air conditioning RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 92 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Coolant temperature management

13

13-41

Coolant temperature management

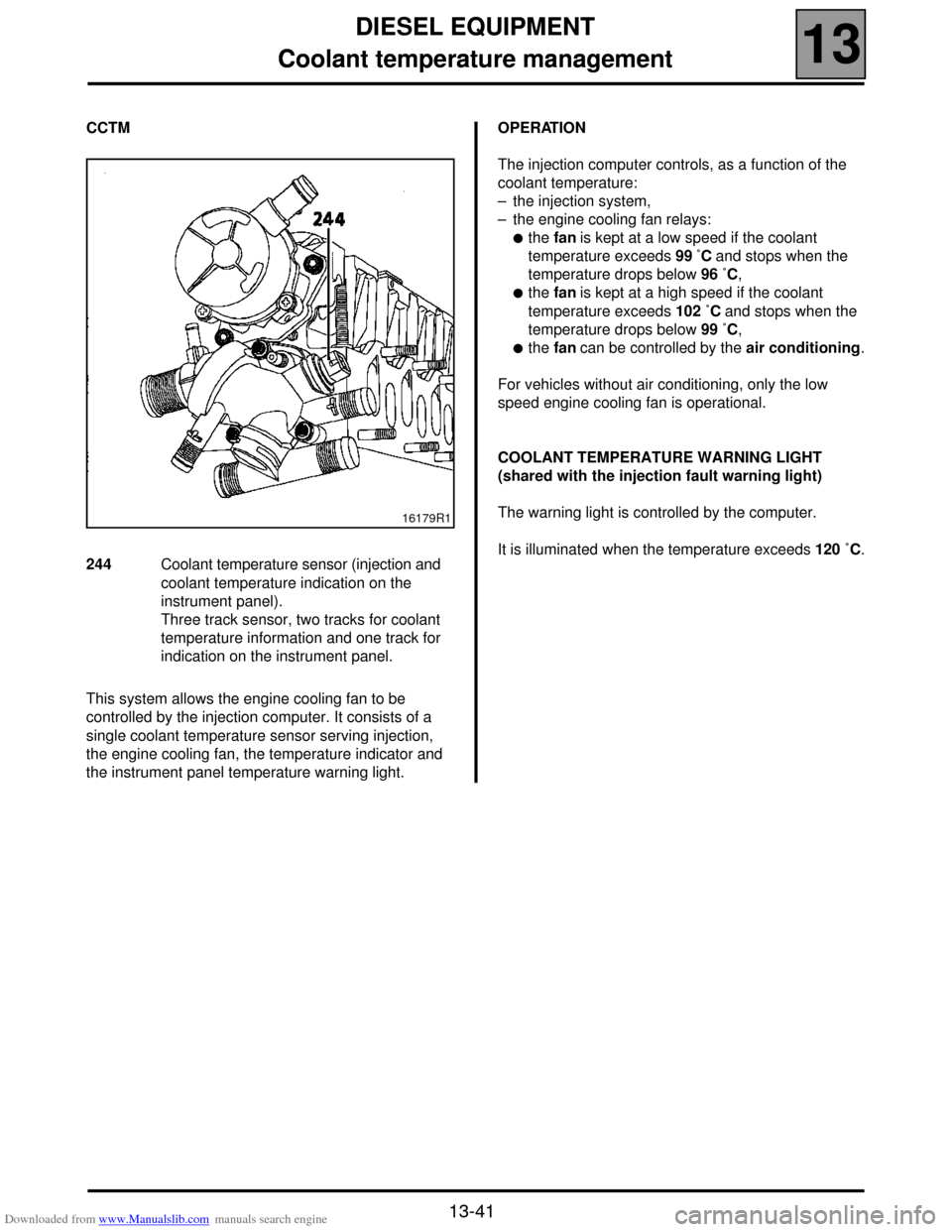

CCTM

This system allows the engine cooling fan to be

controlled by the injection computer. It consists of a

single coolant temperature sensor serving injection,

the engine cooling fan, the temperature indicator and

the instrument panel temperature warning light.OPERATION

The injection computer controls, as a function of the

coolant temperature:

– the injection system,

– the engine cooling fan relays:

!the fan is kept at a low speed if the coolant

temperature exceeds 99 ˚C and stops when the

temperature drops below 96 ˚C,

!the fan is kept at a high speed if the coolant

temperature exceeds 102 ˚C and stops when the

temperature drops below 99 ˚C,

!the fan can be controlled by the air conditioning.

For vehicles without air conditioning, only the low

speed engine cooling fan is operational.

COOLANT TEMPERATURE WARNING LIGHT

(shared with the injection fault warning light)

The warning light is controlled by the computer.

It is illuminated when the temperature exceeds 120 ˚C.

16179R1

244 Coolant temperature sensor (injection and

coolant temperature indication on the

instrument panel).

Three track sensor, two tracks for coolant

temperature information and one track for

indication on the instrument panel.

