air condition RENAULT SCENIC 2007 J84 / 2.G Automatic Transmission Siemens TA2005 Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2007, Model line: SCENIC, Model: RENAULT SCENIC 2007 J84 / 2.GPages: 139, PDF Size: 0.43 MB

Page 130 of 139

AUTOMATIC TRANSMISSION

Fault finding - Fault Finding Chart23A

23A -130V5 MR-372-J84-23A100$928.mif

SIEMENS TA2005

Vdiag No.: 14-18

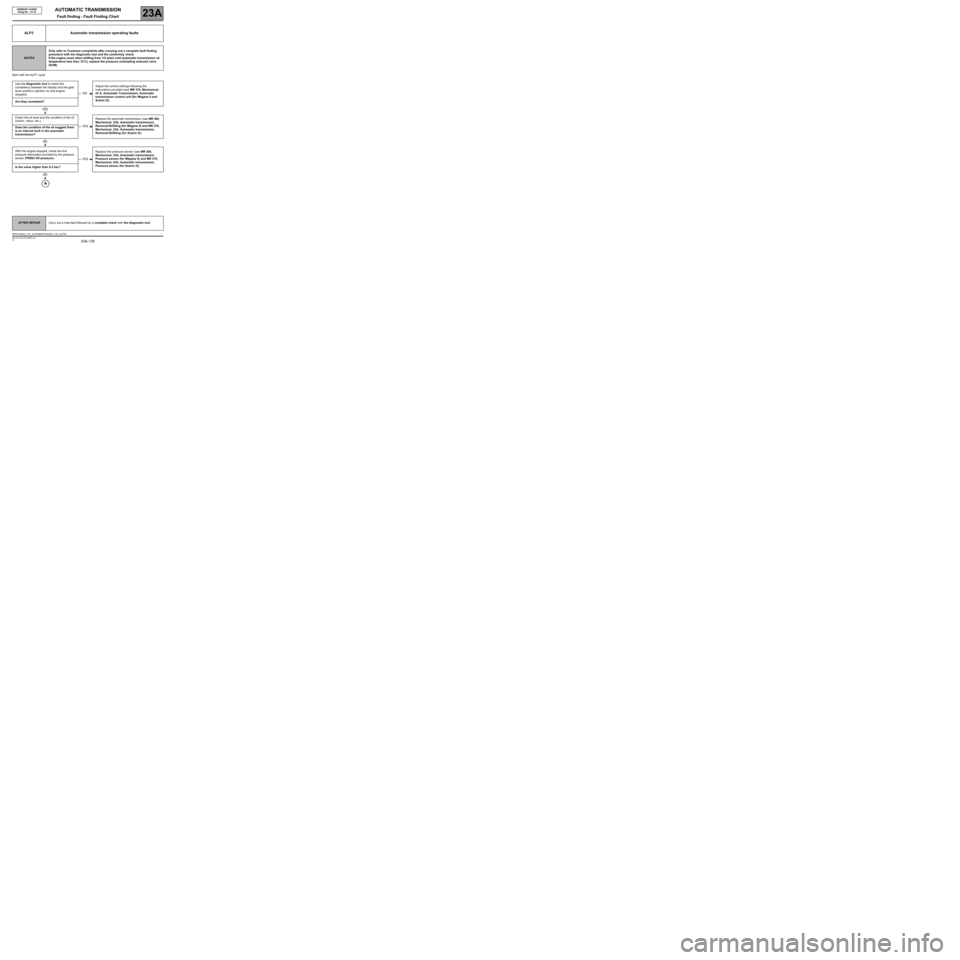

Start with the ALP1 cycle

ALP3 Automatic transmission operating faults

NOTESOnly refer to Customer complaints after carrying out a complete fault finding

procedure with the diagnostic tool and the conformity check.

If the engine races when shifting from 1/2 when cold (automatic transmission oil

temperature less than 15˚C), replace the pressure modulating solenoid valve

(EVM).

Use the diagnostic tool to check the

consistency between the display and the gear

lever positions (ignition on and engine

stopped).Adjust the control settings following the

instructions provided (see MR 370, Mechanical,

23 A, Automatic Transmission, Automatic

transmission control unit (for Mégane II and

Scénic II)).

Are they consistent?

