RENAULT SCENIC 2007 J84 / 2.G Electrical Equipment - Xenon Bulbs Workshop Manual

Manufacturer: RENAULT, Model Year: 2007, Model line: SCENIC, Model: RENAULT SCENIC 2007 J84 / 2.GPages: 38, PDF Size: 0.12 MB

Page 1 of 38

8Electrical equipment

V2 MR-372-J84-80C000$TOC.mif

V2

80C

"The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories from

which his vehicles are constructed."

V2

All rights reserved by Renault s.a.s.

Edition Anglaise

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault s.a.s.

© Renault s.a.s. 2007

XENON BULBS

Program No.: V010

Vdiag No.: 05

Fault finding – Introduction 80C - 2

Fault finding – System operation 80C - 6

Fault finding – Component replacement 80C - 9

Fault finding – Configurations and programming 80C - 10

Fault finding – Fault summary table 80C - 13

Fault finding – Interpretation of faults 80C - 14

Fault finding – Conformity check 80C - 26

Fault finding – Interpretation of statuses 80C - 29

Fault finding – Parameter summary table 80C - 30

Fault finding – Interpretation of parameters 80C - 31

Fault finding – Customer complaints 80C - 34

Fault finding – Fault finding charts 80C - 35

Page 2 of 38

80C -2V2 MR-372-J84-80C000$010.mif

80C

Program No.: V010

Vdiag No.: 05

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type:

Fault finding procedures (this document):

–Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu-Schéma (CD-ROM).

Type of diagnostic tools:

–CLIP + multiplex line sensor

Special tooling required

3. REMINDERS

Procedure

To run fault finding on the vehicle's computers, switch on the ignition in fault finding mode (forced + after ignition

feed).

Proceed as follows:

–Renault card in the card reader (keyless vehicle scenario 1, entry level, not hands-free and scenario 2, top of the

range, hands-free),

–press and hold Start button (longer than 5 seconds) with start-up conditions not fulfilled,

–connect the diagnostic tool and perform the required operations.

To cut off + after ignition feed, proceed as follows:

–disconnect the diagnostic tool,

–Press the start button twice briefly (less than 3 seconds),

–Check that the + after ignition feed has been cut off by checking that the computer warning lights on the instrument

panel have gone out. Vehicle(s): Scénic II, Laguna II ph1, Velsatis

ph1, Espace IV ph1

Function concerned: xenon bulbsName of computer: Xenon bulb computer

Program No.: V010

VDIAG No.: 05

Special tooling required

Diagnostic tool

Multimeter

CLIP + CAN probe (Elé. 1674)

LAD_V05_PRELI

XENON BULBS

Fault finding – Introduction

Page 3 of 38

80C -3V2 MR-372-J84-80C000$010.mif

XENON BULBS

Fault finding – Introduction80C

Program No.: V010

Vdiag No.: 05

Faults

Faults are classed as either present or stored (having appeared in a certain situation and then disappeared, or being

still present but not diagnosed in the current situation).

The present or stored status of faults should be taken into consideration when the diagnostic tool is switched on

following + after ignition feed being activated (without any system components being active).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the instructions in the Notes section.

If the fault is confirmed when the notes are applied, the fault is present. Deal with the fault.

If the fault is not confirmed, check:

–The electric lines on which there is a fault;

–The connectors on those lines (corrosion, bent pins, etc.);

–The resistance of the faulty component;

–The condition of the wires (insulation melted or split, chafing, etc.).

Conformity check

The aim of the conformity check is to check statuses and parameters that do not produce a fault display on the

diagnostic tool when they are inconsistent. Therefore, this stage is used to:

–perform fault finding on faults that do not have a fault display, and which may correspond to a customer complaint.

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section features the fault finding procedures for statuses and parameters, and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the diagnostic tool check is correct, but the customer complaint is still present, it should be dealt with according

to the customer complaint.

Asummary of t he overall procedure t o f ollow is provided on the following page in the form of a flow cha rt.

