torque RENAULT SCENIC 2009 J84 / 2.G Automatic Transmission AJ0 BVA Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 162

Page 9 of 162

AUTOMATIC TRANSMISSION

Fault finding - Role of components

23A

23A - 9V3 MR-372-J84-23A000$135.mif

AJ0 BVA

Vdiag No.: 04, 05AUTOMATIC TRANSMISSION

Fault finding - Role of components

Role of main automatic transmission components

Automatic transmission computer:

The gearbox computer is used to manage the entire system.

Its role is to define the optimum operating mode for the automatic transmission (modify the torque transmitted to the

drive wheels by the automatic transmission), inform the driver (instrument panel, information display, buzzer) and

communicate with the other computers.

To carry out this function, the transmission computer takes account of:

–the operation of the gearbox,

–signals exchanged with other computers,

–driver requests.

Transmission oil temperature sensor:

Its role is to inform the automatic transmission computer of the transmission oil temperature.

Transmission input speed sensor:

Its role is to inform the automatic transmission computer of the turbine speed.

Transmission output speed sensor:

Its role is to inform the automatic transmission computer of the vehicle speed.

Brake light switch:

Its role is to inform the automatic transmission computer that the driver has depressed the brake pedal.

Multifunction switch:

Its role is to inform the automatic transmission computer of the gear lever position.

Shift-lock:

The role of this function is to lock the lever in position "P" and to immobilise the vehicle when stationary.

Solenoid valves:

The solenoid valves are fitted in the factory and cannot be removed from the hydraulic distributor to ensure optimum

gearbox operation, therefore they cannot be replaced separately.

The automatic transmission has two types of solenoid valve:

–2 "all or nothing" solenoid valves,

–6 "progressive" solenoid valves.

Of these 8 solenoid valves, 7 are used to control gear changes in automatic and manual modes, and one solenoid

valve controls the oil pressure in the automatic transmission hydraulic distributor.

Instrument panel display:

The purpose of this function is to manage the transmission of multiplex line signals required for the instrument panel

display.

On the instrument panel:

–a fault warning light,

–a message on the instrument panel in case of irregularity,

–an information display: gear lever position/gear engaged/brake pedal depressed indicator light/lever position in P

or N request indicator light.

On the gear lever:

–Position: P / R / N / D / M+/-,

–Shift-lock: lever lock.

