RENAULT SCENIC 2007 J84 / 2.G Automatic Transmission Siemens TA2005 Workshop Manual

Manufacturer: RENAULT, Model Year: 2007, Model line: SCENIC, Model: RENAULT SCENIC 2007 J84 / 2.GPages: 139, PDF Size: 0.43 MB

Page 1 of 139

2Transmission

V5 MR-372-J84-23A100$TOC.mif

V5

23A

"The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories from

which his vehicles are constructed."

V5

All rights reserved by Renault s.a.s.

Edition Anglaise

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault s.a.s.

© Renault s.a.s. 2007

AUTOMATIC TRANSMISSION

SIEMENS TA2005

Vdiag No.: 14-18

Fault finding - Introduction 23A - 2

Fault finding - System operation 23A - 7

Fault finding - Replacement of components 23A - 12

Fault finding - Configurations and programming 23A - 13

Fault finding - Fault summary table 23A - 14

Fault finding - Interpretation of faults 23A - 16

Fault finding - Conformity check 23A - 73

Fault finding - Status summary table 23A - 88

Fault finding - Interpretation of statuses 23A - 89

Fault finding - Parameter summary table 23A - 108

Fault finding - Interpretation of parameters 23A - 109

Fault finding - Dealing with command modes 23A - 125

Fault finding - Interpretation of commands 23A - 126

Fault finding - Customer complaints 23A - 127

Fault finding - Fault Finding Chart 23A - 128

Fault finding - Tests 23A - 137

Page 2 of 139

AUTOMATIC TRANSMISSION

Fault finding - Introduction

23A

23A - 2V5 MR-372-J84-23A100$058.mif

123A

SIEMENS TA2005

Vdiag No.: 14-18AUTOMATIC TRANSMISSION

Fault finding - Introduction

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this manual):

–Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu-Schéma (CD-ROM), paper.

Type of diagnostic tools

–CLIP

Special tooling required

3. RECAP

Procedure

To run fault finding on the vehicle computers, switch on the ignition.

Proceed as follows:

–Connect the diagnostic tool and perform the required operations. Vehicle(s): MEGANE II and SCENIC II

Function concerned: Automatic transmissionName of computer: Siemens TA 2005

Vdiag No.: 14-18

Special tooling required

Multimeter

Elé. 1681Universal bornier

WARNING

Computer supply for the fault finding procedure:

To run fault finding on the vehicle computers, proceed as follows:

–Place the vehicle's card in the card reader (keyless vehicle scenario 1 (entry level, not hands-free) and

scenario 2 (top of the range, hands-free),

–Press and hold the Start button (more than 5 seconds) outside start-up conditions,

–Then connect the diagnostic tool and perform the required operations.

DP0TA2005_V14_PRELI/DP0TA2005_V18_PRELI

MR-372-J84-23A100$058.mif

Page 3 of 139

AUTOMATIC TRANSMISSION

Fault finding - Introduction

23A

23A - 3V5 MR-372-J84-23A100$058.mif

SIEMENS TA2005

Vdiag No.: 14-18

Faults

Faults are declared either present or stored (depending on whether they appeared in a certain context and

disappeared since, or whether they remain present but have not been diagnosed within the current context).

The present or stored status of faults should be taken into consideration when the diagnostic tool is switched on

after the + after ignition feed (without any system components being active).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the instructions in the Notes section.

If the fault is confirmed when the instructions in the Notes section are applied, the fault is present. Deal with the

fault.

If the fault is not confirmed, check:

–the electrical lines which correspond to the fault,

–the connectors for these lines (for oxidation, bent pins, etc.),

–the resistance of the component detected as faulty,

–the condition of the wires (melted or split insulation, wear).

Conformity check

The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool because the

data is inconsistent. Therefore, this stage is used to:

–carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint,

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the test with the diagnostic tool is OK but the customer complaint is still present, the fault should be processed by

customer complaint.

A synopsis of the general procedure to follow is provided on the following page in

the form of a flow chart.

