ESP RENAULT SCENIC 2007 J84 / 2.G Automatic Transmission Siemens TA2005 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2007, Model line: SCENIC, Model: RENAULT SCENIC 2007 J84 / 2.GPages: 139, PDF Size: 0.43 MB

Page 3 of 139

AUTOMATIC TRANSMISSION

Fault finding - Introduction

23A

23A - 3V5 MR-372-J84-23A100$058.mif

SIEMENS TA2005

Vdiag No.: 14-18

Faults

Faults are declared either present or stored (depending on whether they appeared in a certain context and

disappeared since, or whether they remain present but have not been diagnosed within the current context).

The present or stored status of faults should be taken into consideration when the diagnostic tool is switched on

after the + after ignition feed (without any system components being active).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the instructions in the Notes section.

If the fault is confirmed when the instructions in the Notes section are applied, the fault is present. Deal with the

fault.

If the fault is not confirmed, check:

–the electrical lines which correspond to the fault,

–the connectors for these lines (for oxidation, bent pins, etc.),

–the resistance of the component detected as faulty,

–the condition of the wires (melted or split insulation, wear).

Conformity check

The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool because the

data is inconsistent. Therefore, this stage is used to:

–carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint,

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the test with the diagnostic tool is OK but the customer complaint is still present, the fault should be processed by

customer complaint.

A synopsis of the general procedure to follow is provided on the following page in

the form of a flow chart.

Page 5 of 139

AUTOMATIC TRANSMISSION

Fault finding - Introduction

23A

23A - 5V5 MR-372-J84-23A100$058.mif

SIEMENS TA2005

Vdiag No.: 14-18

4. FAULT FINDING PROCEDURE (continued)

Wiring check

Fault finding problems

Disconnecting the connectors and/or manipulating the wiring harness may temporarily remove the cause of a fault.

Electrical measurements of the voltage, resistance and insulation are generally correct, especially if the fault is not

present when analysing (stored fault).

Visual inspection

Look for damage under the bonnet and in the passenger compartment.

Carefully check the fuses, insulators and wiring harness routing.

Look for signs of oxidation.

Tactile inspection

While manipulating the wiring harness, use the diagnostic tool to note any change in fault status from stored or

present.

Check that the connectors are correctly locked.

Apply light pressure to the connectors.

Twist the wiring harness.

If there is a change in status, try to locate the source of the fault.

Inspection of each component

Disconnect the connectors and check the appearance of the clips and tabs, as well as the crimping (no crimping on

the insulating section).

Check that the clips and tabs are correctly locked in the sockets.

Make sure that no clips or tabs have been dislodged during connection.

Check the clip contact pressure using an appropriate model of tab.

Check the continuity/insulation

Check the continuity of entire lines, then section by section.

Look for a short circuit to earth, to + 12 V or to another wire.

If a fault is detected, repair or replace the wiring harness.