MR-372-J84-23A000$135.mif

Page 10 of 162

AUTOMATIC TRANSMISSION

Fault finding - Operating diagram

23A

23A - 10V3 MR-372-J84-23A000$180.mif

AJ0 BVA

Vdiag No.: 04, 05AUTOMATIC TRANSMISSION

Fault finding - Operating diagram

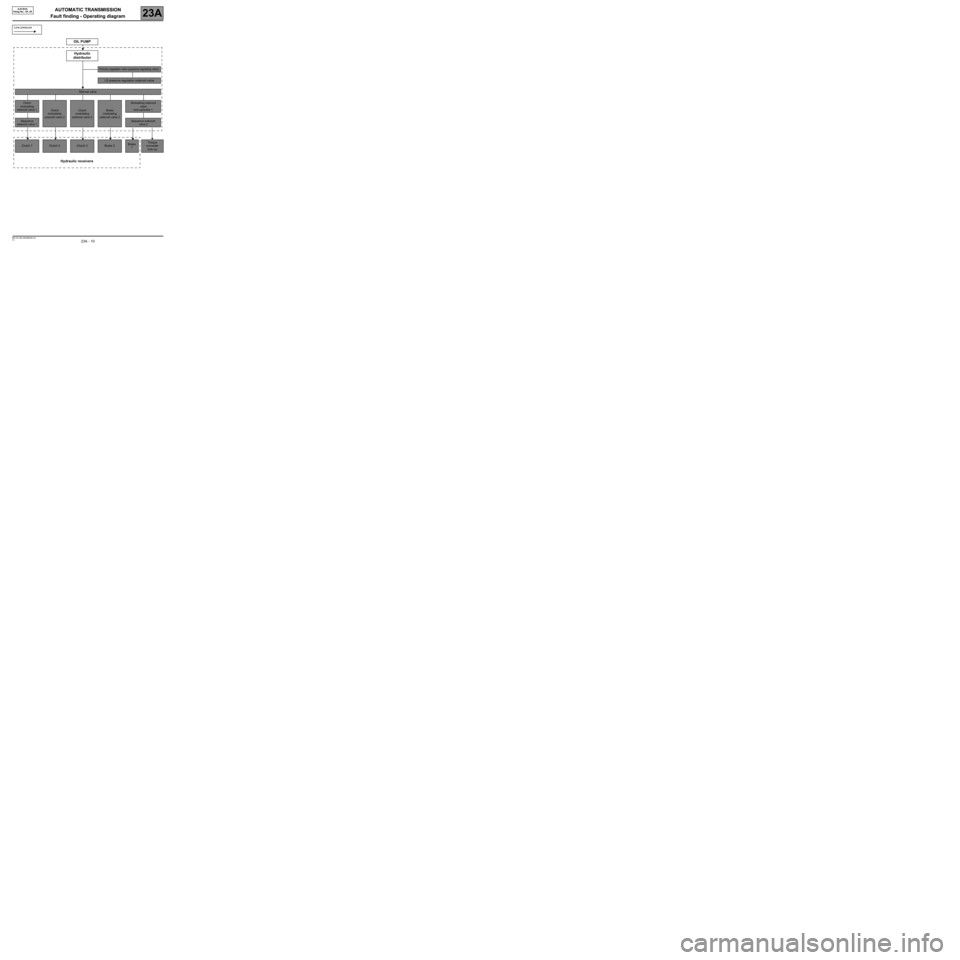

Line pressure

OIL PUMP

Hydraulic

distributor

Primary regulation valve (pressure regulating valve)

