CD changer RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 2 of 118

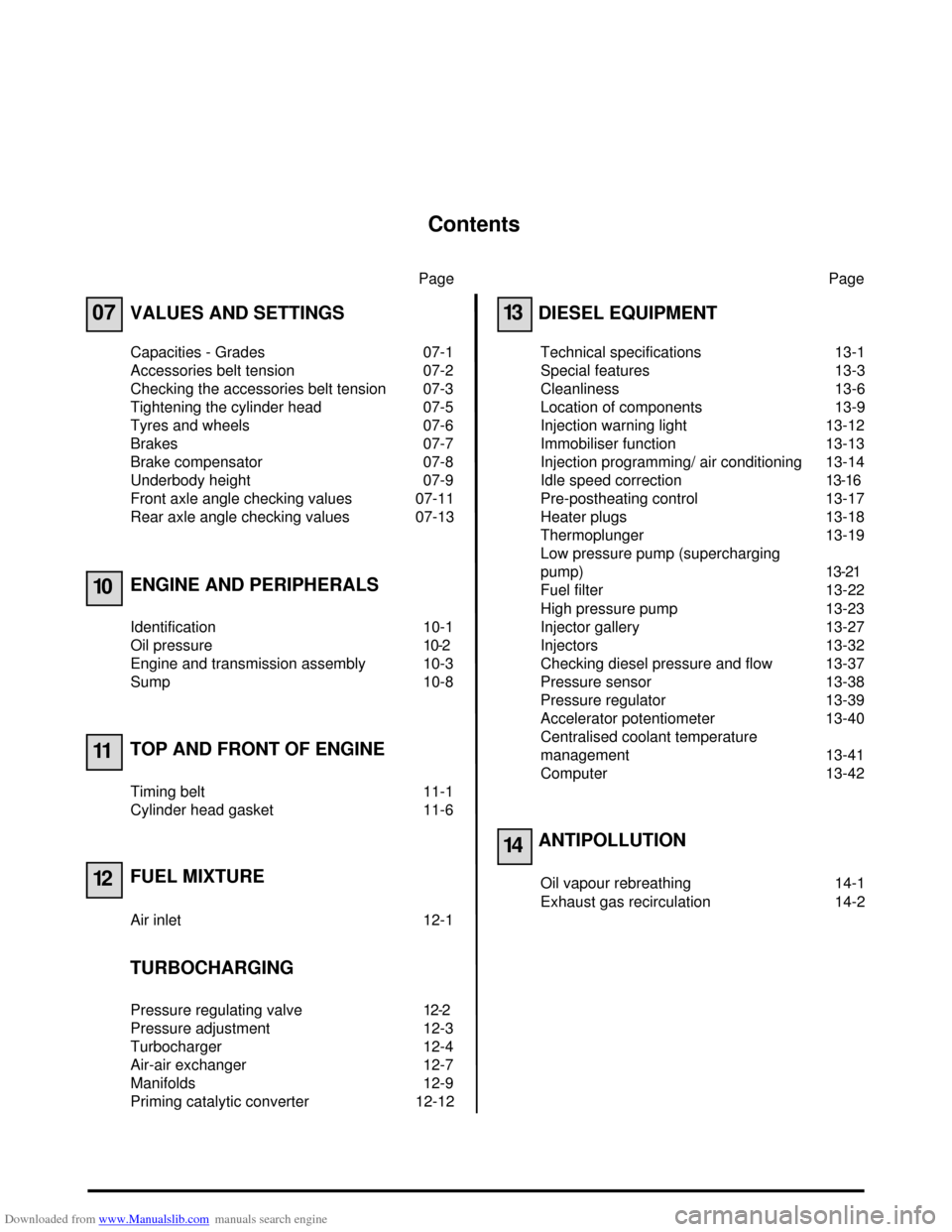

Downloaded from www.Manualslib.com manuals search engine Contents

Page

07

10

11

12

VALUES AND SETTINGS

Capacities - Grades 07-1

Accessories belt tension 07-2

Checking the accessories belt tension 07-3

Tightening the cylinder head 07-5

Tyres and wheels 07-6

Brakes 07-7

Brake compensator 07-8

Underbody height 07-9

Front axle angle checking values 07-11

Rear axle angle checking values 07-13

ENGINE AND PERIPHERALS

Identification 10-1

Oil pressure 10-2

Engine and transmission assembly 10-3

Sump 10-8

TOP AND FRONT OF ENGINE

Timing belt 11-1

Cylinder head gasket 11-6

FUEL MIXTURE

Air inlet 12-1

TURBOCHARGING

Pressure regulating valve 12-2

Pressure adjustment 12-3

Turbocharger 12-4

Air-air exchanger 12-7

Manifolds 12-9

Priming catalytic converter 12-12Page

13

14

DIESEL EQUIPMENT

Technical specifications 13-1

Special features 13-3

Cleanliness 13-6

Location of components 13-9

Injection warning light 13-12

Immobiliser function 13-13

Injection programming/ air conditioning 13-14

Idle speed correction13-16

Pre-postheating control 13-17

Heater plugs 13-18

