battery RENAULT SCENIC 2009 J84 / 2.G Engine And Peripherals EDC16 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 273

Page 179 of 273

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

13B - 179V3 MR-372-J84-13B250$630.mif

INACTIVE

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

ET022

LOW SPEED GMV CONTROL

NOTESSpecial notes:

Only perform these tests if the statuses do not correspond with the system

programming functions.

NOTE:

Status ET022 Low speed GMV request and status ET014 GMV 1 test change their status at the same time.

ACTIVE

The injection computer requests the activation of the low speed GMV when:

–the engine coolant temperature is above 89 ˚C;

–the injection computer has system faults that could lead to the engine overheating,

–the air conditioning is switched on by the driver.

When the high speed fan is supplied:

–status ET022 Low speed GMV request becomes ACTIVE and status ET014 GMV

1 test becomes RUNNING.

The low-speed engine fan assembly stops when:

–the engine coolant temperature is below 89 ˚C;

–no fault which could cause engine overheating is present in the injection

system.

–the air conditioning is not switched on by the driver.

IMPORTANTWARNING

If the UPC does not detect the injection computer frames, the low speed engine

fan is supplied until the battery is completely discharged.

In the event that the low-speed engine fan assembly is faulty, the high-speed

engine fan assembly will then be activated.

AFTER REPAIRCarry out a road test followed by a complete test with the diagnostic tool.

EDC16_V51_ET022

Page 201 of 273

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

13B - 201V3 MR-372-J84-13B250$630.mif

STATUS 18

STATUS 20

STATUS 21

STATUS 11, 22

STATUS 8

STATUS 4, 17

STATUS 2

STATUS 3, 14, 16

STATUSES 1, 5, 6,

7, 9, 10, 12, 13, 15,

19, 23, 24

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

ET651

EGR PROGRAMMING CUT-OFF

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

NONE

No EGR cut-off, the EGR valve is working properly in accordance with the

computer programs.

Switch off the ignition and wait 1 minute.

Switch the ignition on and check for faults.

Check the engine battery voltage with the engine stopped and then running.

If no faults are present or stored, restart the vehicle and test at idle speed.

Do not accelerate too much and reach an engine speed that is too high.

Accelerate above idling speed for a few seconds.

Check that the clutch pedal (ET405 Clutch pedal switch) is not pressed and that the

vehicle has stopped completely.

Test the present and stored faults and repair.

Reinitialise the EGR offsets by consulting the interpretation of command

SC036 Reinitialisation of programming and select EGR valve".

Allow the engine to heat up until this cut-off disappears.

Check that the regeneration of the particle filter in progress has completely finished.

Allow the engine to cool until this cut-off disappears.

Too low atmospheric pressure, the EGR valve is disabled.

AFTER REPAIRSwitch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

EDC16_V51_ET651

Page 215 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -215V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

AC001

PREHEATING UNIT

NOTESThis command is only carried out if the fault DF025 Preheating unit fault finding

connection, or DF017 Preheating unit control circuit is present or stored and if no

other fault is present.

Refer to the Wiring diagrams Technical Note for the vehicle to locate the fuses and

relays concerned.

Connect the diagnostic tool and turn on the ignition.

With the preheating unit connected:

–connect the negative terminal of the voltmeter to track 8 of the preheating unit,

–connect the positive terminal of the voltmeter to the + 12 V battery,

–run command AC001 Preheating unit.

if the voltmeter does not indicate the battery voltage while the command is running (ten 1 second ON/OFF cycles):

1Check the condition of the preheating unit supply fuse F01 (70A).

Replace it if necessary.

2Check the following connections for continuity and the absence of interference resistance:

Injection computer connector C track E2 track 8 of the preheating unit connector

Injection computer connector C track A4 Track 3 of the preheating unit connector

Repair if necessary.

3Check the connections on the pre-postheating unit, heater plugs and injection computer.

Repair if necessary.

4Measure the resistance of the heater plugs. If this resistance is greater than 2 Ω replace the faulty plug(s).

5Check the continuity and absence of interference resistance between:

preheating unit track 1 cylinder 3 heater plug

preheating unit track 2 cylinder 1 heater plug

preheating unit track 6 cylinder 4 heater plug

preheating unit track 7 cylinder 2 heater plug.

