light RENAULT SCENIC 2009 J84 / 2.G Automatic Transmission AJ0 BVA Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 162

Page 2 of 162

AUTOMATIC TRANSMISSION

Fault finding - Introduction

23A

23A-2V3 MR-372-J84-23A000$045.mif

123A

AJ0 BVA

Vdiag No.: 04, 05AUTOMATIC TRANSMISSION

Fault finding - Introduction

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type:

Fault finding procedures (this document):

–Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu-Schéma (CD-ROM)

Type of diagnostic tools:

–CLIP

Special tooling required:

3. REMINDERS

Procedure

To perform fault finding on the vehicle's computers, switch on the ignition in fault finding mode.

Proceed as follows:

–vehicle's card in reader;

–press and hold the Start button (longer than 5 seconds) with start-up conditions not fulfilled,

–connect the diagnostic tool and perform the required operations.

To cut off the + after ignition feed, proceed as follows:

–disconnect the diagnostic tool,

–press the Start button twice briefly (less than 3 seconds),

–ensure that the + after ignition feed has been cut off by checking that the computer indicator lights on the

instrument panel have gone out. Vehicle(s): SCENIC II ph2

Function concerned: Automatic transmissionName of computer: Automatic transmission

Vdiag No.: 04, 05

Special tooling required

Multimeter

Elé. 1681Universal bornier

AJ0_V04_PRELI/AJ0_V05_PRELI

MR-372-J84-23A000$045.mif

Page 5 of 162

AUTOMATIC TRANSMISSION

Fault finding - Introduction

23A

23A-5V3 MR-372-J84-23A000$045.mif

AJ0 BVA

Vdiag No.: 04, 05

4. FAULT FINDING PROCEDURE (continued)

Wiring check

Fault finding problems

Disconnecting the connectors and/or manipulating the wiring may temporarily remove the cause of a fault.

Electrical measurements of voltage, resistance and insulation are generally correct, especially if the fault is not

present when the analysis is made (stored fault).

Visual inspection

Look for damage under the bonnet and in the passenger compartment.

Carefully check the fuses, insulators and wiring harness routing.

Look for signs of oxidation.

Physical inspection

While manipulating the wiring, use the diagnostic tool to note any change in fault status from stored to present.

Make sure that the connectors are properly locked.

Apply light pressure to the connectors.

Twist the wiring harness.

If there is a change in status, try to locate the source of the fault.

Inspection of each component

Disconnect the connectors and check the appearance of the clips and tabs, as well as the crimping (no crimping on

the insulating section).

Make sure that the clips and tabs are properly locked in the sockets.

Check that no clips or tabs have been dislodged during connection.

Check the clip contact pressure using an appropriate model of tab.

Resistance check

Check the continuity of entire lines, then section by section.

Look for a short circuit to earth, to + 12 V or with another wire.

If a fault is detected, repair or replace the wiring harness.

Page 9 of 162

AUTOMATIC TRANSMISSION

Fault finding - Role of components

23A

23A - 9V3 MR-372-J84-23A000$135.mif

AJ0 BVA

Vdiag No.: 04, 05AUTOMATIC TRANSMISSION

Fault finding - Role of components

Role of main automatic transmission components

Automatic transmission computer:

The gearbox computer is used to manage the entire system.

Its role is to define the optimum operating mode for the automatic transmission (modify the torque transmitted to the

drive wheels by the automatic transmission), inform the driver (instrument panel, information display, buzzer) and

communicate with the other computers.

To carry out this function, the transmission computer takes account of:

–the operation of the gearbox,

–signals exchanged with other computers,

–driver requests.

Transmission oil temperature sensor:

Its role is to inform the automatic transmission computer of the transmission oil temperature.

Transmission input speed sensor:

Its role is to inform the automatic transmission computer of the turbine speed.

Transmission output speed sensor:

Its role is to inform the automatic transmission computer of the vehicle speed.

Brake light switch:

Its role is to inform the automatic transmission computer that the driver has depressed the brake pedal.

Multifunction switch:

Its role is to inform the automatic transmission computer of the gear lever position.

Shift-lock:

The role of this function is to lock the lever in position "P" and to immobilise the vehicle when stationary.

Solenoid valves:

The solenoid valves are fitted in the factory and cannot be removed from the hydraulic distributor to ensure optimum

gearbox operation, therefore they cannot be replaced separately.

