RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Owner's Manual

SCENIC 2000 J64 / 1.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1566/w960_1566-0.png

RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Owner's Manual

Page 78 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injector rail

13

13-27

Injector rail

IMPORTANT: before any intervention, connect the

after-sales diagnostic tool, query the injection

computer and check that the injection rail is not under

pressure.

Take note of the fuel temperature.SPECIAL TOOLING REQUIRED

Mot. 1294 -01 Tool for removing windscreen

wiper arms

Mot. 1383 Tool for removing high pressure

pipes

ESSENTIAL SPECIAL TOOLING

"Low torque" torque wrench

TIGHTENING TORQUES (in daN.m)

High pressure pipe nut 2.5±0.2

Injection rail mounting bolt 2.2±0.2

REMOVAL

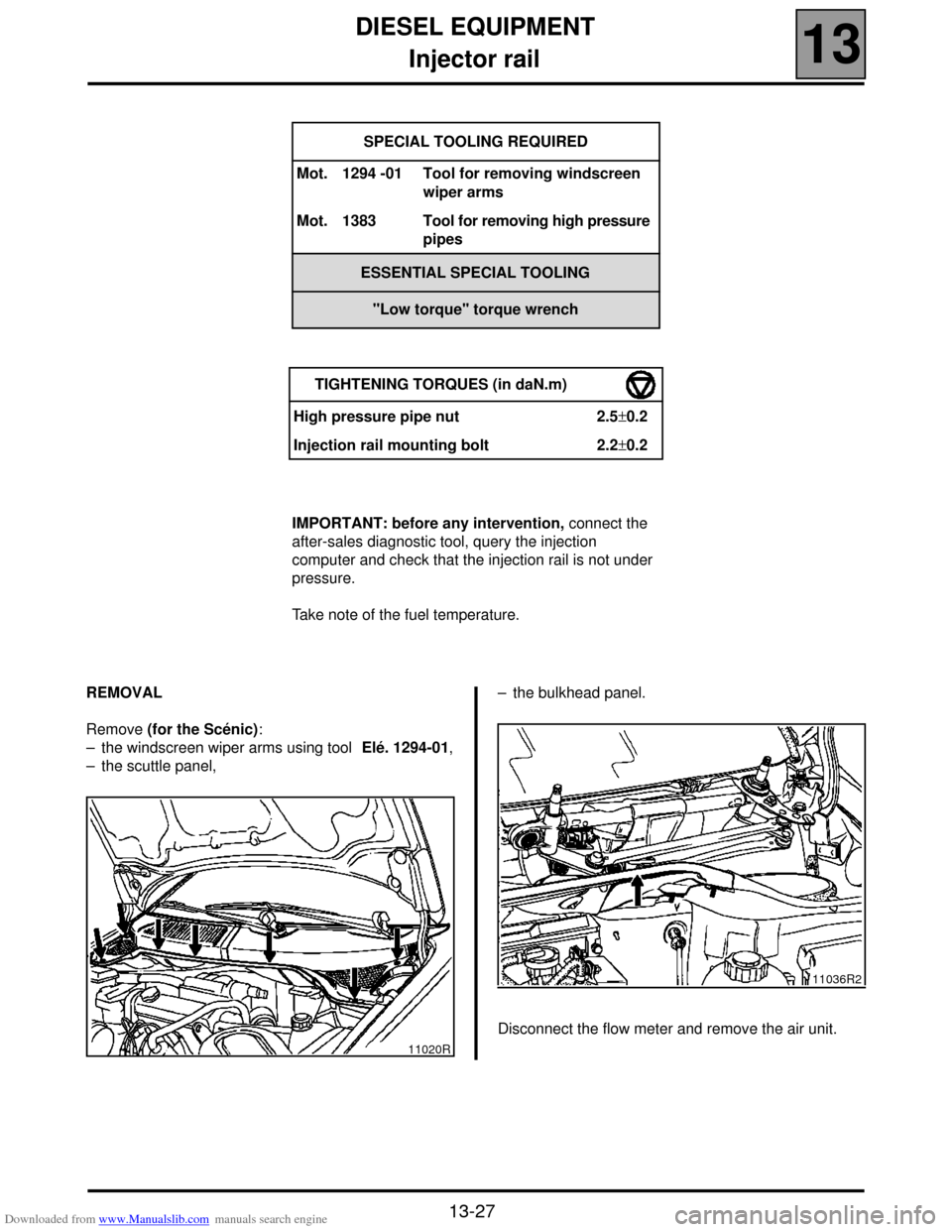

Remove (for the Scénic):

– the windscreen wiper arms using tool Elé. 1294-01,

– the scuttle panel,– the bulkhead panel.

Disconnect the flow meter and remove the air unit.

