charging RENAULT SCENIC 2009 J84 / 2.G Engine And Peripherals EDC16 Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 273

Page 153 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 153V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

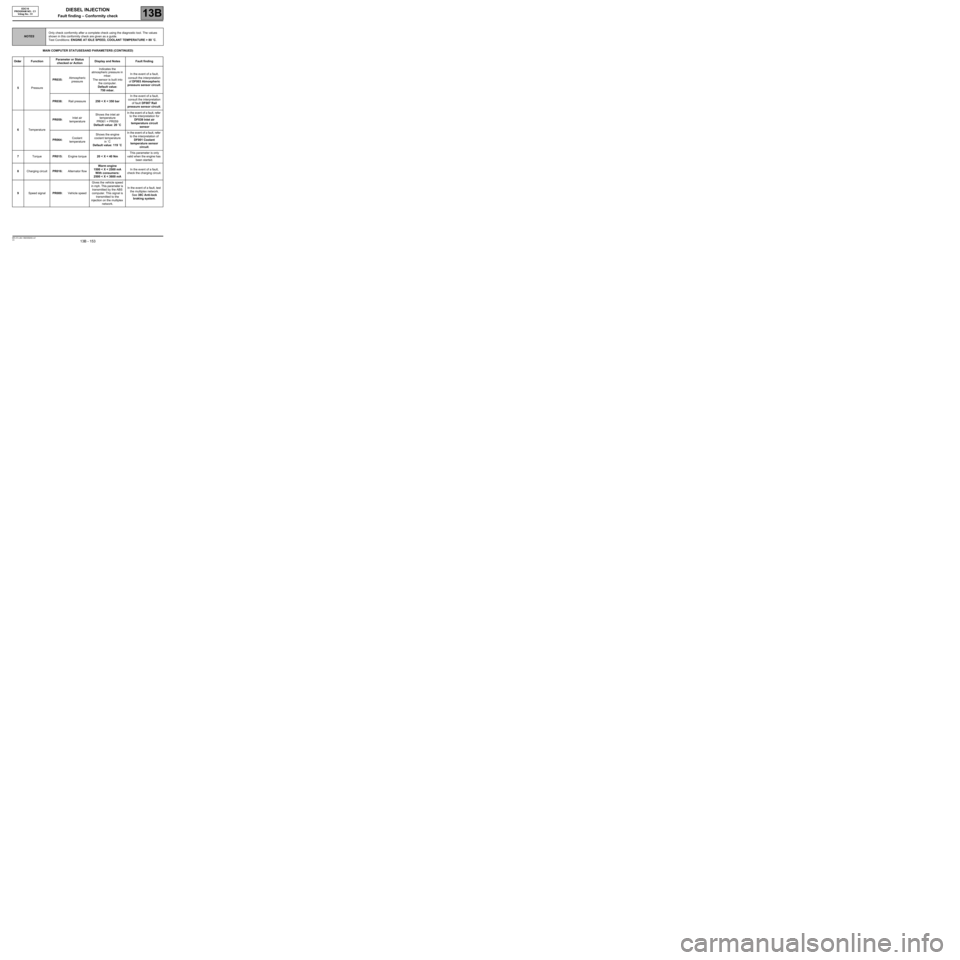

MAIN COMPUTER STATUSES AND PARAMETERS (CONTINUED)

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test Conditions: ENGINE AT IDLE SPEED, COOLANT TEMPERATURE > 80 ˚C.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

5PressurePR035:Atmospheric

pressureIndicates the

atmospheric pressure in

mbar.

The sensor is built into

the computer.

Default value:

750 mbar.In the event of a fault,

consult the interpretation

of DF003 Atmospheric

pressure sensor circuit.

PR038:Rail pressure250 < X < 350 barIn the event of a fault,

consult the interpretation

of fault DF007 Rail

pressure sensor circuit.

6TemperaturePR059:Inlet air

temperatureShows the inlet air

temperature

PR061 = PR059

Default value: 20 ˚CIn the event of a fault, refer

to the interpretation for

DF039 Inlet air

temperature circuit

sensor

PR064:Coolant

temperatureShows the engine

coolant temperature

in ˚C

Default value: 119 ˚CIn the event of a fault, refer

to the interpretation of

DF001 Coolant

temperature sensor

circuit.

7TorquePR015:Engine torque20 < X < 40 NmThis parameter is only

valid when the engine has

been started.