The automatic transmission has two types of solenoid valve:

–2 "all or nothing" solenoid valves,

–6 "progressive" solenoid valves.

Of these 8 solenoid valves, 7 are used to control gear changes in automatic and manual modes, and one solenoid

valve controls the oil pressure in the automatic transmission hydraulic distributor.

Instrument panel display:

The purpose of this function is to manage the transmission of multiplex line signals required for the instrument panel

display.

On the instrument panel:

–a fault warning light,

–a message on the instrument panel in case of irregularity,

–an information display: gear lever position/gear engaged/brake pedal depressed indicator light/lever position in P

or N request indicator light.

On the gear lever:

–Position: P / R / N / D / M+/-,

–Shift-lock: lever lock.

MR-372-J84-23A000$135.mif

Page 20 of 162

AUTOMATIC TRANSMISSION

Fault finding - Role of components

23A

23A - 20V3 MR-372-J84-23A000$225.mif

AJ0 BVA

Vdiag No.: 04, 05

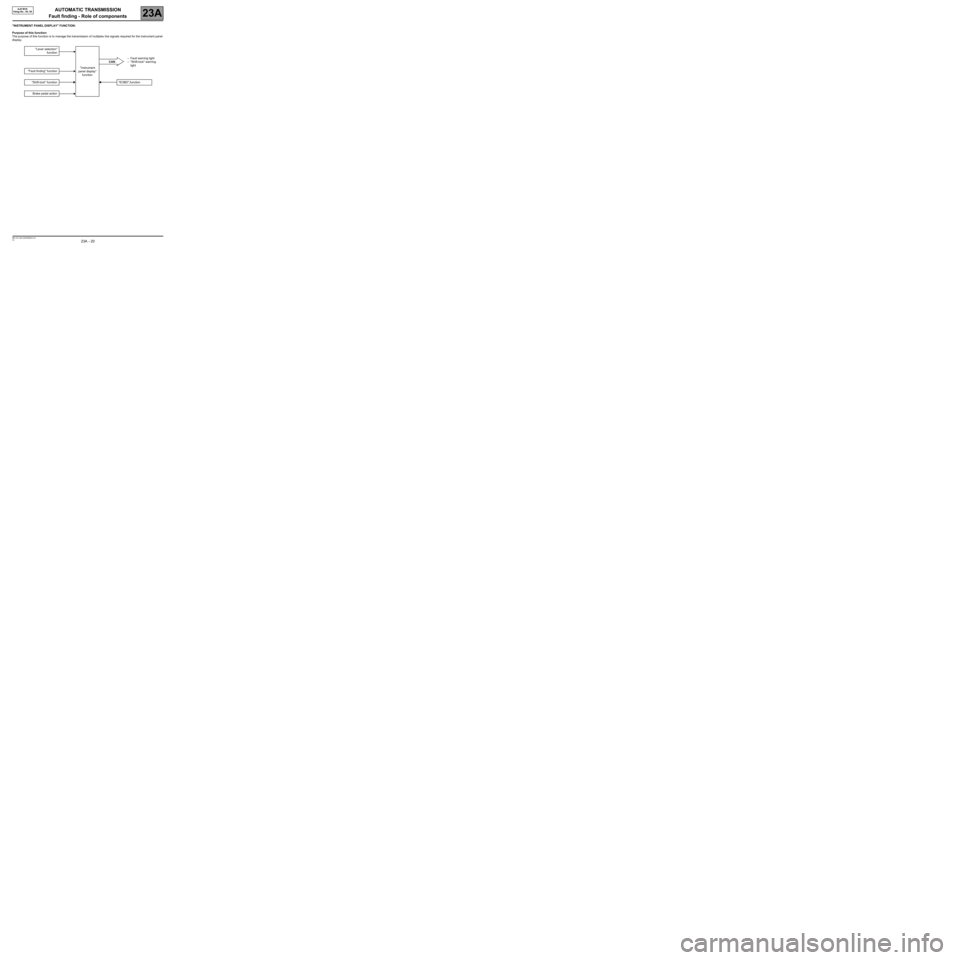

"INSTRUMENT PANEL DISPLAY" FUNCTION:

Purpose of this function:

The purpose of this function is to manage the transmission of multiplex line signals required for the instrument panel

display.

