lock RENAULT SCENIC 2007 J84 / 2.G Electrical Equipment - Xenon Bulbs Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2007, Model line: SCENIC, Model: RENAULT SCENIC 2007 J84 / 2.GPages: 38, PDF Size: 0.12 MB

Page 6 of 38

80C -6V2 MR-372-J84-80C000$020.mif

80C

Program No.: V010

Vdiag No.: 05

1. COMPONENTS OF THE XENON BULB SYSTEM

The system consists of the following components:

–Front vehicle level sensor (the xenon bulb computer is built into this sensor).

–Rear vehicle level sensor.

–Right and left-hand headlight adjustment motor.

–Bulb high-voltage power unit (ballast).

–Xenon bulbs.

The K line can be used for fault finding. The system is not multiplexed.

2. SYSTEM OPERATION

When the control lever is in position (dipped headlights), it sends a signal to the UCH. The UCH processes the signal

and, through the CAN network, asks the Protection and Switching Unit to turn on the xenon bulbs.

When the bulbs come on, the adjustment motor moves through three positions: low, high, initial.

This is its initialisation.

If the vehicle is travelling above 6 mph (10 km/h) when the bulbs come on, there is no initialisation.

The computer manages various signals to adjust the amount of light:

–Vehicle speed: Signal provided by the ABS computer. Above 18 mph (30 km/h), the adjustment motors raise

the bulbs to provide optimum lighting for the driver.

–Vehicle front and rear height: signals from the front and rear height sensors. These sensors track the angular motion

of the vehicle's body (deceleration, acceleration, vehicle loaded). The computer then controls the motors to adjust

the beam and provide optimum lighting.

–System initialisation:

When the vehicle is unlocked, even if the dipped headlights are off, the system moves the adjustment motors

to the low position and then the initial position.

This initialises the system.

XENON BULBS

Fault finding – System operation

Page 7 of 38

80C -7V2 MR-372-J84-80C000$020.mif

XENON BULBS

Fault finding – System operation80C

Program No.: V010

Vdiag No.: 05

3. CONFIGURATION-CALIBRATION OF THE SYSTEM

To calibrate and configure a new computer on a vehicle, follow the configuration procedures in the following order.

a. Vehicle type (CF003)

This configuration activates the adjustment strategies designed for the body type.

The new strategies only take effect after the ignition is switched off and the doors are locked.

Perform configuration as follows:

–Enter the xenon bulbs fault finding mode.

–Make sure that the initial vehicle position indicated by the front and rear sensors is within the allowed range.

–Run configuration CF003 according to the vehicle type:

– Scénic II Strd* (5-seater MPV)

– Scenic II Long (7-seater extended MPV)

– Espace IV

– Velsatis

– Laguna II

–Exit fault finding mode.

–Switch off the ignition.

–Lock the doors using the card.

–The vehicle type has been programmed.

–After unlocking the doors, turn the ignition back on.

–See that the vehicle type has been properly identified by reading configuration LC001, Vehicle type.

b. Computer calibration (CF001)

This calibration must be performed when a system component is replaced (e.g. sensor, headlight etc.).

It enables the computer to store the vehicle's reference level.

To ensure proper configuration and calibration, follow this procedure:

–Check tyre pressure and adjust if faulty.

–Park the vehicle on a level surface under normal driving conditions (luggage compartment empty).

–Vehicle stopped, solid base (no door rattling).

–Driver on board.

–Fuel tank full.

Once computer calibration has been performed, check conformity of the light beam.

If it is incorrect, adjust the headlights manually.

Page 10 of 38

80C-10V2 MR-372-J84-80C000$040.mif

80C

Program No.: V010

Vdiag No.: 05

AFTER REPAIRTurn on dipped-beam headlights.

Check that the system performs its initialisation to verify that the computer has no

faults.

Adjust the headlights manually.