6Then check for + 12 V supply on track 4 of the preheating relay connector.

If the fault is still present, replace the preheating unit.

EDC16_V51_AC001

Page 217 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -217V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

* Opening cyclic ratio signalAC004

CONTINUED

Turbocharger control circuit check (continued)

4) Turbocharger operation check:

a) Connect a vacuum pump to the hose connected to the turbocharger control diaphragm.

Apply a negative pressure of 800 ± 100 mbar:

If there is a leak, replace the turbocharger (diaphragm included).

b) Check the control rod movement and setting (see MR 364, Mechanics, 12B, Turbocharging).

If the control rod is sticking, replace the turbocharger.

c) Engine cold and stopped:

Remove the turbocharger inlet duct and check that the compressor turns freely on the axis.

d) If the fault persists:

Check that the exhaust manifold is not leaking.

Check that the exhaust is not blocked.

Carry out the necessary repairs.

5) Computer output stage check: (solenoid valve connected).

This operation can only be carried out if the checks indicated in step no. 2 are not conclusive.

Either with the voltmeter: Connect the voltmeter earth lead on track 2 of the solenoid valve and the positive

lead on track 1.

Clear any solenoid valve fault then run command AC004:

●The voltmeter should display ten cycles of two successive voltages ~ = battery voltage X opening cycle ratio*

in process.

that is: ~ 2.5 V (opening cyclic ratio* of 20%) then ~ 8.7 V (opening cyclic ratio* of 70%).

Or with the oscilloscope (at 5 V range/division and 1 ms/div time base): Connect the earth lead of the

oscilloscope to the battery earth and the positive test pin to track 2 of the solenoid valve.

Clear any solenoid valve faults, then run command AC004:

●the oscilloscope should display a square wave signal of 12.5 V in amplitude at a frequency of 140 Hz

(with an opening cyclic ratio* passing from ~ 20 to ~ 70%).

If the measurement is correct, replace the solenoid valve.

If the measurement does not show any control or continuous voltage, contact the Techline.

Page 218 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -218V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

* Opening cyclic ratio signalAC011

RAIL PRESSURE REGULATOR

NOTESThis command is used to check:

–the operation of the pressure regulator,

–and the high pressure injection circuit.

Step 1

Measure the pressure regulator resistance between tracks 1 and 2.

–Replace the regulator if its resistance is not approximately: 3 Ω ± 0.5 at 20˚C.

Check the continuity and absence of interference resistance of the following connections:

Injection computer brown 48-track connector B,

track M4track 2 of the rail pressure regulator connector

+ 12 V after relaytrack 1 of the rail pressure regulator connector

If, when running command AC011, you can hear a slight whistling noise and a crunching noise from the pressure

regulator, go to step 2. Otherwise, ensure that the computer output stage is functioning correctly:

Using a voltmeter:

With the solenoid valve connected, connect the voltmeter earth lead to track 2 of the fuel pressure solenoid valve

and the positive cable to track 1. Clear any fuel pressure solenoid valve faults, then run command AC011:

●The voltmeter should display two successive voltages: ~ 2.5 V for an opening cyclic ratio of 20% then ~ 8.75 V

for an opening cyclic ratio* of 70% (ten cycles).

Or using an oscilloscope (range 5 V/division and with time base 1 ms/division):

With the solenoid valve connected, connect the oscilloscope earth to the battery earth and the positive contact point

on track 2 of the fuel pressure solenoid valve; clear any fuel pressure solenoid valve faults then run command

AC011:

●the oscilloscope should display a square wave signal with an amplitude of 12.5 V at a frequency of 185 Hz (with

an OCR* passing from 20 to 70%).

If the measurement is correct, replace the regulator.

If the measurement is not correct, contact the Techline.

EDC16_V51_AC011

Page 223 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -223V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Fault Finding Chart

ALP1 No dialogue with engine management computer

Try to establish dialogue with a computer on another vehicle to make sure that the diagnostic tool is not faulty.

Check the battery voltage and make the necessary adjustments to obtain a correct voltage (9.5 V < Battery

voltage < 17.5 V).