LS pressure regulation solenoid valve

Manual valve

Clutch

modulating

solenoid valve 1

Clutch

modulating

solenoid valve 2Clutch

modulating

solenoid valve 3Brake

modulating

solenoid valve 2Modulating solenoid

valve

lock-up/brake 1

Sequence

solenoid valve 1Sequence solenoid

valve 2

Clutch 1 Clutch 2 Clutch 3 Brake 2Brake

1Torque

converter

lock-up

Hydraulic receivers

MR-372-J84-23A000$180.mif

Page 11 of 162

AUTOMATIC TRANSMISSION

Fault finding - Operating diagram

23A

23A - 11V3 MR-372-J84-23A000$180.mif

AJ0 BVA

Vdiag No.: 04, 05

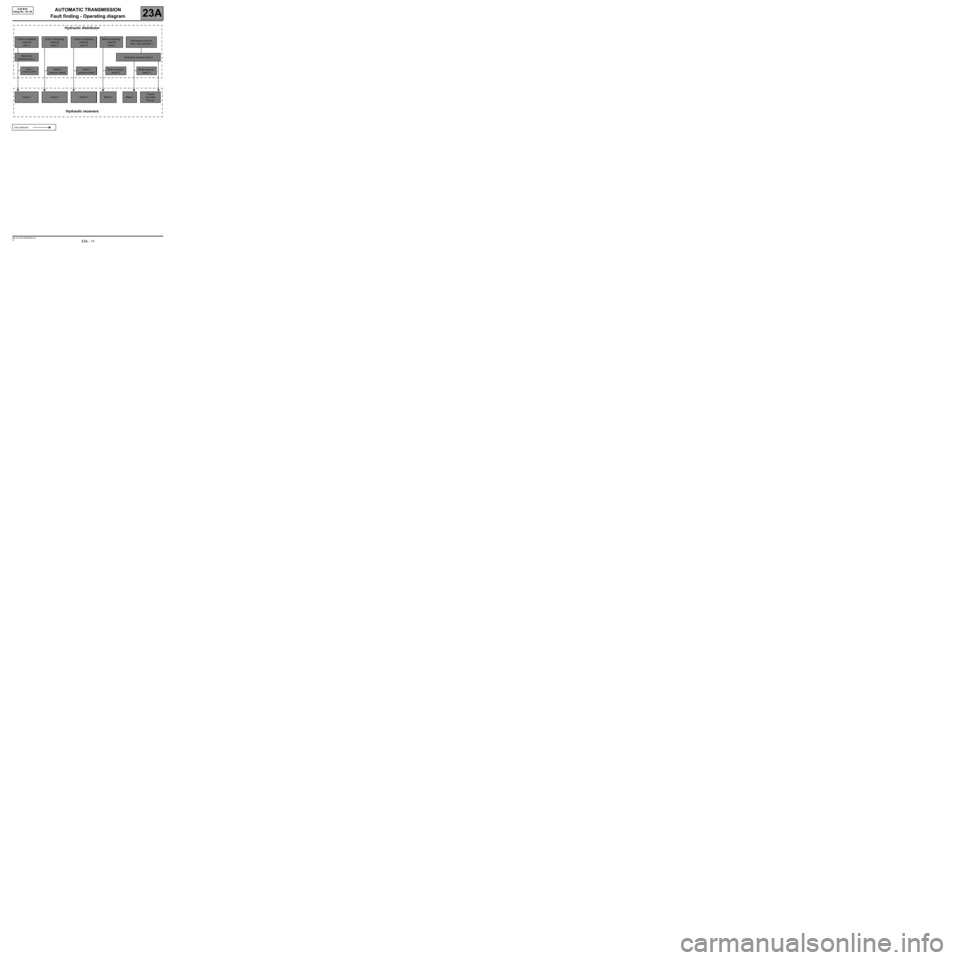

Hydraulic distributor

Clutch modulating

solenoid

valve 1Clutch modulating

solenoid

valve 2Clutch modulating

solenoid

valve 3Brake modulating

solenoid

valve 2Modulating solenoid

valve, lock-up/brake 1

Sequence

solenoid valve 1Sequence solenoid valve 2

Clutch 1

pressure switchClutch 2

pressure switchClutch 3

pressure switchBrake pressure

switch 2Brake pressure

switch 1

Clutch 1 Clutch 2 Clutch 3 Brake 2 Brake 1Torque

converter

lock-up

Hydraulic receivers

Line pressure

Page 14 of 162

AUTOMATIC TRANSMISSION

Fault finding - Role of components

23A

23A - 14V3 MR-372-J84-23A000$225.mif

AJ0 BVA

Vdiag No.: 04, 05

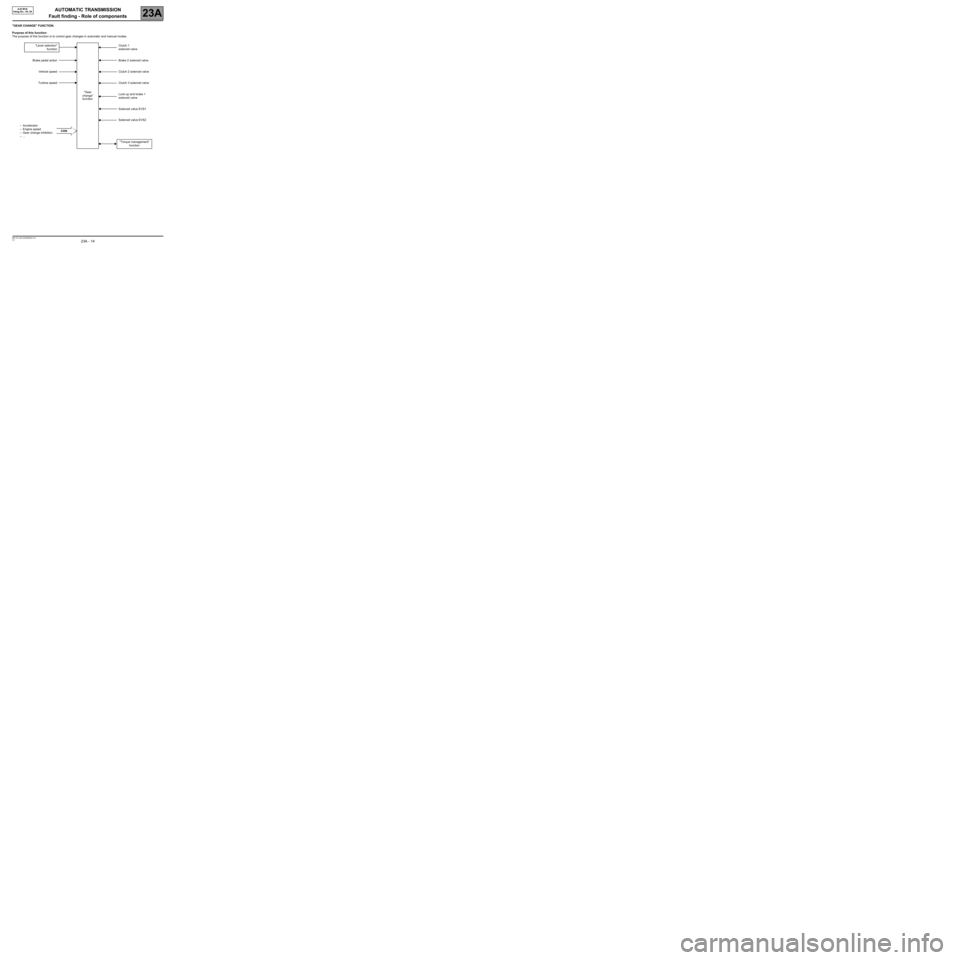

"GEAR CHANGE" FUNCTION:

Purpose of this function:

The purpose of this function is to control gear changes in automatic and manual modes.

"Lever selection"

function

"Gear

change"

functionClutch 1

solenoid valve

Brake pedal action Brake 2 solenoid valve

Vehicle speed Clutch 2 solenoid valve

Turbine speed Clutch 3 solenoid valve

Lock-up and brake 1

solenoid valve

Solenoid valve EVS1

Solenoid valve EVS2

–Accelerator

–Engine speed

–Gear change inhibition

–...CAN

"Torque management"