11020R

11036R2

Page 79 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injector rail

13

13-28

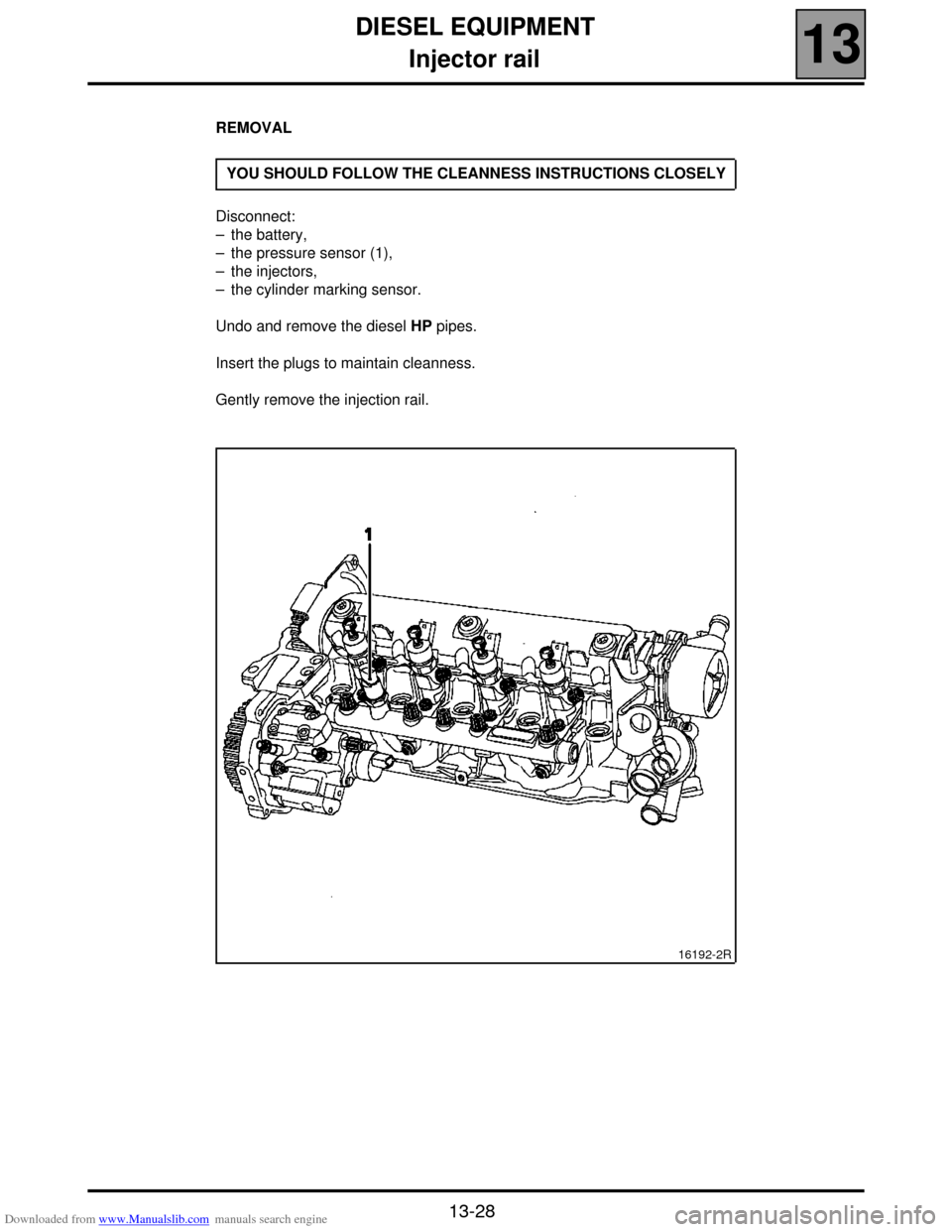

REMOVAL

Disconnect:

– the battery,

– the pressure sensor (1),

– the injectors,

– the cylinder marking sensor.

Undo and remove the diesel HP pipes.

Insert the plugs to maintain cleanness.

Gently remove the injection rail.YOU SHOULD FOLLOW THE CLEANNESS INSTRUCTIONS CLOSELY

