check engine RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 95 of 118

Downloaded from www.Manualslib.com manuals search engine ANTIPOLLUTION

Oil vapour rebreathing

14

14-1

114ANTIPOLLUTION

Oil vapour rebreathing

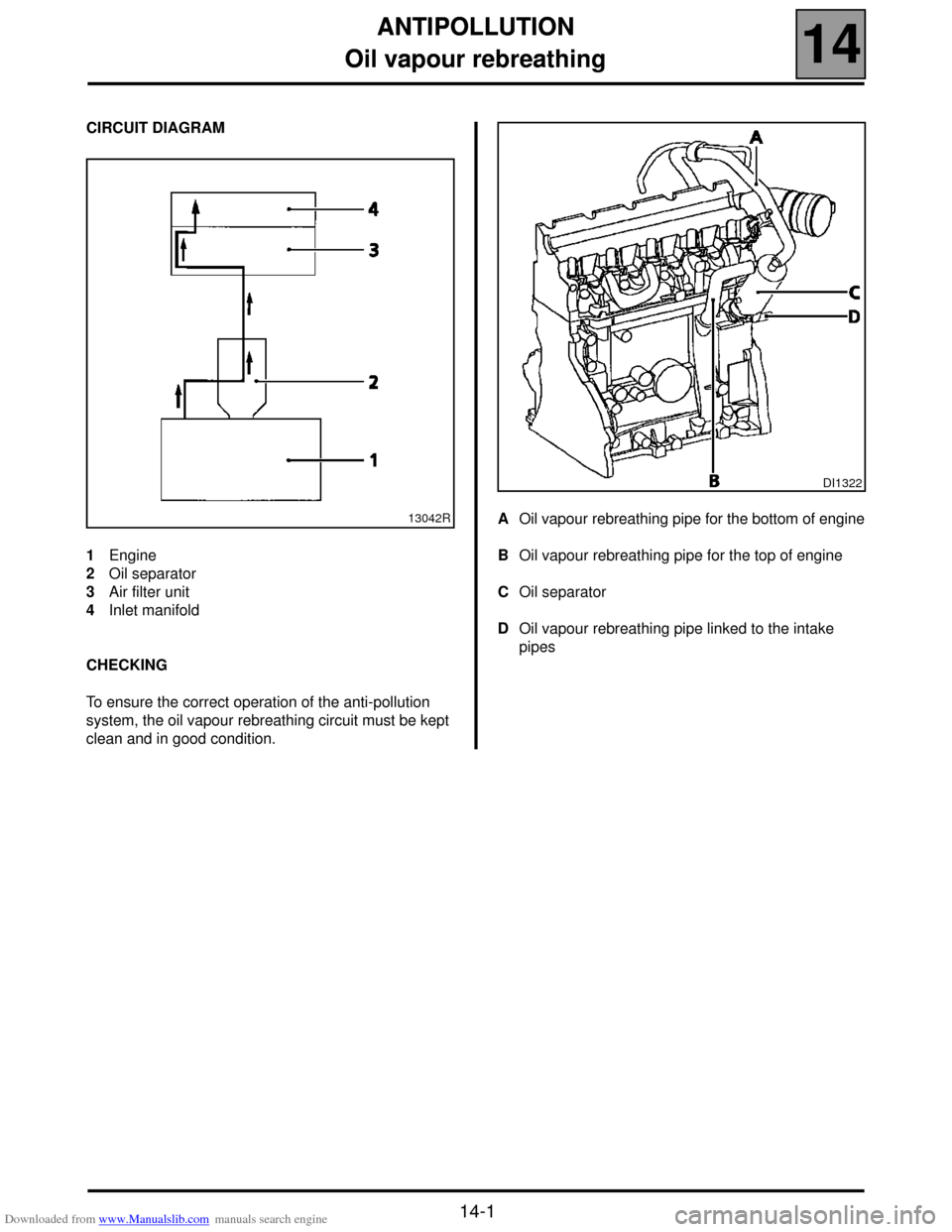

CIRCUIT DIAGRAM

1Engine

2Oil separator

3Air filter unit

4Inlet manifold

CHECKING

To ensure the correct operation of the anti-pollution

system, the oil vapour rebreathing circuit must be kept

clean and in good condition.AOil vapour rebreathing pipe for the bottom of engine