function

Page 16 of 162

AUTOMATIC TRANSMISSION

Fault finding - Role of components

23A

23A - 16V3 MR-372-J84-23A000$225.mif

AJ0 BVA

Vdiag No.: 04, 05

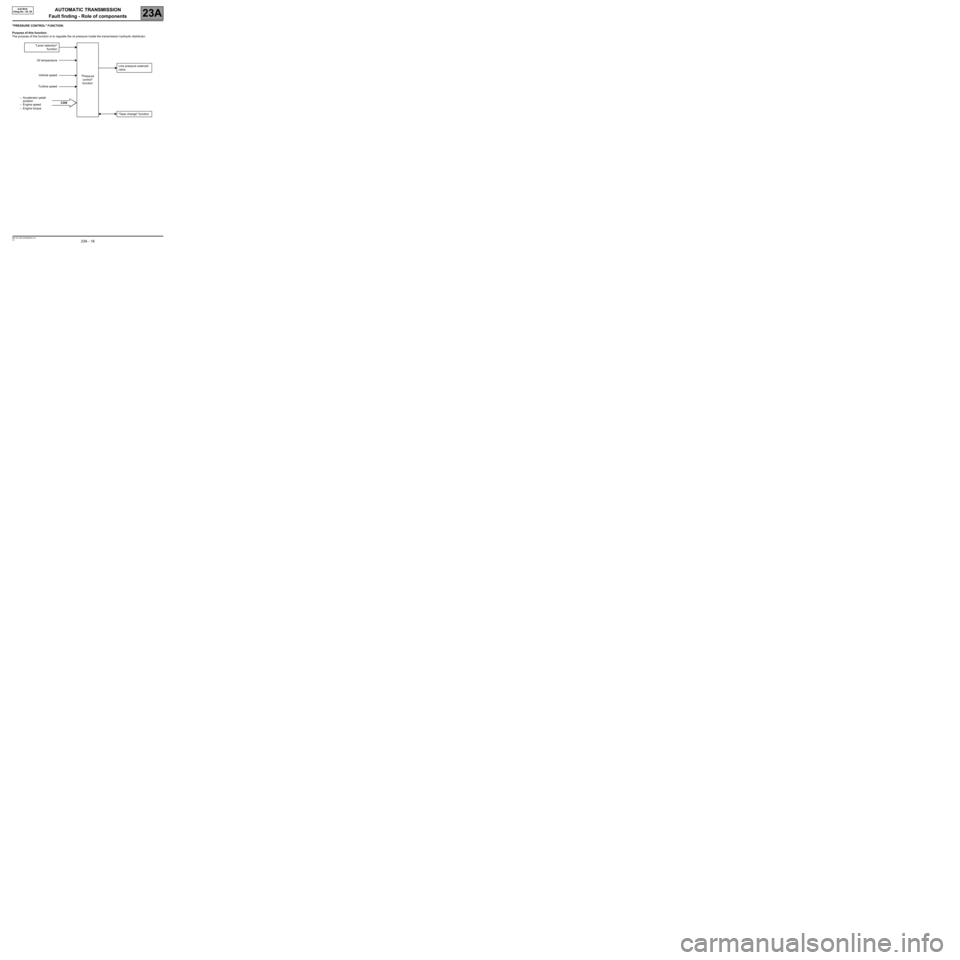

"PRESSURE CONTROL" FUNCTION:

Purpose of this function:

The purpose of this function is to regulate the oil pressure inside the transmission hydraulic distributor.

"Lever selection"

function

"Pressure

control"