Thermoplunger 13-19

Low pressure pump (supercharging

pump)13-21

Fuel filter 13-22

High pressure pump 13-23

Injector gallery 13-27

Injectors 13-32

Checking diesel pressure and flow 13-37

Pressure sensor 13-38

Pressure regulator 13-39

Accelerator potentiometer 13-40

Centralised coolant temperature

management 13-41

Computer 13-42

ANTIPOLLUTION

Oil vapour rebreathing 14-1

Exhaust gas recirculation 14-2

Page 21 of 118

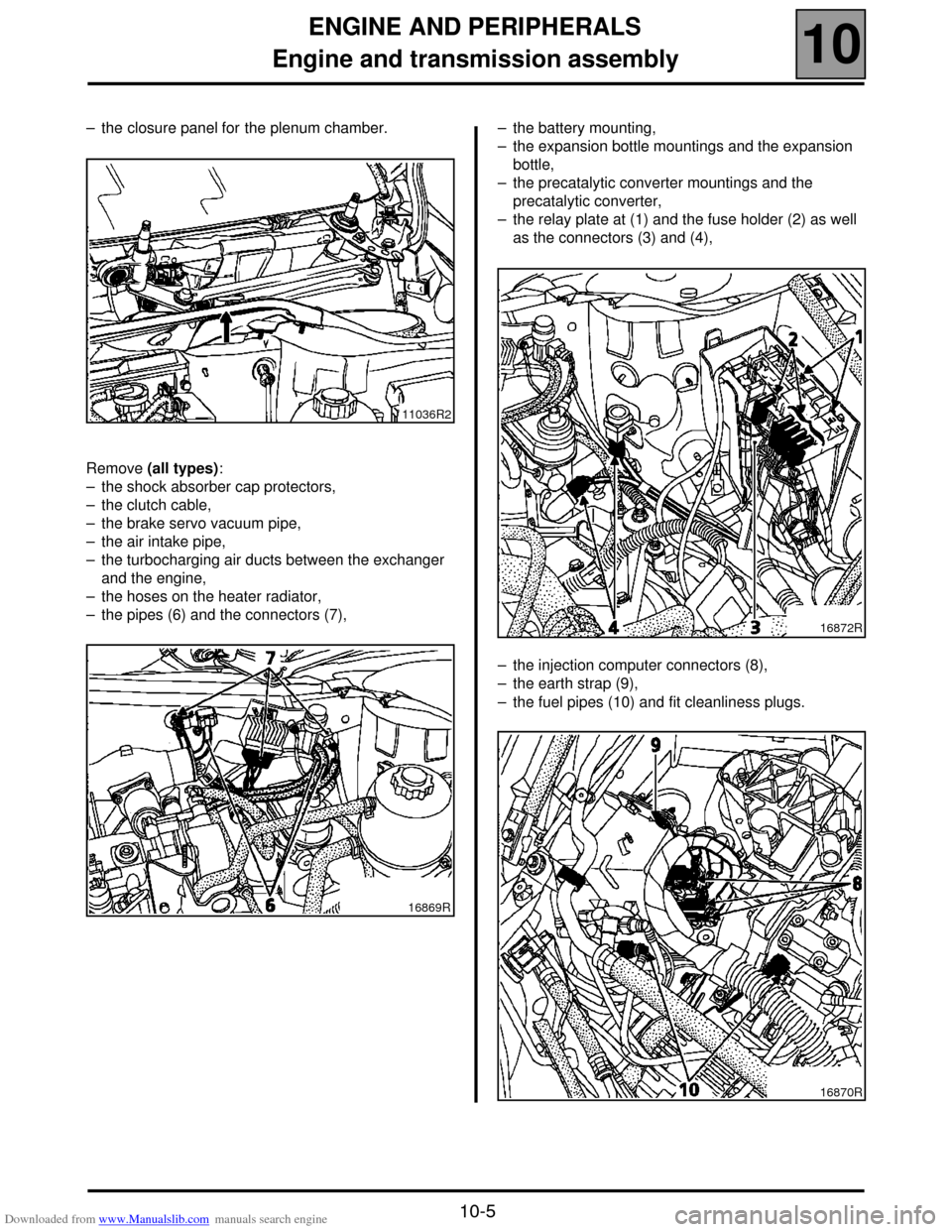

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-5

– the closure panel for the plenum chamber.

Remove (all types):

– the shock absorber cap protectors,

– the clutch cable,

– the brake servo vacuum pipe,

– the air intake pipe,

– the turbocharging air ducts between the exchanger

and the engine,

– the hoses on the heater radiator,

– the pipes (6) and the connectors (7),– the battery mounting,

– the expansion bottle mountings and the expansion

bottle,

– the precatalytic converter mountings and the

precatalytic converter,

– the relay plate at (1) and the fuse holder (2) as well

as the connectors (3) and (4),

– the injection computer connectors (8),

– the earth strap (9),

– the fuel pipes (10) and fit cleanliness plugs.