16192-2R

Page 80 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injector rail

13

13-29

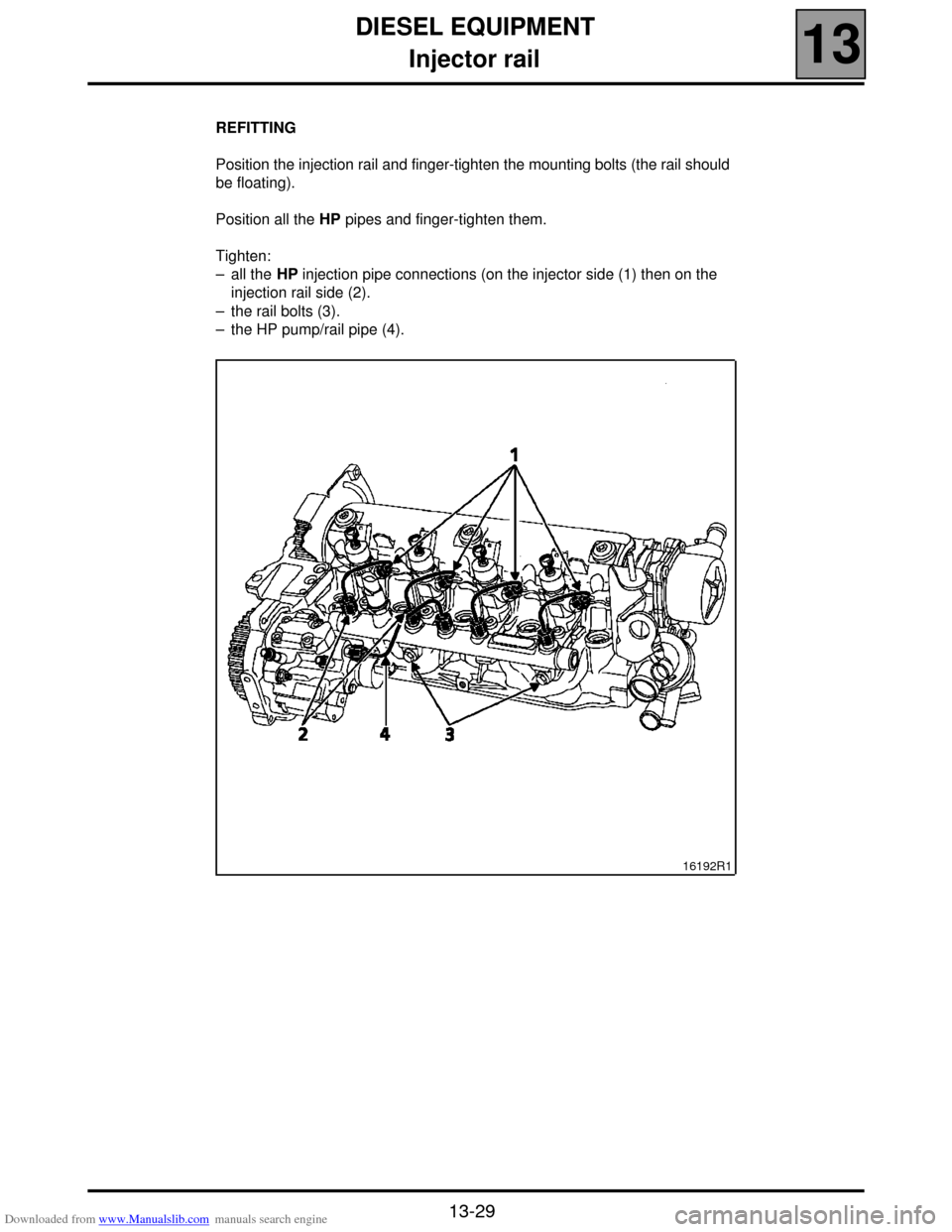

REFITTING

Position the injection rail and finger-tighten the mounting bolts (the rail should

be floating).

Position all the HP pipes and finger-tighten them.

Tighten:

– all the HP injection pipe connections (on the injector side (1) then on the

injection rail side (2).

– the rail bolts (3).

– the HP pump/rail pipe (4).

16192R1

Page 81 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injector rail

13

13-30

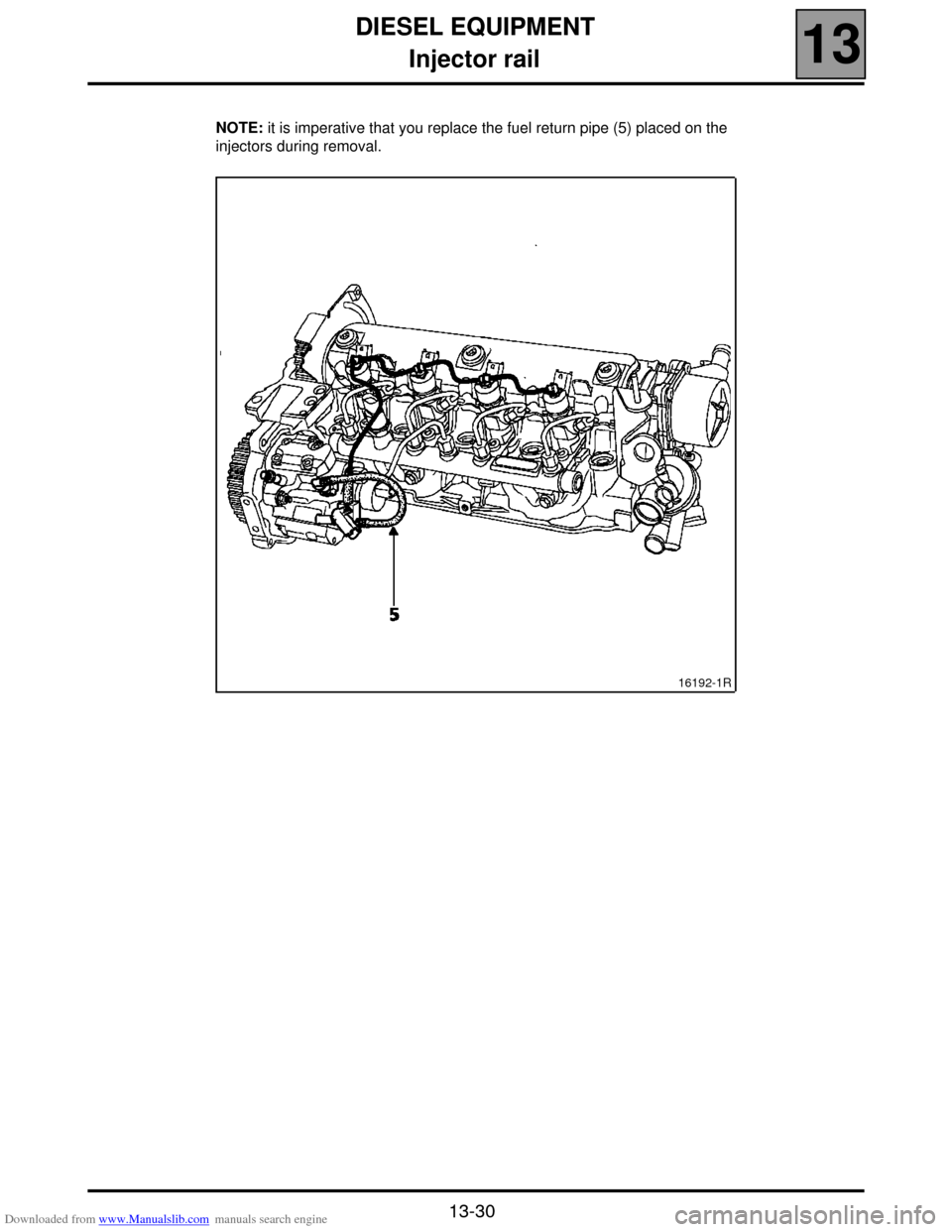

NOTE: it is imperative that you replace the fuel return pipe (5) placed on the

injectors during removal.