Page 4 of 139

AUTOMATIC TRANSMISSION

Fault finding - Introduction

23A

23A - 4V5 MR-372-J84-23A100$058.mif

SIEMENS TA2005

Vdiag No.: 14-18

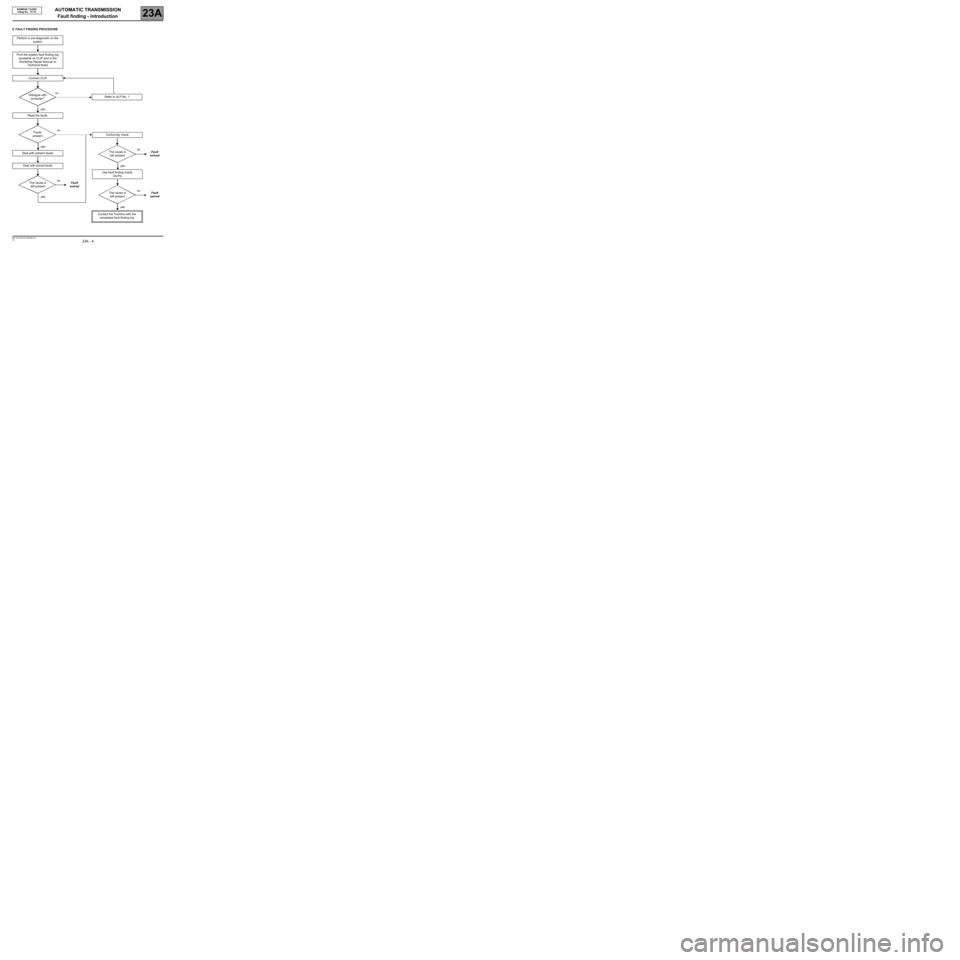

4. FAULT FINDING PROCEDURE

Perform a pre-diagnostic on the

system

Print the system fault finding log

(available on CLIP and in the

Workshop Repair Manual or

Technical Note)

Connect CLIP

no

Dialogue with

computer?

yes

Read the faults

no

Faults

present

yes

Deal with present faults

Deal with stored faults

no

The cause is

still presentFault

solved

yes

Refer to ALP No. 1

Conformity check

no

The cause is

still presentFault

solved

yes

Use fault finding charts

(ALPs)

no

The cause is

still presentFault

solved

yes

Contact the Techline with the

completed fault finding log

Page 5 of 139

AUTOMATIC TRANSMISSION

Fault finding - Introduction

23A

23A - 5V5 MR-372-J84-23A100$058.mif

SIEMENS TA2005

Vdiag No.: 14-18

4. FAULT FINDING PROCEDURE (continued)

Wiring check

Fault finding problems

Disconnecting the connectors and/or manipulating the wiring harness may temporarily remove the cause of a fault.

Electrical measurements of the voltage, resistance and insulation are generally correct, especially if the fault is not

present when analysing (stored fault).

Visual inspection

Look for damage under the bonnet and in the passenger compartment.

Carefully check the fuses, insulators and wiring harness routing.

Look for signs of oxidation.

Tactile inspection

While manipulating the wiring harness, use the diagnostic tool to note any change in fault status from stored or

present.

Check that the connectors are correctly locked.

Apply light pressure to the connectors.

Twist the wiring harness.

If there is a change in status, try to locate the source of the fault.

