check engine RENAULT SCENIC 2008 J84 / 2.G Gas Injection LPG 3000 Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2008, Model line: SCENIC, Model: RENAULT SCENIC 2008 J84 / 2.GPages: 107, PDF Size: 0.31 MB

Page 74 of 107

17C-74

MR-372-J84-17C000$472.mif

V2

LPG 3000

Program No.

Vdiag No: 08/10GAS INJECTION

Fault finding - Conformity check17C

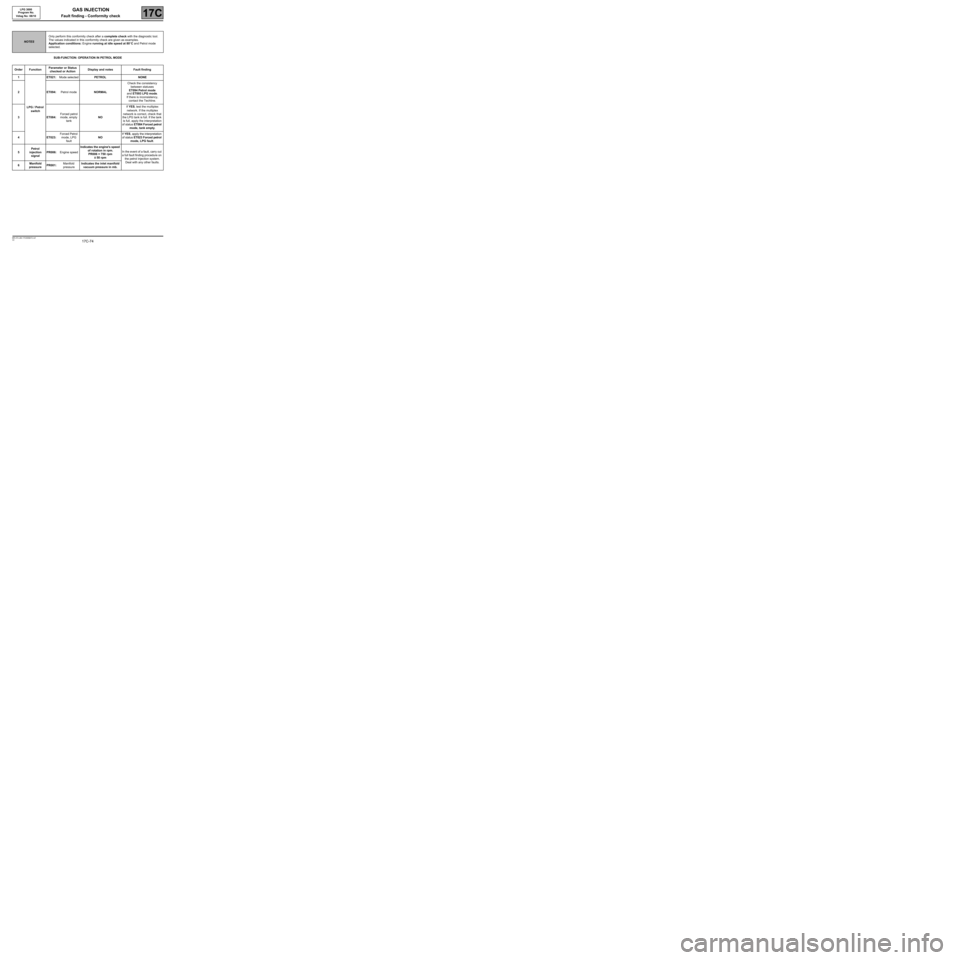

SUB-FUNCTION: OPERATION IN PETROL MODE

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values indicated in this conformity check are given as examples.

Application conditions: Engine running at idle speed at 80°C and Petrol mode

selected.

Order FunctionParameter or Status

checked or ActionDisplay and notes Fault finding

1

LPG / Petrol

switchET021:Mode selectedPETROL NONE

2ET094:Petrol modeNORMALCheck the consistency

between statuses

ET094 Petrol mode

and ET093 LPG mode.