CF001COMPUTER CALIBRATION

NOTESThis configuration enables the computer to store the vehicle's reference level.

Begin by configuring the vehicle type; then calibrate the vehicle level.

The vehicle must be stationary. Also, the front and rear sensor values must be within

the permissible range.

To calibrate the computer, proceed as follows:

–Check tyre pressure and adjust if faulty.

–Park the vehicle on a level horizontal surface.

–Make sure that the headlights have been properly adjusted manually.

–Position the vehicle with the wheels set straight ahead, engine switched off, driver behind the wheel and dipped

headlights on.

–Turn on the ignition and enter xenon bulbs fault finding mode.

–Select Configuration mode.

–Run configuration CF001.

–When calibration is complete, exit fault finding mode.

–Lock and unlock the vehicle doors with the card.

–The computer has now been calibrated.

–Check status LC010, which should indicate Completed.

LC010COMPUTER CALIBRATIONNot completed

Completed

The configuration reading LC010 can have either of two statuses:

–Not completed: The computer has not been calibrated, the vehicle's reference level is unknown, and the

maximum and minimum body height levels have not been programmed.

–Completed: The computer has been calibrated. Normal system operation. The sensor reference levels have

been programmed.

XENON BULBS

Fault finding – Configurations and programming

Page 11 of 38

80C-11

AFTER REPAIRTurn on dipped-beam headlights.

Check that the system performs its initialisation to verify that the computer has no

faults.

Adjust the headlights manually.

V2 MR-372-J84-80C000$040.mif

XENON BULBS

Fault finding – Configurations and programming80C

Program No.: V010

Vdiag No.: 05

* Strd: standard

CF003VEHICLE TYPE

NOTESThis configuration is performed after replacing the computer.

Configuration procedure:

–Connect the CLIP tool and turn on the ignition.

–Enter Xenon bulbs fault finding mode.

–Select configuration CF003 Vehicle type.

–Select the type of vehicle.

–Confirm the configuration.

–Exit fault finding mode and switch off the ignition.

–Lock and unlock the vehicle doors with the card.

–Re-enter "Discharge bulbs" fault finding mode and read LC001 "Vehicle type".

–See that the vehicle type has been properly identified by reading configuration LC001.

LC001VEHICLE TYPE

Not defined

Scénic II Strd*

Scénic II long

Velsatis

Laguna II

Espace IV

Configuration LC001 can have one of six statuses:

–Not defined: Configuration CF003 Vehicle type, has been completed, but the vehicle type programmed does

not match the vehicle diagnosed.

–Scénic II Strd*: Configuration correct: the vehicle type is Scénic.

–Scénic II long: Configuration correct: the vehicle type is the extended Scénic.

–Velsatis: Configuration correct: the vehicle type is Velsatis.

–Laguna II: Configuration correct: the vehicle type is Laguna II.

–Espace IV: Configuration correct: the vehicle type is Espace IV.

Page 15 of 38

80C-15V2 MR-372-J84-80C000$060.mif

XENON BULBS

Fault finding – Interpretation of faults80C

Program No.: V010

Vdiag No.: 05

AFTER REPAIRTurn on the dipped headlights and check that initialisation is performed.

If there is no initialisation, deal with the system faults.

Adjust the headlights manually after each computer calibration.

Carry out a road test followed by a check with the diagnostic tool.