If the tool is not at fault, and dialogue cannot be established with any other computer on the same vehicle, the cause

could be a faulty computer interfering on the multiplex network.

disconnect the engine management computer.

try to establish dialogue with another computer.

if the fault is still present, reconnect the computer and proceed by elimination by successively disconnecting all the

following computers (according to wiring diagram and equipment): air conditioning, airbag, abs and esp, uch,

instrument panel, central communication unit, proximity sensor.

Try to establish dialogue after disconnecting each line:

if, after a disconnection, you manage to establish dialogue, perform the fault finding procedure for the relevant

computer.

perform fault finding on the multiplex network using the diagnostic tool.

Check for the presence and the condition of the injection fuses on the UPC, and/or the engine fuse box.

check the connection of the computer connectors and the condition of its connections.

Check the injection computer earths (quality, oxidation, earth bolts secure on the battery terminal).

Check that the supply to the computer is correct:

Earth on tracks H1, G4 and H4 of black 32-track connector A.

+ after ignition feed on track D1 of black 32 track connector A.

Check that the power supply to the diagnostic socket is correct:

+ before ignition feed on track 16.

+ after ignition feed on track 1.

Earth on tracks 4 and 5.

If dialogue has still not been established after these checks, contact the techline.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V51_ALP1

Page 248 of 273

DIESEL INJECTION

Fault finding – Test13B

13B -248V3 MR-372-J84-13B250$900.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

TEST5 Turbocharger control solenoid valve test

Start the engine and let it run at idle speed for 1 min.

Check the battery voltage.

If the value of PR071 Computer power supply voltage is greater than 13 V, continue the test.

If not, check the charging circuit, then carry out a road test to confirm that the fault has disappeared.

Checking the vacuum at the pressure regulator inlet

Let the engine idle.

Check the engine temperature using the CLIP parameter PR064 Coolant temperature.

Let the engine warm up until the temperature reaches 80˚C.

Disconnect the vacuum pipe from the pressure regulator end piece.

Connect a vacuum pressure gauge to the end of the disconnected pipe and put it in the vacuum measurement

position.

Accelerate rapidly by fully depressing the accelerator pedal and releasing it immediately.

The total duration of pressing and holding in the full load position must not exceed 1 second.

During this acceleration, the engine speed must reach a value between 3000 and 4000 rpm.

Repeat the operation three times.

Read the maximum vacuum displayed by the pressure gauge during the increase in speed, the decrease in speed

and after returning to idle speed.

Tolerance intervals to be respected for the vacuum value:

-1 bar < CORRECT vacuum value < - 0.6 bar

-0.6 bar < INCORRECT vacuum value < 0 bar

Does the vacuum at the turbocharger pressure regulator inlet, displayed by the pressure gauge, respect

the tolerance interval?

NO YES

The solenoid valve is correct.

If the customer complaint is Smoke from the

exhaust, apply ALP11 Smoke from the exhaust.

Otherwise, apply test 6 Turbocharger.