Page 4 of 38

80C -4V2 MR-372-J84-80C000$010.mif

XENON BULBS

Fault finding – Introduction80C

Program No.: V010

Vdiag No.: 05

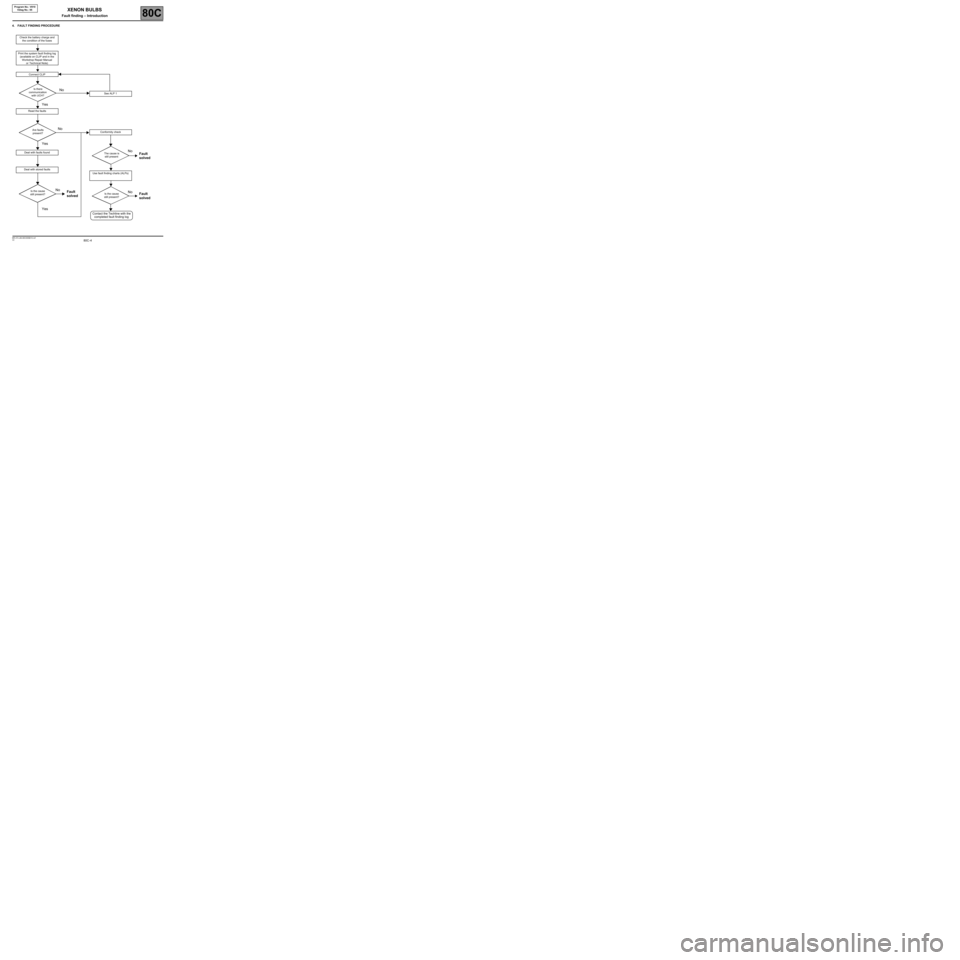

4. FAULT FINDING PROCEDURE

Check the battery charge and

the condition of the fuses

Print the system fault finding log

(available on CLIP and in the

Workshop Repair Manual

or Technical Note)

Connect CLIP

See ALP 1

Read the faults

Deal with faults found

Deal with stored faults

Conformity check

Use fault finding charts (ALPs)

Is there

communication

with UCH?

Are faults

present?

The cause is

still present

Is the cause

still present?Is the cause

still present?