Page 93 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Computer

13

13-42

Computer

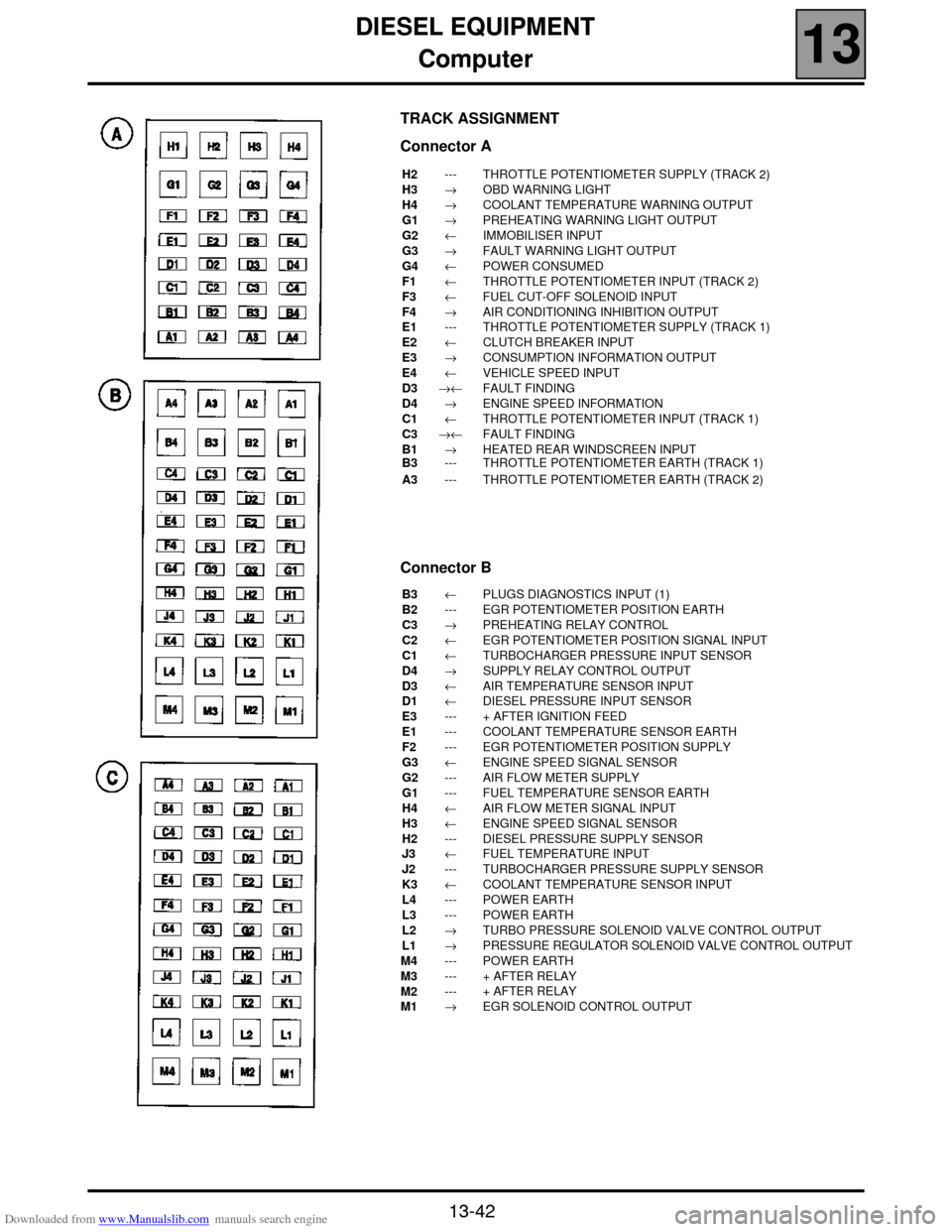

TRACK ASSIGNMENT

Connector A

H2

H3

H4

G1

G2

G3

G4

F1

F3

F4

E1

E2

E3

E4

D3

D4

C1

C3

B1

B3

A3---

→

→

→

←

→

←

←

←

→

---

←

→

←

→←

→

←

→←

→

---

---THROTTLE POTENTIOMETER SUPPLY (TRACK 2)

OBD WARNING LIGHT

COOLANT TEMPERATURE WARNING OUTPUT

PREHEATING WARNING LIGHT OUTPUT

IMMOBILISER INPUT

FAULT WARNING LIGHT OUTPUT

POWER CONSUMED

THROTTLE POTENTIOMETER INPUT (TRACK 2)

FUEL CUT-OFF SOLENOID INPUT

AIR CONDITIONING INHIBITION OUTPUT

THROTTLE POTENTIOMETER SUPPLY (TRACK 1)

CLUTCH BREAKER INPUT

CONSUMPTION INFORMATION OUTPUT

VEHICLE SPEED INPUT

FAULT FINDING

ENGINE SPEED INFORMATION

THROTTLE POTENTIOMETER INPUT (TRACK 1)

FAULT FINDING

HEATED REAR WINDSCREEN INPUT

THROTTLE POTENTIOMETER EARTH (TRACK 1)

THROTTLE POTENTIOMETER EARTH (TRACK 2)

Connector B

B3

B2

C3

C2

C1

D4

D3

D1

E3

E1

F2

G3

G2

G1

H4

H3

H2

J3

J2

K3

L4

L3

L2

L1

M4

M3

M2

M1←

---

→

←

←

→

←

←

---

---

---

←

---

---

←

←

---

←

---

←

---

---

→

→

---

---

---

→PLUGS DIAGNOSTICS INPUT (1)