11036R2

16869R

16872R

16870R

Page 39 of 118

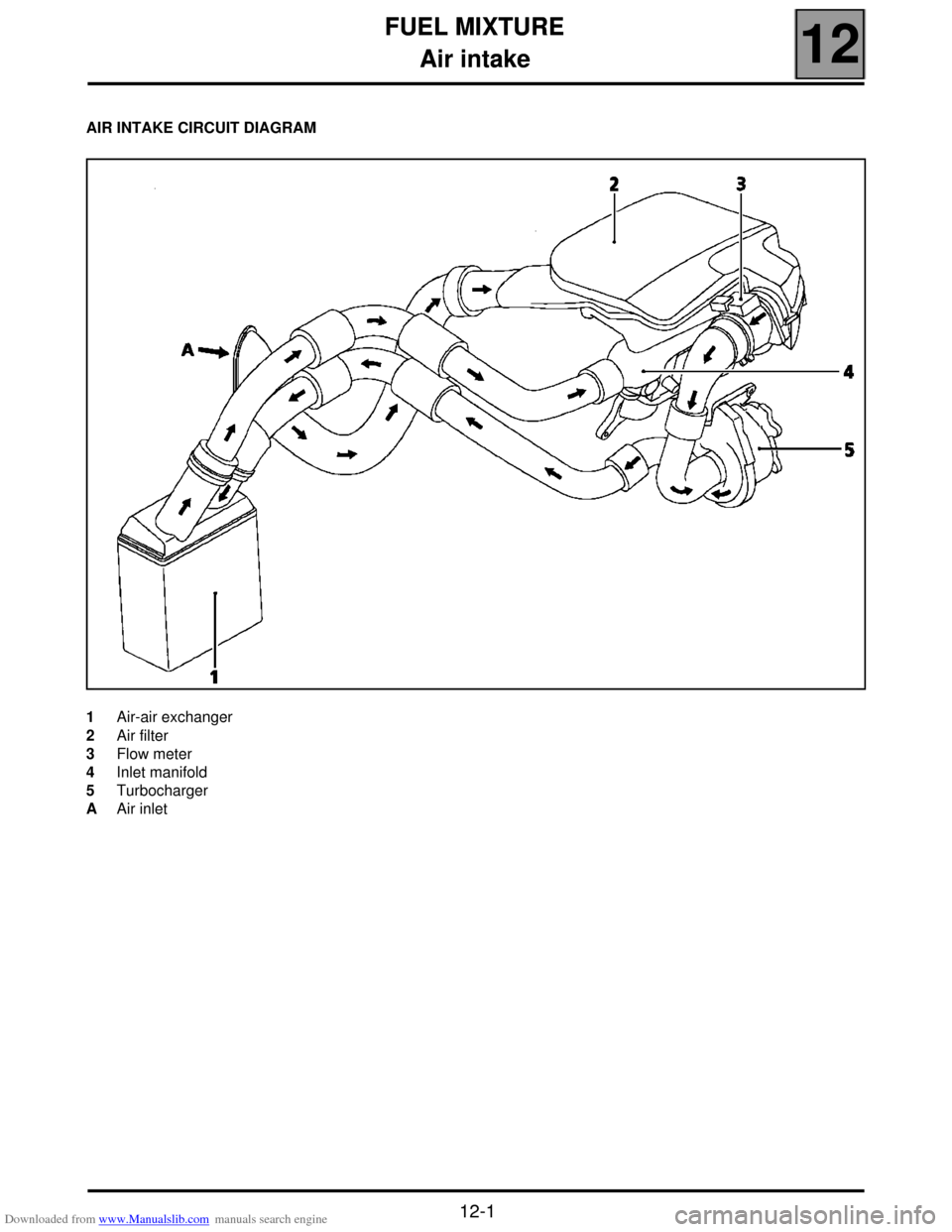

Downloaded from www.Manualslib.com manuals search engine FUEL MIXTURE

Air intake

12

112

FUEL MIXTURE

Air intake

AIR INTAKE CIRCUIT DIAGRAM

1 Air-air exchanger

2 Air filter

3 Flow meter

4 Inlet manifold

5 Turbocharger

A Air inlet

12-1

Page 44 of 118

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

12-6

REFITTING

For refitting operations, use the same procedure as for

removal in reverse.

IMPORTANT: you must change the copper gasket at

the turbo oil inlet connection.

IMPORTANT:

Before starting the engine disconnect the pressure

regulator manifold on the high pressure pump.

Then run the starter motor until the oil pressure

warning light goes out (wait a few seconds).

Reconnect the regulator, preheat and start the engine.

Run the engine at idling speed and check that there

are no leaks at the oil connections.

Erase the fault and check the turbocharging pressure

solenoid valve sensor.