If there is inconsistency,

contact the Techline.

3ET084:Forced petrol

mode, empty

tankNOIf YES, test the multiplex

network. If the multiplex

network is correct, check that

the LPG tank is full. If the tank

is full, apply the interpretation

of status ET084 Forced petrol

mode, tank empty.

4ET023:Forced Petrol

mode, LPG

faultNOIf YES, apply the interpretation

of status ET023 Forced petrol

mode, LPG fault.

5Petrol

injection

signalPR006: Engine speedIndicates the engine's speed

of rotation in rpm.

PR006 = 750 rpm

± 50 rpmIn the event of a fault, carry out

a full fault finding procedure on

the petrol injection system.

Deal with any other faults.

6Manifold

pressurePR001:Manifold

pressureIndicates the inlet manifold

vacuum pressure in mb.

Page 75 of 107

17C-75

MR-372-J84-17C000$472.mif

V2

LPG 3000

Program No.

Vdiag No: 08/10GAS INJECTION

Fault finding - Conformity check17C

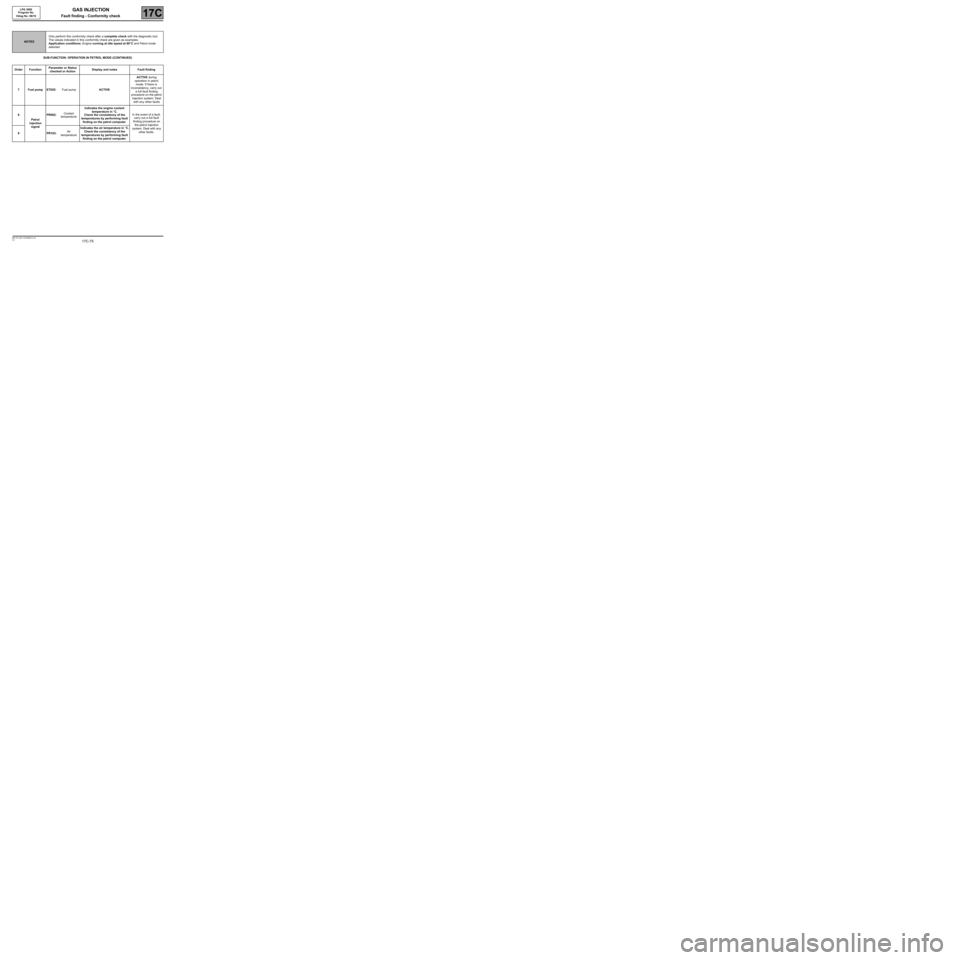

SUB-FUNCTION: OPERATION IN PETROL MODE (CONTINUED)

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values indicated in this conformity check are given as examples.