EGR POTENTIOMETER POSITION EARTH

PREHEATING RELAY CONTROL

EGR POTENTIOMETER POSITION SIGNAL INPUT

TURBOCHARGER PRESSURE INPUT SENSOR

SUPPLY RELAY CONTROL OUTPUT

AIR TEMPERATURE SENSOR INPUT

DIESEL PRESSURE INPUT SENSOR

+ AFTER IGNITION FEED

COOLANT TEMPERATURE SENSOR EARTH

EGR POTENTIOMETER POSITION SUPPLY

ENGINE SPEED SIGNAL SENSOR

AIR FLOW METER SUPPLY

FUEL TEMPERATURE SENSOR EARTH

AIR FLOW METER SIGNAL INPUT

ENGINE SPEED SIGNAL SENSOR

DIESEL PRESSURE SUPPLY SENSOR

FUEL TEMPERATURE INPUT

TURBOCHARGER PRESSURE SUPPLY SENSOR

COOLANT TEMPERATURE SENSOR INPUT

POWER EARTH

POWER EARTH

TURBO PRESSURE SOLENOID VALVE CONTROL OUTPUT

PRESSURE REGULATOR SOLENOID VALVE CONTROL OUTPUT

POWER EARTH

+ AFTER RELAY

+ AFTER RELAY

EGR SOLENOID CONTROL OUTPUT

Page 99 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-2

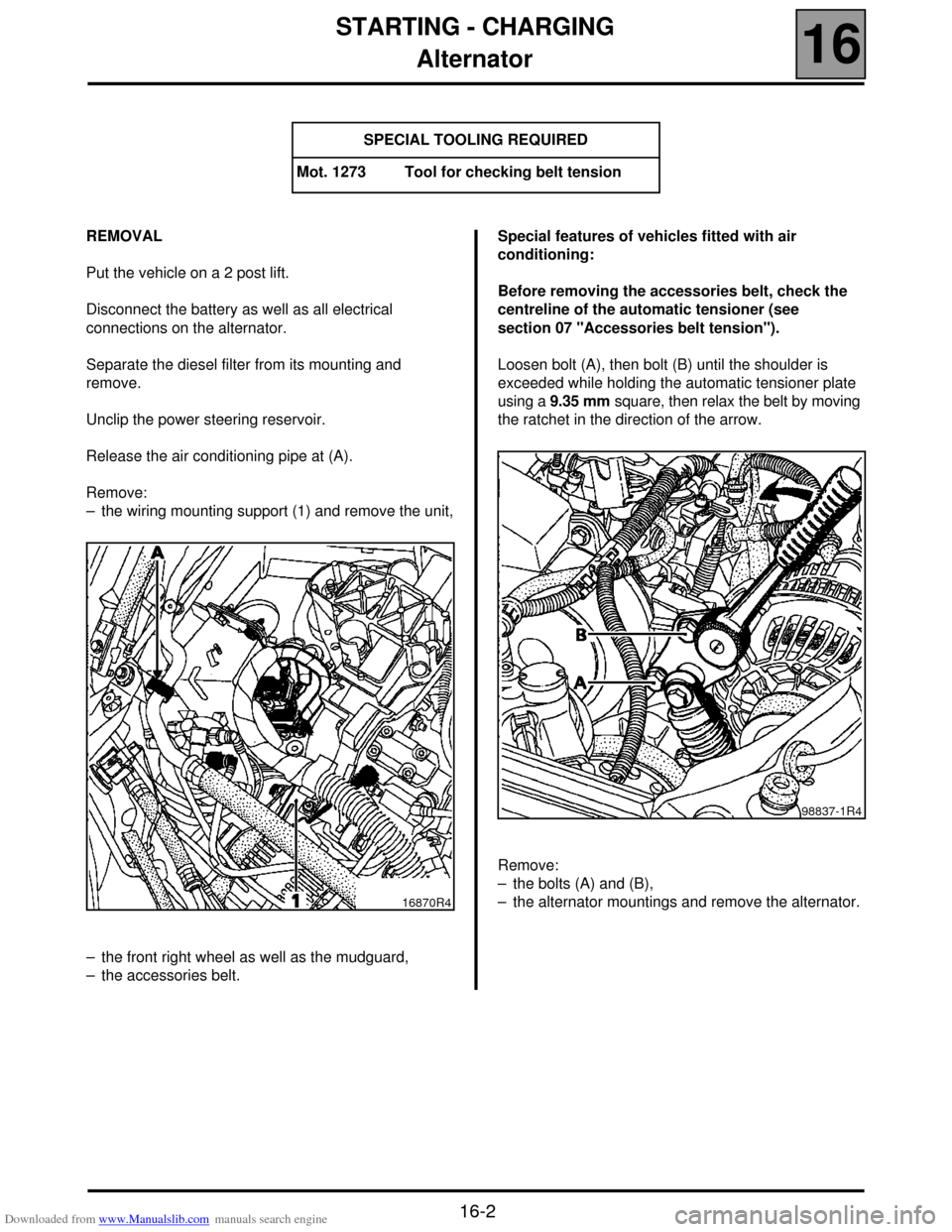

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery as well as all electrical

connections on the alternator.

Separate the diesel filter from its mounting and

remove.

Unclip the power steering reservoir.

Release the air conditioning pipe at (A).

Remove:

– the wiring mounting support (1) and remove the unit,

– the front right wheel as well as the mudguard,

– the accessories belt.Special features of vehicles fitted with air

conditioning:

Before removing the accessories belt, check the

centreline of the automatic tensioner (see

section 07 "Accessories belt tension").

Loosen bolt (A), then bolt (B) until the shoulder is

exceeded while holding the automatic tensioner plate

using a 9.35 mm square, then relax the belt by moving

the ratchet in the direction of the arrow.