BOil vapour rebreathing pipe for the top of engine

COil separator

DOil vapour rebreathing pipe linked to the intake

pipes

13042R

DI1322

Page 98 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

116STARTING - CHARGING

Alternator

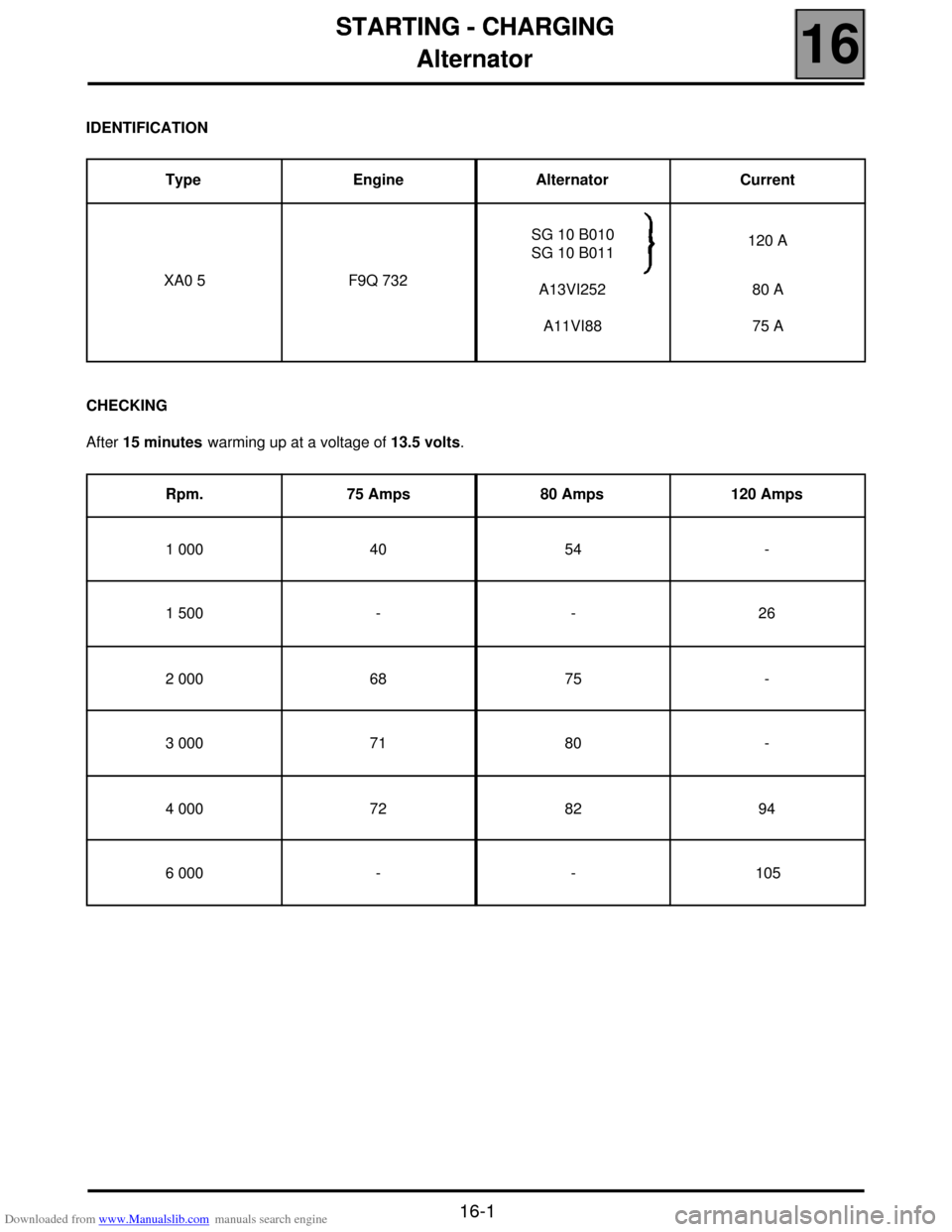

IDENTIFICATION

CHECKING

After 15 minutes warming up at a voltage of 13.5 volts. Type Engine Alternator Current