Inspection of each component

Disconnect the connectors and check the appearance of the clips and tabs, as well as the crimping (no crimping on

the insulating section).

Check that the clips and tabs are correctly locked in the sockets.

Make sure that no clips or tabs have been dislodged during connection.

Check the clip contact pressure using an appropriate model of tab.

Check the continuity/insulation

Check the continuity of entire lines, then section by section.

Look for a short circuit to earth, to + 12 V or to another wire.

If a fault is detected, repair or replace the wiring harness.

Page 6 of 139

AUTOMATIC TRANSMISSION

Fault finding - Introduction

23A

23A - 6V5 MR-372-J84-23A100$058.mif

SIEMENS TA2005

Vdiag No.: 14-18

5. FAULT FINDING LOG

You will always be asked for this log:

–when requesting technical assistance from Techline,

–for approval requests when replacing parts for which approval is mandatory,

–to be attached to monitored parts for which reimbursement is requested. The log is needed for warranty

reimbursement, and enables better analysis of the parts removed.

6. SAFETY ADVICE

Safety rules must be observed during any work on a component to prevent any damage or injury:

–check the battery voltage to avoid incorrect operation of computer functions,

–use the appropriate tools,

–immobilise the vehicle for all tests in the workshop on the automatic transmission with the engine running. IMPORTANTIMPORTANT

Any fault on a complex system requires thorough fault finding with the appropriate tools. The

FAULT FINDING LOG, which should be completed during the procedure, enables you to keep

track of the procedure which is carried out. It is an essential document when consulting the

manufacturer.

IT IS THEREFORE MANDATORY TO FILL OUT A FAULT FINDING LOG EACH TIME FAULT FINDING IS

CARRIED OUT.

Page 7 of 139

Fault finding - System operation23A

23A - 7V5 MR-372-J84-23A100$116.mif

SIEMENS TA2005

Vdiag No.: 14-18AUTOMATIC TRANSMISSION

Fault finding - System operation

GENERAL OPERATION

The automatic transmission on this model is a DP0, which is also found on other Renault vehicles including the

Clio II, Kangoo or Mégane.

The automatic transmission computer controls gear-shifting based on several parameters, among them engine

torque and the type of driving adopted by the driver.

All signals travel to the computer by wire, except for those from the injection computer, which use the multiplex

network.

Fault finding on the computer is carried out via the multiplex network (multiplex line).