Check the oil level and the condition of the oil

(colour, odour, etc.).Replace the automatic transmission (see MR 364,

Mechanical, 23A, Automatic transmission,

Removal-Refitting (for Mégane II) and MR 370,

Mechanical, 23A, Automatic transmission,

Removal-Refitting (for Scénic II)). Does the condition of the oil suggest there

is an internal fault in the automatic

transmission?

With the engine stopped, check the line

pressure information provided by the pressure

sensor (PR003 Oil pressure).Replace the pressure sensor (see MR 364,

Mechanical, 23A, Automatic transmission,

Pressure sensor (for Mégane II) and MR 370,

Mechanical, 23A, Automatic transmission,

Pressure sensor (for Scénic II)).

Is the value higher than 0.2 bar?

NO

YES

YES

NO

YES

NO

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

DP0TA2005_V14_ALP03/DP0TA2005_V18_ALP03

Page 131 of 139

AUTOMATIC TRANSMISSION

Fault finding - Fault Finding Chart23A

23A -131V5 MR-372-J84-23A100$928.mif

SIEMENS TA2005

Vdiag No.: 14-18

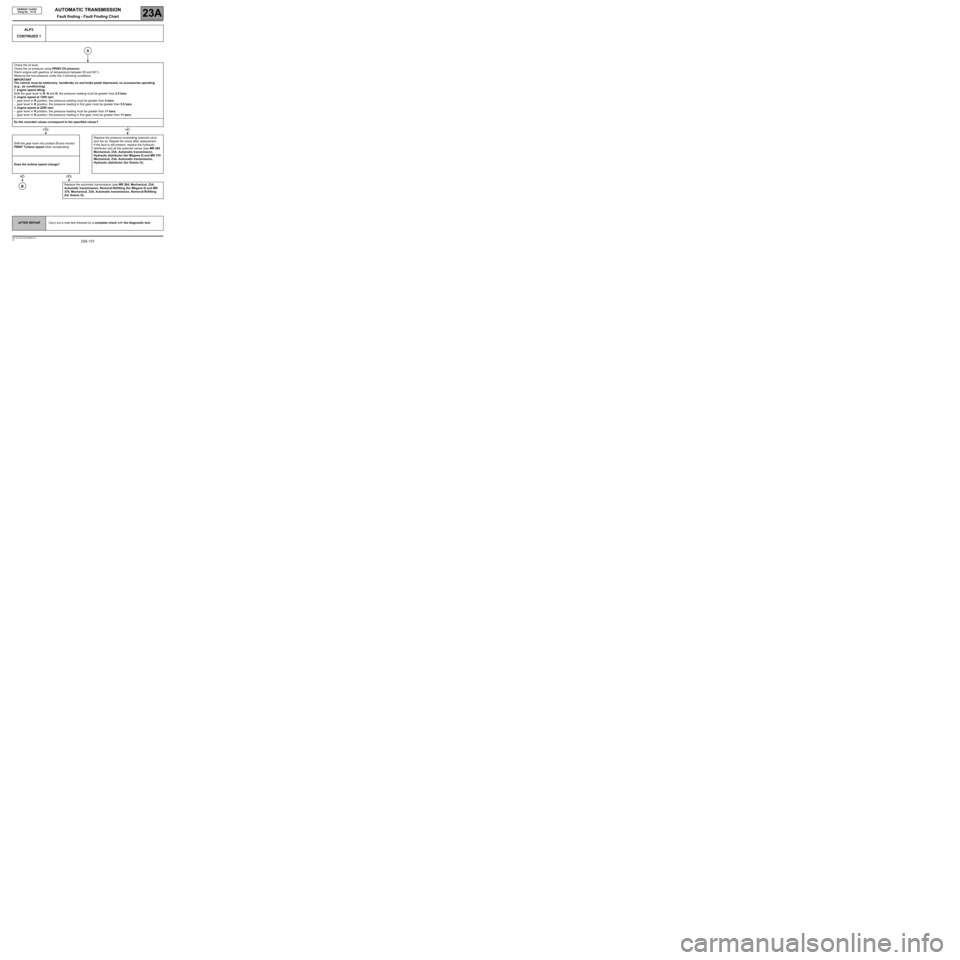

ALP3

CONTINUED 1

Check the oil level.

Check the oil pressure using PR003 Oil pressure:

Warm engine with gearbox oil temperature between 65 and 90˚C.

Measure the line pressure under the 3 following conditions:

IMPORTANT

The vehicle must be stationary: handbrake on and brake pedal depressed, no accessories operating

(e.g.: air conditioning)

1engine speed idling:

Shift the gear lever to R, N and D, the pressure reading must be greater than 2.5 bars.