XA0 5 F9Q 732

SG 10 B010

SG 10 B011

A13VI252

A11VI88120 A

80 A

75 A

Rpm. 75 Amps 80 Amps 120 Amps

1 000 40 54 -

1 500 - - 26

2 000 68 75 -

3 000 71 80 -

4 000 72 82 94

6 000 - - 105

16-1

Page 99 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Alternator

16

16-2

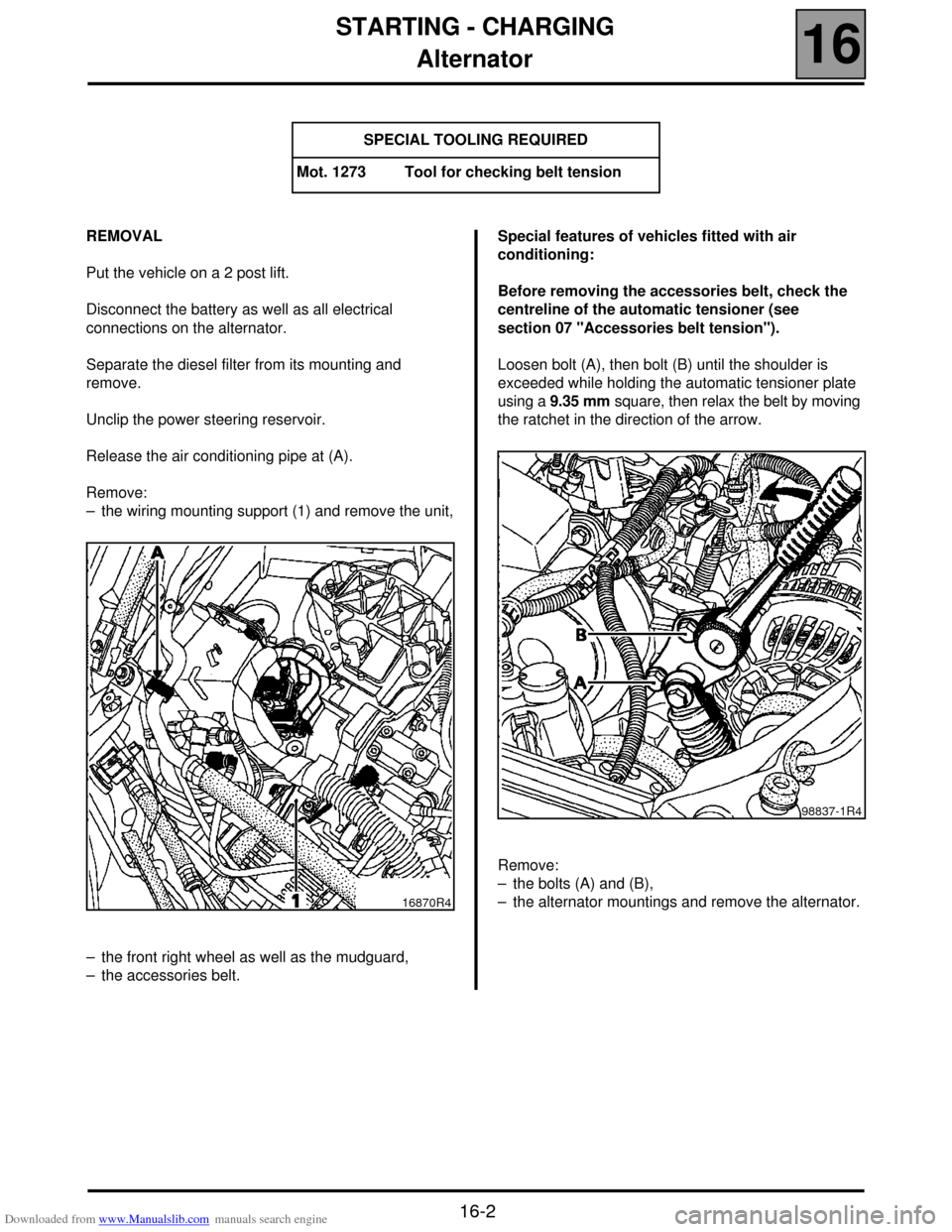

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery as well as all electrical

connections on the alternator.

Separate the diesel filter from its mounting and

remove.

Unclip the power steering reservoir.

Release the air conditioning pipe at (A).

Remove:

– the wiring mounting support (1) and remove the unit,

– the front right wheel as well as the mudguard,

– the accessories belt.Special features of vehicles fitted with air

conditioning:

Before removing the accessories belt, check the

centreline of the automatic tensioner (see

section 07 "Accessories belt tension").

Loosen bolt (A), then bolt (B) until the shoulder is

exceeded while holding the automatic tensioner plate

using a 9.35 mm square, then relax the belt by moving

the ratchet in the direction of the arrow.

Remove:

– the bolts (A) and (B),

– the alternator mountings and remove the alternator. SPECIAL TOOLING REQUIRED

Mot. 1273 Tool for checking belt tension

16870R4

98837-1R4

Page 102 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Starter

16

16-5

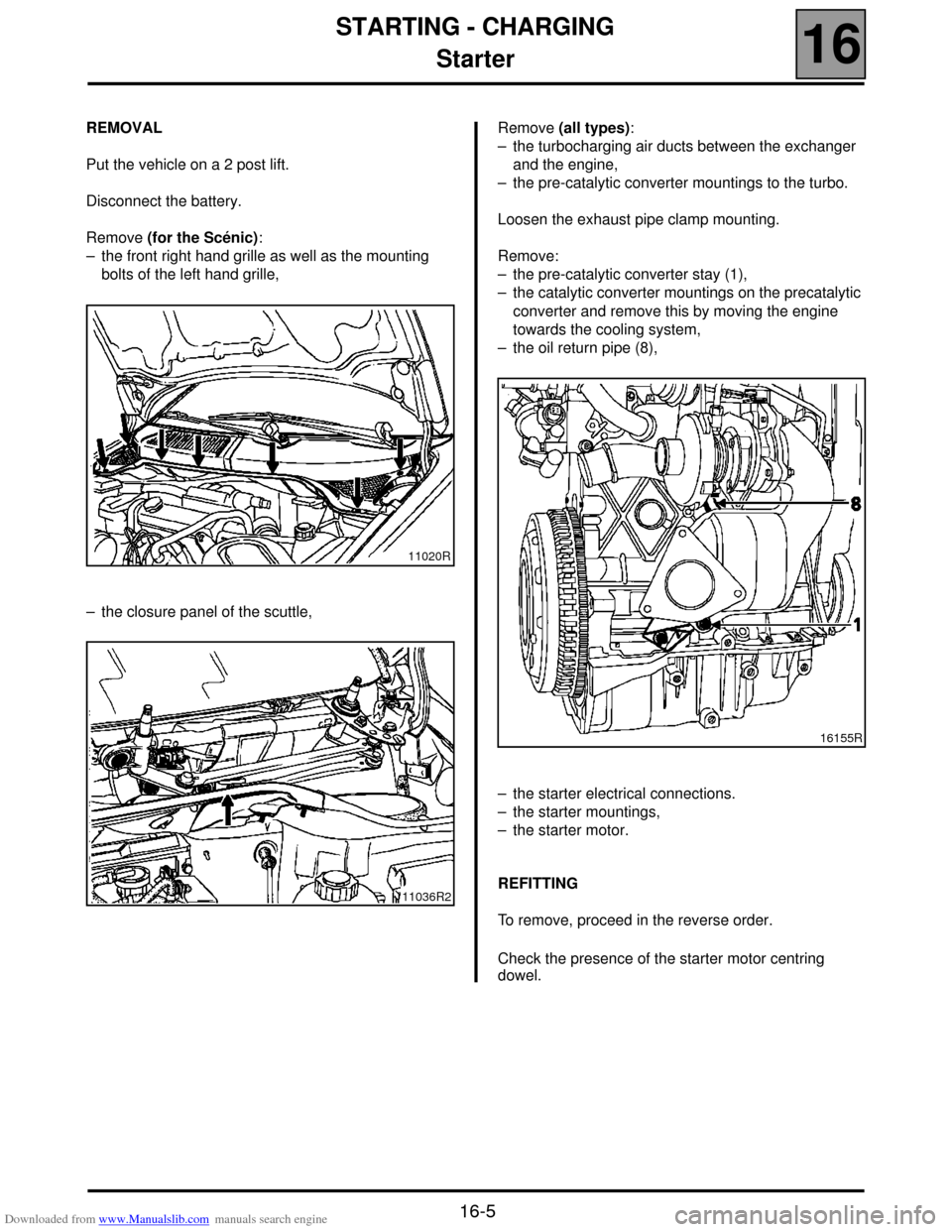

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Remove (for the Scénic):

– the front right hand grille as well as the mounting

bolts of the left hand grille,

– the closure panel of the scuttle,Remove (all types):

– the turbocharging air ducts between the exchanger

and the engine,

– the pre-catalytic converter mountings to the turbo.

Loosen the exhaust pipe clamp mounting.

Remove:

– the pre-catalytic converter stay (1),

– the catalytic converter mountings on the precatalytic

converter and remove this by moving the engine

towards the cooling system,

– the oil return pipe (8),

– the starter electrical connections.

– the starter mountings,

– the starter motor.

REFITTING

To remove, proceed in the reverse order.

Check the presence of the starter motor centring

dowel.

11020R

11036R2

16155R

Page 103 of 118

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Filling and bleeding

19

119 COOLING SYSTEM

Filling and bleeding

There is no heater matrix water control valve.

Water flow is continuous in the heater matrix, which

contributes to the cooling of the engine.

FILLING

It is essential to open the bleed screw on the

cylinder head coolant pipe housing outlet.

Fill the circuit through the expansion bottle opening.

Close the bleed screw as soon as the fluid runs out in

a continuous jet.

Start the engine (2500 rpm).

Adjust the level by overflow for a period of about

4 minutes.

Tighten the expansion bottle cap.

BLEEDING

Let the engine run for 20 minutes at 2500 rpm, until

the engine cooling fan operates (time required for

automatic degassing).

Check the liquid level is at the "Maximum" marker.

DO NOT OPEN THE BLEED SCREW(S) WITH THE

ENGINE RUNNING.

REFIT THE EXPANSION BOTTLE CAP WHILE THE

ENGINE IS WARM.