16192-1R

Page 83 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injectors

13

13-32

Injectors

IT IS FORBIDDEN TO REMOVE THE INTERIOR OF

AN INJECTOR OR TO SEPARATE THE INJECTOR

HOLDER FROM THE PIPE.

IMPORTANT: before any intervention, connect the

after-sales diagnostic tool, query the injection

computer and check that the injection rail is not under

pressure. Take note of the fuel temperature.SPECIAL TOOLING REQUIRED

Elé. 1294 -01 Tool for removing windscreen

wiper arms

Mot. 1383 Tool for removing high pressure

pipes

TIGHTENING TORQUES (in daN.m)

Injector clamp mounting bolt 2 ± 0.2

High pressure pipe nut 2.5 ± 0.2

Page 84 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injectors

13

13-33

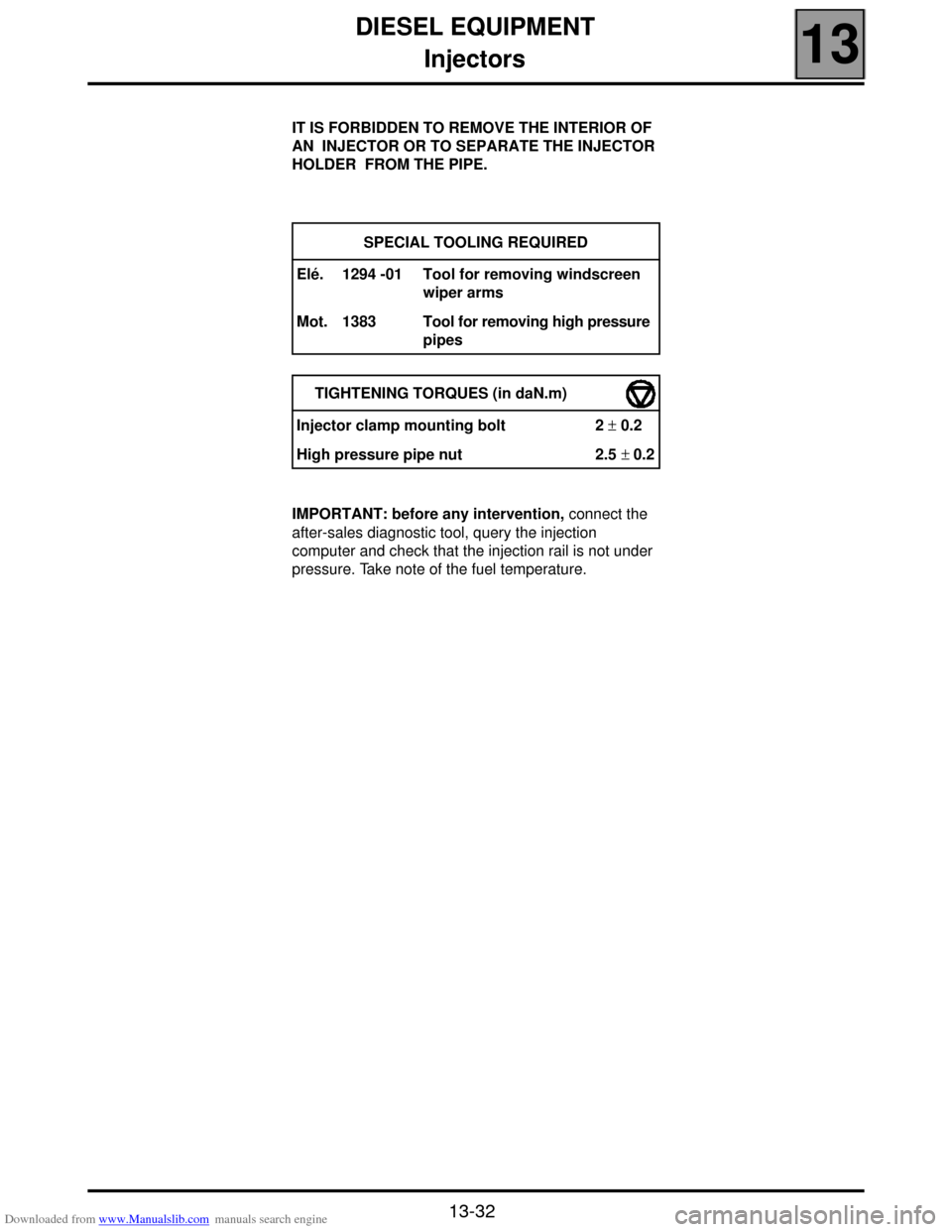

REMOVAL

If necessary, remove:

– the bulkhead panel using tool Elé. 1294-01,

– the scuttle panel,

– the air unit.