1

EDC16_V51_TEST5

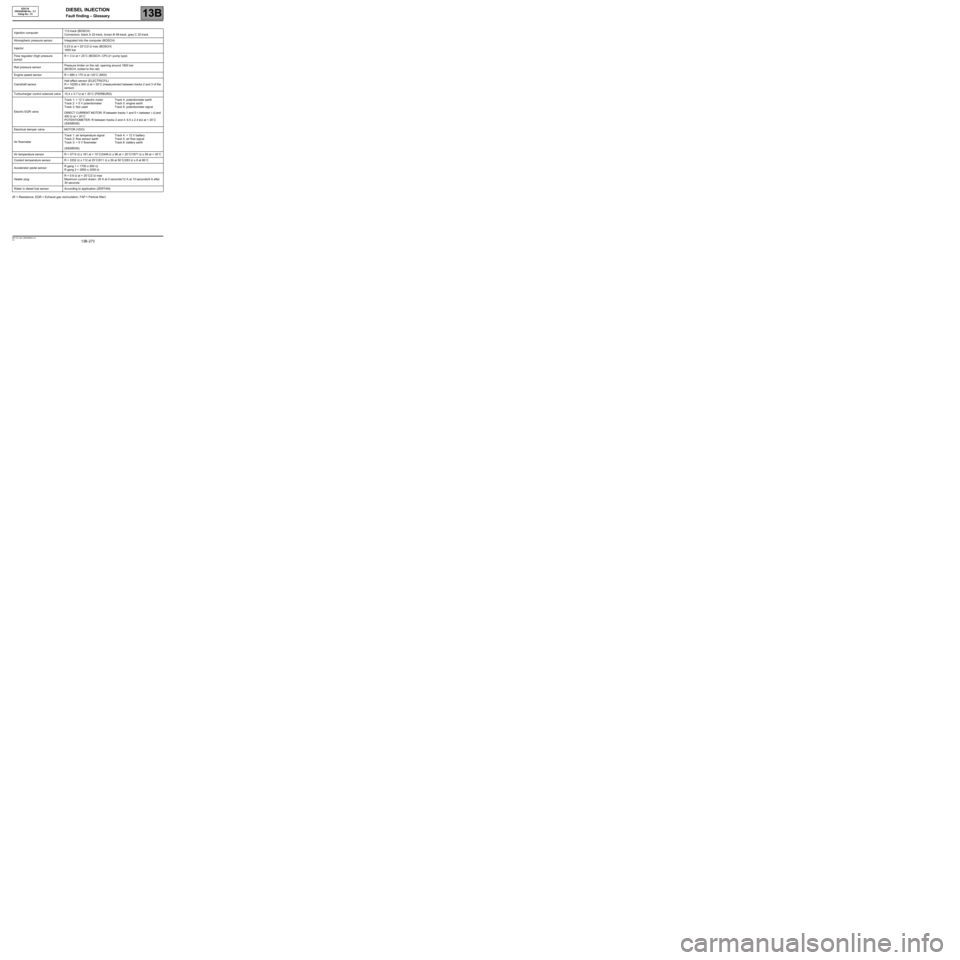

Page 273 of 273

DIESEL INJECTION

Fault finding – Glossary13B

13B -273V3 MR-372-J84-13B250$945.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Glossary

(R = Resistance, EGR = Exhaust gas recirculation, FAP = Particle filter)Injection computer112-track (BOSCH)

Connectors: black A 32-track, brown B 48-track, grey C 32-track

Atmospheric pressure sensor Integrated into the computer (BOSCH)

Injector0.23 Ω at + 20˚C/2 Ω max (BOSCH)

1600 bar

Flow regulator (high pressure

pump)R = 3 Ω at + 20˚C (BOSCH, CP3.2+ pump type)

Rail pressure sensorPressure limiter on the rail: opening around 1800 bar

(BOSCH, bolted to the rail)

Engine speed sensor R = 680 ± 170 Ω at +20˚C (MGI)

Camshaft sensorHall effect sensor (ELECTRICFIL)

R = 10250 ± 500 Ω at + 20˚C (measurement between tracks 2 and 3 of the

sensor)

Turbocharger control solenoid valve 15.4 ± 0.7 Ω at + 20˚C (PIERBURG)

Electric EGR valveTrack 1: + 12 V electric motor

Track 2: + 5 V potentiometer

Track 3: Not usedTrack 4: potentiometer earth

Track 5: engine earth

Track 6: potentiometer signal

DIRECT CURRENT MOTOR: R between tracks 1 and 5 = between 1 Ω and

400 Ω at + 20˚C

POTENTIOMETER: R between tracks 2 and 4: 6.5 ± 2.4 kΩ at + 20˚C

(SIEMENS)

Electrical damper valve MOTOR (VDO)

Air flowmeterTrack 1: air temperature signal

Track 2: flow sensor earth

Track 3: + 5 V flowmeterTrack 4: + 12 V battery

Track 5: air flow signal

Track 6: battery earth

(SIEMENS)

Air temperature sensor R = 3714 Ω ± 161 at + 10˚C/2448 Ω ± 96 at + 20˚C/1671 Ω ± 59 at + 30˚C

Coolant temperature sensor R = 2252 Ω ± 112 at 25˚C/811 Ω ± 39 at 50˚C/283 Ω ± 8 at 80˚C

Accelerator pedal sensorR gang 1 = 1700 ± 900 Ω;

R gang 2 = 2850 ± 2050 Ω

Heater plugR = 0.6 Ω at + 20˚C/2 Ω max

Maximum current drawn: 28 A at 0 seconds/12 A at 10 seconds/9 A after

30 seconds

Water in diesel fuel sensor According to application (ZERTAN)