16869S

Special precautions

!Before refitting, make sure that the lubrication is

correct for the turbocharger bearings. To do this

activate the starter motor having first

disconnected the high pressure manifold regulator

(do not start the engine) (erase the computer

memory). Sufficient oil should arrive via the oil

pressure pipes (place a container below). If this is

not the case, change the lubrication pipe.

!Ensure that no foreign bodies enter the turbine or

compressor during the refitting operation.

!If there has been a fault in the turbocharger, check

that the air-air exchanger is not full of oil.

If the air-air exchanger is full of oil, it must be

removed, flushed with a cleaning agent and then

left to drain properly.

!Check that the turbocharger oil return pipe is not

partially or completely blocked by scale. Check

also that it is perfectly tight. If not, replace it.

Page 45 of 118

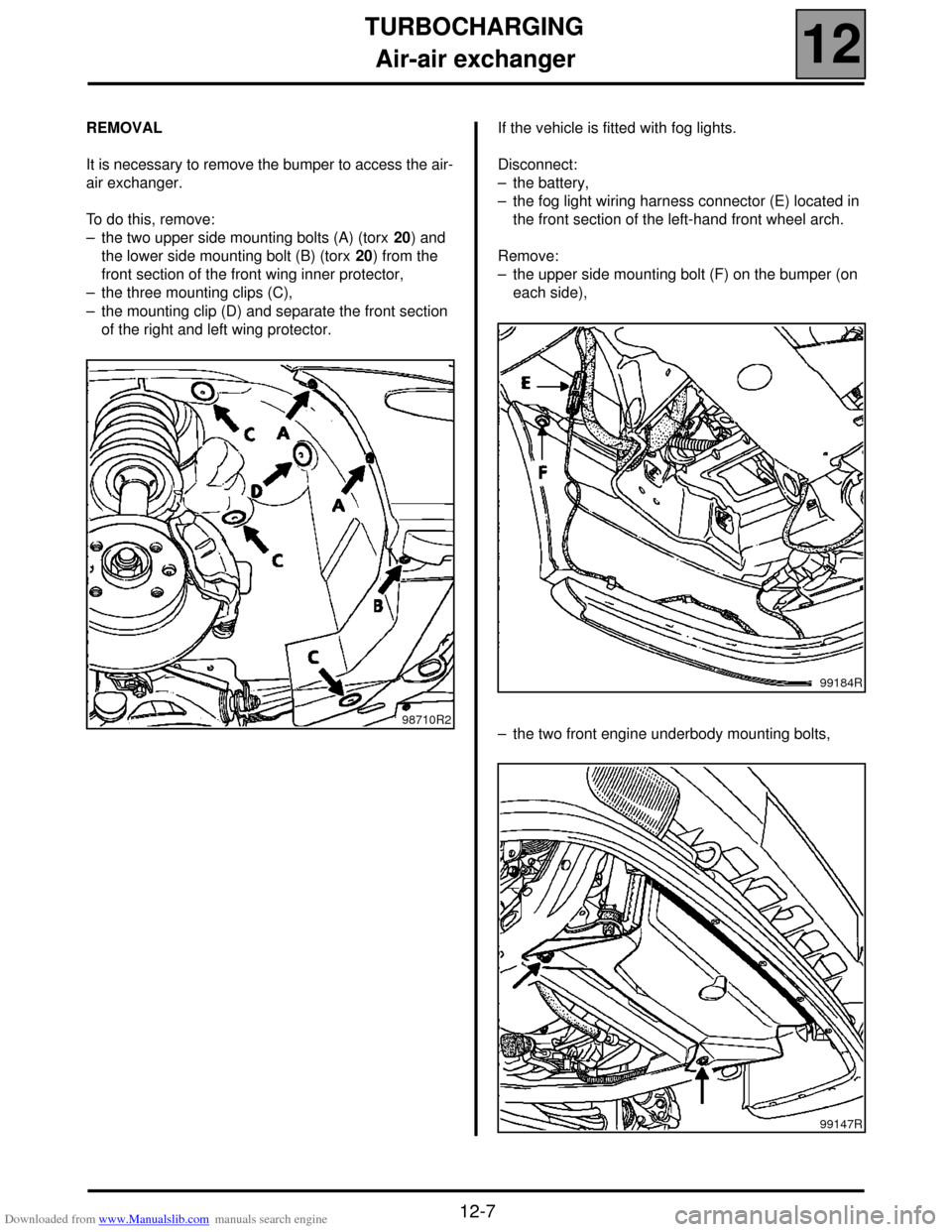

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Air-air exchanger

12

12-7

Air-air exchanger

REMOVAL

It is necessary to remove the bumper to access the air-

air exchanger.

To do this, remove:

– the two upper side mounting bolts (A) (torx 20) and

the lower side mounting bolt (B) (torx 20) from the

front section of the front wing inner protector,

– the three mounting clips (C),

– the mounting clip (D) and separate the front section

of the right and left wing protector.If the vehicle is fitted with fog lights.