NOTE: the injectors may be replaced individually.

Remove the HP pipe using the tool Mot. 1383.

Insert the plugs to maintain cleanness.

Remove:

– the injector mounting clamp,

– the injector,

– the flame shield washer.YOU SHOULD FOLLOW THE CLEANNESS INSTRUCTIONS CLOSELY

16192-2S

Page 86 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injectors

13

13-35

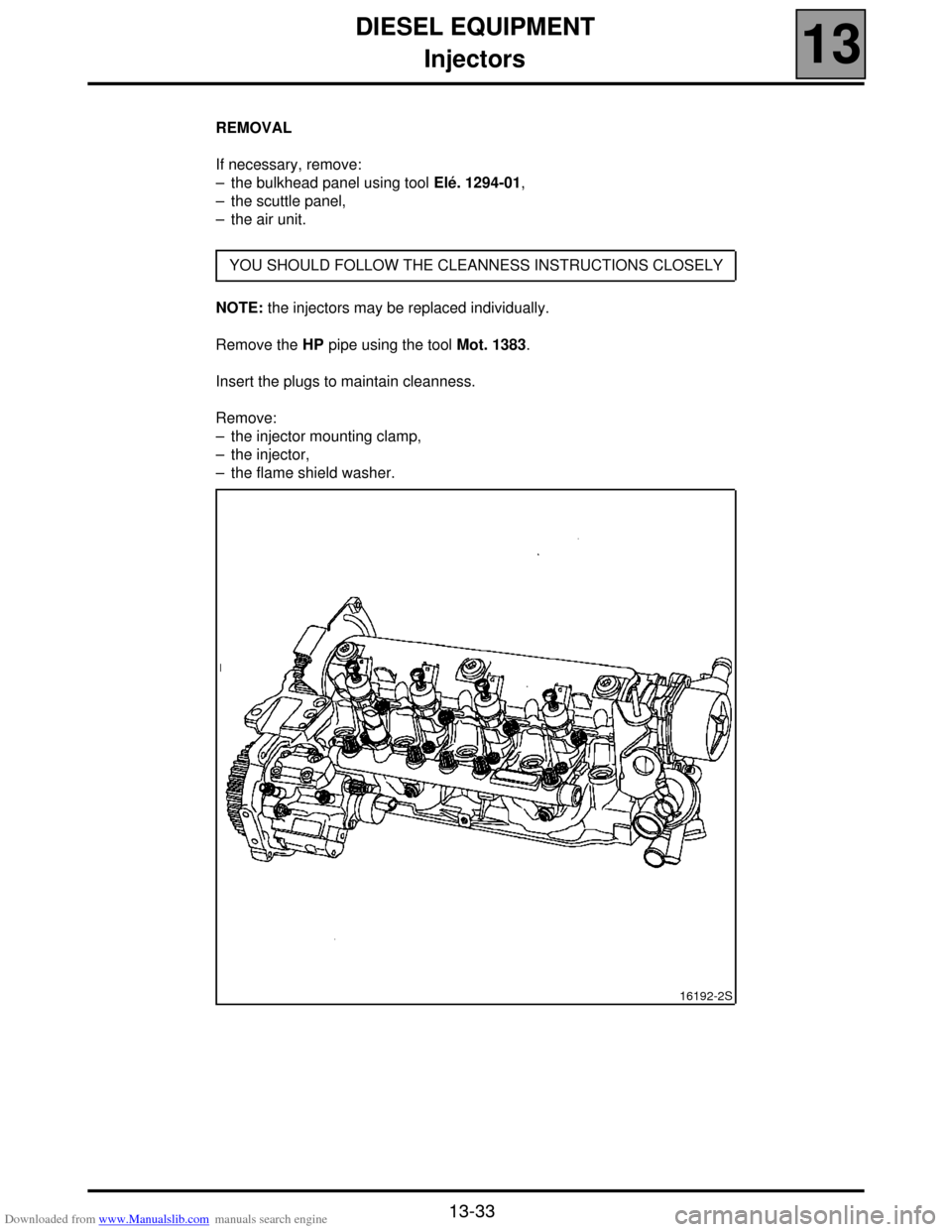

NOTE: be careful when refitting that you do not stress the HP pipe. Remove

the injection rail.

Fit:

– the injector,

– the diesel return pipe.