Application conditions: Engine running at idle speed at 80°C and Petrol mode

selected.

Order FunctionParameter or Status

checked or ActionDisplay and notes Fault finding

7Fuel pump ET025:Fuel pumpACTIVEACTIVE during

operation in petrol

mode. If there is

inconsistency, carry out

a full fault finding

procedure on the petrol

injection system. Deal

with any other faults

8

Petrol

injection

signalPR002:Coolant

temperatureIndicates the engine coolant

temperature in °C.

Check the consistency of the

temperatures by performing fault

finding on the petrol computer.In the event of a fault,

carry out a full fault

finding procedure on

the petrol injection

system. Deal with any

other faults.

9PR103:Air

temperatureIndicates the air temperature in °C.

Check the consistency of the

temperatures by performing fault

finding on the petrol computer.

Page 77 of 107

17C-77

MR-372-J84-17C000$590.mif

V2

17C

GAS INJECTION

Fault finding - Interpretation of statuses

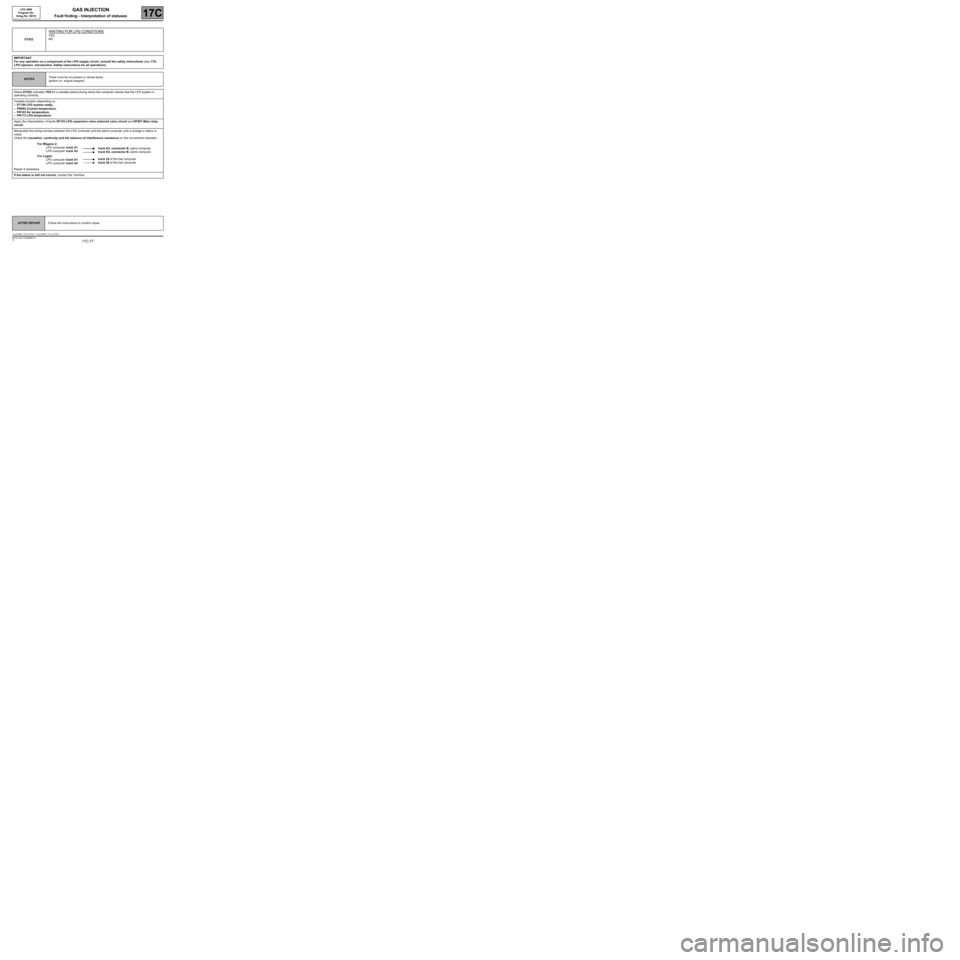

ET022

WAITING FOR LPG CONDITIONS

YES

NO

IMPORTANT

For any operation on a component of the LPG supply circuit, consult the safety instructions (see 17D,

LPG injection, Introduction, Safety instructions for all operations).