8Charging circuitPR016:Alternator flowWarm engine

1500 < X < 2500 mA

With consumers:

2500 < X < 3600 mAIn the event of a fault,

check the charging circuit.

9Speed signalPR089:Vehicle speedGives the vehicle speed

in mph. This parameter is

transmitted by the ABS

computer. This signal is

transmitted to the

injection on the multiplex

network.In the event of a fault, test

the multiplex network.

See 38C Anti-lock

braking system.

Page 154 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 154V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

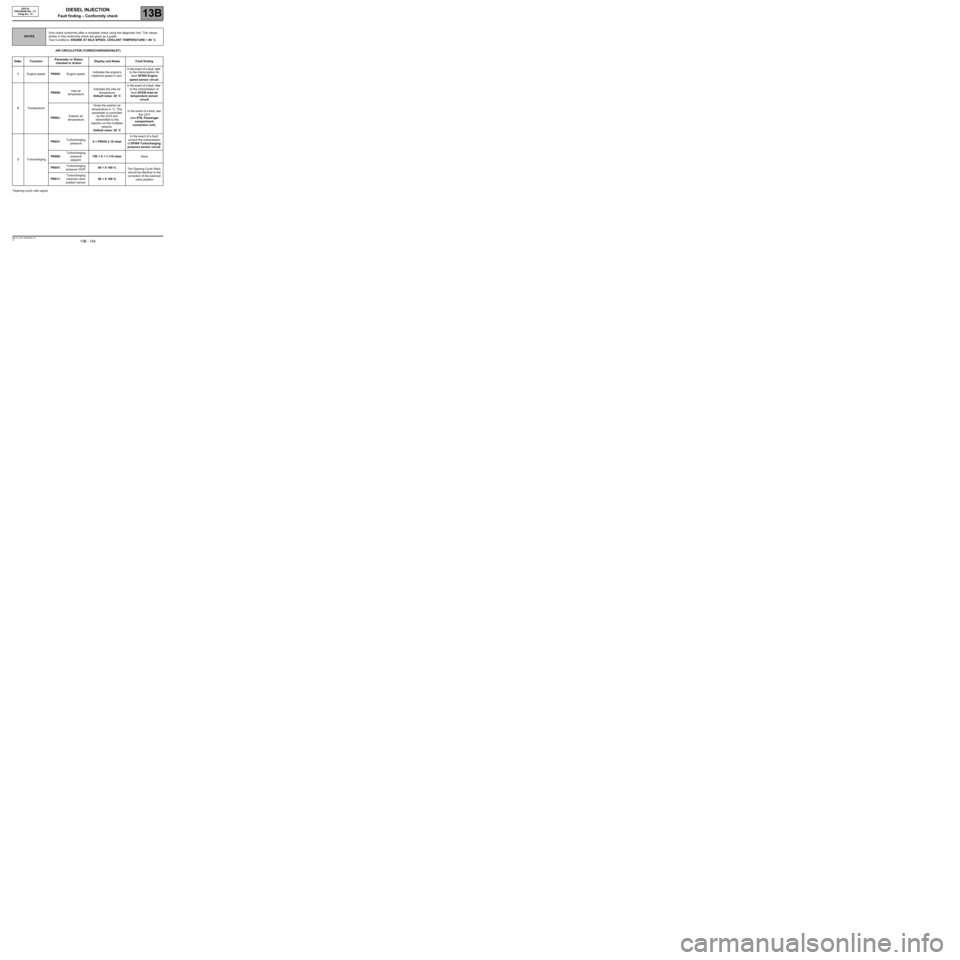

AIR CIRCULATION (TURBOCHARGING/INLET)

*Opening cyclic ratio signal

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test Conditions: ENGINE AT IDLE SPEED, COOLANT TEMPERATURE > 80 ˚C.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Engine speedPR055:Engine speedIndicates the engine's

rotational speed in rpm.In the event of a fault, refer

to the interpretation for

fault DF005 Engine

speed sensor circuit.

2TemperaturePR059:Inlet air

temperatureIndicates the inlet air

temperature

Default value: 20 ˚CIn the event of a fault, refer

to the interpretation of

fault DF039 Inlet air

temperature sensor

circuit

PR061:Exterior air

temperatureGives the exterior air

temperature in ˚C. This

parameter is controlled

by the UCH and

transmitted to the

injection on the multiplex

network.