"Lever selection"

function

"Instrument

panel display"

functionCAN–Fault warning light

–"Shift-lock" warning

light

"Fault finding" function

"Shift-lock" function "EOBD",function

Brake pedal action

Page 28 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 28V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

DF023

PRESENT

OR

STOREDGEARBOX OIL TEMPERATURE SENSOR CIRCUIT

1.DEF: Open circuit or short circuit

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after:

–in the event of open circuit or short circuit+:

–+ after ignition feed,

–oil temperature ≤ - 40 ˚C,

–vehicle speed > 6 mph (10 km/h).

–in the event of short circuit-:

–+ after ignition feed,

–oil temperature > 180 ˚C,

–vehicle speed > 6 mph (10 km/h).

–accelerator pedal > 12.5 % and engine speed > 305 rpm.

(detection time in the event of short circuit- is 10 minutes).

Effect on system:

–in the event of open circuit or short circuit+:

Gear change quality is reduced.

lock-up is inhibited.

–in the event of short circuit-:

The transmission operates as if the temperature had increased.

Customer complaint:

–in the event of open circuit or short circuit+:

If the fault occurs while driving, the transmission engages fixed 5th gear.

Restarting is in 3rd gear.

Gear change quality is reduced.

Fault warning light on

–in the event of short circuit-:

Fault warning light on

Use the Wiring Diagrams Technical Note, SCENIC II ph2.

Check that the coolant temperature (see 13B, Diesel injection, EDC16, CP33 M9R 721 Conformity check)

is ≥ - 40 ˚C (the transmission oil temperature sensor is within its operating range).

If the oil temperature ≤ - 40 ˚C, move on to step 1.

If the oil temperature is ≥ - 40 ˚C, deal with the fault; move on to step 2.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

AJ0_V04_DF023/AJ0_V05_DF023

MR-372-J84-23A000$405.mif

Page 31 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 31V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05

DF038

PRESENT

OR

STOREDTURBINE SPEED SENSOR CIRCUIT

1.DEF: Open circuit or short circuit

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after:

–+ after ignition feed,

–with the engine running,

–vehicle speed > 24 mph (40 km/h),

–engine speed > 1500 rpm,

–turbine speed < 600 rpm and accelerator pedal > 0 %.

Effect on system:

Impossible to calculate gear.

Customer complaint:

Gear on which fault occurred is fixed. Restarting in fixed 3rd gear (no more gear

changes). Manual mode is inhibited. Fault warning light comes on.

Use the Wiring Diagrams Technical Note, SCENIC II ph2.

Look for any damage to the wiring harness, and check the condition and connection of the transmission

computer and the turbine speed sensor.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check for + after ignition feed on connection AP4 of component 1060.

Is the + after ignition feed still present?

If YES, move on to step 1.

If NO, move on to step 2.

Step 1:

Check the continuity and insulation of the following connections:

●Connection code 5HN.

●Connection code 5DA.

Between components 119 and 1060.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the intermediate connector R22, if the fault is still present, replace component 1060.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

AJ0_V04_DF038/AJ0_V05_DF038

Page 33 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 33V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05

If the fault is stored:DF067

PRESENT

OR

STORED

LEVER POSITION SWITCH CIRCUIT

1.DEF: Open circuit or short circuit

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after:

–in the event of open circuit or short circuit-:

–+ after ignition feed and change of lever position.

–in the event of short circuit+:

–+ after ignition feed, initial lever position: Position "P", "R", "N" or "D".

Effect on system:

The lever value is held at its previous valid position until the fault is confirmed. Then

the lever position becomes DRIVE (internal software variable) irrespective of the fault.

–If the fault is present and the lever in position "P", the transmission is in "N", hydraulic

neutral.

–If the fault is present and the lever in position "R", the transmission is in "R", hydraulic

reverse.

–If the fault is present and the lever in position "N", the transmission is in "N", hydraulic

neutral.

–If the fault is present and the lever in position "D", the transmission is in "D", hydraulic

forward gear.

lock-up is inhibited.

Customer complaint:

No lever position display on the instrument panel following fault confirmation and

starting impossible.

If the engine is already running when the fault occurs, there is jolting when shifting from

"P" or "N" to "R" or "D".

Fault warning light comes on.

Use the Wiring Diagrams Technical Note, SCENIC II ph2.