Disconnect:

– the battery,

– the fog light wiring harness connector (E) located in

the front section of the left-hand front wheel arch.

Remove:

– the upper side mounting bolt (F) on the bumper (on

each side),

– the two front engine underbody mounting bolts,

98710R2

99184R

99147R

Page 46 of 118

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Air-air exchanger

12

12-8

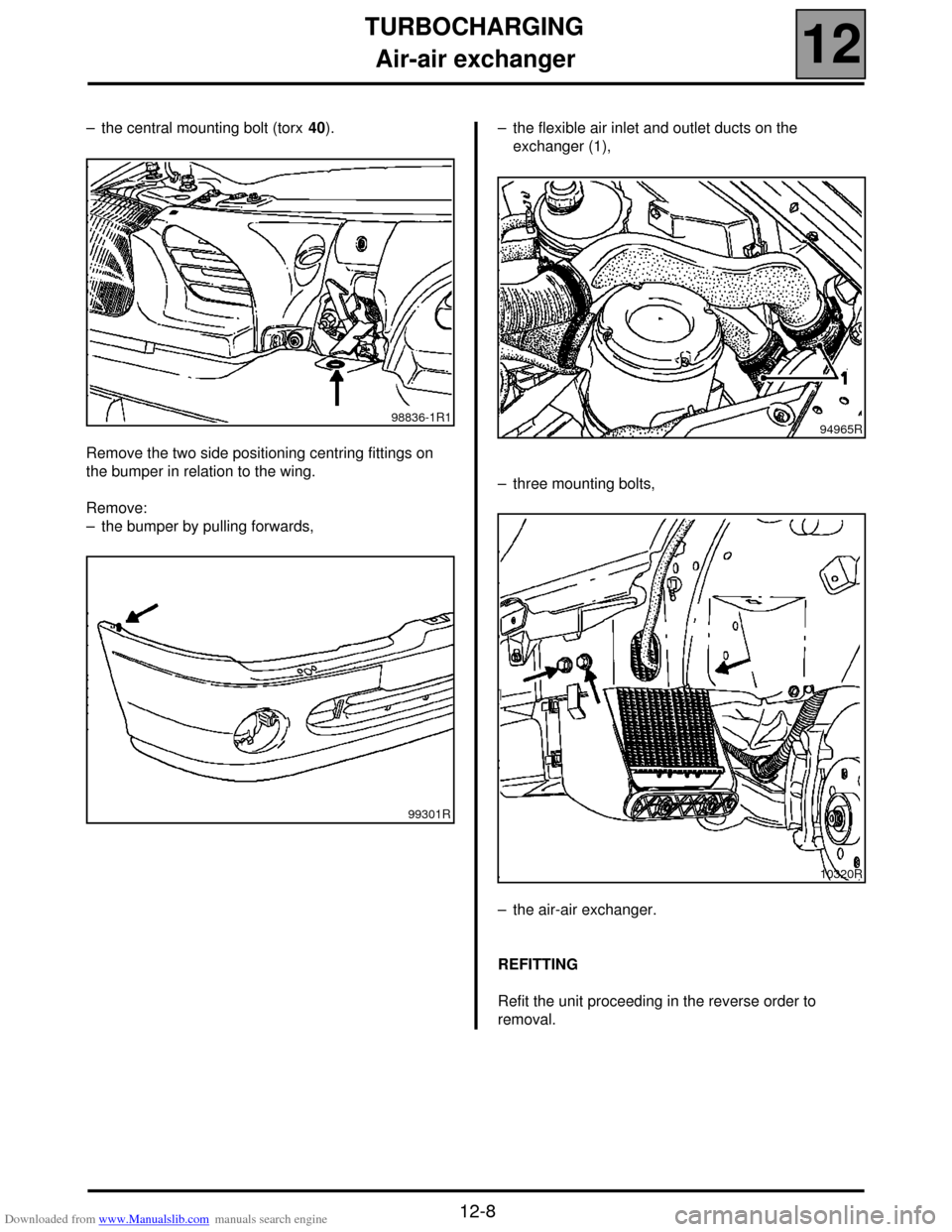

– the central mounting bolt (torx 40).

Remove the two side positioning centring fittings on

the bumper in relation to the wing.

Remove:

– the bumper by pulling forwards,– the flexible air inlet and outlet ducts on the

exchanger (1),

– three mounting bolts,

– the air-air exchanger.

REFITTING

Refit the unit proceeding in the reverse order to

removal.

