ESP RENAULT SCENIC 2006 J84 / 2.G Tyre Pressure Monitoring Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2006, Model line: SCENIC, Model: RENAULT SCENIC 2006 J84 / 2.GPages: 37, PDF Size: 0.15 MB

Page 2 of 37

TYRE PRESSURE MONITOR

ABBREVIATIONS

35B

35B-1

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

135BTYRE PRESSURE MONITOR

ABBREVIATIONS

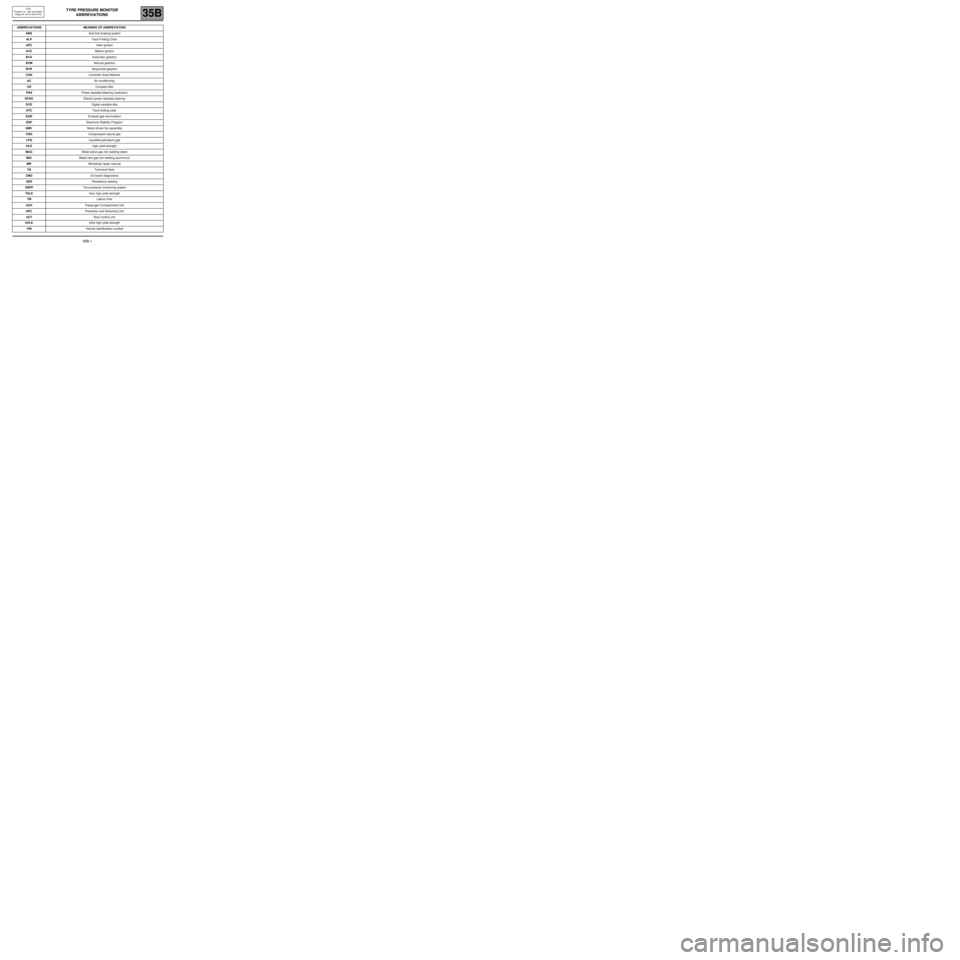

ABBREVIATIONS MEANING OF ABBREVIATION

ABSAnti-lock braking system

ALPFault Finding Chart

APCAfter ignition

AVCBefore ignition

BVAAutomatic gearbox

BVMManual gearbox

BVRSequential gearbox

CANController Area Network

ACAir conditioning

CDCompact disc

PASPower assisted steering (hydraulic)