Remove:

– the bolts (A) and (B),

– the alternator mountings and remove the alternator. SPECIAL TOOLING REQUIRED

Mot. 1273 Tool for checking belt tension

16870R4

98837-1R4

Page 100 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-3

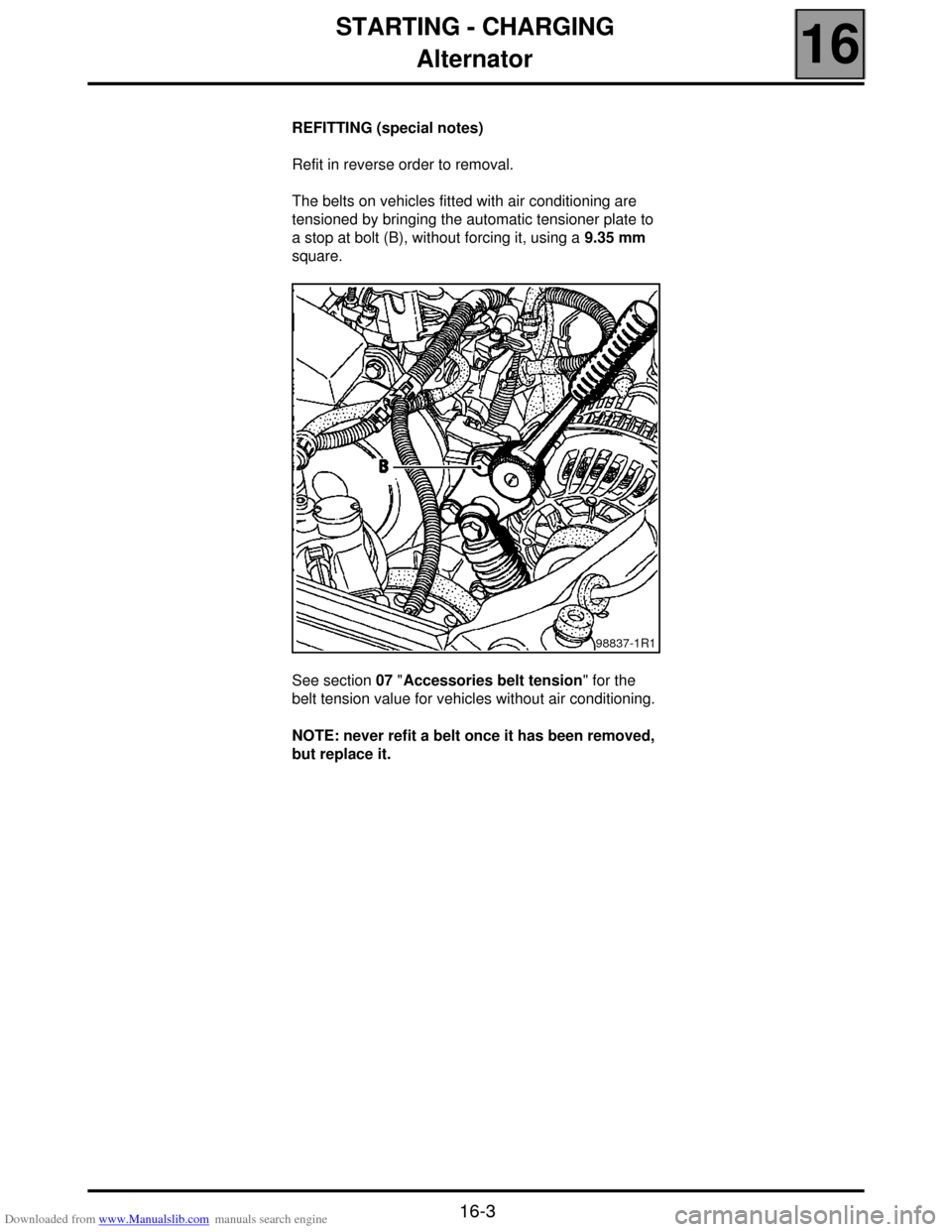

REFITTING (special notes)

Refit in reverse order to removal.

The belts on vehicles fitted with air conditioning are

tensioned by bringing the automatic tensioner plate to

a stop at bolt (B), without forcing it, using a 9.35 mm

square.

See section 07 "Accessories belt tension" for the

belt tension value for vehicles without air conditioning.

NOTE: never refit a belt once it has been removed,

but replace it.

98837-1R1

Page 112 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

General

62

162AIR CONDITIONING

General

CONSUMABLES

– Oil for DELPHI HARRISON compressor:

PLANETELF PAG 488: 220 cm

3 ± 15

(to be ordered from ELF).

– Refrigerant:

R134a: 780 g ± 35 (Mégane)

R134a: 680 g ± 35 (Scénic)

– Compressor:

DELPHI HARRISON V5

62-1

Page 113 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Compressor

62

62-2

SCENIC Compressor

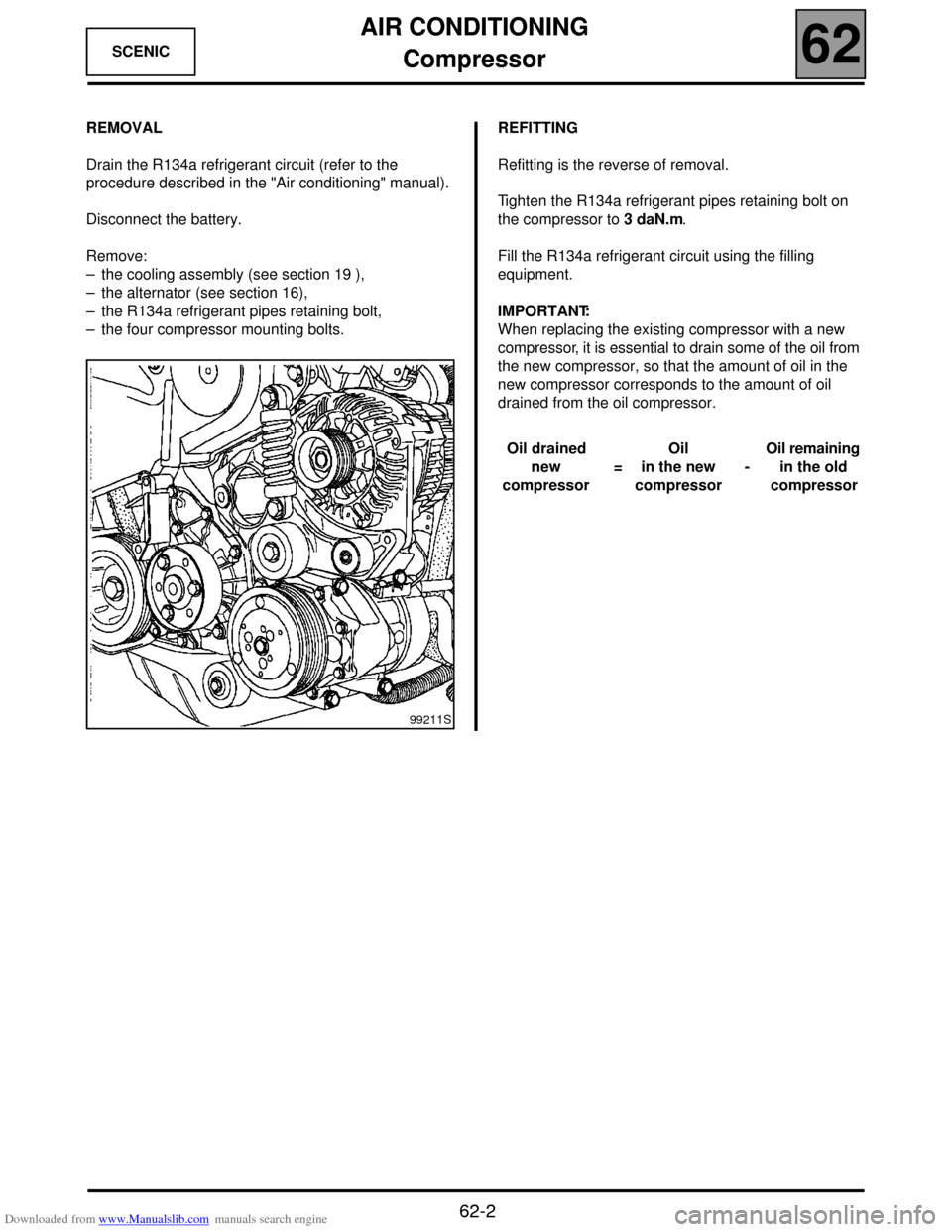

REMOVAL

Drain the R134a refrigerant circuit (refer to the

procedure described in the "Air conditioning" manual).

Disconnect the battery.

Remove:

– the cooling assembly (see section 19 ),

– the alternator (see section 16),

– the R134a refrigerant pipes retaining bolt,

– the four compressor mounting bolts.REFITTING

Refitting is the reverse of removal.

Tighten the R134a refrigerant pipes retaining bolt on

the compressor to 3 daN.m.

Fill the R134a refrigerant circuit using the filling

equipment.

IMPORTANT:

When replacing the existing compressor with a new

compressor, it is essential to drain some of the oil from

the new compressor, so that the amount of oil in the

new compressor corresponds to the amount of oil

drained from the oil compressor.

99211S

Oil drained

new

compressor=Oil

in the new

compressor-Oil remaining

in the old

compressor

Page 114 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Dehydration canister