98836-1R1

99301R94965R

10320R

Page 73 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Fuel filter

13

13-22

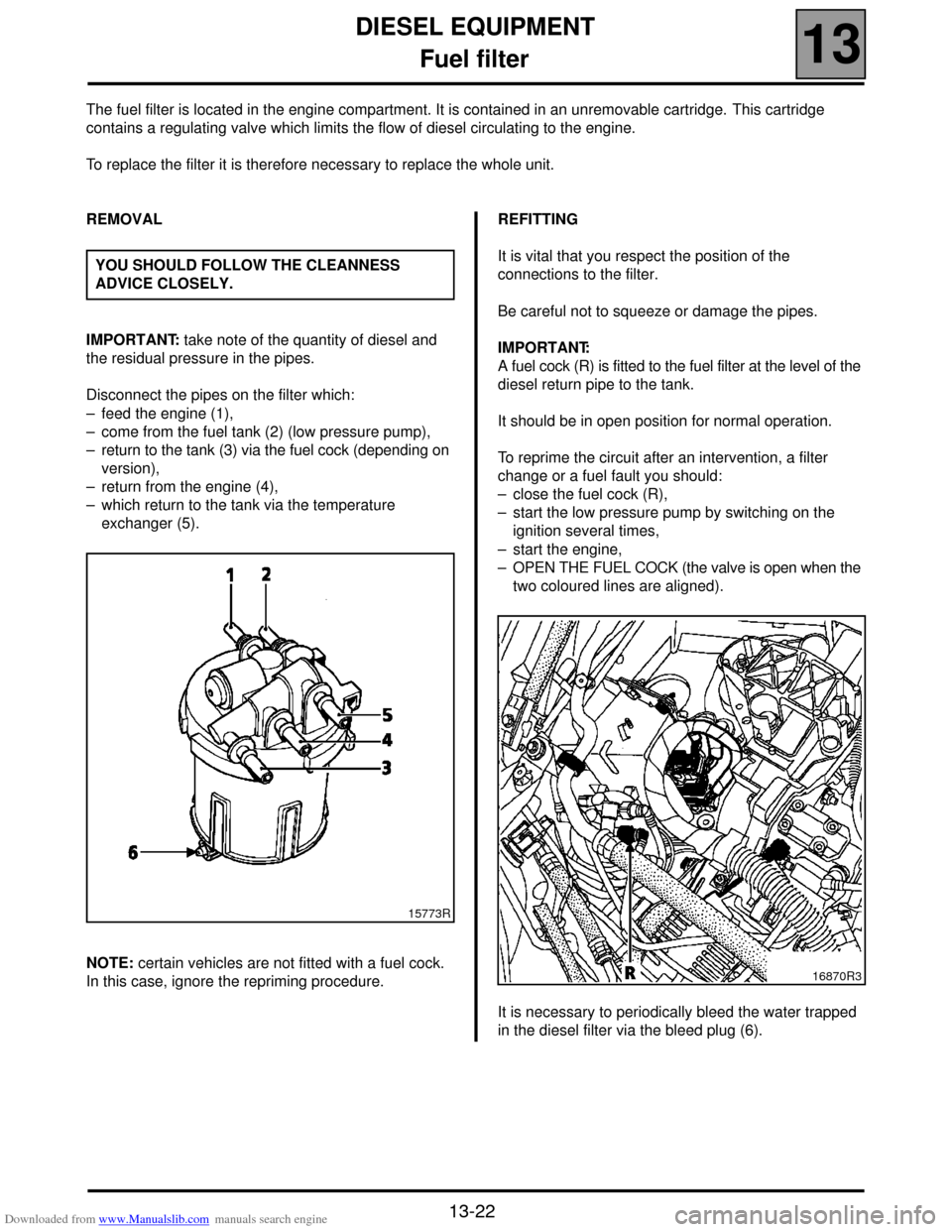

Fuel filter

The fuel filter is located in the engine compartment. It is contained in an unremovable cartridge. This cartridge

contains a regulating valve which limits the flow of diesel circulating to the engine.

To replace the filter it is therefore necessary to replace the whole unit.

REMOVAL

IMPORTANT: take note of the quantity of diesel and

the residual pressure in the pipes.

Disconnect the pipes on the filter which:

– feed the engine (1),

– come from the fuel tank (2) (low pressure pump),

– return to the tank (3) via the fuel cock (depending on

version),

– return from the engine (4),

– which return to the tank via the temperature

exchanger (5).

NOTE: certain vehicles are not fitted with a fuel cock.

In this case, ignore the repriming procedure.REFITTING

It is vital that you respect the position of the

connections to the filter.

Be careful not to squeeze or damage the pipes.

IMPORTANT:

A fuel cock (R) is fitted to the fuel filter at the level of the

diesel return pipe to the tank.

It should be in open position for normal operation.

To reprime the circuit after an intervention, a filter

change or a fuel fault you should:

– close the fuel cock (R),

– start the low pressure pump by switching on the

ignition several times,

– start the engine,

– OPEN THE FUEL COCK (the valve is open when the

two coloured lines are aligned).

It is necessary to periodically bleed the water trapped

in the diesel filter via the bleed plug (6). YOU SHOULD FOLLOW THE CLEANNESS

ADVICE CLOSELY.