Contact the Techline with the

completed fault finding log

No

NoNo

No No

Yes

Yes

YesFault

solvedFault

solved Fault

solved

Page 5 of 38

80C -5V2 MR-372-J84-80C000$010.mif

XENON BULBS

Fault finding – Introduction80C

Program No.: V010

Vdiag No.: 05

5. FAULT FINDING LOG

You will always be asked for this log:

–when requesting technical assistance from Techline,

–for approval requests when replacing parts for which approval is mandatory,

–to be attached to monitored parts for which reimbursement is requested. The log is needed for warranty

reimbursement, and enables better analysis of the parts removed.

6. SAFETY INSTRUCTIONS

All work on components requires that the safety rules be obeyed to prevent damage or injury:

–Check the battery voltage to avoid incorrect operation of computer functions.

–Use the appropriate tools.

–Do not touch the discharge bulbs.

–Never work on the discharge bulb system while it is in operation: the voltage is 20,000 V or more. IMPORTANTIMPORTANT

All faults involving a complex system call for thorough diagnostics with the appropriate tools.

The FAULT FINDING LOG, which should be completed during the fault finding procedure,

ensures a record is kept of the procedure carried out. It is an essential item for communication

with the manufacturer.

IT IS THEREFORE OBLIGATORY TO FILL A FAULT FINDING LOG WHENEVER

THE TECHLINE OR THE WARRANTY RETURNS DEPARTMENT REQUESTS IT.

Page 6 of 38

80C -6V2 MR-372-J84-80C000$020.mif

80C

Program No.: V010

Vdiag No.: 05

1. COMPONENTS OF THE XENON BULB SYSTEM

The system consists of the following components:

–Front vehicle level sensor (the xenon bulb computer is built into this sensor).

–Rear vehicle level sensor.

–Right and left-hand headlight adjustment motor.

–Bulb high-voltage power unit (ballast).

–Xenon bulbs.

The K line can be used for fault finding. The system is not multiplexed.

2. SYSTEM OPERATION

When the control lever is in position (dipped headlights), it sends a signal to the UCH. The UCH processes the signal

and, through the CAN network, asks the Protection and Switching Unit to turn on the xenon bulbs.

When the bulbs come on, the adjustment motor moves through three positions: low, high, initial.

This is its initialisation.

If the vehicle is travelling above 6 mph (10 km/h) when the bulbs come on, there is no initialisation.

The computer manages various signals to adjust the amount of light:

–Vehicle speed: Signal provided by the ABS computer. Above 18 mph (30 km/h), the adjustment motors raise

the bulbs to provide optimum lighting for the driver.

–Vehicle front and rear height: signals from the front and rear height sensors. These sensors track the angular motion

of the vehicle's body (deceleration, acceleration, vehicle loaded). The computer then controls the motors to adjust

the beam and provide optimum lighting.

–System initialisation:

When the vehicle is unlocked, even if the dipped headlights are off, the system moves the adjustment motors

to the low position and then the initial position.

This initialises the system.

XENON BULBS

Fault finding – System operation

Page 7 of 38

80C -7V2 MR-372-J84-80C000$020.mif

XENON BULBS

Fault finding – System operation80C

Program No.: V010

Vdiag No.: 05

3. CONFIGURATION-CALIBRATION OF THE SYSTEM

To calibrate and configure a new computer on a vehicle, follow the configuration procedures in the following order.

a. Vehicle type (CF003)

This configuration activates the adjustment strategies designed for the body type.

The new strategies only take effect after the ignition is switched off and the doors are locked.

Perform configuration as follows:

–Enter the xenon bulbs fault finding mode.

–Make sure that the initial vehicle position indicated by the front and rear sensors is within the allowed range.

–Run configuration CF003 according to the vehicle type:

– Scénic II Strd* (5-seater MPV)

– Scenic II Long (7-seater extended MPV)

– Espace IV

– Velsatis

– Laguna II

–Exit fault finding mode.

–Switch off the ignition.

–Lock the doors using the card.

–The vehicle type has been programmed.

–After unlocking the doors, turn the ignition back on.

–See that the vehicle type has been properly identified by reading configuration LC001, Vehicle type.

b. Computer calibration (CF001)

This calibration must be performed when a system component is replaced (e.g. sensor, headlight etc.).

