sensor RENAULT SCENIC 2007 J84 / 2.G Electrical Equipment - Xenon Bulbs User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2007, Model line: SCENIC, Model: RENAULT SCENIC 2007 J84 / 2.GPages: 38, PDF Size: 0.12 MB

Page 23 of 38

80C-23V2 MR-372-J84-80C000$060.mif

XENON BULBS

Fault finding – Interpretation of faults80C

Program No.: V010

Vdiag No.: 05

AFTER REPAIRTurn on the dipped headlights and check that initialisation is performed.

If there is no initialisation, deal with the system faults.

Adjust the headlights manually after each computer calibration.

Carry out a road test followed by a check with the diagnostic tool.

DF009

CONTINUED 2

3.DEFNOTESNone.

Check the condition of the rear sensor linkage and that it is correctly fitted.

Replace if necessary.

Check the condition of the contacts and connections of the xenon bulb computer and rear level sensor.

Check the continuity and absence of interference resistance between:

Track 6 of the rear level sensor connectorTrack 3 of the xenon bulb computer connector

Track 5 of the rear level sensor connectorTrack 8 of the xenon bulb computer connector

Next check the insulation of these connections against earth, and then against + 12 V.

If the problem is still present, contact the Techline.

4.DEF

NOTESNone.

Check the condition of the rear sensor linkage and that it is correctly fitted.

Replace if necessary.

Check the condition of the contacts and connections of the xenon bulb computer and rear level sensor.

Check the continuity and absence of interference resistance between:

Track 6 of the rear level sensor connectorTrack 3 of the xenon bulb computer connector

Track 5 of the rear level sensor connectorTrack 8 of the xenon bulb computer connector

Next check the insulation of these connections against earth, and then against + 12 V.

If the problem is still present, contact the Techline.

Page 24 of 38

80C-24V2 MR-372-J84-80C000$060.mif

XENON BULBS

Fault finding – Interpretation of faults80C

Program No.: V010

Vdiag No.: 05

AFTER REPAIRTurn on the dipped headlights and check that initialisation is performed.

If there is no initialisation, deal with the system faults.

Adjust the headlights manually after each computer calibration.

Carry out a road test followed by a check with the diagnostic tool.

DF009

CONTINUED 3

5.DEFNOTESNone.

Check the condition of the rear level sensor linkage.

Replace if necessary.

Check the condition of the contacts and connections of the xenon bulb computer and rear level sensor.

Check the continuity and absence of interference resistance between:

Track 6 of the rear level sensor connectorTrack 3 of the xenon bulb computer connector

Track 5 of the rear level sensor connectorTrack 8 of the xenon bulb computer connector

Next check the insulation of these connections against earth, and then against + 12 V.

If the problem is still present, contact the Techline.