62

62-3

SCENIC Dehydration canister

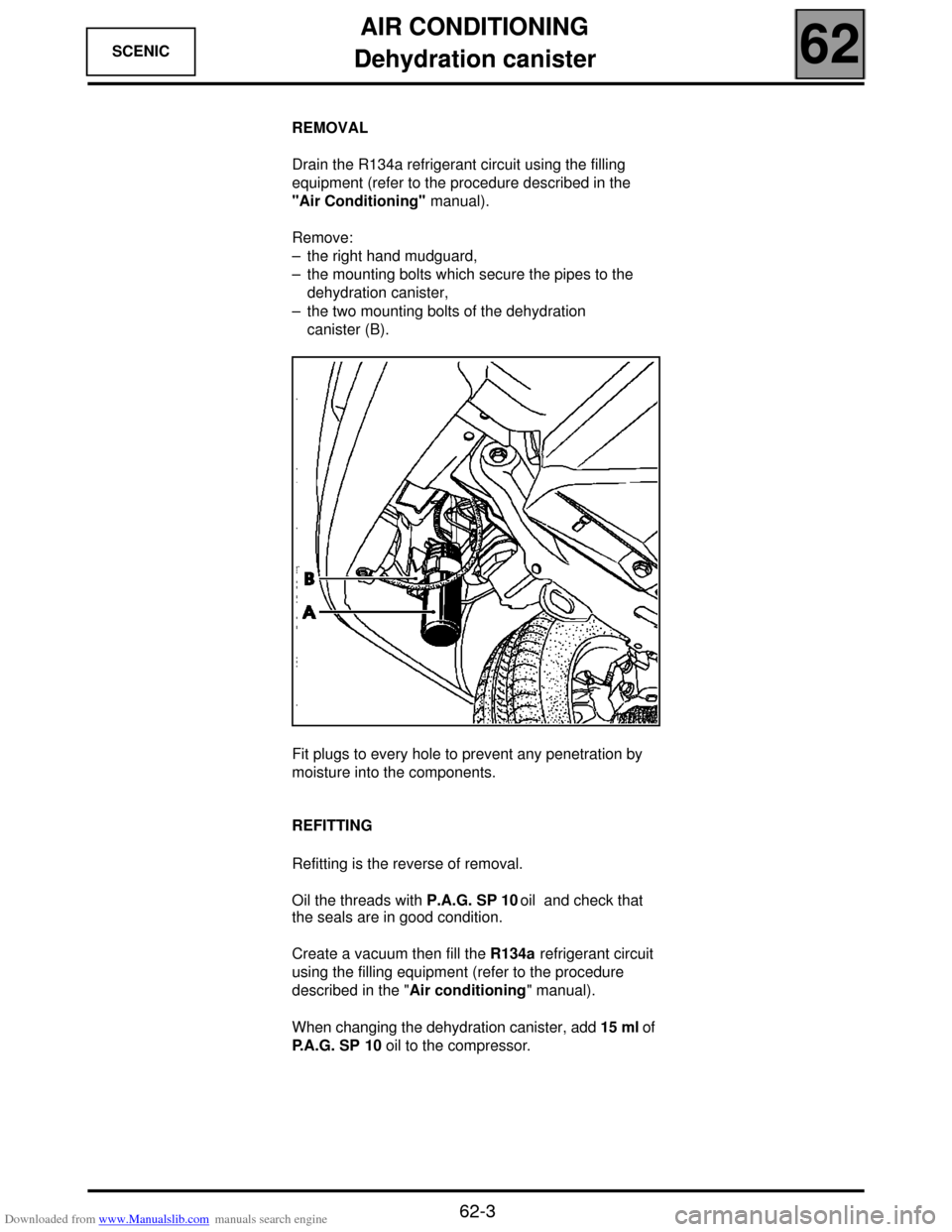

REMOVAL

Drain the R134a refrigerant circuit using the filling

equipment (refer to the procedure described in the

"Air Conditioning" manual).

Remove:

– the right hand mudguard,

– the mounting bolts which secure the pipes to the

dehydration canister,

– the two mounting bolts of the dehydration

canister (B).

Fit plugs to every hole to prevent any penetration by

moisture into the components.

REFITTING

Refitting is the reverse of removal.

Oil the threads with P.A.G. SP 10 oil and check that

the seals are in good condition.

Create a vacuum then fill the R134a refrigerant circuit

using the filling equipment (refer to the procedure

described in the "Air conditioning" manual).

When changing the dehydration canister, add 15 ml of

P.A.G. SP 10 oil to the compressor.