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Status ET022 indicates YES for a variable period during which the computer checks that the LPG system is

operating correctly.

Variable duration depending on:

–ET100 LPG system ready,

–PR002 Coolant temperature,

–PR103 Air temperature,

–PR113 LPG temperature.

Apply the interpretation of faults DF103 LPG expansion valve solenoid valve circuit and DF007 Main relay

circuit.

Manipulate the wiring harness between the LPG computer and the petrol computer until a change in status is

noted.

Check the insulation, continuity and the absence of interference resistance on the connections between:

For Mégane 2:

LPG computer track A1

LPG computer track A2

For Logan:

LPG computer track A1

LPG computer track A2track K3, connector B, petrol computer

track K4, connector B, petrol computer

track 25 of the fuel computer

track 26 of the fuel computer

Repair if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

GAZ3000_V08_ET022 / GAZ3000_V10_ET022

LPG 3000

Program No.

Vdiag No: 08/10

MR-372-J84-17C000$590.mif

Page 78 of 107

17C-78

MR-372-J84-17C000$590.mif

V2

GAS INJECTION

Fault finding - Interpretation of statuses

LPG 3000

Program No.

Vdiag No: 08/10

17C

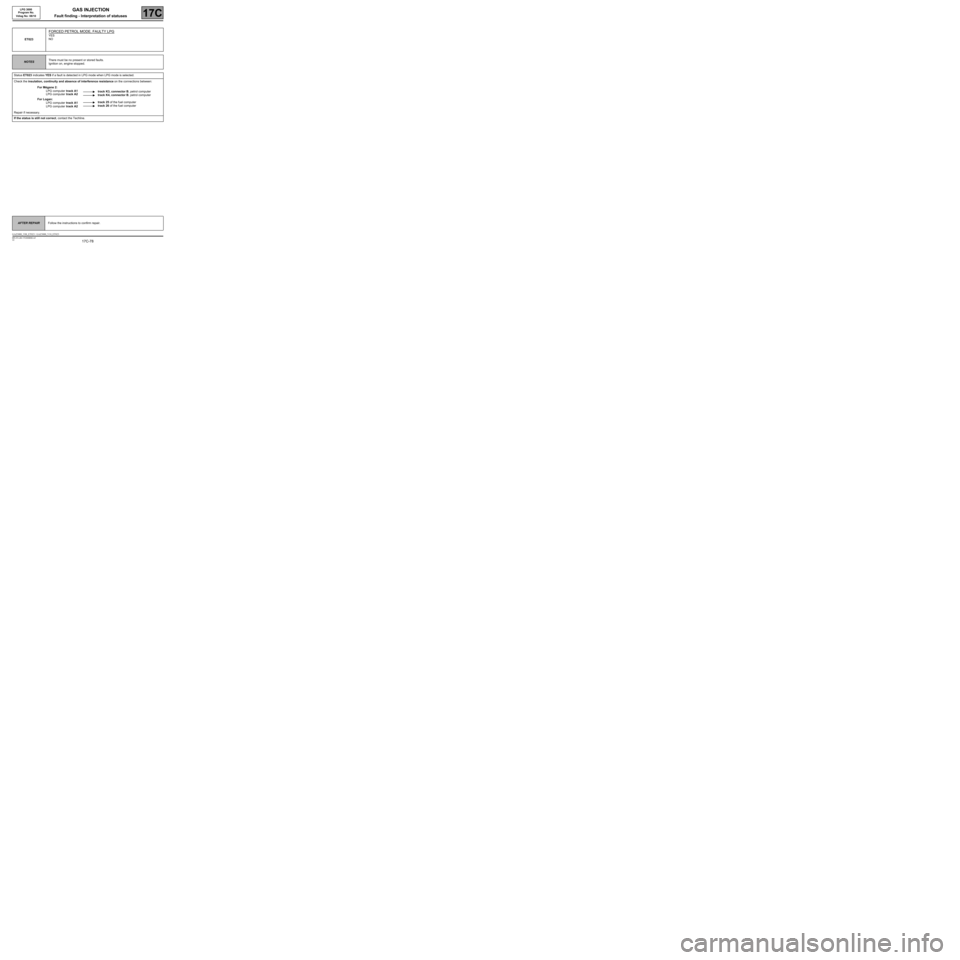

ET023

FORCED PETROL MODE, FAULTY LPG

YES

NO

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Status ET023 indicates YES if a fault is detected in LPG mode when LPG mode is selected.

Check the insulation, continuity and absence of interference resistance on the connections between:

For Mégane 2:

LPG computer track A1

LPG computer track A2

For Logan:

LPG computer track A1

LPG computer track A2track K3, connector B, petrol computer

track K4, connector B, petrol computer

track 25 of the fuel computer

track 26 of the fuel computer

Repair if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

GAZ3000_V08_ET023 / GAZ3000_V10_ET023

Page 79 of 107

17C-79

MR-372-J84-17C000$590.mif

V2

GAS INJECTION

Fault finding - Interpretation of statuses

LPG 3000

Program No.

Vdiag No: 08/10

17C

ET084

FORCED PETROL MODE WITH EMPTY TANK

YES

NO

IMPORTANT