Default value: 20 ˚CIn the event of a fault, see

the UCH

(see 87B, Passenger

compartment

connection unit).

3TurbochargingPR041:Turbocharging

pressureX = PR035 ± 10 mbarIn the event of a fault,

consult the interpretation

of DF004 Turbocharging

pressure sensor circuit.

PR009:Turbocharging

pressure

setpoint790 < X < 1,110 mbarNone

PR047:Turbocharging

pressure OCR*60 < X <90 %

The Opening Cyclic Ratio

should be identical to the

correction of the solenoid

valve position PR011:Turbocharging

solenoid valve

position sensor60 < X <90 %

Page 155 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 155V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

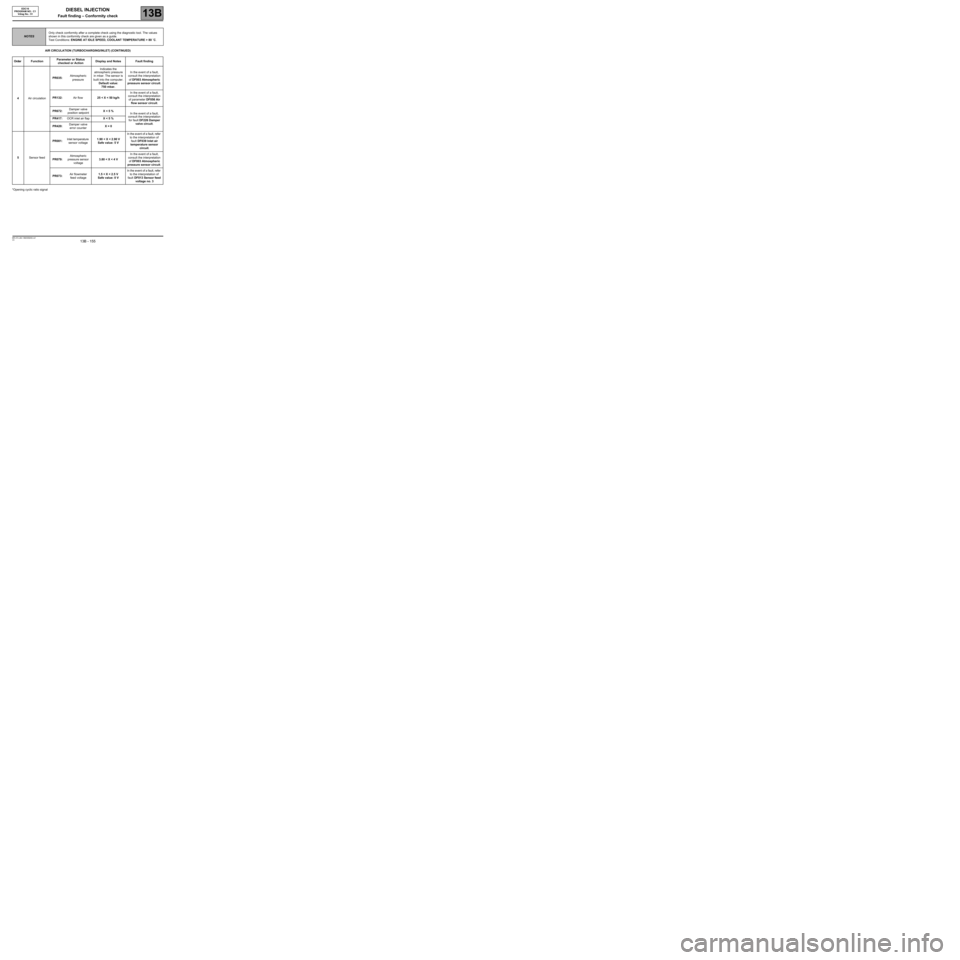

AIR CIRCULATION (TURBOCHARGING/INLET) (CONTINUED)

*Opening cyclic ratio signal

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test Conditions: ENGINE AT IDLE SPEED, COOLANT TEMPERATURE > 80 ˚C.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

4Air circulationPR035:Atmospheric

pressureIndicates the

atmospheric pressure

in mbar. The sensor is

built into the computer.

Default value:

750 mbar.In the event of a fault,

consult the interpretation

of DF003 Atmospheric

pressure sensor circuit.

PR132:Air flow25 < X < 50 kg/hIn the event of a fault,

consult the interpretation

of parameter DF056 Air

flow sensor circuit.