2engine speed at 1200 rpm:

–gear lever in R position, the pressure reading must be greater than 4 bars.

–gear lever in D position, the pressure reading in first gear must be greater than 5.5 bars.

3engine speed at 2200 rpm:

–gear lever in R position, the pressure reading must be greater than 11 bars.

–gear lever in D position, the pressure reading in first gear must be greater than 11 bars.

Do the recorded values correspond to the specified values?

Shift the gear lever into position D and monitor

PR007 Turbine speed when accelerating.Replace the pressure modulating solenoid valve

and the oil. Repeat the check after replacement.

If the fault is still present, replace the hydraulic

distributor and all the solenoid valves (see MR 364

Mechanical, 23A, Automatic transmission,

Hydraulic distributor (for Mégane II) and MR 370

Mechanical, 23A, Automatic transmission,

Hydraulic distributor (for Scénic II)).

Does the turbine speed change?

Replace the automatic transmission (see MR 364, Mechanical, 23A,

Automatic transmission, Removal-Refitting (for Mégane II) and MR

370, Mechanical, 23A, Automatic transmission, Removal-Refitting

(for Scénic II)).

A

YESNO

NOYES

B

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 133 of 139

AUTOMATIC TRANSMISSION

Fault finding - Fault Finding Chart23A

23A -133V5 MR-372-J84-23A100$928.mif

SIEMENS TA2005

Vdiag No.: 14-18

ALP4 Automatic transmission malfunctioning on gear changing

NOTESOnly refer to Customer complaints after carrying out a complete fault finding

procedure with the diagnostic tool and the conformity check.

Automatic transmission malfunctions may be noted during gear changing without any fault being stored in the

computer.

These malfunctions may be linked to:

–connection faults (insulation: creates a fault, resistance) in the sequence solenoid valve control wiring

harnesses (EVS1 to EVS6).

Check the tightness and condition of the clips on all the solenoid valve control wiring connections from the

computer to each solenoid valve.

Use command AC024 Sequential actuators control to find any faults.

–Hydraulic distributor faults (hydraulic slide valve seizing, strainer/distributor seal) preventing the sequence

solenoid valves from working properly.

Check the oil's condition (colour, burnt or not) its level and pressure: increasing with engine/turbine speed.

–Loss of pressure when changing gear (clutch brakes/cylinder leaks)

Read the values of the following parameters (gear lever in position D or R: vehicle stationary and handbrake

applied) on the CLIP tool:

–PR003 Oil pressure,

–PR006 Engine speed,

–PR007 Turbine speed,

–PR138 Reference pressure,

–PR008 Computer feed voltage.

These parameters are associated with automatic transmission operation.

If one of the values is incorrect, note the fault it causes.

Replace the faulty part if necessary and carry out a check.

If the fault is still present, contact Techline.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

DP0TA2005_V14_ALP04/DP0TA2005_V18_ALP04

Page 135 of 139

AUTOMATIC TRANSMISSION

Fault finding - Fault Finding Chart23A

23A -135V5 MR-372-J84-23A100$928.mif

SIEMENS TA2005

Vdiag No.: 14-18

ALP6 Reversing lights do not work

NOTESOnly refer to Customer complaints after carrying out a complete fault finding

procedure with the diagnostic tool and the conformity check.

Check:

–the condition of the fuses in the UPC.

–the condition of the bulbs.

–the condition of the bulb contacts. Repair if necessary.

–Check that the earth is present for the following connections:

●connection code MAQ of component 172,

●connection code MZ of component 173.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring. Otherwise replace the wiring.

Switch off the ignition and disconnect the modular connector.

Switch on the ignition again and check for + 12 V after ignition feed on connection AP11 of component 485.

Switch off the ignition and check the continuity on the following connections, with the gear lever in position R:

●connection code H66P, between components 485 and 1337,

●connection code AP11, between components 485 and 1337.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring. Otherwise replace the wiring.

Check that the gear lever cable is correctly adjusted and check the instrument panel display.

If the continuity is faulty, replace the multifunction switch.

Switch on the ignition.

With the gear lever in position "R", check for + 12 V after ignition feed on the following connections:

●connection code H66P between components 172 and 1337,

●connection code H66P, between components 173 and 1337.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring. Otherwise replace the wiring.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

DP0TA2005_V14_ALP06/DP0TA2005_V18_ALP06