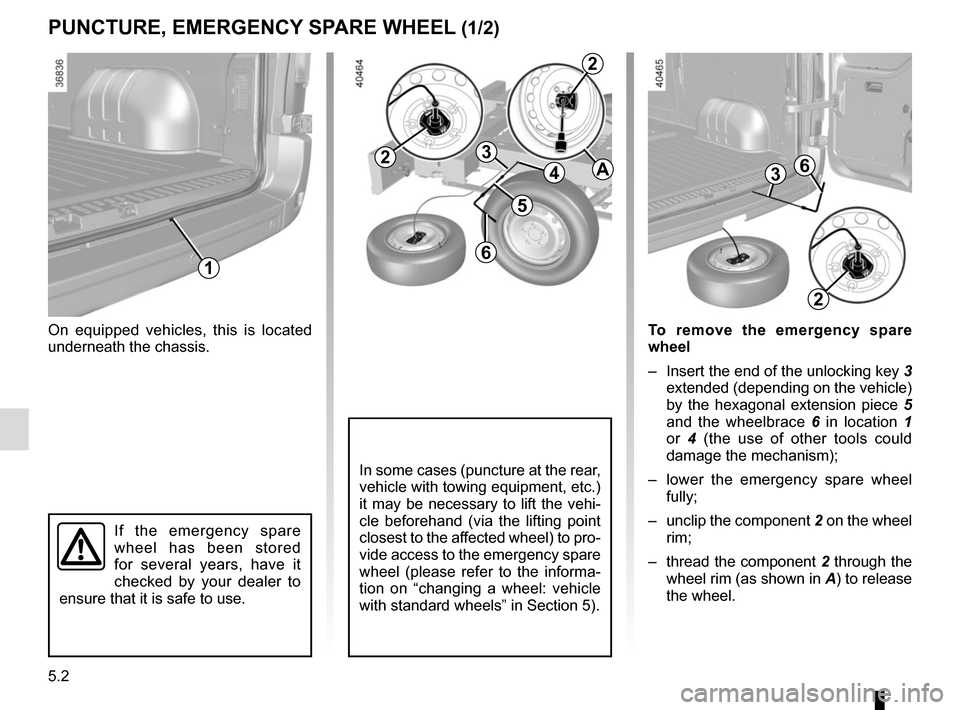

PUNCTURE, EMERGENCY SPARE WHEEL (1/2)

On equipped vehicles, this is located

underneath the chassis.

If the emergency spare

wheel has been stored

for several years, have it

checked by your dealer to

ensure that it is safe to use.

In some cases (puncture at the rear,

vehicle with towing equipment, etc.)

it may be necessary to lift the vehi-

cle beforehand (via the lifting point

closest to the affected wheel) to pro-

vide access to the emergency spare

wheel (please refer to the informa-

tion on “changing a wheel: vehicle

with standard wheels” in Section 5).

1

4

3

5

6

2

2

A

2

36

To remove the emergency spare

wheel

– Insert the end of the unlocking key 3

extended (depending on the vehicle)

by the hexagonal extension piece 5

and the wheelbrace 6 in location 1

or 4 (the use of other tools could

damage the mechanism);

– lower the emergency spare wheel fully;

– unclip the component 2 on the wheel

rim;

– thread the component 2 through the

wheel rim (as shown in A) to release

the wheel.