PR672:Damper valve

position setpointX < 5 %

In the event of a fault,

consult the interpretation

for fault DF226 Damper

valve circuit. PR417:OCR inlet air flapX < 5 %

PR420:Damper valve

error counterX = 0

5Sensor feedPR081:Inlet temperature

sensor voltage1.90 < X < 2.90 V

Safe value: 5 VIn the event of a fault, refer

to the interpretation of

fault DF039 Inlet air

temperature sensor

circuit.

PR079:Atmospheric

pressure sensor

voltage3.80 < X < 4 VIn the event of a fault,

consult the interpretation

of DF003 Atmospheric

pressure sensor circuit.

PR073:Air flowmeter

feed voltage1.5 < X < 2.5 V

Safe value: 0 VIn the event of a fault, refer

to the interpretation of

fault DF013 Sensor feed

voltage no. 3

Page 169 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 169V3 MR-372-J84-13B250$540.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

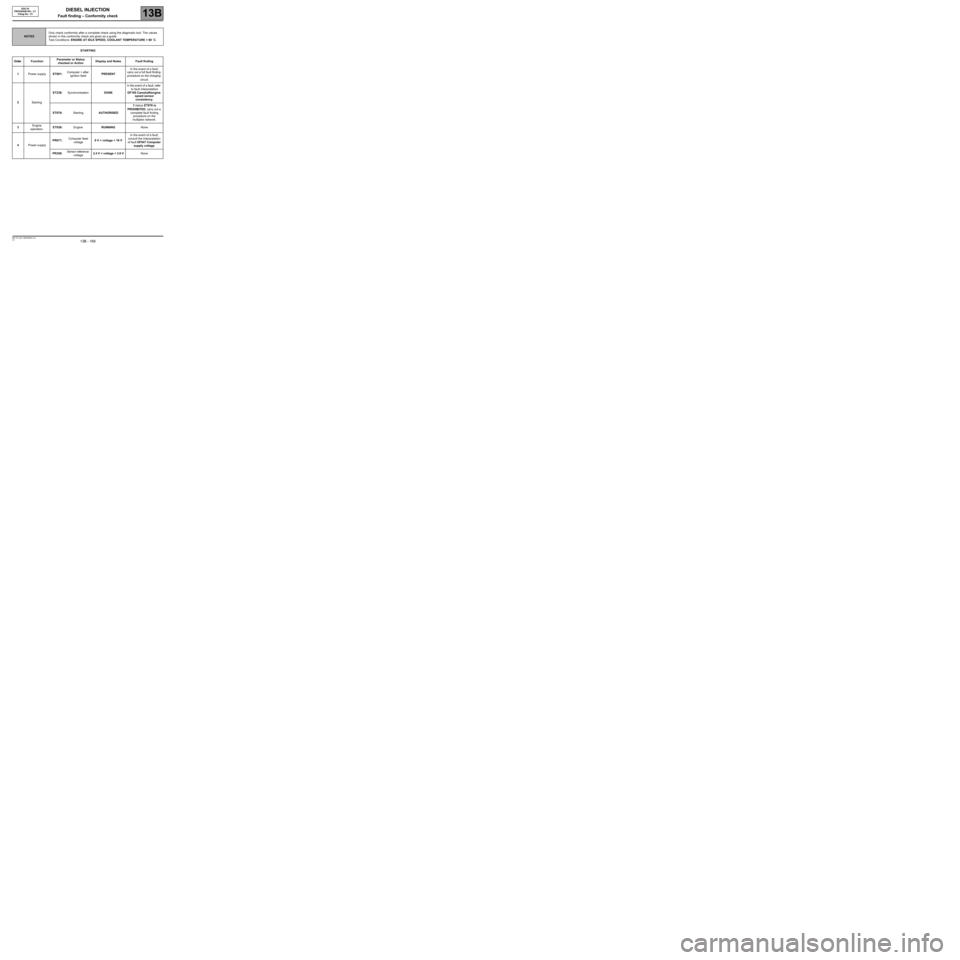

STARTING

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test Conditions: ENGINE AT IDLE SPEED, COOLANT TEMPERATURE > 80 ˚C.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Power supplyET001:Computer + after

ignition feedPRESENTIn the event of a fault,

carry out a full fault finding

procedure on the charging

circuit.