19-1

Page 111 of 118

Downloaded from www.Manualslib.com manuals search engine MANUAL GEARBOXES

Capacities - Lubricants

21

21-2

521MANUAL GEARBOXES

Capacities - Lubricants

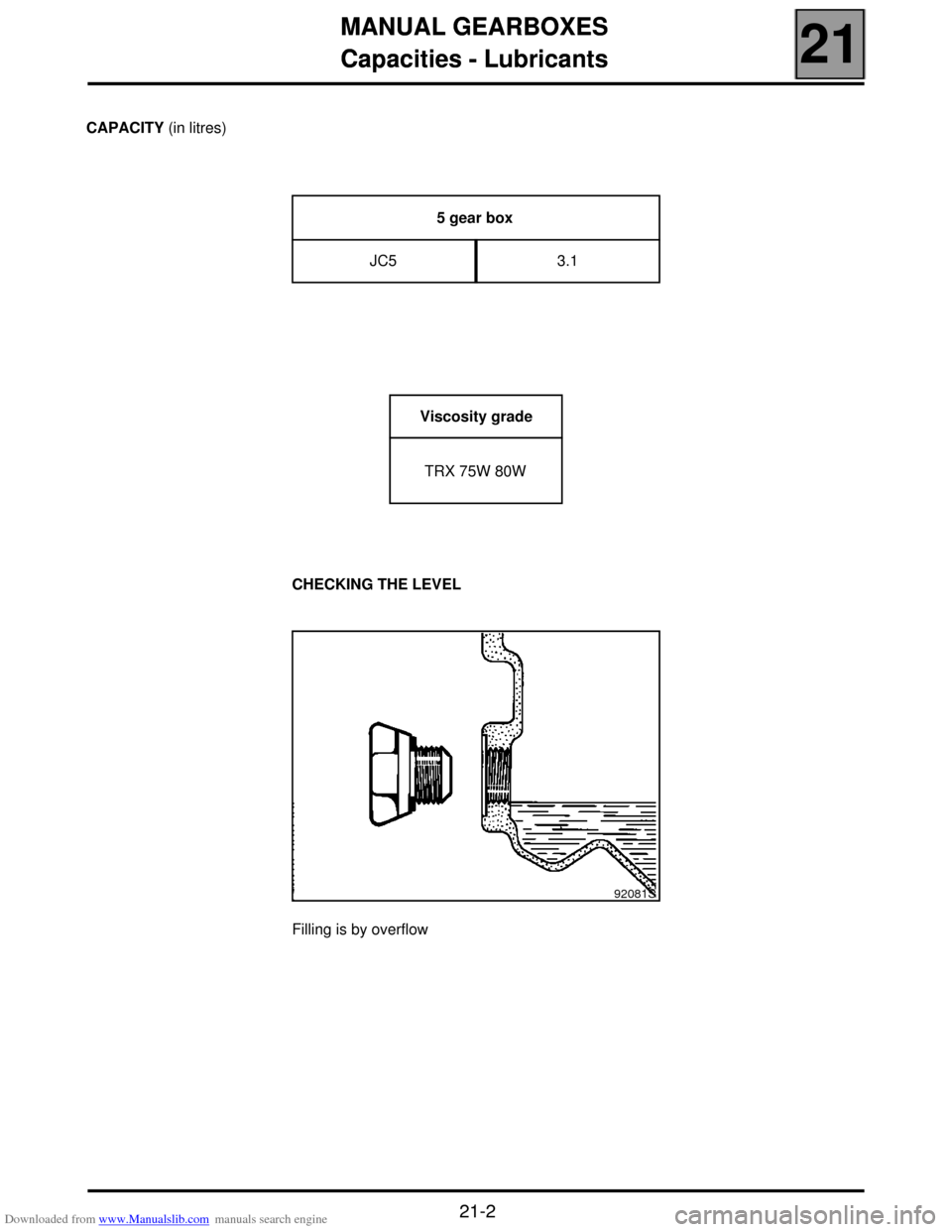

CAPACITY (in litres)

CHECKING THE LEVEL

Filling is by overflow5 gear box

JC5 3.1

Viscosity grade

TRX 75W 80W

92081S

Page 114 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Dehydration canister