Page 213 of 286

5.3

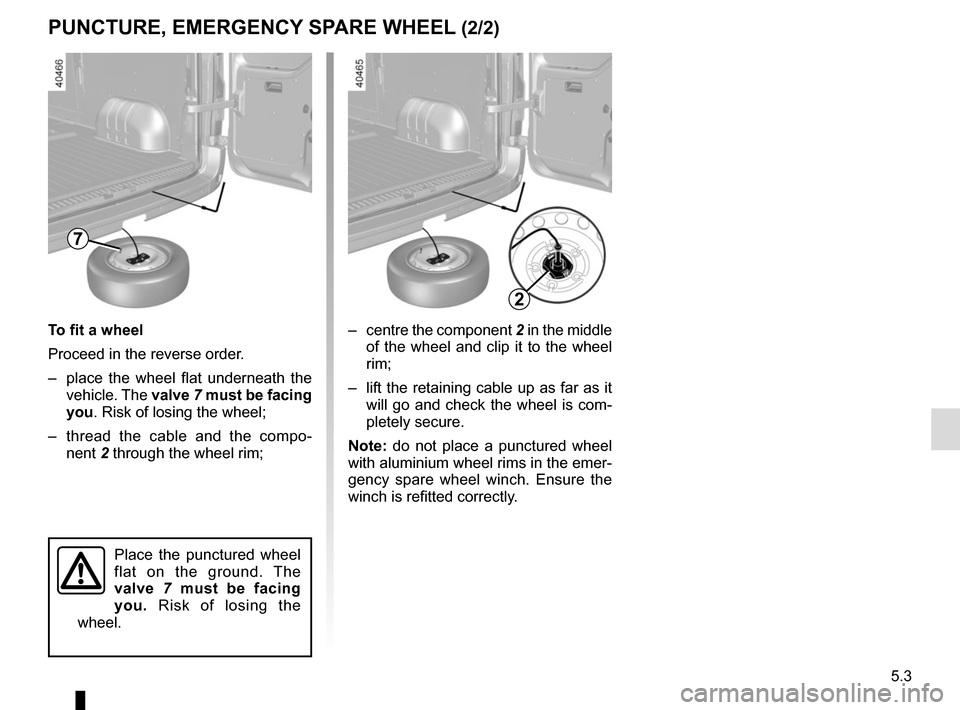

PUNCTURE, EMERGENCY SPARE WHEEL (2/2)

– centre the component 2 in the middle

of the wheel and clip it to the wheel

rim;

– lift the retaining cable up as far as it will go and check the wheel is com-

pletely secure.

Note: do not place a punctured wheel

with aluminium wheel rims in the emer-

gency spare wheel winch. Ensure the

winch is refitted correctly.

To fit a wheel

Proceed in the reverse order.

– place the wheel flat underneath the

vehicle. The valve 7 must be facing

you. Risk of losing the wheel;

– thread the cable and the compo- nent 2 through the wheel rim;

7

Place the punctured wheel

flat on the ground. The

valve 7 must be facing

you. Risk of losing the

wheel.

2

Page 214 of 286

5.4

TOOL KIT

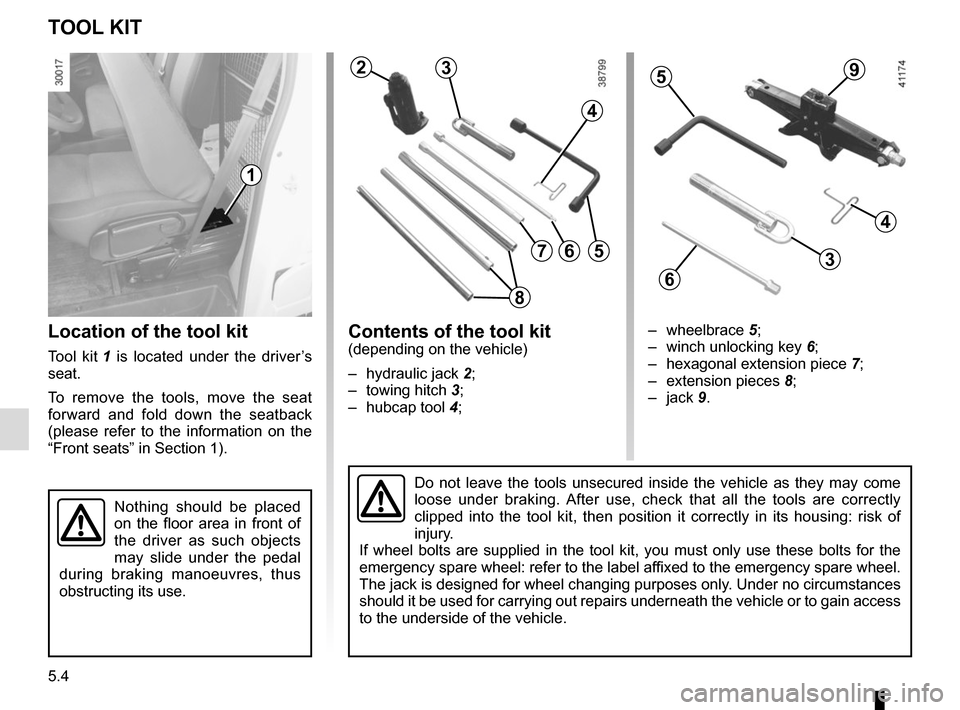

Location of the tool kit

Tool kit 1 is located under the driver’s

seat.

To remove the tools, move the seat

forward and fold down the seatback

(please refer to the information on the

“Front seats” in Section 1).

Contents of the tool kit(depending on the vehicle)

– hydraulic jack 2;

– towing hitch 3;

– hubcap tool 4;

1

Do not leave the tools unsecured inside the vehicle as they may come

loose under braking. After use, check that all the tools are correctly

clipped into the tool kit, then position it correctly in its housing: ri\

sk of

injury.