2StartingET238:SynchronisationDONEIn the event of a fault, refer

to fault interpretation

DF195 Camshaft/engine

speed sensor

consistency.

ET076:StartingAUTHORISEDIf status ET076 is

PROHIBITED, carry out a

complete fault finding

procedure on the

multiplex network.

3Engine

operation.ET038:EngineRUNNINGNone

4Power supplyPR071:Computer feed

voltage9 V < voltage < 16 VIn the event of a fault,

consult the interpretation

of fault DF047 Computer

supply voltage.

PR358:Sensor reference

voltage3.4 V < voltage < 3.8 VNone

Page 206 of 273

DIESEL INJECTION

Fault finding – Parameter summary table13B

13B - 206V3 MR-372-J84-13B250$675.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Parameter summary table

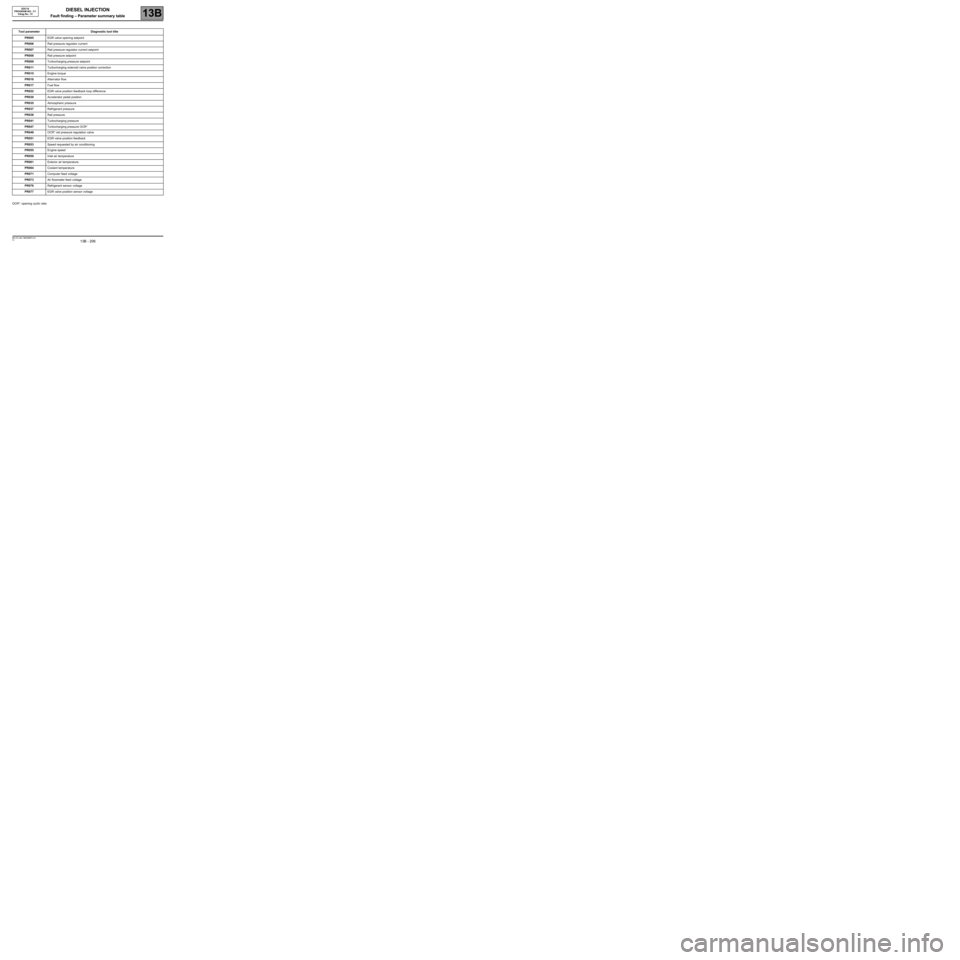

OCR*: opening cyclic ratioTool parameter Diagnostic tool title

PR005EGR valve opening setpoint

PR006Rail pressure regulator current

PR007Rail pressure regulator current setpoint

PR008Rail pressure setpoint

PR009Turbocharging pressure setpoint

PR011Turbocharging solenoid valve position correction

PR015Engine torque

PR016Alternator flow

PR017Fuel flow

PR022EGR valve position feedback loop difference

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR041Turbocharging pressure

PR047Turbocharging pressure OCR*

PR048OCR* rail pressure regulation valve

PR051EGR valve position feedback

PR053Speed requested by air conditioning

PR055Engine speed

PR059Inlet air temperature

PR061Exterior air temperature

PR064Coolant temperature

PR071Computer feed voltage

PR073Air flowmeter feed voltage

PR076Refrigerant sensor voltage

PR077EGR valve position sensor voltage

MR-372-J84-13B250$675.mif

Page 208 of 273

DIESEL INJECTION

Fault finding – Command summary table13B

13B -208V3 MR-372-J84-13B250$720.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Command summary table