function Oil temperature

Line pressure solenoid

valve

Vehicle speed

Turbine speed

–Accelerator pedal

position

–Engine speed

–Engine torqueCAN

"Gear change" function

Page 17 of 162

AUTOMATIC TRANSMISSION

Fault finding - Role of components

23A

23A - 17V3 MR-372-J84-23A000$225.mif

AJ0 BVA

Vdiag No.: 04, 05

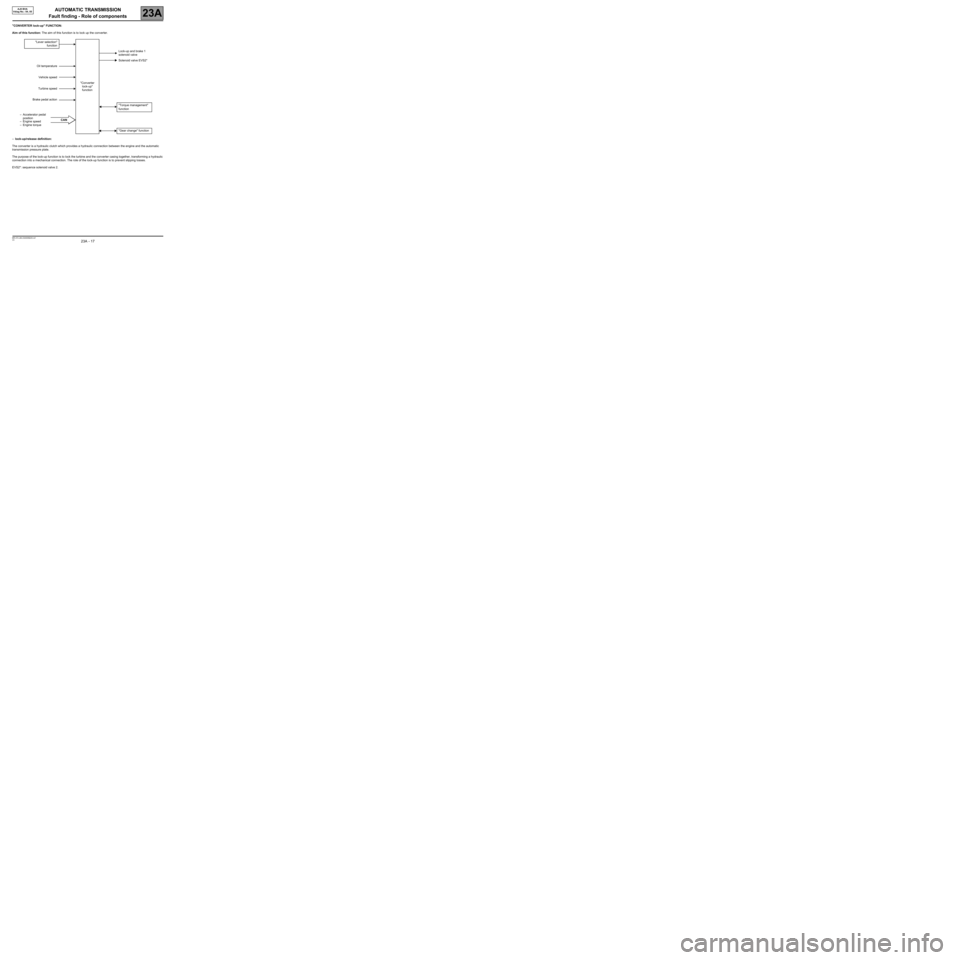

"CONVERTER lock-up" FUNCTION:

Aim of this function: The aim of this function is to lock up the converter.

–lock-up/release definition:

The converter is a hydraulic clutch which provides a hydraulic connection between the engine and the automatic

transmission pressure plate.

The purpose of the lock-up function is to lock the turbine and the converter casing together, transforming a hydraulic

connection into a mechanical connection. The role of the lock-up function is to prevent slipping losses.

EVS2*: sequence solenoid valve 2."Lever selection"

function

"Converter

lock-up"

functionLock-up and brake 1

solenoid valve

Solenoid valve EVS2*

Oil temperature

Vehicle speed

Turbine speed

Brake pedal action

"Torque management"