EPASElectric power assisted steering

DVDDigital versatile disc

DTCFault finding code

EGRExhaust gas recirculation

ESPElectronic Stability Program

GMVMotor-driven fan assembly

CNGCompressed natural gas

LPGLiquefied petroleum gas

HLEHigh yield strength

MAGMetal active gas (for welding steel)

MIGMetal inert gas (for welding aluminium)

MRWorkshop repair manual

TNTechnical Note

OBDOn board diagnostics

SERResistance welding

SSPPTyre pressure monitoring system

THLEVery high yield strength

TMLabour time

UCHPassenger Compartment Unit

UPCProtection and Switching Unit

UCTRoof control unit

UHLEUltra high yield strength

VINVehicle identification number

Page 4 of 37

TYRE PRESSURE MONITOR

Fault finding - Introduction

35B

35B-3

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

To cut off + after ignition, proceed as follows:

–Disconnect the diagnostic tool.

–Press the Start button twice briefly (less than 3 seconds),

–See that the + after ignition feed has been cut off by checking that the computer warning lights on the

instrument panel have gone out.

Faults

The current status of faults must be considered when the diagnostic tool is used following switching to + after

ignition (with no action on the system components).

For a present fault, handle the fault according to the procedure listed in the section on Interpretation of faults in

Workshop Repair Manual 372 Section 87B Passenger compartment connection unit.

There is no stored fault on the tyre pressure monitor.

Conformity check

The aim of the conformity check is to check statuses and parameters that do not produce a fault display on the

diagnostic tool when they are inconsistent. Therefore, this stage is used to:

–carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint.

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section features the fault finding procedure for statuses and parameters, and the conditions for checking them.

If a status is not operating normally or a parameter is outside permitted tolerance values, you should consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the check using the diagnostic tool is satisfactory but the customer complaint is still present, the fault should be

treated as a customer complaint.

A summary of the overall procedure to follow is provided on the following page

in the form of a flow chart.

Edition 4

Page 5 of 37

TYRE PRESSURE MONITOR

Fault finding - Introduction

35B

35B-4

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

4. FAULT FINDING PROCEDURE

Procedure to be carried out before entering fault finding mode with the tool:

–Are the faulty wheels equipped with tyre pressure monitor wheel sensors, or were they so at the time of

the fault?

–Check the position of the wheels on the vehicle (wheel sensor colour code). Put the wheels back in

position and program the codes of the four wheel sensors if the wheels are not in their original position.

–Check the wheel pressures with a pressure gauge. Do they correspond to the pressures noted inside

the door or in the driver's handbook for that size of tyres?

A summary of the overall procedure to follow is provided on the following page

in the form of a flow chart.