62

62-3

SCENIC Dehydration canister

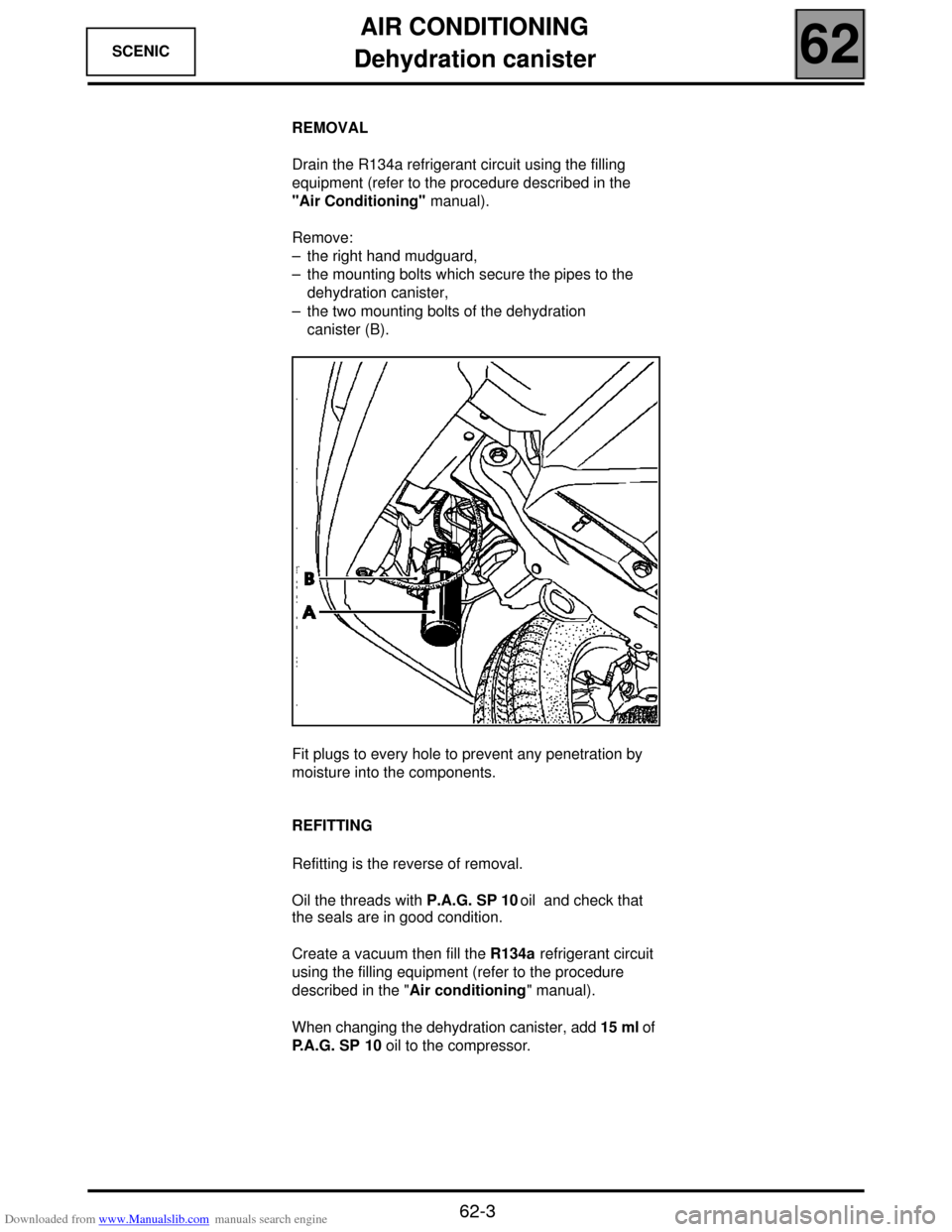

REMOVAL

Drain the R134a refrigerant circuit using the filling

equipment (refer to the procedure described in the

"Air Conditioning" manual).

Remove:

– the right hand mudguard,

– the mounting bolts which secure the pipes to the

dehydration canister,

– the two mounting bolts of the dehydration

canister (B).

Fit plugs to every hole to prevent any penetration by

moisture into the components.

REFITTING

Refitting is the reverse of removal.

Oil the threads with P.A.G. SP 10 oil and check that

the seals are in good condition.

Create a vacuum then fill the R134a refrigerant circuit

using the filling equipment (refer to the procedure

described in the "Air conditioning" manual).

When changing the dehydration canister, add 15 ml of

P.A.G. SP 10 oil to the compressor.

16763R

Page 117 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Connecting pipes

62

62-6

SCENIC Connecting pipes

Disconnect the battery.

Drain the R134a refrigerant circuit using the filling equipment (refer to the procedure described in the "Air

Conditioning" manual).