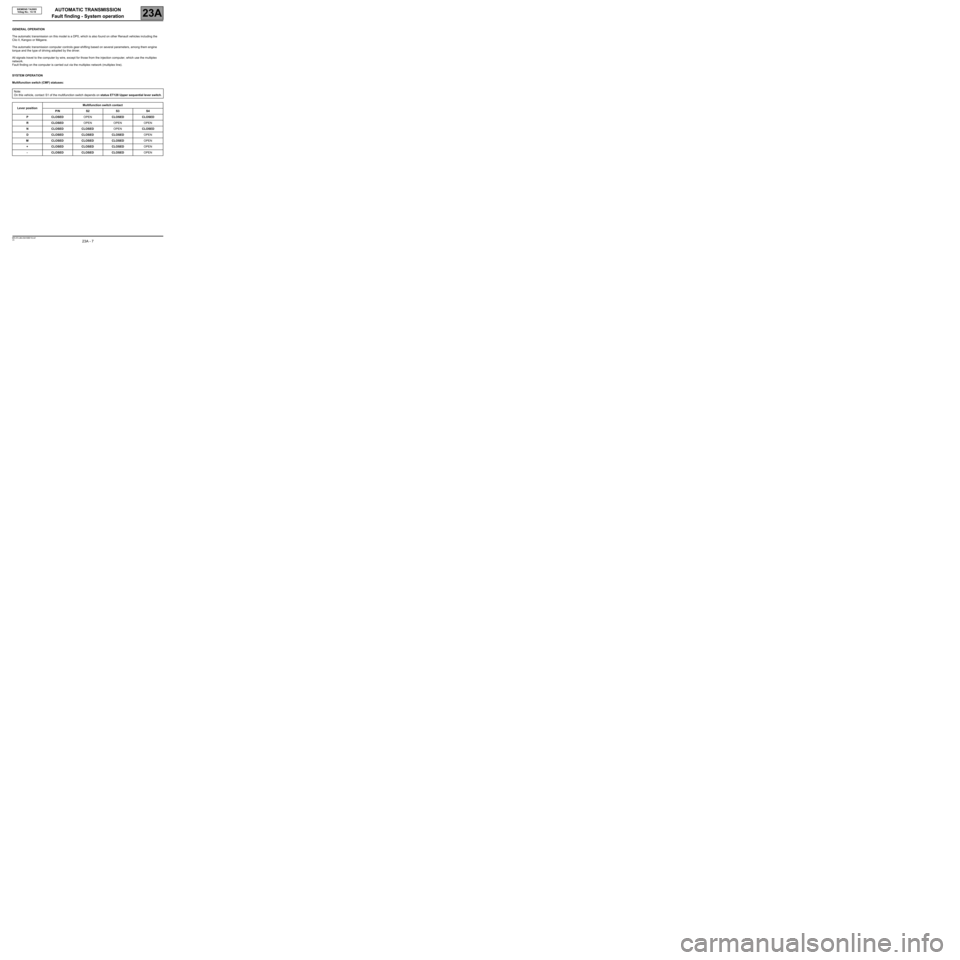

SYSTEM OPERATION

Multifunction switch (CMF) statuses:

Note:

On this vehicle, contact S1 of the multifunction switch depends on status ET128 Upper sequential lever switch.

Lever positionMultifunction switch contact

P/N S2 S3 S4

PCLOSEDOPENCLOSED CLOSED

RCLOSEDOPEN OPEN OPEN

NCLOSED CLOSEDOPENCLOSED

DCLOSED CLOSED CLOSEDOPEN

M CLOSED CLOSED CLOSEDOPEN

+CLOSED CLOSED CLOSEDOPEN

-CLOSED CLOSED CLOSEDOPEN

MR-372-J84-23A100$116.mif

Page 8 of 139

AUTOMATIC TRANSMISSION

Fault finding - System operation

23A

23A - 8V5 MR-372-J84-23A100$116.mif

SIEMENS TA2005

Vdiag No.: 14-18

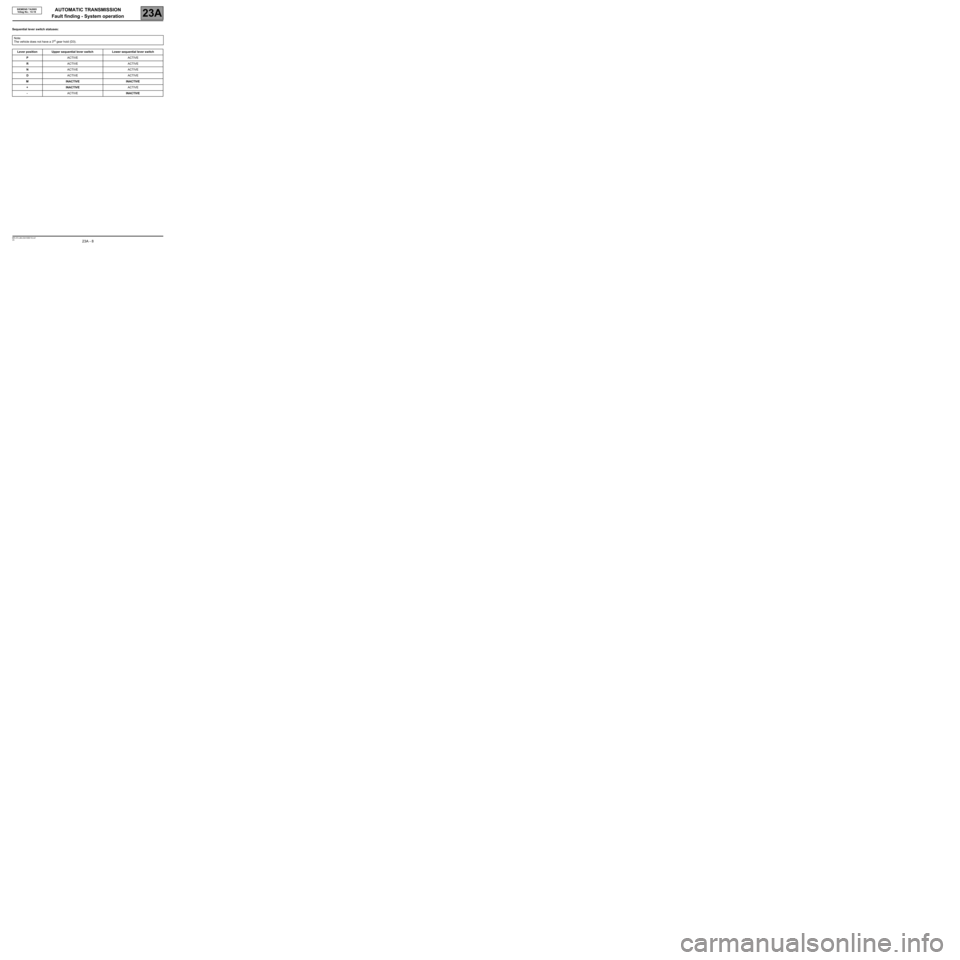

Sequential lever switch statuses:

Note:

The vehicle does not have a 3

rd gear hold (D3).