For any operation on a component of the LPG supply circuit, consult the safety instructions (see 17D,

LPG injection, Introduction, Safety instructions for all operations).

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Special note

Check that there is LPG in the tank.

Check that there is no fault on the petrol injection computer.

Test the petrol injection computer (see 17B, Petrol injection).

Status ET084 indicates YES if the LPG tank is empty and LPG mode is selected.

Using parameters PR001 Manifold pressure and PR112 LPG pressure downstream of the expansion valve,

check that PR112 - PR001 = 800 mbar.

If PR112 - PR001 < 800 mbar, check:

–the LPG tank solenoid valve (see DF013 Tank solenoid valve circuit),

–the expansion valve,

–the LPG pressure downstream of the expansion valve (see PR112 LPG pressure downstream of

expansion valve).

Repair or replace the faulty components, if necessary.

If the status is still not correct, check:

–that the injectors are functioning correctly, using commands AC018 Cylinder 4 injector, AC019 Cylinder 3

injector, AC020 Cylinder 2 injector and AC021 Cylinder 1 injector,

–the condition of the hoses between the expansion valve and the injectors.

Repair the faulty components if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

GAZ3000_V08_ET084 / GAZ3000_V10_ET084

Page 80 of 107

17C-80

MR-372-J84-17C000$590.mif

V2

GAS INJECTION

Fault finding - Interpretation of statuses

LPG 3000

Program No.

Vdiag No: 08/10

17C

ET095

LPG TO PETROL TRANSITION

YES

NO

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Status ET095 indicates YES for a variable period during the transition from LPG to petrol mode.

Check that the fuel pump starts when petrol mode is entered.

Check that status ET025 Fuel pump becomes ACTIVE.

If the fuel pump does not start, check:

–the fuel pump cut-off relay (see DF024 Fuel pump cut-off relay circuit),

–the petrol computer (see 17B, Petrol injection).

Repair or replace the faulty components, if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

GAZ3000_V08_ET095 / GAZ3000_V10_ET095

Page 81 of 107

17C-81

MR-372-J84-17C000$590.mif

V2

GAS INJECTION

Fault finding - Interpretation of statuses

LPG 3000

Program No.