Page 27 of 38

80C-27V2 MR-372-J84-80C000$070.mif

XENON BULBS

Fault finding – Conformity check80C

Program No.: V010

Vdiag No.: 05

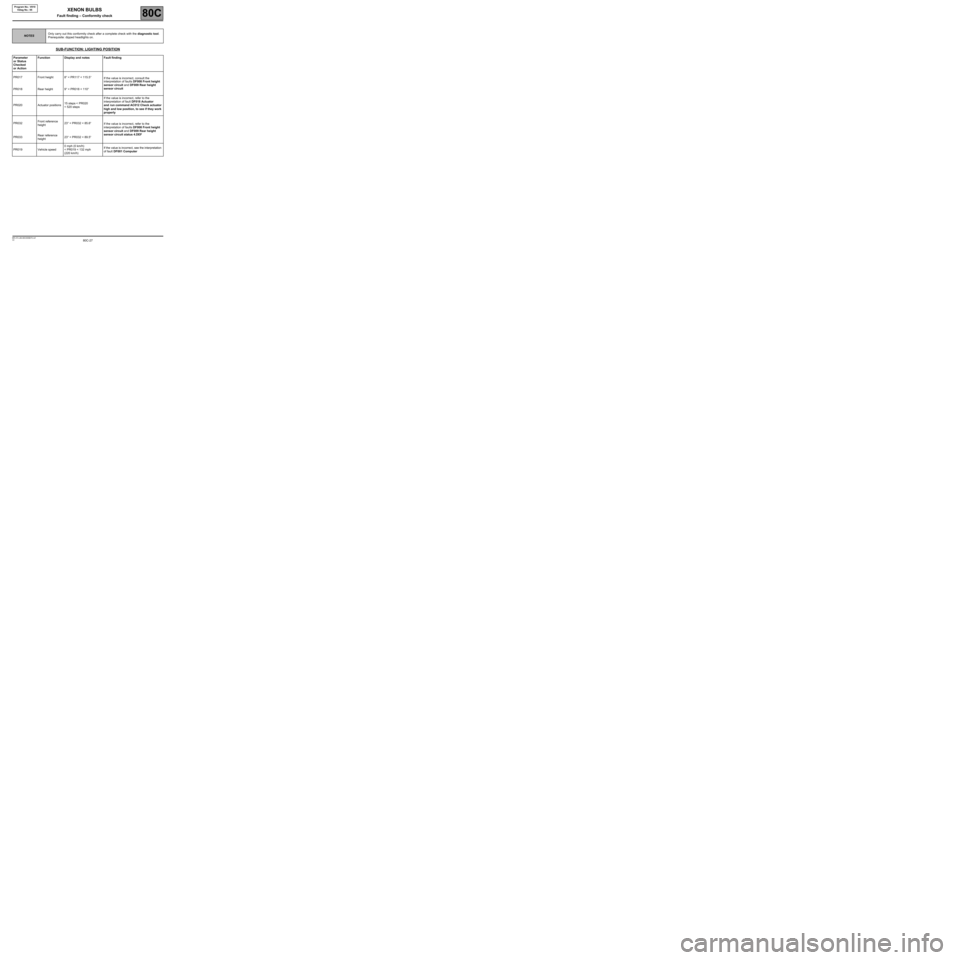

SUB-FUNCTION: LIGHTING POSITION

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool.

Prerequisite: dipped headlights on.

Parameter

or Status

Checked

or ActionFunction Display and notes Fault finding

PR017 Front height 8° < PR117 < 115.5°

If the value is incorrect, consult the

interpretation of faults DF008 Front height

sensor circuit and DF009 Rear height

sensor circuit

PR018 Rear height 9° < PR018 < 110°

PR020 Actuator positions15 steps < PR020

< 520 stepsIf the value is incorrect, refer to the

interpretation of fault DF018 Actuator

and run command AC012 Check actuator

high and low position, to see if they work

properly

PR032Front reference

height23° < PR032 < 85.6°

If the value is incorrect, refer to the

interpretation of faults DF008 Front height

sensor circuit and DF009 Rear height

sensor circuit status 4.DEF

PR033Rear reference

height23° < PR032 < 89.5°

PR019 Vehicle speed0 mph (0 km/h)

< PR019 < 132 mph

(220 km/h)If the value is incorrect, see the interpretation

of fault DF001 Computer

Page 31 of 38

80C-31V2 MR-372-J84-80C000$100.mif

80C

Program No.: V010

Vdiag No.: 05

AFTER REPAIRCarry out another fault finding check on the system.

Clear the fault memory.

Deal with any other faults.

PR017

AND

PR018FRONT HEIGHT

REAR HEIGHT

NOTESThere must be no present or stored faults.

Carry out fault finding only if the values of this parameter are inconsistent.

If the values indicated by the vehicle do not match those of the conformity check, see faults DF008 Front height

sensor circuit and DF009 Rear height sensor circuit, and follow the fault finding procedure.

LAD_V05_PR017 / LAD_V05_PR018

XENON BULBS

Fault finding – Interpretation of parameters

Page 33 of 38

80C-33

AFTER REPAIRCarry out another fault finding check on the system.

Clear the fault memory.

Deal with any other faults.