It enables the computer to store the vehicle's reference level.

To ensure proper configuration and calibration, follow this procedure:

–Check tyre pressure and adjust if faulty.

–Park the vehicle on a level surface under normal driving conditions (luggage compartment empty).

–Vehicle stopped, solid base (no door rattling).

–Driver on board.

–Fuel tank full.

Once computer calibration has been performed, check conformity of the light beam.

If it is incorrect, adjust the headlights manually.

Page 8 of 38

80C -8V2 MR-372-J84-80C000$020.mif

XENON BULBS

Fault finding – System operation80C

Program No.: V010

Vdiag No.: 05

4. DEFECT MODE

If a system component is defective, no indicator lights up on the instrument panel.

The system then switches to defect mode.

If the computer detects a system fault, it sets the adjustment motors to the low or initial position.

If the computer detects a fault, there is no longer any initialisation when the lights are turned on.

* Strd: standard

Page 9 of 38

80C -9V2 MR-372-J84-80C000$030.mif

80C

Program No.: V010

Vdiag No.: 05

The xenon bulbs fitted to the system require a voltage of 20,000 V when switched on, then run on 85 V AC.

You must always disconnect the battery before doing any work on the headlights, bulbs, and high-voltage headlight

power transformer units.

To follow the method of removal-refitting of the constituent components of the system, see MR 370 (Scenic II)

or MR 361 (Espace IV) or MR 353 (Velsatis), Mechanical systems, 80C - Xenon Bulbs, Xenon bulb computer:

Removal – Refitting or MR 339 (Laguna II), Mechanical systems, 80 – Headlights, Xenon headlights.

It is forbidden to supply a bulb if it is not installed in the headlight (danger that you might damage your eyes).

The computer must be calibrated using CF001computer calibration (see Configuration and programming) each

time a front or rear level sensor is replaced.

The following procedure should be applied before adjusting the headlight beam:

–check that there are no faults

–configure the vehicle type using command CF003 Vehicle type (see Configuration and programming)

–calibrate the computer using command CF001 (see Configuration and programming)

Next adjust the headlights manually, (see MR 370 (Scenic II) or MR 361 (Espace IV) or MR 353 (Velsatis),

Mechanical systems, 80C - Xenon bulbs, Xenon headlight: Adjustment or MR 339 (Laguna II), Mechanical

systems, 80 – Headlights, Xenon headlights).

XENON BULBS

Fault finding – Component replacement

Page 10 of 38

80C-10V2 MR-372-J84-80C000$040.mif

80C

Program No.: V010

Vdiag No.: 05

AFTER REPAIRTurn on dipped-beam headlights.

Check that the system performs its initialisation to verify that the computer has no

faults.

Adjust the headlights manually.

CF001COMPUTER CALIBRATION

NOTESThis configuration enables the computer to store the vehicle's reference level.

Begin by configuring the vehicle type; then calibrate the vehicle level.

The vehicle must be stationary. Also, the front and rear sensor values must be within

the permissible range.

To calibrate the computer, proceed as follows:

–Check tyre pressure and adjust if faulty.

–Park the vehicle on a level horizontal surface.

–Make sure that the headlights have been properly adjusted manually.

–Position the vehicle with the wheels set straight ahead, engine switched off, driver behind the wheel and dipped

headlights on.

–Turn on the ignition and enter xenon bulbs fault finding mode.

–Select Configuration mode.

–Run configuration CF001.

–When calibration is complete, exit fault finding mode.

–Lock and unlock the vehicle doors with the card.

–The computer has now been calibrated.

–Check status LC010, which should indicate Completed.

LC010COMPUTER CALIBRATIONNot completed

Completed

The configuration reading LC010 can have either of two statuses:

–Not completed: The computer has not been calibrated, the vehicle's reference level is unknown, and the

maximum and minimum body height levels have not been programmed.

–Completed: The computer has been calibrated. Normal system operation. The sensor reference levels have

been programmed.

XENON BULBS

Fault finding – Configurations and programming