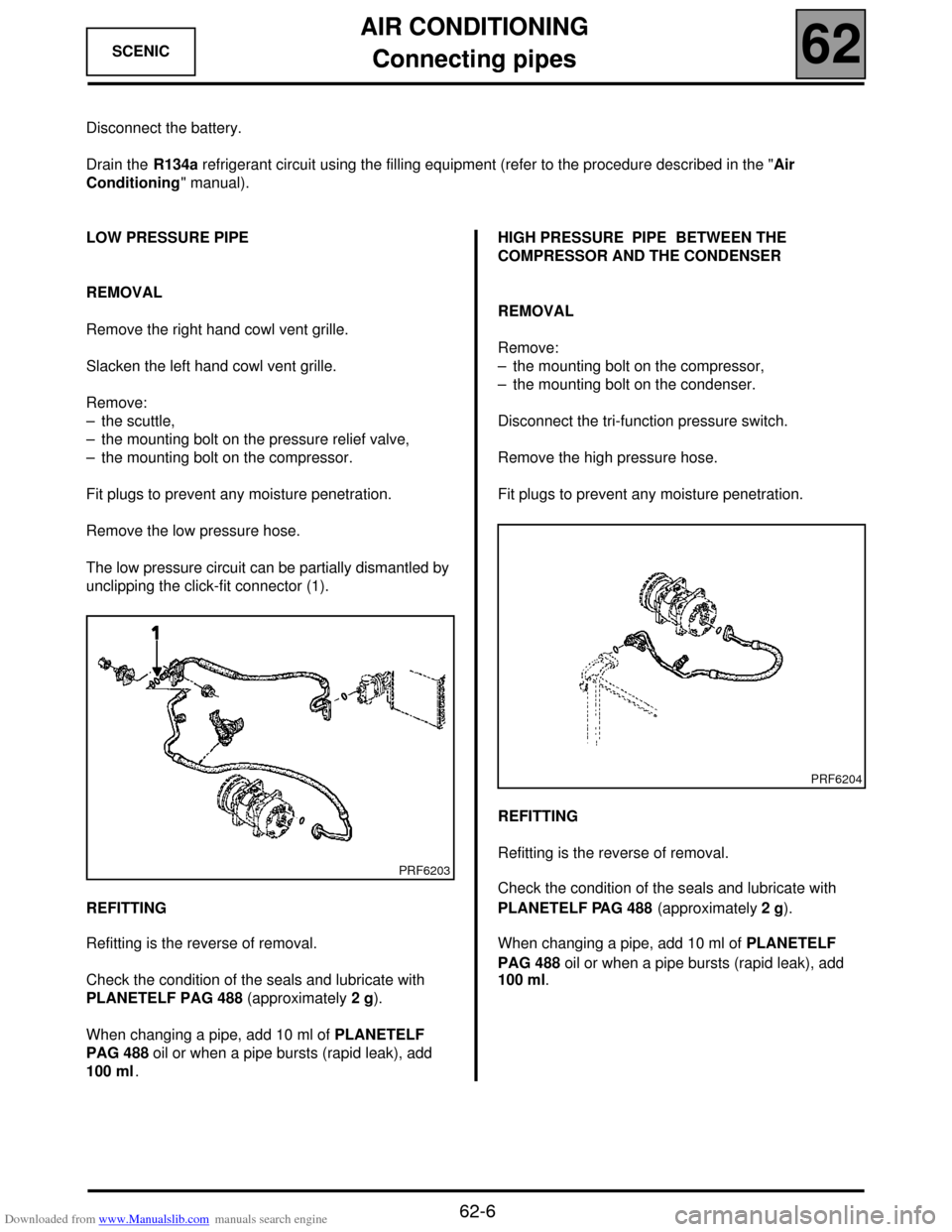

LOW PRESSURE PIPE

REMOVAL

Remove the right hand cowl vent grille.

Slacken the left hand cowl vent grille.

Remove:

– the scuttle,

– the mounting bolt on the pressure relief valve,

– the mounting bolt on the compressor.

Fit plugs to prevent any moisture penetration.

Remove the low pressure hose.

The low pressure circuit can be partially dismantled by

unclipping the click-fit connector (1).

REFITTING

Refitting is the reverse of removal.

Check the condition of the seals and lubricate with

PLANETELF PAG 488 (approximately 2 g).

When changing a pipe, add 10 ml of PLANETELF

PAG 488 oil or when a pipe bursts (rapid leak), add

100 ml.HIGH PRESSURE PIPE BETWEEN THE

COMPRESSOR AND THE CONDENSER

REMOVAL

Remove:

– the mounting bolt on the compressor,

– the mounting bolt on the condenser.

Disconnect the tri-function pressure switch.

Remove the high pressure hose.

Fit plugs to prevent any moisture penetration.

REFITTING

Refitting is the reverse of removal.

Check the condition of the seals and lubricate with

PLANETELF PAG 488 (approximately 2 g).

When changing a pipe, add 10 ml of PLANETELF

PAG 488 oil or when a pipe bursts (rapid leak), add

100 ml.

PRF6203

PRF6204

Page 118 of 118

Downloaded from www.Manualslib.com manuals search engine AIR CONDITIONING

Connecting pipes

62

62-7

SCENIC

Disconnect the battery.

Drain the R134a refrigerant circuit using the filling equipment (refer to the procedure described in the "Air

Conditioning" manual).