16192-1S

Page 87 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injectors

13

13-36

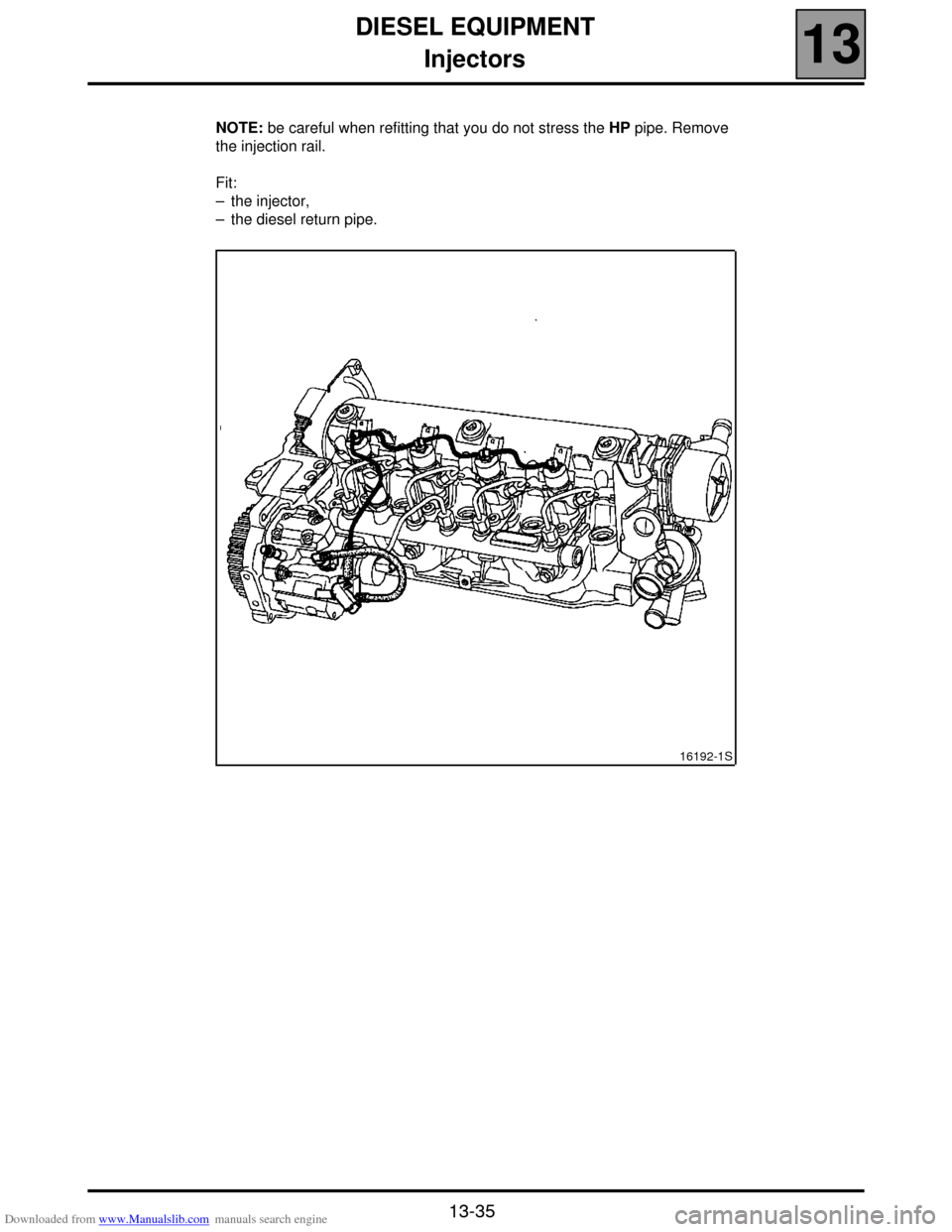

Fit the high pressure pipe.

Loosen the high pressure pump/rail pipe.

Tighten to torque:

– the injector,

– the injector side connections, then the injection rail connections,

– the rail.

– the pump/rail pipe (high pressure pump side under pressure).

NOTE: it is essential that you replace the fuel return pipe placed on the

injectors during removal.

16192S

After any intervention, check that there are no leaks in the diesel circuit.

Start the engine at idling speed until the fan starts up, then accelerate

several times under no load.