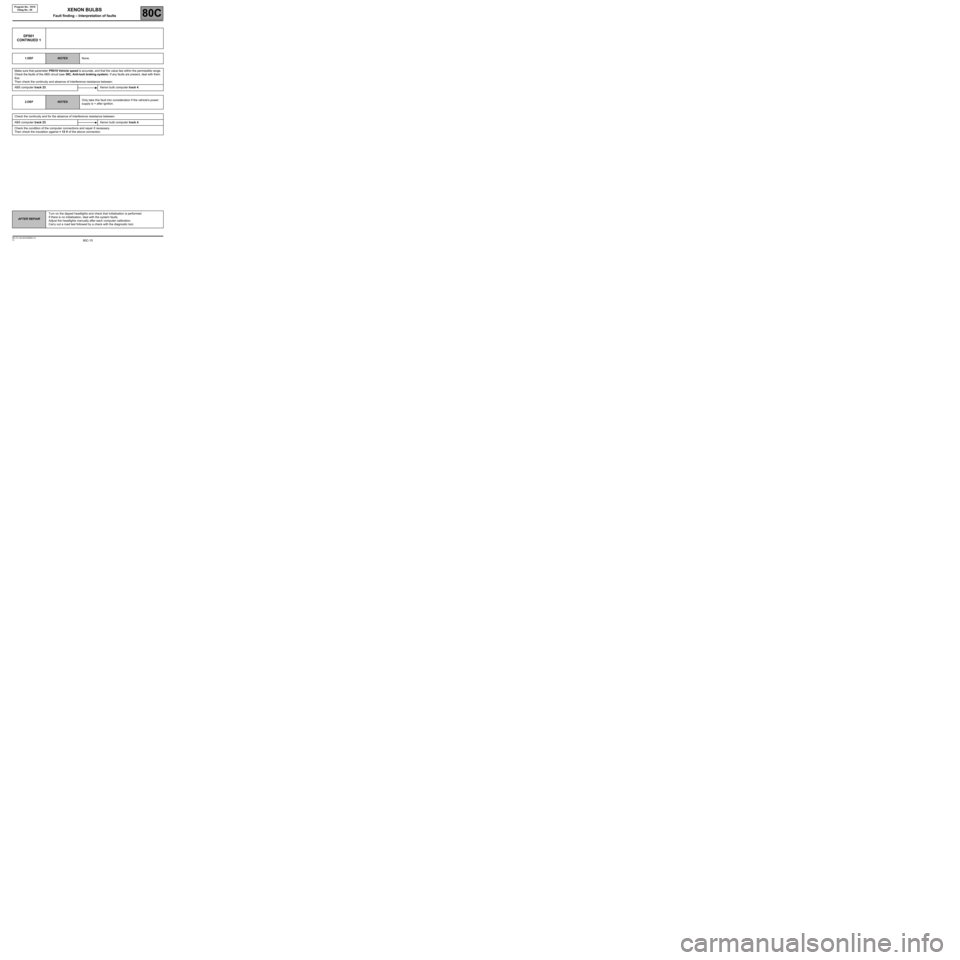

DF001

CONTINUED 1

1.DEFNOTESNone.

Make sure that parameter PR019 Vehicle speed is accurate, and that the value lies within the permissible range.

Check the faults of the ABS circuit (see 38C, Anti-lock braking system). If any faults are present, deal with them

first.

Then check the continuity and absence of interference resistance between:

ABS computer track 23.Xenon bulb computer track 4.

2.DEF

NOTESOnly take this fault into consideration if the vehicle's power

supply is + after ignition.

Check the continuity and for the absence of interference resistance between:

ABS computer track 23.Xenon bulb computer track 4.

Check the condition of the computer connections and repair if necessary.

Then check the insulation against + 12 V of the above connection.

Page 16 of 38

80C-16V2 MR-372-J84-80C000$060.mif

XENON BULBS

Fault finding – Interpretation of faults80C

Program No.: V010

Vdiag No.: 05

AFTER REPAIRTurn on the dipped headlights and check that initialisation is performed.

If there is no initialisation, deal with the system faults.

Adjust the headlights manually after each computer calibration.

Carry out a road test followed by a check with the diagnostic tool.