Vdiag No: 08/10

17C

ET096

PETROL TO LPG TRANSITION

YES

NO

IMPORTANT

For any operation on a component of the LPG supply circuit, consult the safety instructions (see 17D,

LPG injection, Introduction, Safety instructions for all operations).

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Special note

The duration of the transition varies according to the outside temperature.

Status ET095 indicates YES for a variable period during the transition from LPG to petrol mode.

Check that the fuel pump starts when petrol mode is entered.

Check that status ET025 Fuel pump becomes ACTIVE.

If the fuel pump does not start, check:

–the fuel pump cut-off relay (see DF024 Fuel pump cut-off relay circuit),

–the petrol computer (see 17B, Petrol injection).

Repair or replace the faulty components, if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRFollow the instructions to confirm the repair:

GAZ3000_V08_ET096 / GAZ3000_V10_ET096

Page 82 of 107

17C-82

MR-372-J84-17C000$590.mif

V2

GAS INJECTION

Fault finding - Interpretation of statuses

LPG 3000

Program No.

Vdiag No: 08/10

17C

ET100

LPG SYSTEM READY

YES

NO

IMPORTANT

For any operation on a component of the LPG supply circuit, consult the safety instructions (see 17D,

LPG injection, Introduction, Safety instructions for all operations).

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Status ET100 indicates YES if no LPG fault is present.

Check:

–the LPG tank solenoid valve (see DF013 Tank solenoid valve circuit),

–the general relay (see DF007 Main relay circuit),

–the LPG expansion valve solenoid valve (see DF103 LPG expansion valve solenoid valve),

–the LPG pressure sensor (see DF092 Expansion valve downstream pressure sensor circuit),

–the LPG pressure in the tank (see DF031 LPG pressure downstream of expansion valve).

Repair or replace the faulty components, if necessary.

Check:

–the LPG filling hoses,

–the supply hoses upstream of the expansion valve,

–the expansion valve,

–the hoses downstream of the expansion valve.

Repair or replace the faulty components, if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

GAZ3000_V08_ET100 / GAZ3000_V10_ET100

Page 84 of 107

17C-84

MR-372-J84-17C000$708.mif

V2

17C

GAS INJECTION

Fault finding - Interpretation of parameters

PR003

PRESSURE DIFFERENCE: LPG/ MANIFOLD

IMPORTANT

For an operation on a component of the LPG supply circuit, consult the safety instructions (see 17D,

Gas injection, Introduction, Safety instructions for all operations).

NOTESThere must be no present or stored faults.

Engine running in LPG mode.

Check that the pressure difference is 800 mbar.

Check the consistency in pressure difference using parameters PR001 Manifold pressure, PR003 Pressure

difference: LPG/manifold and PR112 LPG pressure downstream of expansion valve and ensure that

PR003 = PR112 - PR001.

If the fault is still present, manipulate the wiring harness between the manifold pressure sensor and the LPG

pressure/temperature sensor in order to produce a change in status.

Check the connection and condition of the manifold pressure sensor and the LPG pressure / temperature

sensor, and its connections.

If necessary, repair or replace the connector.

If the pressure difference is still inconsistent, apply the interpretation of fault DF031 LPG pressure downstream

of expansion valve.

If the fault is still present, replace the LPG pressure/temperature sensor (see MR 364 Mechanical, 17D,

LPG injection).

If the fault is still present, check the manifold pressure sensor by testing the Petrol computer (see 17B,

Petrol injection, Interpretation of faults).

If the fault is still present, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

GAZ3000_V08_PR003 / GAZ3000_V10_PR003

LPG 3000

Program No.

Vdiag No: 08/10

MR-372-J84-17C000$708.mif

Page 85 of 107

17C-85

MR-372-J84-17C000$708.mif

V2

GAS INJECTION

Fault finding - Interpretation of parameters

LPG 3000

Program No.