15773R

16870R3

Page 102 of 118

Downloaded from www.Manualslib.com manuals search engine STARTING - CHARGING

Starter

16

16-5

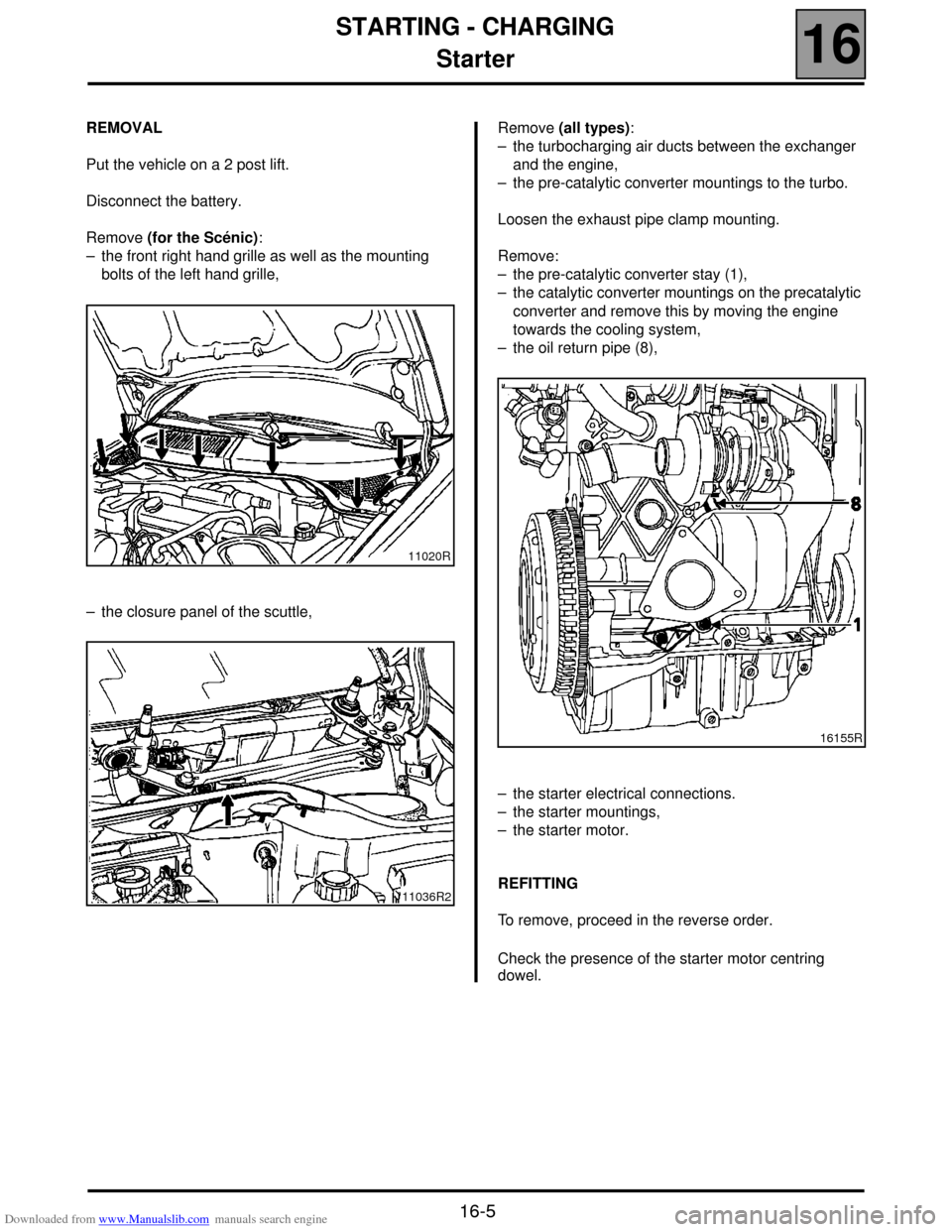

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Remove (for the Scénic):

– the front right hand grille as well as the mounting

bolts of the left hand grille,

– the closure panel of the scuttle,Remove (all types):

– the turbocharging air ducts between the exchanger

and the engine,

– the pre-catalytic converter mountings to the turbo.

Loosen the exhaust pipe clamp mounting.

Remove:

– the pre-catalytic converter stay (1),

– the catalytic converter mountings on the precatalytic

converter and remove this by moving the engine

towards the cooling system,

– the oil return pipe (8),

– the starter electrical connections.

– the starter mountings,

– the starter motor.

REFITTING

To remove, proceed in the reverse order.

Check the presence of the starter motor centring

dowel.