Page 15 of 139

AUTOMATIC TRANSMISSION

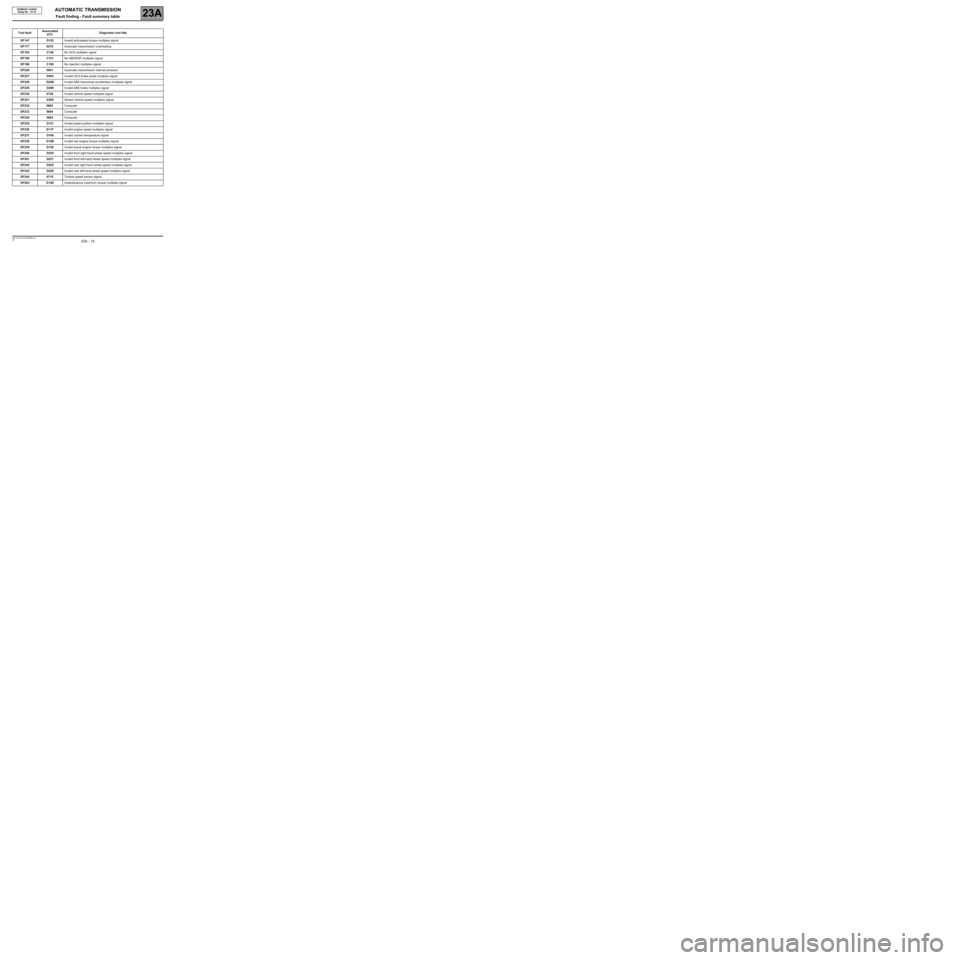

Fault finding - Fault summary table23A

23A - 15V5 MR-372-J84-23A100$290.mif

SIEMENS TA2005

Vdiag No.: 14-18

Tool faultAssociated

DTCDiagnostic tool title

DF147 D122Invalid anticipated torque multiplex signal

DF177 0218Automatic transmission overheating

DF183 C140No UCH multiplex signal

DF185 C121No ABS/ESP multiplex signal

DF186 C100No injection multiplex signal

DF226 0841Automatic transmission internal pressure

DF227 D403Invalid UCH brake pedal multiplex signal

DF228 D22BInvalid ABS transverse acceleration multiplex signal

DF229 D208Invalid ABS brake multiplex signal

DF230 0720Invalid vehicle speed multiplex signal

DF231 D200Absent vehicle speed multiplex signal

DF232 0603Computer

DF233 0604Computer

DF234 0605Computer

DF235 D121Invalid pedal position multiplex signal

DF236 D11FInvalid engine speed multiplex signal

DF237 D100Invalid coolant temperature signal

DF238 D12BInvalid raw engine torque multiplex signal

DF239 D120Invalid actual engine torque multiplex signal

DF240 D220Invalid front right-hand wheel speed multiplex signal

DF241 D221Invalid front left-hand wheel speed multiplex signal

DF242 D225Invalid rear right-hand wheel speed multiplex signal

DF243 D226Invalid rear left-hand wheel speed multiplex signal

DF244 0715Turbine speed sensor signal

DF263 D12DInstantaneous maximum torque multiplex signal

Page 50 of 139

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A-50V5 MR-372-J84-23A100$406.mif

SIEMENS TA2005

Vdiag No.: 14-18

DF185

PRESENT

OR

STOREDNO ABS/ESP MULTIPLEX SIGNAL

1.DEF: Carry out the multiplex network fault finding procedure

NOTESNone.

Run a multiplex network test (see 88B, Multiplex).

If the fault is still present, carry out fault finding on the system (see 38C, ABS).