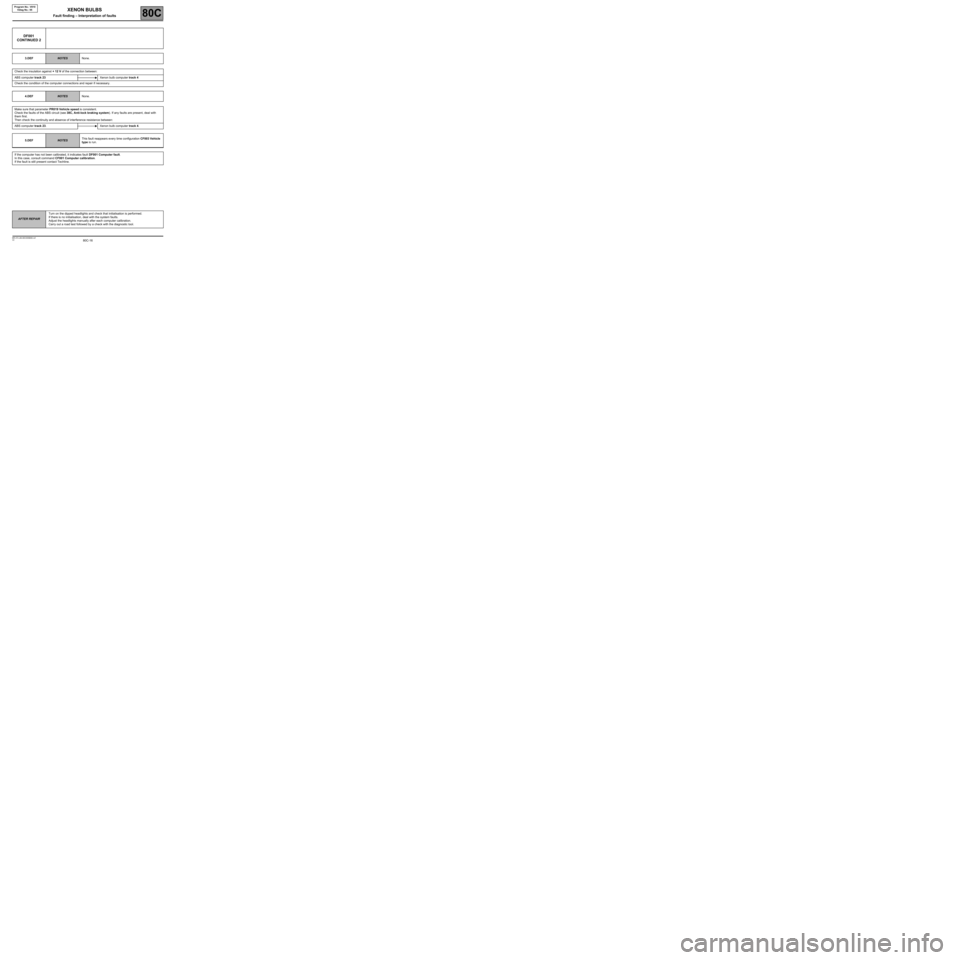

DF001

CONTINUED 2

3.DEFNOTESNone.

Check the insulation against + 12 V of the connection between:

ABS computer track 23Xenon bulb computer track 4

Check the condition of the computer connections and repair if necessary.

4.DEF

NOTESNone.

Make sure that parameter PR019 Vehicle speed is consistent.

Check the faults of the ABS circuit (see 38C, Anti-lock braking system). If any faults are present, deal with

them first.

Then check the continuity and absence of interference resistance between:

ABS computer track 23.Xenon bulb computer track 4.

5.DEF

NOTESThis fault reappears every time configuration CF003 Vehicle

type is run.

If the computer has not been calibrated, it indicates fault DF001 Computer fault.

In this case, consult command CF001 Computer calibration.

If the fault is still present contact Techline.

Page 36 of 38

80C-36

AFTER REPAIRPerform a check using the diagnostic tool.

Deal with any faults found.