11020R

11036R2

16155R

Page 104 of 118

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Diagram

19

19-2

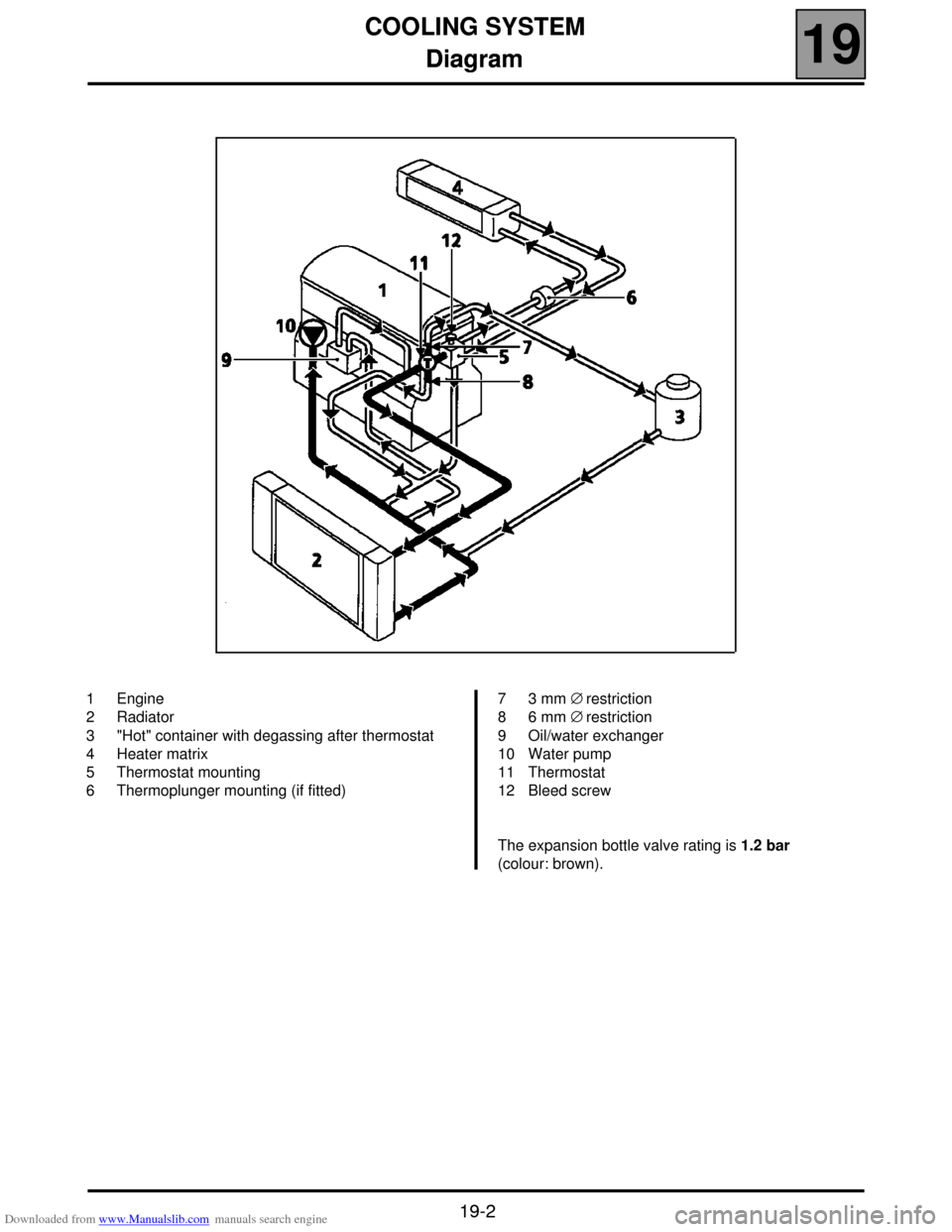

Diagram

1 Engine

2 Radiator

3 "Hot" container with degassing after thermostat

4 Heater matrix

5 Thermostat mounting

6 Thermoplunger mounting (if fitted)7 3 mm ∅ restriction

8 6 mm ∅ restriction

9 Oil/water exchanger

10 Water pump

11 Thermostat

12 Bleed screw

The expansion bottle valve rating is 1.2 bar

(colour: brown).

Page 106 of 118

Downloaded from www.Manualslib.com manuals search engine COOLING SYSTEM

Radiator

19

19-4

Radiator

REMOVAL

Put the vehicle on a two post lift.

Disconnect the battery.

Remove the engine undertray.

Drain the cooling circuit through the lower radiator

hose.

Disconnect the wiring of the fan unit.

Unclip the power steering reservoir and remove it.

Remove:

– the upper cross member,

– the upper radiator mountings,

– the upper hoses on the radiator,

– the inlet manifold-air exchanger duct,

– the fan unit mountings on the radiator and remove

the fan,

– the radiator mountings on the condenser and remove

the radiator.REFITTING

Refitting is the reverse of removal.

Fill and bleed the cooling circuit (see section 19

"Filling and bleeding").

NOTE: ensure that the fins of the radiator or of the

condenser (if fitted) are not damaged when

removing-refitting, and protect them if necessary. SPECIAL TOOLING REQUIRED

Mot. 1202 -01

Hose clip pliers

Mot. 1202 -02

Mot. 1448 Long nose pliers for hose clips