Lever position Upper sequential lever switch Lower sequential lever switch

PACTIVE ACTIVE

RACTIVE ACTIVE

NACTIVE ACTIVE

DACTIVE ACTIVE

M INACTIVE INACTIVE

+INACTIVEACTIVE

-ACTIVEINACTIVE

Page 9 of 139

AUTOMATIC TRANSMISSION

Fault finding - System operation

23A

23A - 9V5 MR-372-J84-23A100$116.mif

SIEMENS TA2005

Vdiag No.: 14-18

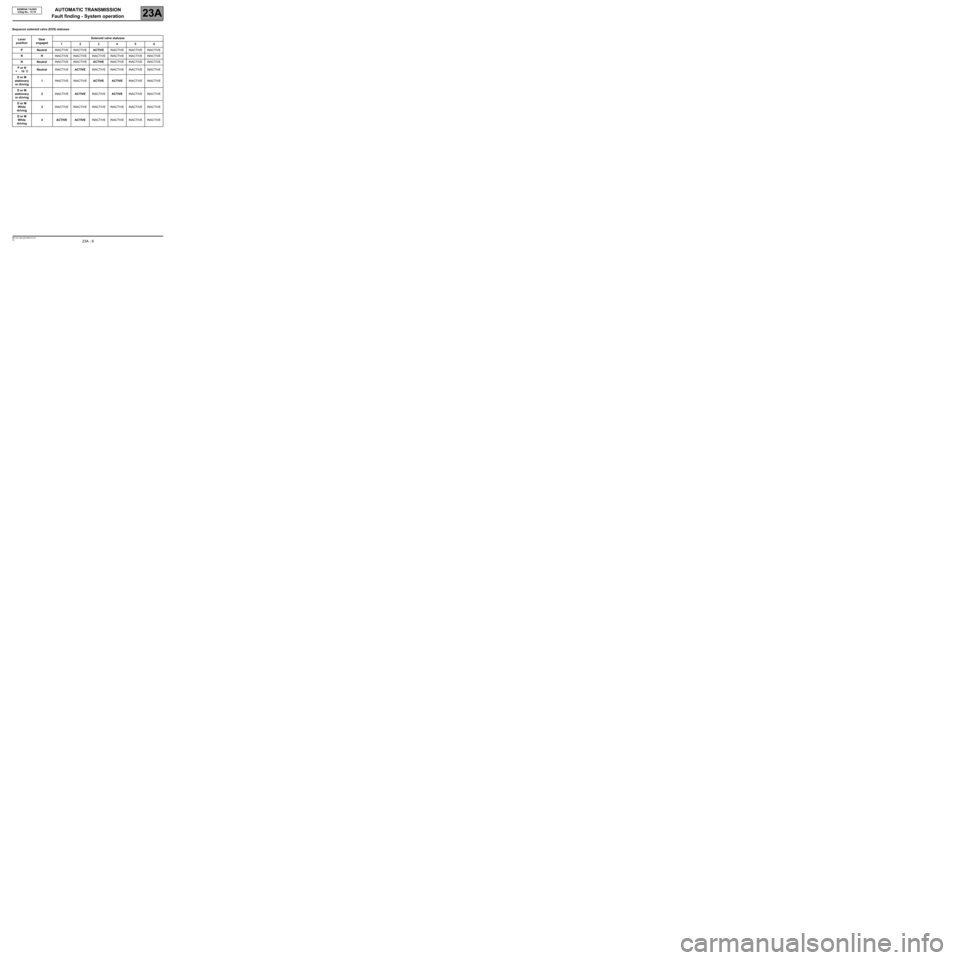

Sequence solenoid valve (EVS) statuses:

Lever

positionGear

engagedSolenoid valve statuses

123456

PNeutralINACTIVE INACTIVEACTIVEINACTIVE INACTIVE INACTIVE

RRINACTIVE INACTIVE INACTIVE INACTIVE INACTIVE INACTIVE

NNeutralINACTIVE INACTIVEACTIVEINACTIVE INACTIVE INACTIVE

P or N

< � 10 ˚CNeutralINACTIVEACTIVEINACTIVE INACTIVE INACTIVE INACTIVE

D or M

stationary

or driving1INACTIVE INACTIVEACTIVE ACTIVEINACTIVE INACTIVE

D or M

stationary

or driving 2INACTIVEACTIVEINACTIVEACTIVEINACTIVE INACTIVE

D or M

While

driving3INACTIVE INACTIVE INACTIVE INACTIVE INACTIVE INACTIVE

D or M

While

driving4ACTIVE ACTIVEINACTIVE INACTIVE INACTIVE INACTIVE

Page 10 of 139

AUTOMATIC TRANSMISSION

Fault finding - System operation

23A

23A - 10V5 MR-372-J84-23A100$116.mif

SIEMENS TA2005

Vdiag No.: 14-18

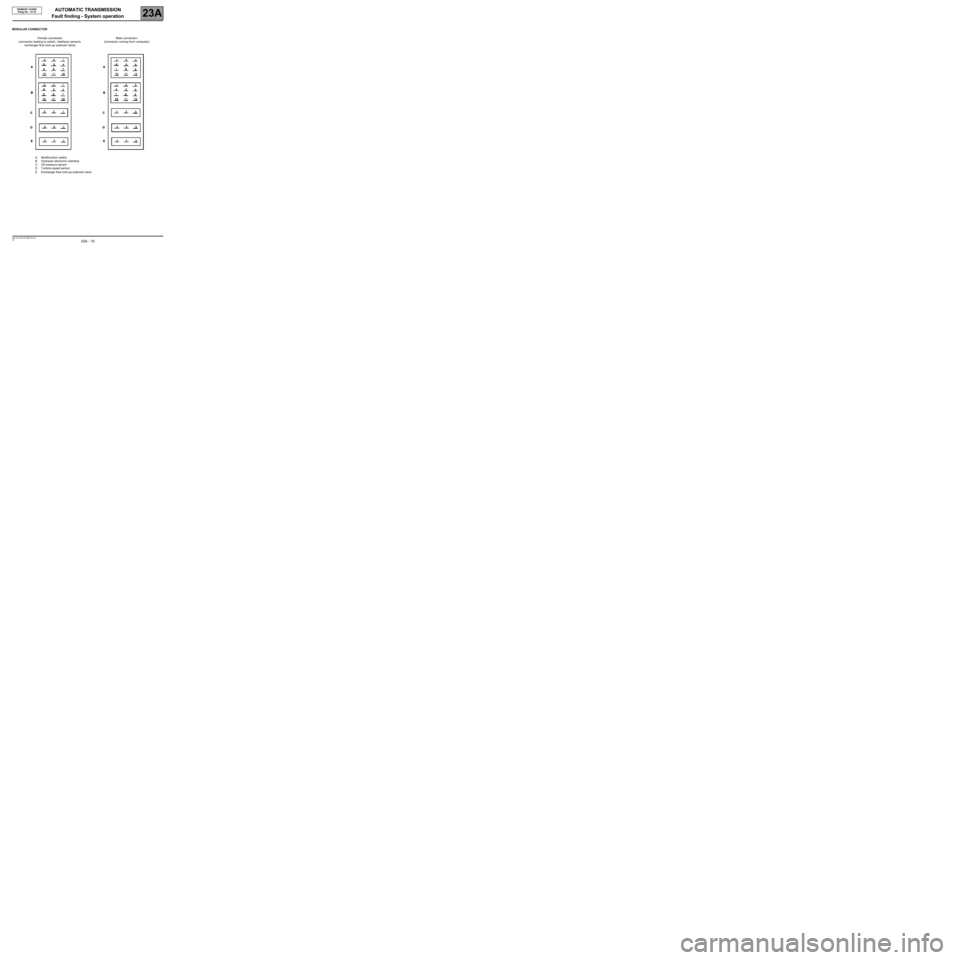

MODULAR CONNECTOR

Female connection

(connector leading to switch, interface) sensors,

exchanger flow lock-up solenoid valve).Male connection

(connector coming from computer)

AMultifunction switch

BHydraulic electronic interface

COil pressure sensor

DTurbine speed sensor

EExchanger flow lock-up solenoid valve