V2 MR-372-J84-80C000$120.mif

XENON BULBS

Fault finding – Fault finding charts80C

Program No.: V010

Vdiag No.: 05

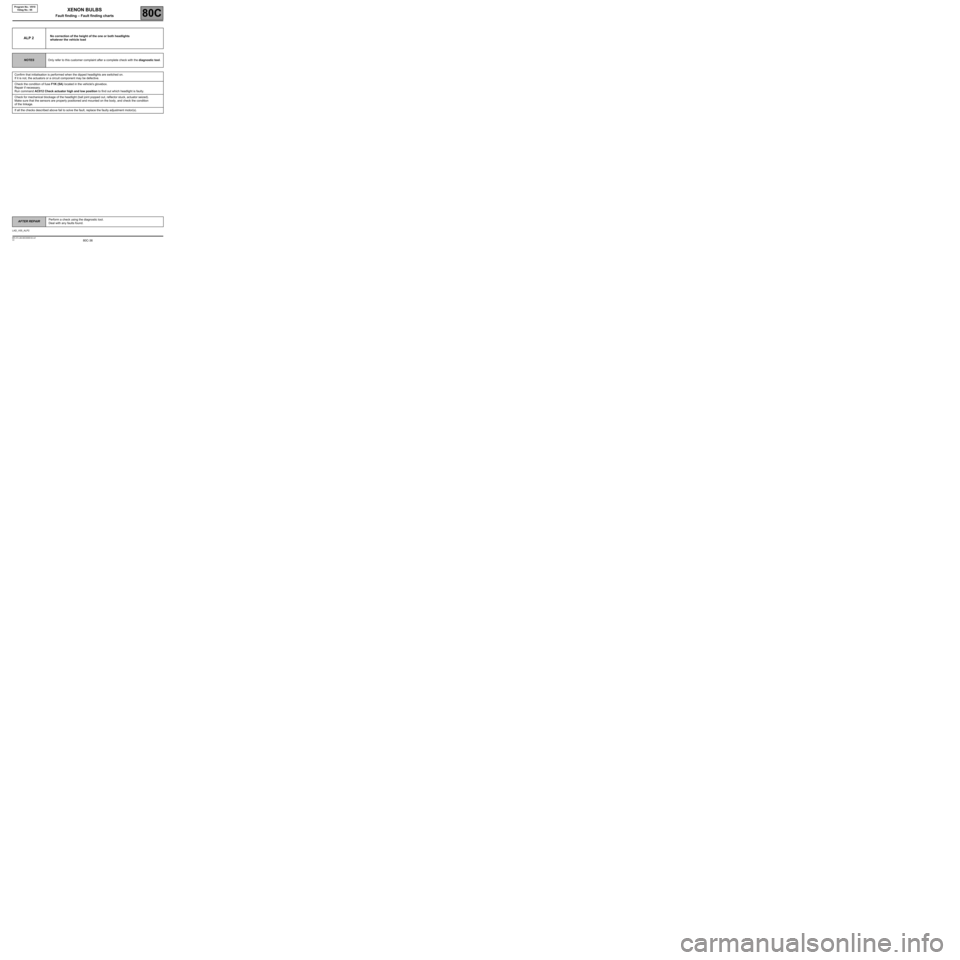

ALP 2No correction of the height of the one or both headlights

whatever the vehicle load

NOTESOnly refer to this customer complaint after a complete check with the diagnostic tool.

Confirm that initialisation is performed when the dipped headlights are switched on.

If it is not, the actuators or a circuit component may be defective.

Check the condition of fuse F1K (5A) located in the vehicle's glovebox.

Repair if necessary.

Run command AC012 Check actuator high and low position to find out which headlight is faulty.

Check for mechanical blockage of the headlight (ball joint popped out, reflector stuck, actuator seized).

Make sure that the sensors are properly positioned and mounted on the body, and check the condition

of the linkage.

If all the checks described above fail to solve the fault, replace the faulty adjustment motor(s).

LAD_V05_ALP2