16763R

Page 115 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Condenser

62

62-4

SCENIC Condenser

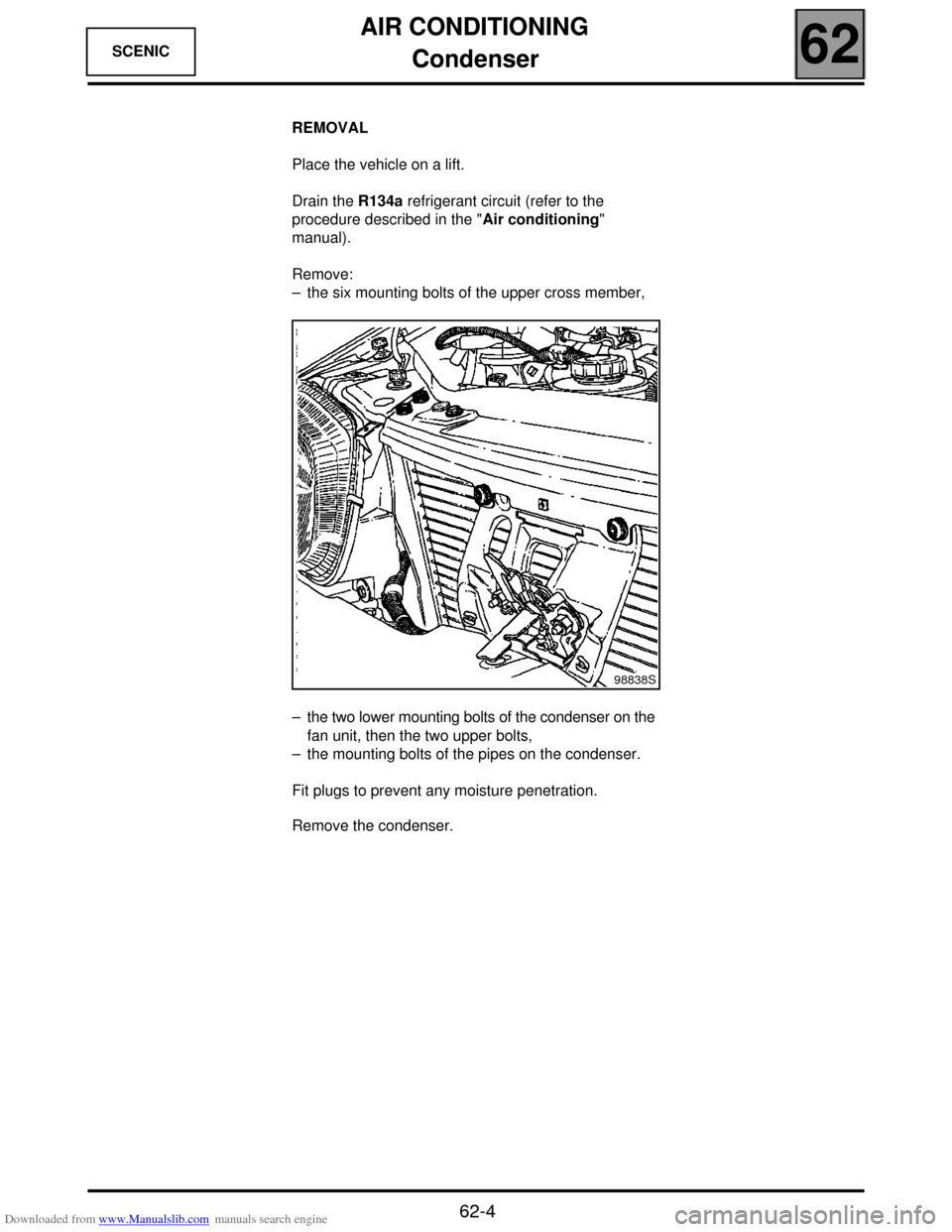

REMOVAL

Place the vehicle on a lift.

Drain the R134a refrigerant circuit (refer to the

procedure described in the "Air conditioning"

manual).

Remove:

– the six mounting bolts of the upper cross member,

– the two lower mounting bolts of the condenser on the

fan unit, then the two upper bolts,

– the mounting bolts of the pipes on the condenser.

Fit plugs to prevent any moisture penetration.

Remove the condenser.

98838S

Page 116 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Pressure relief valve

62

62-5

SCENIC Pressure relief valve

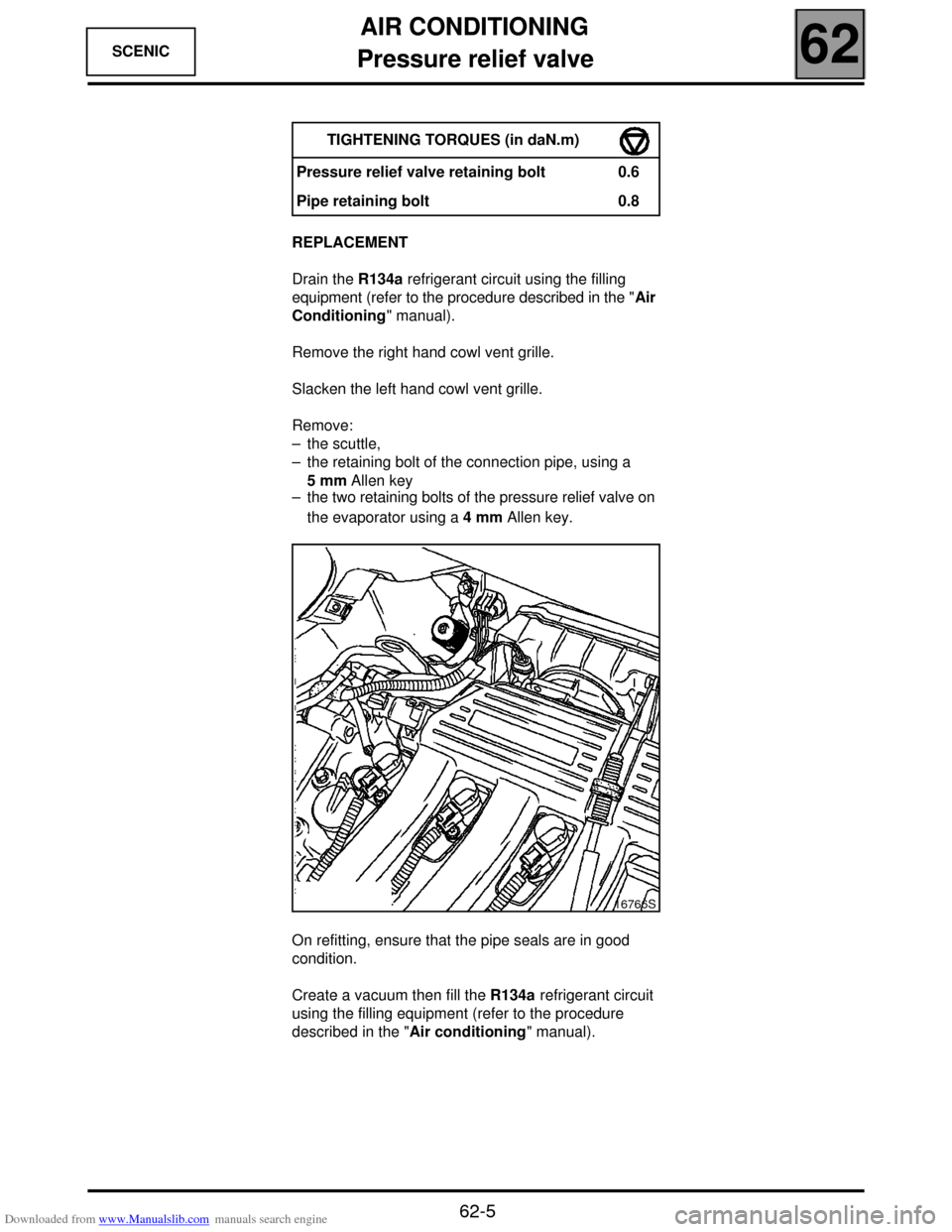

REPLACEMENT

Drain the R134a refrigerant circuit using the filling

equipment (refer to the procedure described in the "Air

Conditioning" manual).

Remove the right hand cowl vent grille.

Slacken the left hand cowl vent grille.

Remove:

– the scuttle,

– the retaining bolt of the connection pipe, using a

5 mm Allen key

– the two retaining bolts of the pressure relief valve on

the evaporator using a 4 mm Allen key.

On refitting, ensure that the pipe seals are in good

condition.