function

–Accelerator pedal

position

–Engine speed

–Engine torqueCAN

"Gear change" function

Page 18 of 162

AUTOMATIC TRANSMISSION

Fault finding - Role of components

23A

23A - 18V3 MR-372-J84-23A000$225.mif

AJ0 BVA

Vdiag No.: 04, 05

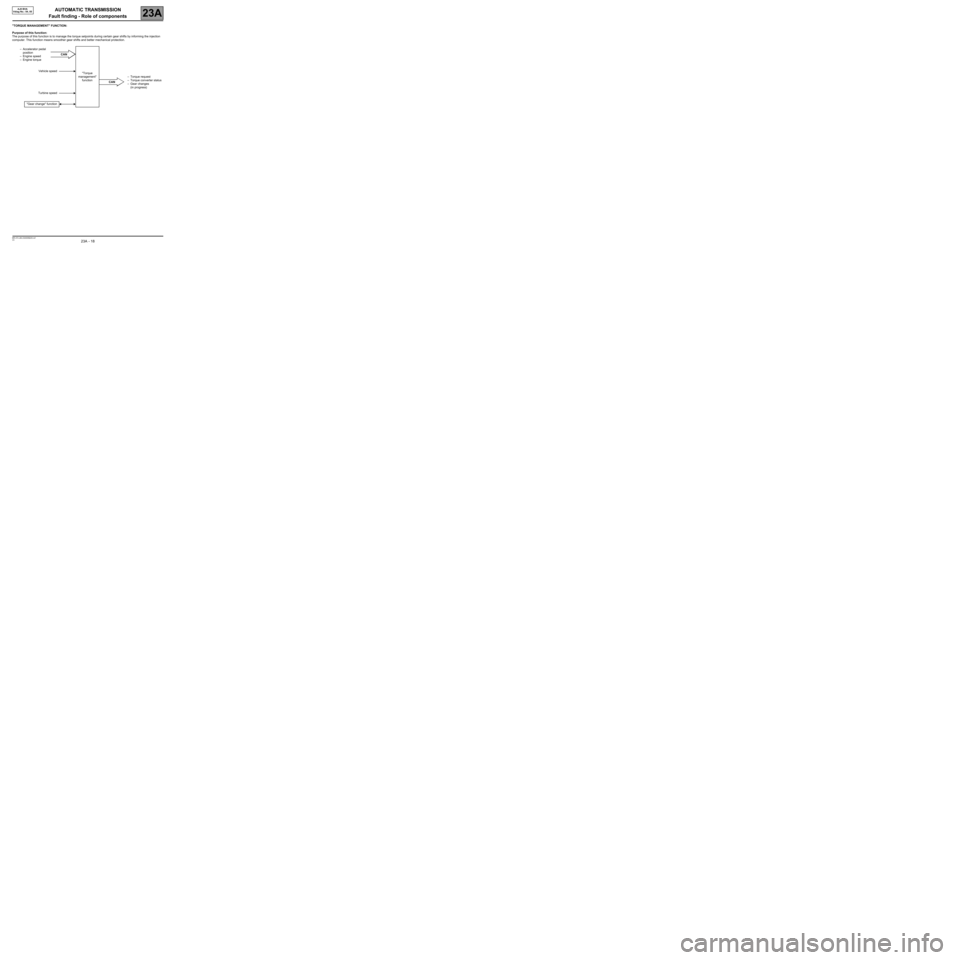

"TORQUE MANAGEMENT" FUNCTION:

Purpose of this function:

The purpose of this function is to manage the torque setpoints during certain gear shifts by informing the injection

computer. This function means smoother gear shifts and better mechanical protection.

–Accelerator pedal

position

–Engine speed

–Engine torqueCAN

"Torque

management"

function Vehicle speed

CAN–Torque request

–Torque converter status

–Gear changes

(in progress)