Page 95 of 118

Downloaded from www.Manualslib.com manuals search engine ANTIPOLLUTION

Oil vapour rebreathing

14

14-1

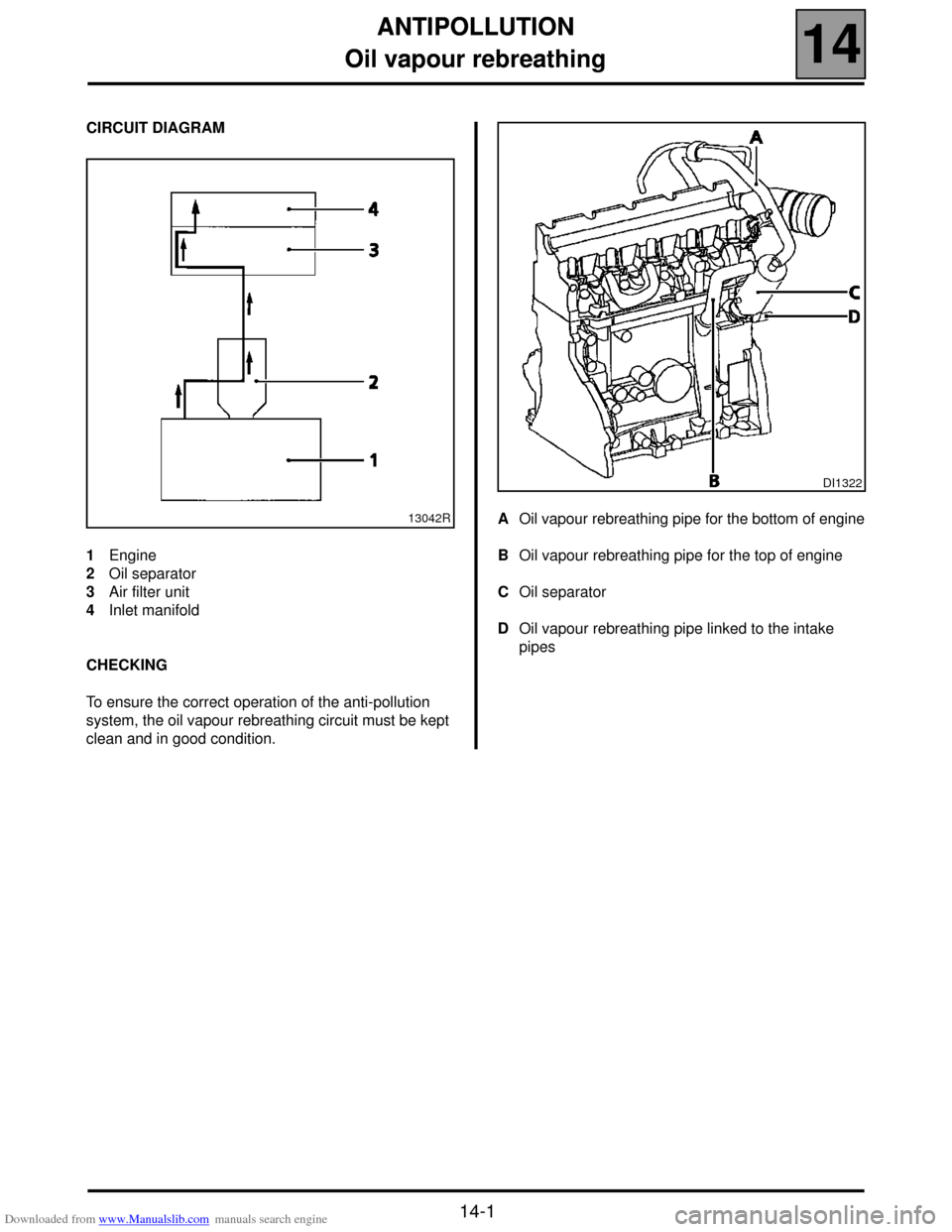

114ANTIPOLLUTION

Oil vapour rebreathing

CIRCUIT DIAGRAM

1Engine

2Oil separator

3Air filter unit

4Inlet manifold

CHECKING

To ensure the correct operation of the anti-pollution

system, the oil vapour rebreathing circuit must be kept

clean and in good condition.AOil vapour rebreathing pipe for the bottom of engine