Edition 4

Page 9 of 37

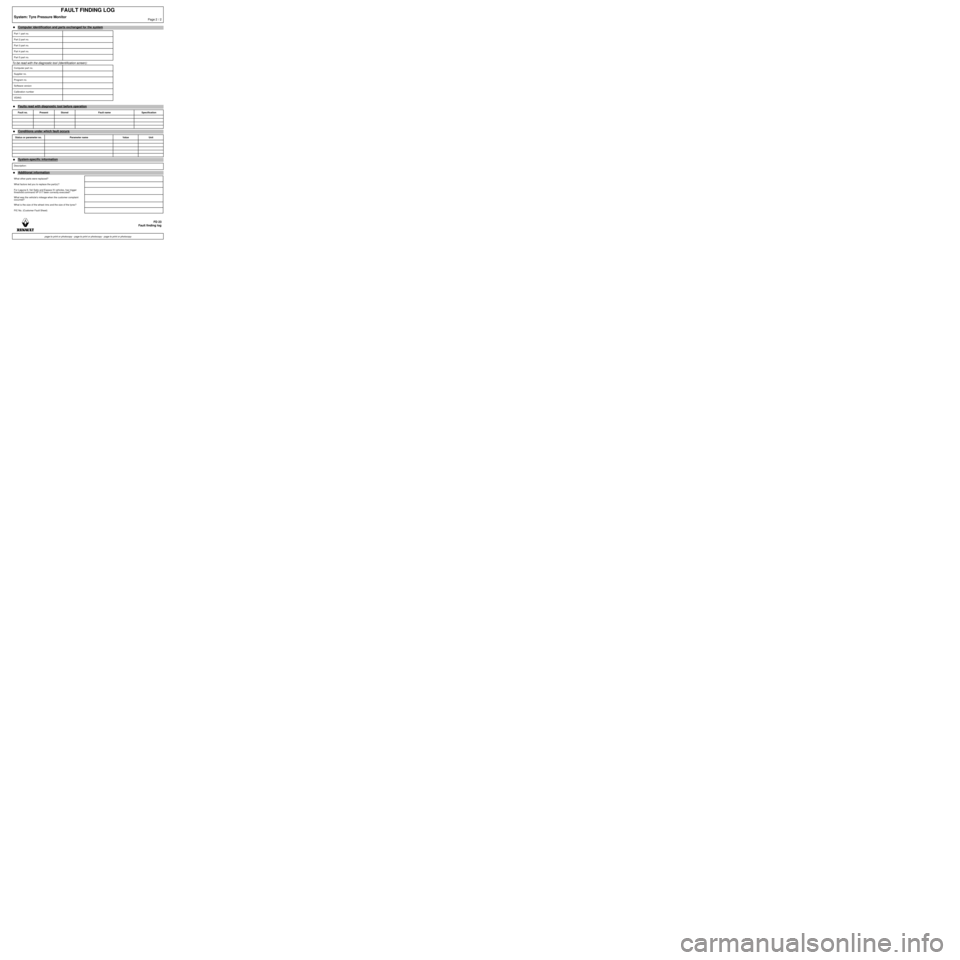

To be read with the diagnostic tool (Identification screen):

FAULT FINDING LOG

System: Tyre Pressure MonitorPage 2 / 2

●Computer identification and parts exchanged for the system

Part 1 part no.

Part 2 part no.

Part 3 part no.

Part 4 part no.

Part 5 part no.

Computer part no.

Supplier no.

Program no.

Software version

Calibration number

VDIAG

●

Faults read with diagnostic tool before operation

Fault no. Present Stored Fault name Specification

●

Conditions under which fault occurs

Status or parameter no. Parameter name Value Unit

●

System-specific information

Description:

●

Additional information

What other parts were replaced?

What factors led you to replace the part(s)?

For Laguna II, Vel Satis and Espace IV vehicles, has trigger

threshold command VP 017 been correctly executed?

What was the vehicle's mileage when the customer complaint

occurred?

What is the size of the wheel rims and the size of the tyres?

FIC No. (Customer Fault Sheet)

FD 23

Fault finding log

page to print or photocopy - page to print or photocopy - page to print or photocopy

Page 11 of 37

TYRE PRESSURE MONITOR

Fault finding - System operation

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

System operation:

–The valves are activated after driving at a speed greater than 12 mph (20 km/h).

–During driving, the valves emit signals every minute.

–The valves remain active for 15 minutes after the vehicle stops, then switch to standby mode.

–In standby mode, the valves emit signals only if they detect a pressure difference between two successive

measurements greater than 68 mbar or if the pressure difference since last emitting is greater than 68 mbar (due

to tyre cooling).

–The tyres are considered to be cold when the vehicle speed has been zero for 1h 45 min.

–The minimum time for detection of a leak is approximately 15 minutes.

–The message Pressure unsuitable for the speed is activated only if the vehicle travels at more than 102 mph

(170 km/h) (as an indication) for 3 minutes and the pressure on at least one of the tyres is 400 mbar less than the

recommended pressure at low speed. This message is inactive if the tyres are inflated to motorway pressure,

irrespective of the vehicle speed.