Turbine speed

"Gear change" function

Page 21 of 162

AUTOMATIC TRANSMISSION

Fault finding - Replacement of components

23A

23A-21V3 MR-372-J84-23A000$270.mif

AJ0 BVA

Vdiag No.: 04, 05AUTOMATIC TRANSMISSION

Fault finding - Replacement of components

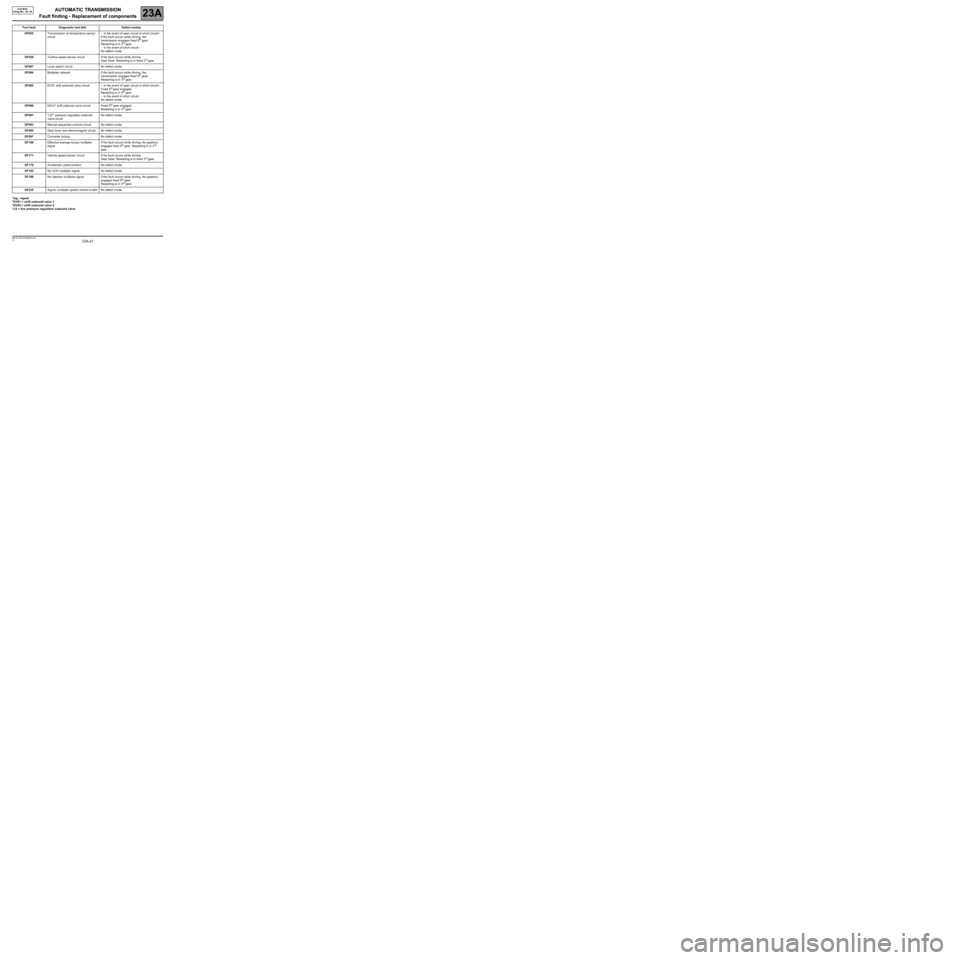

*sig.: signal

*EVS1 = shift solenoid valve 1

*EVS2 = shift solenoid valve 2

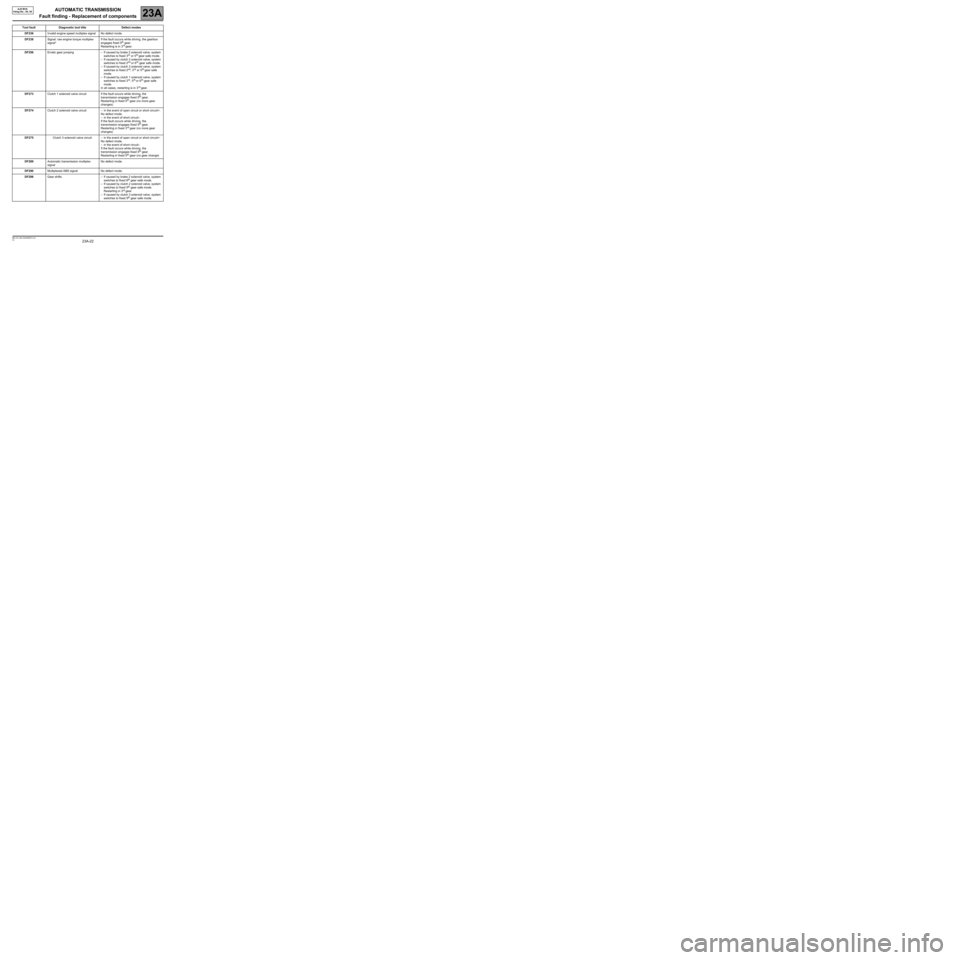

*LS = line pressure regulation solenoid valveTool fault Diagnostic tool title Defect modes

DF023Transmission oil temperature sensor

circuit–in the event of open circuit or short circuit+:

If the fault occurs while driving, the

transmission engages fixed 5

th gear.

Restarting is in 3rd gear.

–in the event of short circuit-:

No defect mode.

DF038Turbine speed sensor circuit If the fault occurs while driving:

Gear fixed. Restarting is in fixed 3

rd gear.

DF067Lever switch circuit No defect mode.

DF084Multiplex network If the fault occurs while driving, the

transmission engages fixed 5

th gear.

Restarting is in 3rd gear.

DF085EVS1 shift solenoid valve circuit – in the event of open circuit or short circuit+:

Fixed 5

th gear engaged.

Restarting is in 5th gear.

–in the event of short circuit-:

No defect mode.

DF086ESV2* shift solenoid valve circuit Fixed 5

th gear engaged.

Restarting is in 3rd gear.

DF091"LS"* pressure regulation solenoid

valve circuitNo defect mode.

DF093Manual sequential controls circuit No defect mode.

DF095Gear lever lock electromagnet circuit No defect mode.

DF097Converter lockup No defect mode.

DF108Effective average torque multiplex

signalIf the fault occurs while driving, the gearbox

engages fixed 5

th gear. Restarting is in 3rd

gear.

DF171Vehicle speed sensor circuit If the fault occurs while driving:

Gear fixed. Restarting is in fixed 3

rd gear.

DF178Accelerator pedal position No defect mode.

DF183No UCH multiplex signal. No defect mode.

DF186No injection multiplex signal If the fault occurs while driving, the gearbox

engages fixed 5

th gear.

Restarting is in 3rd gear.

DF230Signal: multiplex speed vehicle invalid No defect mode.