BOil vapour rebreathing pipe for the top of engine

COil separator

DOil vapour rebreathing pipe linked to the intake

pipes

13042R

DI1322

Page 99 of 118

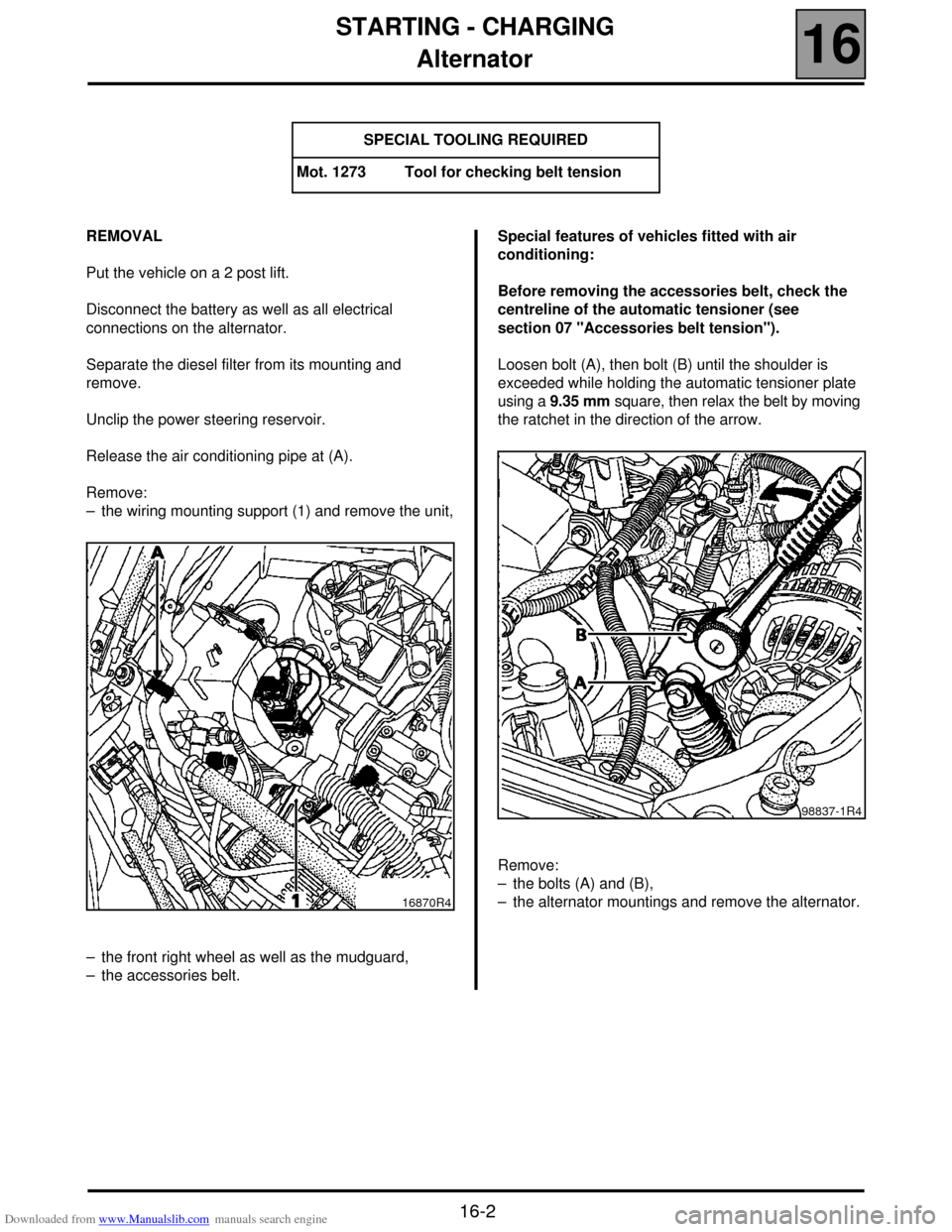

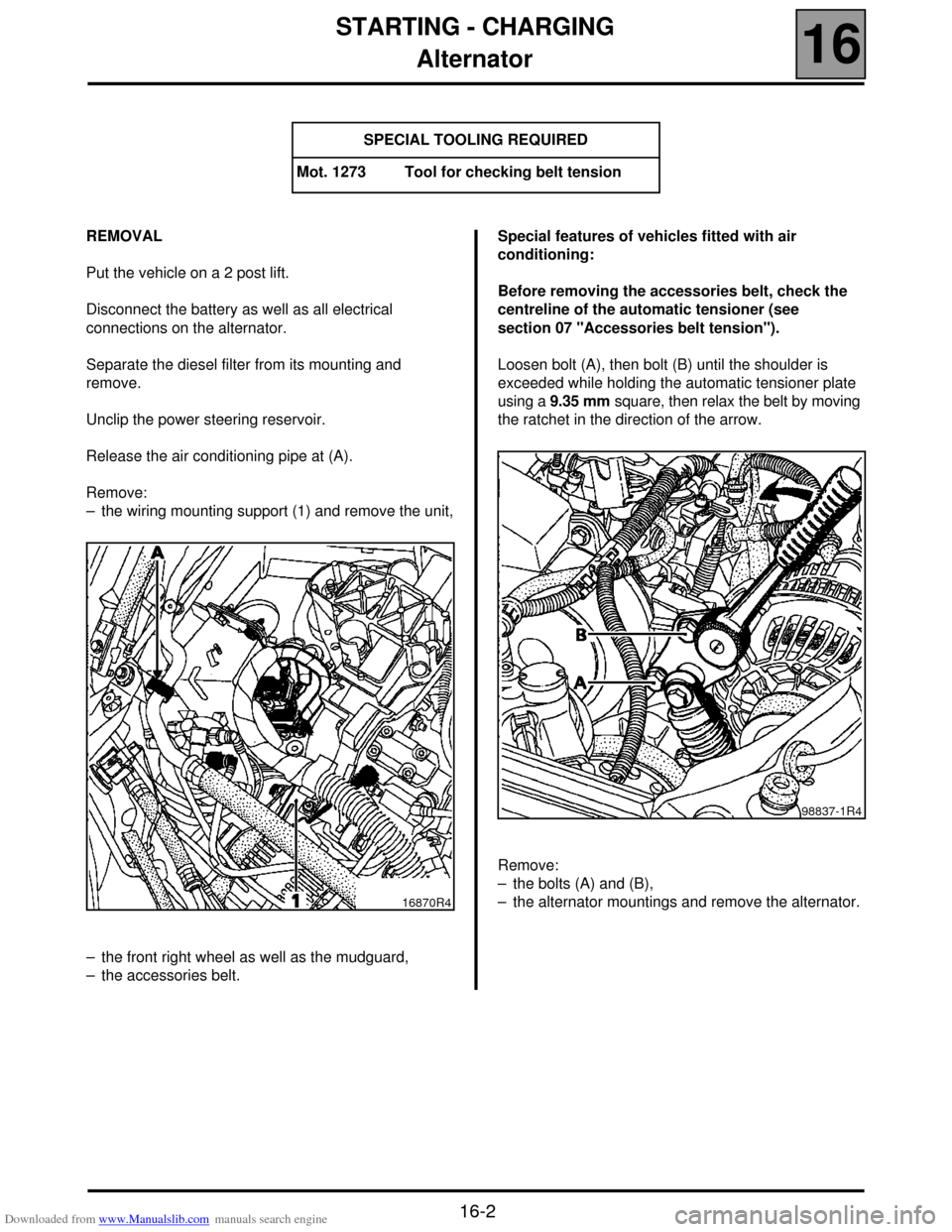

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-2

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery as well as all electrical

connections on the alternator.

Separate the diesel filter from its mounting and

remove.

Unclip the power steering reservoir.

Release the air conditioning pipe at (A).

Remove:

– the wiring mounting support (1) and remove the unit,

– the front right wheel as well as the mudguard,

– the accessories belt.Special features of vehicles fitted with air

conditioning:

Before removing the accessories belt, check the

centreline of the automatic tensioner (see

section 07 "Accessories belt tension").

Loosen bolt (A), then bolt (B) until the shoulder is

exceeded while holding the automatic tensioner plate

using a 9.35 mm square, then relax the belt by moving

the ratchet in the direction of the arrow.

Remove:

– the bolts (A) and (B),

– the alternator mountings and remove the alternator. SPECIAL TOOLING REQUIRED

Mot. 1273 Tool for checking belt tension

16870R4

98837-1R4