If the problem is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

DP0TA2005_V14_DF185/DP0TA2005_V18_DF185

Page 131 of 139

AUTOMATIC TRANSMISSION

Fault finding - Fault Finding Chart23A

23A -131V5 MR-372-J84-23A100$928.mif

SIEMENS TA2005

Vdiag No.: 14-18

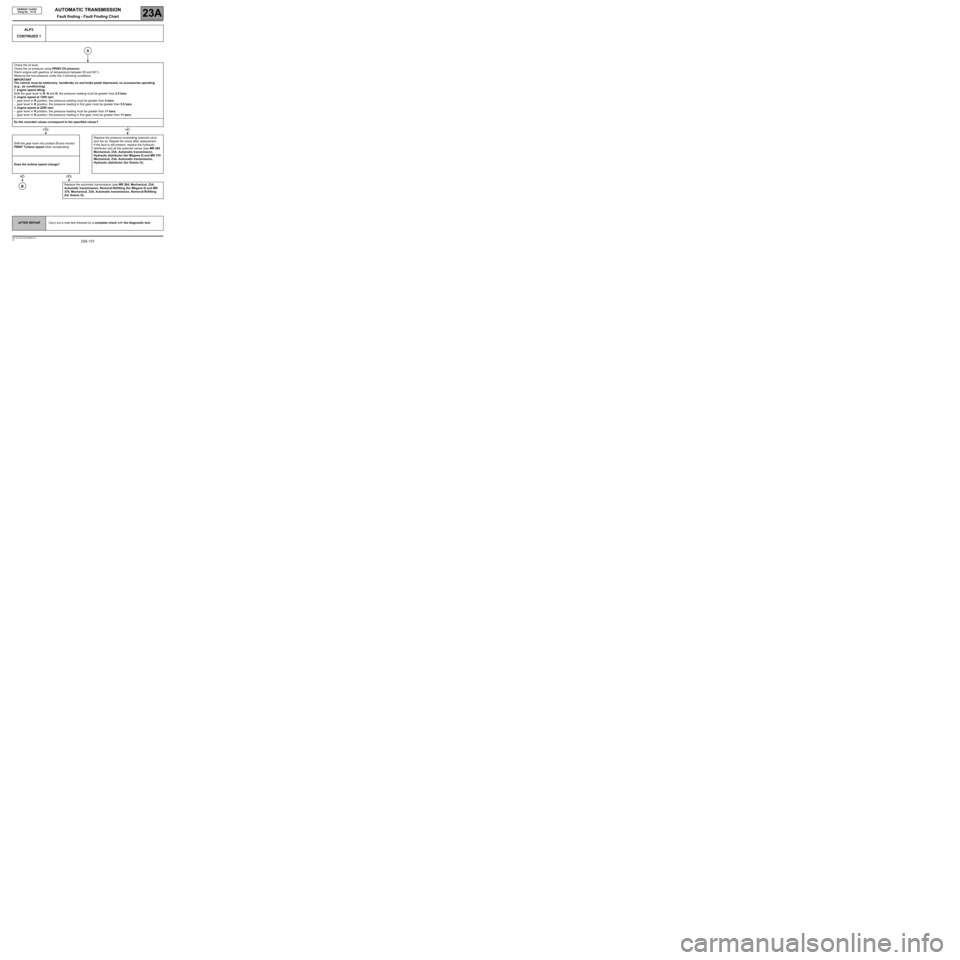

ALP3

CONTINUED 1

Check the oil level.

Check the oil pressure using PR003 Oil pressure:

Warm engine with gearbox oil temperature between 65 and 90˚C.

Measure the line pressure under the 3 following conditions:

IMPORTANT

The vehicle must be stationary: handbrake on and brake pedal depressed, no accessories operating

(e.g.: air conditioning)

1engine speed idling:

Shift the gear lever to R, N and D, the pressure reading must be greater than 2.5 bars.

2engine speed at 1200 rpm:

–gear lever in R position, the pressure reading must be greater than 4 bars.

–gear lever in D position, the pressure reading in first gear must be greater than 5.5 bars.

3engine speed at 2200 rpm:

–gear lever in R position, the pressure reading must be greater than 11 bars.

–gear lever in D position, the pressure reading in first gear must be greater than 11 bars.

Do the recorded values correspond to the specified values?

Shift the gear lever into position D and monitor

PR007 Turbine speed when accelerating.Replace the pressure modulating solenoid valve

and the oil. Repeat the check after replacement.

If the fault is still present, replace the hydraulic

distributor and all the solenoid valves (see MR 364

Mechanical, 23A, Automatic transmission,

Hydraulic distributor (for Mégane II) and MR 370

Mechanical, 23A, Automatic transmission,

Hydraulic distributor (for Scénic II)).

Does the turbine speed change?

Replace the automatic transmission (see MR 364, Mechanical, 23A,

Automatic transmission, Removal-Refitting (for Mégane II) and MR

370, Mechanical, 23A, Automatic transmission, Removal-Refitting

(for Scénic II)).

A

YESNO

NOYES

B

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.