MR-372-J84-23A000$270.mif

Page 22 of 162

AUTOMATIC TRANSMISSION

Fault finding - Replacement of components

23A

23A-22V3 MR-372-J84-23A000$270.mif

AJ0 BVA

Vdiag No.: 04, 05

Tool fault Diagnostic tool title Defect modes

DF236Invalid engine speed multiplex signal No defect mode.

DF238Signal: raw engine torque multiplex

signal*If the fault occurs while driving, the gearbox

engages fixed 5

th gear.

Restarting is in 3rd gear.

DF256Erratic gear jumping – If caused by brake 2 solenoid valve, system

switches to fixed 3

rd or 5th gear safe mode.

–If caused by clutch 2 solenoid valve, system

switches to fixed 2

nd or 6th gear safe mode.

–If caused by clutch 3 solenoid valve, system

switches to fixed 2

nd, 3rd or 5th gear safe

mode.

–If caused by clutch 1 solenoid valve, system

switches to fixed 3

rd, 5th or 6th gear safe

mode.

In all cases, restarting is in 3

rd gear.

DF273Clutch 1 solenoid valve circuit If the fault occurs while driving, the

transmission engages fixed 5

th gear.

Restarting in fixed 5th gear (no more gear

changes).

DF274Clutch 2 solenoid valve circuit – in the event of open circuit or short circuit+:

No defect mode.

–in the event of short circuit-:

If the fault occurs while driving, the

transmission engages fixed 5

th gear.

Restarting in fixed 3rd gear (no more gear

changes)

DF275Clutch 3 solenoid valve circuit – in the event of open circuit or short circuit+:

No defect mode.

–in the event of short circuit-:

If the fault occurs while driving, the

transmission engages fixed 5

th gear.

Restarting in fixed 5th gear (no gear change)

DF289Automatic transmission multiplex

signalNo defect mode.

DF290Multiplexed ABS signal No defect mode.

DF298Gear shifts – If caused by brake 2 solenoid valve, system

switches to fixed 6

th gear safe mode.

–If caused by clutch 2 solenoid valve, system

switches to fixed 5

th gear safe mode.

Restarting in 3rd gear.

–If caused by clutch 3 solenoid valve, system

switches to fixed 5

th gear safe mode.

Page 24 of 162

AUTOMATIC TRANSMISSION

Fault finding - Replacement of components

23A

23A-24V3 MR-372-J84-23A000$270.mif

AJ0 BVA

Vdiag No.: 04, 05

Replacing the transmission computer:

Remove the automatic transmission computer (see MR 370 mechanical, 23A, Automatic transmission,

Automatic transmission computer, Removal - Refitting).

Refit the automatic transmission computer (see MR 370 mechanical, 23A, Automatic transmission,

Automatic transmission computer, Removal - Refitting).

Establish dialogue with the diagnostic tool.

Use command VP001 Enter VIN.

Run command VP009 Write last After-Sales Service operation date.

Do not carry out any automatic programming if replacing the automatic transmission computer. Automatic

programming is finalised when the vehicle is driven.

In order to optimise the automatic programming before delivering the vehicle to the customer, apply the

"Programming procedure" shown below.

Replacing the hydraulic distributor:

Remove the transmission hydraulic distributor (see MR 370 mechanical, 23A, Automatic transmission,

Hydraulic distributor, Removal - Refitting).

Refit the transmission hydraulic distributor (see MR 370 Mechanical, 23A, Automatic transmission, Hydraulic

distributor, Removal - Refitting).

Replacing the automatic transmission

Remove the transmission (see MR 370,Mechanical, 23A, Automatic transmission, Removal - Refitting).

Refit the transmission (see MR 370, Mechanical, 23A, Automatic transmission, Removal - Refitting).

Establish communication with the diagnostic tool.

Initialise all the programming, use the command RZ009 Self-adapting clearing (Vdiag05 only).

Run command VP009 Write last After-Sales Service operation date.

The self-programming functions are performed when the vehicle is being driven.

In order to optimise the automatic programming before delivering the vehicle to the customer, apply the

"Programming procedure" shown below.

* APV: After-SalesPROGRAMMING PROCEDURE:

Programming conditions:

The automatic gearbox oil temperature should be between 60˚C and 100˚C.

Stationary, engine running, brake pedal depressed:

Engage neutral at least 5 times to consolidate the programming.

While driving:

Engage the same gear at least 5 times (i.e. in the same conditions) to consolidate the programming.

Note:

Gear changes are slow and harsh the first few times the vehicle is driven, until the automatic transmission computer

has carried out its automatic programming.

During upshifts and downshifts, the system analyses variations in oil pressure, components (play in the brakes and

clutches, changes to spring stiffness due to ageing) and input torque, then corrects them in order to maintain the

quality of gear changes.

The system analyses the turbine speed during the 3 phases of drag reduction (selection of Neutral when stationary,

regulation during drag reduction and deselection of Neutral) and corrects this speed by adjusting the converter

lock-up solenoid valve pressure.