Create a vacuum then fill the R134a refrigerant circuit

using the filling equipment (refer to the procedure

described in the "Air conditioning" manual). TIGHTENING TORQUES (in daN.m)

Pressure relief valve retaining bolt 0.6

Pipe retaining bolt 0.8

16766S

Page 117 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Connecting pipes

62

62-6

SCENIC Connecting pipes

Disconnect the battery.

Drain the R134a refrigerant circuit using the filling equipment (refer to the procedure described in the "Air

Conditioning" manual).

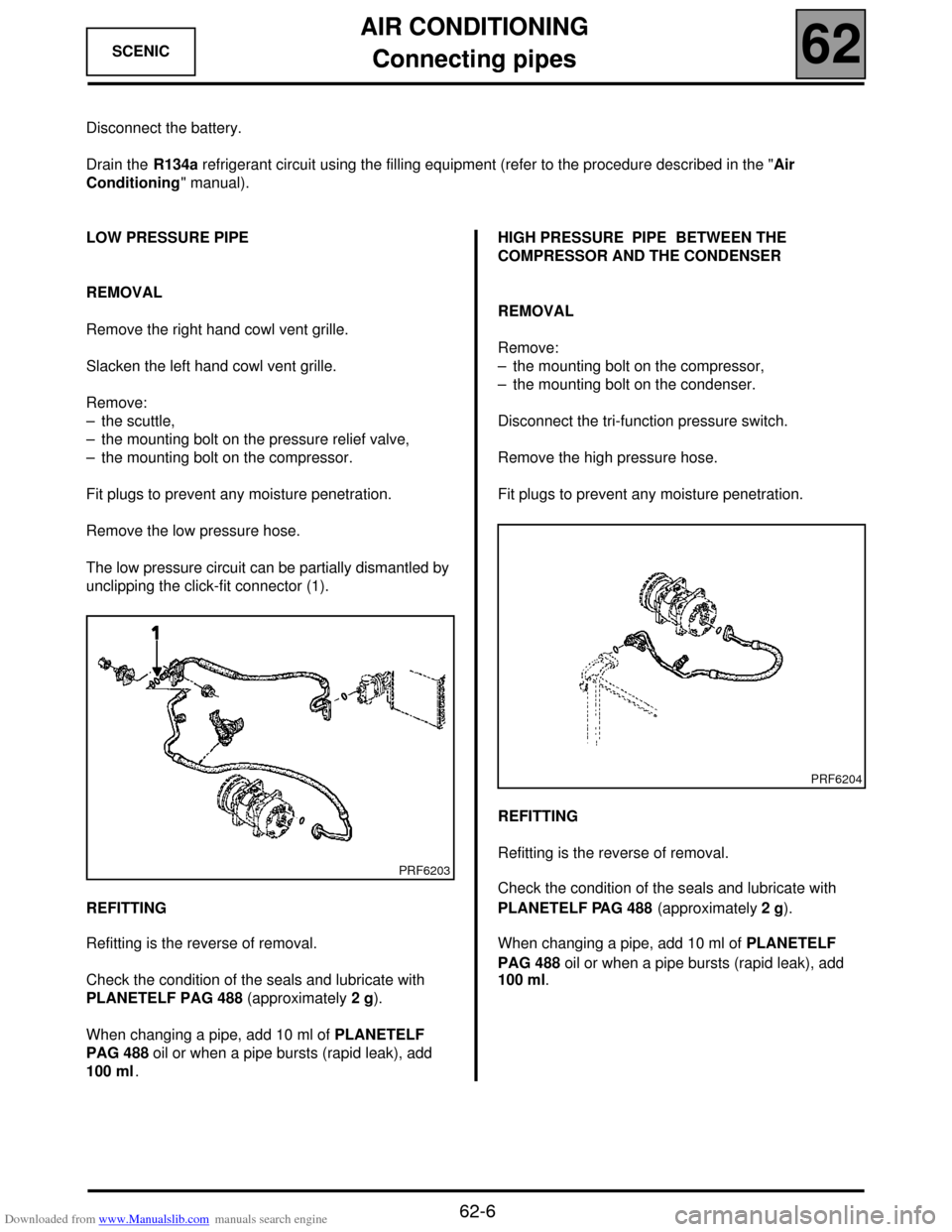

LOW PRESSURE PIPE

REMOVAL

Remove the right hand cowl vent grille.

Slacken the left hand cowl vent grille.

Remove:

– the scuttle,

– the mounting bolt on the pressure relief valve,

– the mounting bolt on the compressor.

Fit plugs to prevent any moisture penetration.

Remove the low pressure hose.

The low pressure circuit can be partially dismantled by

unclipping the click-fit connector (1).

REFITTING

Refitting is the reverse of removal.

Check the condition of the seals and lubricate with

PLANETELF PAG 488 (approximately 2 g).

When changing a pipe, add 10 ml of PLANETELF

PAG 488 oil or when a pipe bursts (rapid leak), add

100 ml.HIGH PRESSURE PIPE BETWEEN THE

COMPRESSOR AND THE CONDENSER

REMOVAL

Remove:

– the mounting bolt on the compressor,

– the mounting bolt on the condenser.

Disconnect the tri-function pressure switch.

Remove the high pressure hose.

Fit plugs to prevent any moisture penetration.

REFITTING

Refitting is the reverse of removal.

Check the condition of the seals and lubricate with

PLANETELF PAG 488 (approximately 2 g).

When changing a pipe, add 10 ml of PLANETELF

PAG 488 oil or when a pipe bursts (rapid leak), add

100 ml.

PRF6203

PRF6204