–Alert thresholds:

–over-inflated while cold =recommended pressure + 700 mbar

–over-inflated while warm = recommended pressure + 850 mbar

–under-inflated = recommended pressure - 400 mbar

–very under-inflated = recommended pressure - 600 mbar

–imbalance = difference in pressure between the left-hand and right-hand wheels on the same axle greater

than 500 mbar

–Tyre pressure monitor information messages for the driver:

–"PUNCTURE: CHANGE TYRE" + STOP warning light + highlighting of the wheel concerned on the

instrument panel display + buzzer.

–"ADJUST TYRE PRESSURE" + highlighting of the wheel concerned on the instrument panel.

–"INFLATE TYRES MOTORWAY" + highlighting of all four wheels on the instrument panel.

–"TYRE SENSOR INOPERATIVE" + clearing of the wheel concerned.

–"ELECTRONIC FAULT" + "Service" warning light + the wheels concerned disappear from the

instrument panel.

–Tyre pressure monitor information messages for a puncture with the PAX System:

–"PUNCTURE: REPAIR TYRE" + highlighting of the wheel concerned on the instrument panel.

–"PUNCTURE: SLOW DOWN" + buzzer (if vehicle speed > 48 mph (80 km/h)).

–"DRIVING WITH FLAT: X MILES REMAINING" (X decreases from 120 miles (200 km) to 0) + STOP

warning light when X = 0 + highlighting of the wheel concerned on the instrument panel.

⇒

No instrument panel display of tyre pressure on the SCENIC II.

Edition 435B-10

Page 17 of 37

TYRE PRESSURE MONITOR

Fault finding - Configurations and programming

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

CF023:

TYRE PRESSURE MONITOR FUNCTION

(in programming command SC008 UCH type)

WRITING THE CONFIGURATION WITH OR WITHOUT TYRE PRESSURE MONITOR:

–Select the repair mode menu.

–Select the Programming menu

Select line SC008 UCH type, then the line CF023 Tyre Pressure Monitor function then with or without

Confirm the selection.

Check that the configuration has been stored correctly.

IMPORTANT

CONFIGURATION INCONSISTENCY BETWEEN THE INSTRUMENT PANEL AND UCH

1

st case: If the instrument panel detects the tyre pressure monitor system programmed in the UCH but

not in its own configuration. The message ELECTRONIC FAULT appears, the four wheels

disappear on the instrument panel display, and the Service warning light comes on.

2

nd case: The instrument panel detects that the Tyre pressure monitor is programmed in its own

configuration but the UCH fails to respond to any requests from the instrument panel (not

configured in UCH). The message TYRE SENSOR INOPERATIVE will appear, the four wheels

will disappear from the instrument panel display and the Service warning light will come on.

Edition 435B-16

Page 24 of 37

TYRE PRESSURE MONITOR

Fault finding - Interpretation of statuses

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50TYRE PRESSURE MONITOR

Fault finding - Interpretation of statuses

ET032

ET033

ET034

ET035FRONT LEFT-HAND WHEEL VALVE SIGNAL

FRONT RIGHT-HAND WHEEL VALVE SIGNAL

REAR RIGHT-HAND WHEEL VALVE SIGNAL

REAR LEFT-HAND WHEEL VALVE SIGNAL

NOTESBefore carrying out any operation, apply the fault finding procedure (see Introduction).

Special notes: If a tyre pressure sensor is present in the wheel, precautions must

be taken when removing/refitting tyres. Failure to take the precautions specified

in Section 35 of the Workshop Repair Manual could result in the sensor being

damaged, and potential operating faults in the tyre pressure monitor.

OK:

Absent:

Over-inflated:

Punctured:

Under-inflated: The sensor is operating correctly and the pressure is correct.

The sensor does not transmit or is not present on the vehicle.

The sensor sends a "tyre over-inflated" signal.

The sensor sends a "tyre very under-inflated" signal (recommended pressure 0.6 bar) or a

rapid pressure loss signal.

The sensor sends a "tyre under-inflated" signal.

Make sure the signal sent by the sensor corresponds to the pressure measured with the pressure gauge.

If it does not, inflate or deflate the tyres and check that they change status.