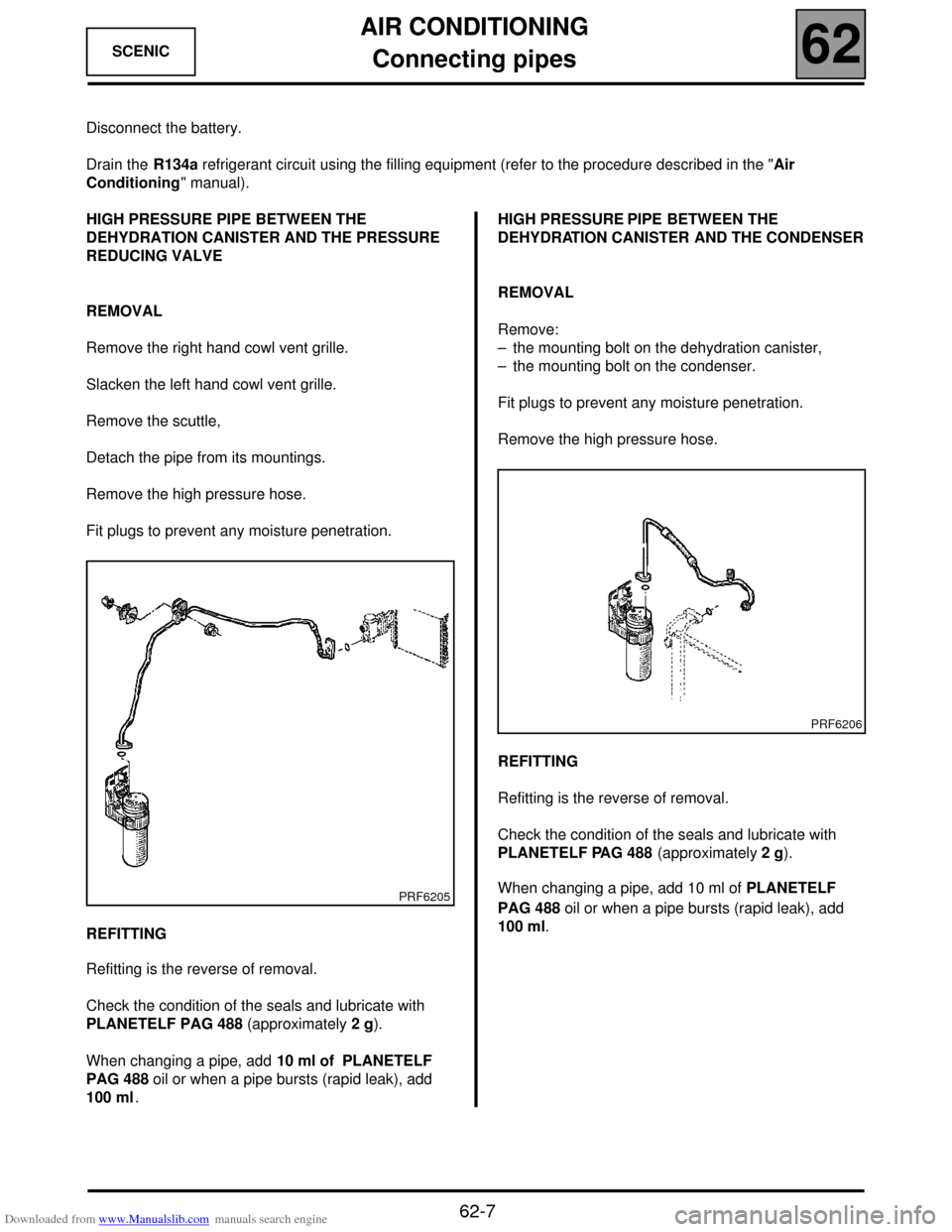

HIGH PRESSURE PIPE BETWEEN THE

DEHYDRATION CANISTER AND THE PRESSURE

REDUCING VALVE

REMOVAL

Remove the right hand cowl vent grille.

Slacken the left hand cowl vent grille.

Remove the scuttle,

Detach the pipe from its mountings.

Remove the high pressure hose.

Fit plugs to prevent any moisture penetration.

REFITTING

Refitting is the reverse of removal.

Check the condition of the seals and lubricate with

PLANETELF PAG 488 (approximately 2 g).

When changing a pipe, add 10 ml of PLANETELF

PAG 488 oil or when a pipe bursts (rapid leak), add

100 ml.HIGH PRESSURE PIPE BETWEEN THE

DEHYDRATION CANISTER AND THE CONDENSER

REMOVAL

Remove:

– the mounting bolt on the dehydration canister,

– the mounting bolt on the condenser.

Fit plugs to prevent any moisture penetration.

Remove the high pressure hose.

REFITTING

Refitting is the reverse of removal.

Check the condition of the seals and lubricate with

PLANETELF PAG 488 (approximately 2 g).

When changing a pipe, add 10 ml of PLANETELF

PAG 488 oil or when a pipe bursts (rapid leak), add

100 ml.

PRF6205

PRF6206