Vdiag No: 08/10

17C

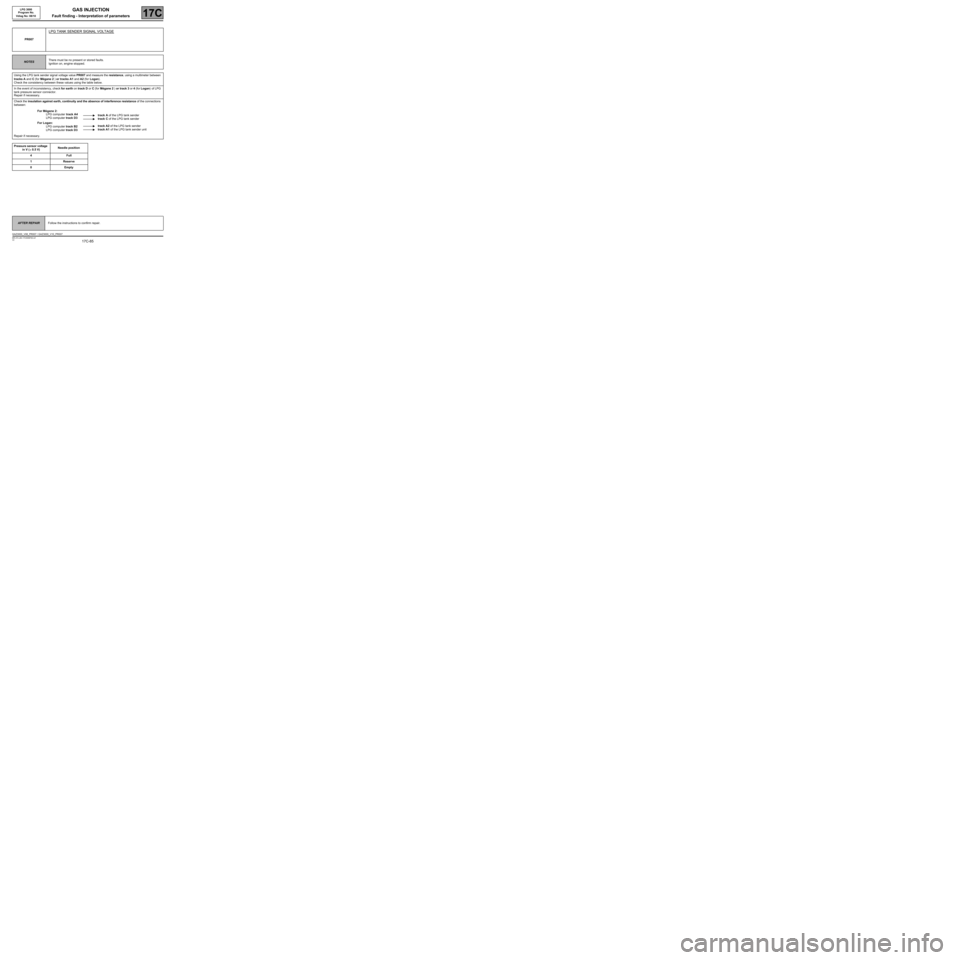

PR007

LPG TANK SENDER SIGNAL VOLTAGE

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Using the LPG tank sender signal voltage value PR007 and measure the resistance, using a multimeter between

tracks A and C (for Mégane 2 ) or tracks A1 and A2 (for Logan).

Check the consistency between these values using the table below.

In the event of inconsistency, check for earth on track D or C (for Mégane 2 ) or track 3 or 4 (for Logan) of LPG

tank pressure sensor connector.

Repair if necessary.

Check the insulation against earth, continuity and the absence of interference resistance of the connections

between:

For Mégane 2:

LPG computer track A4

LPG computer track D3

For Logan:

LPG computer track B2

LPG computer track D3track A of the LPG tank sender

track C of the LPG tank sender

track A2 of the LPG tank sender

track A1 of the LPG tank sender unit

Repair if necessary.

Pressure sensor voltage

in V (± 0.5 V)Needle position

4Full

1Reserve

0Empty

AFTER REPAIRFollow the instructions to confirm repair.

GAZ3000_V08_PR007 / GAZ3000_V10_PR007