IMPORTANT

Wait 90 seconds before checking the change of status.

Original status = over-inflated

Original status = punctured or under-

inflatedDeflate

InflateFinal status = OK or punctured or under-

inflated

Final status = OK or over-inflated

If the status still displays an incorrect signal as compared to the tyre inflation level, refer to the fault finding chart.

–If the original status is: over-inflated or under-inflated

See ALP 2 and 3 Pressure adjustment.

–If the original status is: Punctured

See ALP 7 Puncture: change the tyre.

–If the original status is: Absent

See ALP 4, 5 and 6 Sensor out of order.

–If the status does not change, replace the sensor on the wheel concerned by following the instructions and

programming procedure for the four valve codes, SC002 Program four valve codes (see Configuration and

programming).

AFTER REPAIRDeal with any other possible faults.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

SSPP_V48_ET032/SSPP_V4C_ET032 /SSPP_V4D_ET032/SSPP_V4F_ET032 /SSPP_V50_ET032/

SSPP_V48_ET033/SSPP_V4C_ET033 /SSPP_V4D_ET033/SSPP_V4F_ET033 /SSPP_V50_ET033/

SSPP_V48_ET034/SSPP_V4C_ET034 /SSPP_V4D_ET034/SSPP_V4F_ET034 /SSPP_V50_ET034/

SSPP_V48_ET035/SSPP_V4C_ET035 /SSPP_V4D_ET035/SSPP_V4F_ET035 /SSPP_V50_ET035

Edition 4

35B-23

Page 25 of 37

TYRE PRESSURE MONITOR

Fault finding - Interpretation of statuses

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

ET036

TYRE PRESSURE IMBALANCE

NOTESBefore carrying out any operation, apply the fault finding procedure (see Introduction).

None

Note:

The threshold of imbalance between the left-hand and right-hand wheels on the same axle is 500 mbar.

Check, using a pressure gauge, that the inflation pressure of the tyres fitted on the vehicle indeed corresponds

to the pressures noted on the door, in the Driver’s Handbook or in MR 370, 35A, and if not readjust the

pressures. Ensure the correct balance of the pressures or axle(s) concerned.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other possible faults.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

SSPP_V48_ET036/SSPP_V4C_ET036 /SSPP_V4D_ET036/SSPP_V4F_ET036 /SSPP_V50_ET036

Edition 4

35B-24

Page 26 of 37

TYRE PRESSURE MONITOR

Fault finding - Interpretation of statuses

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

ET037

TYRE PRESSURE APPROPRIATE FOR SPEED

NOTESBefore carrying out any operation, apply the fault finding procedure (see 35B

Introduction).

NO: If the vehicle speed is above 102 mph (170 km/h) (as an indication) for more than

3 minutes and the pressure on at least one of the tyres is 400 mbar or more below

"motorway" pressure.

YES: if the vehicle speed is below 102 mph (170 km/h) (as an indication) or if the

pressure of the four tyres corresponds to the pressure of parameters PR011 and

PR012 High speed recommended pressure, whatever the speed.

Make sure that the tyre pressures are at the recommended "motorway" pressure (see MR 370, 35A or Driver's

Handbook), and reinflate the tyres if necessary.

Check that the pressures entered (PR009 to PR012) match the manufacturer's specifications.

If the pressures entered do not correspond to the manufacturer's values, write the recommended pressures

using procedure VP005 "Write recommended pressures (see Configuration and programming.

If status ET037 remains NO, contact the Techline.