V2 MR-372-J84-80C000$100.mif

XENON BULBS

Fault finding – Interpretation of parameters80C

Program No.: V010

Vdiag No.: 05

IMPORTANT

Even though a height sensor or actuator is defective, the value of parameter PR020 will always be determined by the

computer.

Parameter PR020 will therefore always be within a range of allowed values even if a component is defective.

PR020ACTUATOR POSITIONS

NOTESThere must be no present or stored faults.

Carry out fault finding only if the values of this parameter are inconsistent.

If the values indicated by the vehicle do not match those of the conformity check, see fault DF018, Actuators,

and follow the fault finding procedure.

To find out if an actuator is malfunctioning, see command AC012 Check actuator high and low position.

LAD_V05_PR020

Page 36 of 38

80C-36

AFTER REPAIRPerform a check using the diagnostic tool.

Deal with any faults found.

V2 MR-372-J84-80C000$120.mif

XENON BULBS

Fault finding – Fault finding charts80C

Program No.: V010

Vdiag No.: 05

ALP 2No correction of the height of the one or both headlights

whatever the vehicle load

NOTESOnly refer to this customer complaint after a complete check with the diagnostic tool.

Confirm that initialisation is performed when the dipped headlights are switched on.

If it is not, the actuators or a circuit component may be defective.

Check the condition of fuse F1K (5A) located in the vehicle's glovebox.

Repair if necessary.

Run command AC012 Check actuator high and low position to find out which headlight is faulty.

Check for mechanical blockage of the headlight (ball joint popped out, reflector stuck, actuator seized).

Make sure that the sensors are properly positioned and mounted on the body, and check the condition

of the linkage.

If all the checks described above fail to solve the fault, replace the faulty adjustment motor(s).

LAD_V05_ALP2

Page 37 of 38

80C-37V2 MR-372-J84-80C000$120.mif

XENON BULBS

Fault finding – Fault finding charts80C

Program No.: V010

Vdiag No.: 05

ALP 3Glare, or beam too high

NOTESOnly refer to this customer complaint after a complete check with the diagnostic tool.

Check that headlights are mounted correctly.

Check that the right-hand and left-hand headlights light at the same level.

If the headlights differ in height, adjust the headlights manually.

Check the condition of system mechanical components (sensor mounting, links).

Check whether the initial front and rear heights PR032 Reference front height and PR033 Reference rear

height are similar.

If there is a major difference between these two parameters, perform a computer calibration (CF001 Computer

calibration described in the Configurations and Programming section).

Run actuator command AC012 Check actuator high and low position.

If the light beam moves: adjust the headlights manually.

If the light beam does not move:

Check that the adjustment motors are actuated when the command is run (motor noise + vibration).

If the motors are actuated but the beam does not move, check the condition of the adjustment motor/headlight

coupling rods. Replace the faulty headlight(s).

LAD_V05_ALP3

AFTER REPAIRPerform a check using the diagnostic tool.

Deal with any faults found.

Page 38 of 38

80C-38V2 MR-372-J84-80C000$120.mif

XENON BULBS

Fault finding – Fault finding charts80C

Program No.: V010

Vdiag No.: 05

ALP 4The left-hand and right-hand dipped headlight beams do not light at the same

height

NOTESOnly refer to this customer complaint after a complete check with the diagnostic tool.

Check that headlights are mounted correctly.

Check that the right-hand and left-hand headlights light at the same level.

If the headlights differ in height, adjust the headlights manually.

Check the condition of system mechanical components (sensor mounting, links).

Check whether the initial front and rear heights PR032 Reference front height and PR033 Reference rear

height are similar.

If there is a major difference between these two parameters, perform a computer calibration (CF001 Computer

calibration described in the Configurations and Programming section).

Run actuator command AC012 Check actuator high and low position.

If the light beam moves: adjust the headlights manually.

If the light beam does not move:

Check that the adjustment motors are actuated when the command is run (motor noise + vibration).

If the motors are actuated but the beam does not move, check the condition of the adjustment motor/headlight

coupling rods. Replace the faulty headlight(s).

LAD_V05_ALP4

AFTER REPAIRPerform a check using the diagnostic tool.

Deal with any faults found.