If wheel bolts are supplied in the tool kit, you must only use these bol\

ts for the

emergency spare wheel: refer to the label affixed to the emergency spare wheel.

The jack is designed for wheel changing purposes only. Under no circumstances

should it be used for carrying out repairs underneath the vehicle or to \

gain access

to the underside of the vehicle.

Nothing should be placed

on the floor area in front of

the driver as such objects

may slide under the pedal

during braking manoeuvres, thus

obstructing its use.

23

4

56

– wheelbrace 5;

– winch unlocking key 6;

– hexagonal extension piece 7;

– extension pieces 8;

– jack 9.

59

4

3

6

7

8

Page 215 of 286

5.5

TYRE INFLATION KIT (1/6)

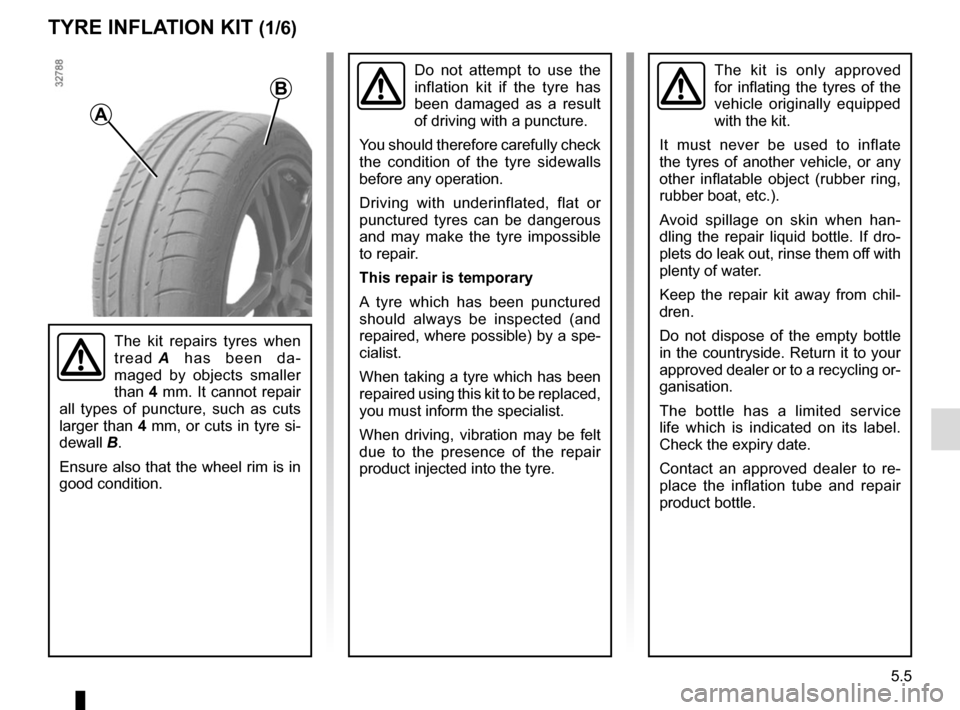

A

B

Do not attempt to use the

inflation kit if the tyre has

been damaged as a result

of driving with a puncture.

You should therefore carefully check

the condition of the tyre sidewalls

before any operation.

Driving with underinflated, flat or

punctured tyres can be dangerous

and may make the tyre impossible

to repair.

This repair is temporary

A tyre which has been punctured

should always be inspected (and

repaired, where possible) by a spe-

cialist.

When taking a tyre which has been

repaired using this kit to be replaced,

you must inform the specialist.

When driving, vibration may be felt

due to the presence of the repair

product injected into the tyre.The kit is only approved

for inflating the tyres of the

vehicle originally equipped

with the kit.

It must never be used to inflate

the tyres of another vehicle, or any

other inflatable object (rubber ring,

rubber boat, etc.).

Avoid spillage on skin when han-

dling the repair liquid bottle. If dro-

plets do leak out, rinse them off with

plenty of water.

Keep the repair kit away from chil-

dren.

Do not dispose of the empty bottle

in the countryside. Return it to your

approved dealer or to a recycling or-

ganisation.

The bottle has a limited service

life which is indicated on its label.

Check the expiry date.

Contact an approved dealer to re-

place the inflation tube and repair

product bottle.

The kit repairs tyres when

tread A has been da-

maged by objects smaller

than 4 mm. It cannot repair

all types of puncture, such as cuts

larger than 4 mm, or cuts in tyre si-

dewall B.

Ensure also that the wheel rim is in

good condition.