AFTER REPAIRDeal with any other possible faults.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

SSPP_V48_ET037/SSPP_V4C_ET037 /SSPP_V4D_ET037/SSPP_V4F_ET037 /SSPP_V50_ET037

Edition 4

35B-25

Page 37 of 37

TYRE PRESSURE MONITOR

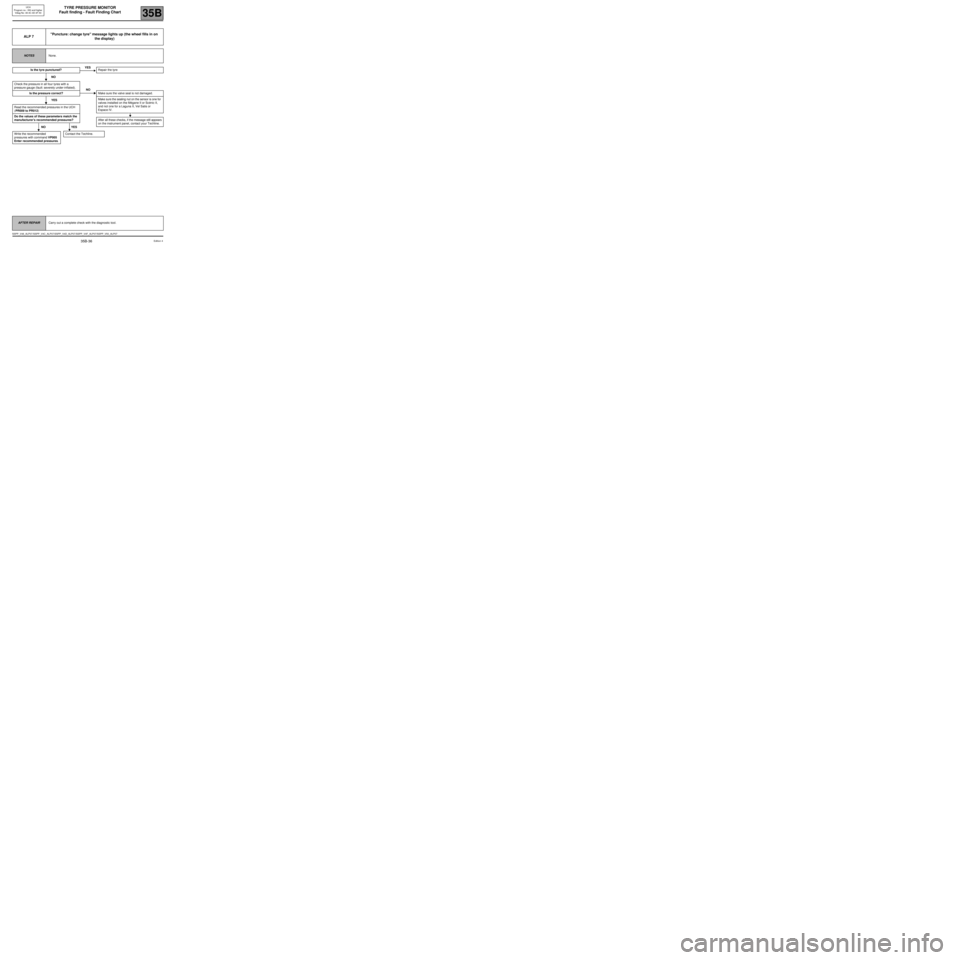

Fault finding - Fault Finding Chart

35B

ALP 7"Puncture: change tyre" message lights up (the wheel fills in on

the display)

NOTESNone.

Is the tyre punctured?

NO

Check the pressure in all four tyres with a

pressure gauge (fault: severely under-inflated).

NO

Is the pressure correct?

YES

Read the recommended pressures in the UCH

(PR009 to PR012)

Do the values of these parameters match the

manufacturer's recommended pressures?

NO YES

Write the recommended

pressures with command VP005

Enter recommended pressures.

Contact the Techline.

YES

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

Repair the tyre

Make sure the valve seal is not damaged.

Make sure the sealing nut on the sensor is one for

valves installed on the Mégane II or Scénic II,

and not one for a Laguna II, Vel Satis or

Espace IV.

After all these checks, if the message still appears

on the instrument panel, contact your Techline.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

35B-36

SSPP_V48_ALP07 /SSPP_V4C_ALP07/SSPP_V4D_ALP07/SSPP_V4F_ALP07/SSPP_V50_ALP07

Edition 4