Note:

It is possible to produce this fault if the driver or operator voluntarily keep the lever between two normal positions

for longer than 2 seconds.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

AJ0_V04_DF067/AJ0_V05_DF067

Page 37 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 37V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05

DF085

PRESENT

OR

STOREDEVS1 SEQUENCE SOLENOID VALVE CIRCUIT

CO.1 : Open circuit or short circuit

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after:

–in the event of short circuit+:

Lever in "Drive" position, Gear engaged = 1, 2, 3, 4,

and Inconsistency between the solenoid valve control status and the control voltage

–in the event of open circuit:

Lever in "Drive" position, Gear engaged = 1, 2, 3, 4,

and Inconsistency between the solenoid valve control status and the control voltage.

–in the event of short circuit-:

Lever in "Drive" position, Gear engaged = 5, 6,

and Inconsistency between the solenoid valve control status and the control voltage.

OR

Running command AC002 "Sequence solenoid valve 1".

Effect on system:

–in the event of short circuit+:

Neutral engaged.

–in the event of open circuit or short circuit-:

No effect.

Customer complaint:

–in the event of short circuit+:

If the fault occurs while driving, the transmission engages fixed 5th gear.

Restarting is in 5th gear.

Fault warning light comes on.

–in the event of open circuit:

If the fault occurs while driving, the transmission engages fixed 5th gear.

Restarting is in 5th gear.

Fault warning light comes on.

–in the event of short circuit-:

Fault warning light comes on.

Use the Wiring Diagrams Technical Note, SCENIC II ph2.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

AJ0_V04_DF085/AJ0_V05_DF085

Page 41 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 41V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05

DF086

PRESENT

OR

STOREDEVS2 SEQUENCE SOLENOID VALVE CIRCUIT

CO.1: Short circuit or open circuit to + 12 V

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after:

–in the event of short circuit+:

Lever in "Drive" position, gear engaged = 2, 3, 4, 5, 6,

and Inconsistency between the solenoid valve control status and the control voltage.

–in the event of open circuit:

Lever in "Drive" position, lock-up closed, gear engaged = 2, 3, 4, 5, 6,

and Inconsistency between the solenoid valve control status and the control voltage.

–in the event of short circuit-:

Lever in "Drive" position, lock-up open, gear engaged = 1, 2, 3, 4, 5, 6,

OR Gear 1 with engine braking,

and Inconsistency between the solenoid valve control status and the control voltage.

OR

Running command AC002 "Shift solenoid 2".

Effect on system:

–in the event of short circuit+:

If the fault appears with the lock-up closed, gear engaged in "Drive" position = 2, 3, 4,

5, 6, automatic transmission is locked.

–in the event of open circuit:

No effect.

–in the event of short circuit-:

Risk of stalling in 1st with engine braking.

Customer complaint:

If the fault occurs while driving, the transmission engages fixed 5th gear.

Restarting is in 3rd gear.

Fault warning light comes on.

Use the Wiring Diagrams Technical Note, SCENIC II ph2.

Look for any damage to the harness and check the condition and connection of the automatic transmission

computer and automatic transmission connectors.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check for + after ignition feed on connection 5LW of component 754.

If + after ignition feed is present, move on to step 1.

If + after ignition feed is not present, move on to step 8.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

AJ0_V04_DF086/AJ0_V05_DF086

Page 45 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 45V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05

DF091

PRESENT

OR

STORED"LS" PRESSURE REGULATION SOLENOID VALVE CIRCUIT

1.DEF: Open circuit or short circuit

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after:

–in the event of short circuit+ or short circuit-:

difference between current measured and solenoid valve control.

–in the event of open circuit:

Current setpoint > 625 mA.

OR

Running command AC086 ""LS" pressure regulation solenoid valve".

Effect on system:

–in the event of short circuit+:

The line pressure is at its minimum value.

lock-up open.

–in the event of open circuit:

No effect

–in the event of short circuit-:

The line pressure is at its maximum value.

Customer complaint:

–in the event of short circuit+:

Fault warning light comes on.

–in the event of open circuit or short circuit-:

Possible increase in fuel consumption.

Possible jolting during gear changes.

Fault warning light comes on.

Use the Wiring Diagrams Technical Note, SCENIC II ph2.

Look for any damage to the harness and check the condition and connection of the automatic transmission

computer and automatic transmission connectors.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check for + after ignition feed on connection 5LW of component 754.

If + after ignition feed is present, move on to step 1.

If + after ignition feed is not present, move on to step 8.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

AJ0_V04_DF091//AJ0_V05_DF091