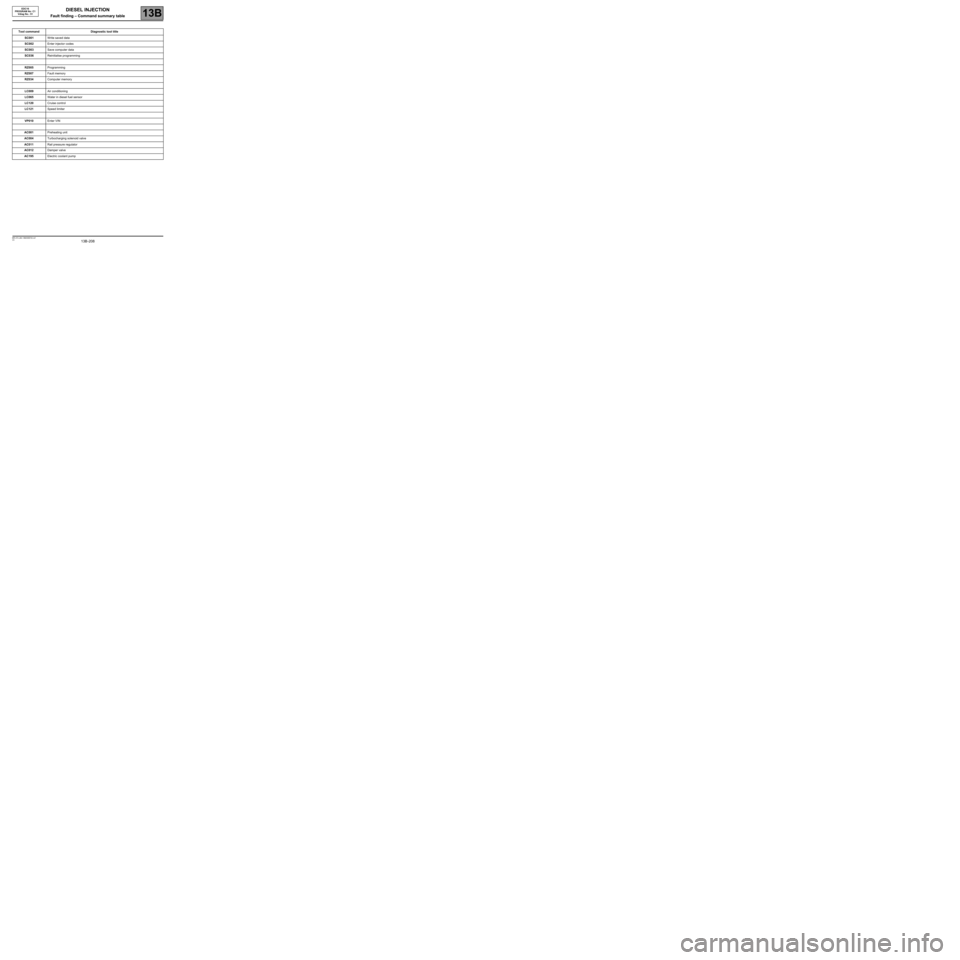

Tool command Diagnostic tool title

SC001Write saved data

SC002Enter injector codes

SC003Save computer data

SC036Reinitialise programming

RZ005Programming

RZ007Fault memory

RZ034Computer memory

LC009Air conditioning

LC065Water in diesel fuel sensor

LC120Cruise control

LC121Speed limiter

VP010Enter VIN

AC001Preheating unit

AC004Turbocharging solenoid valve

AC011Rail pressure regulator

AC012Damper valve

AC195Electric coolant pump

Page 216 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -216V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

AC004

TURBOCHARGING SOLENOID VALVE

NOTESThis command is used to check the turbocharging circuit.

This command checks that the turbocharger and the control circuit are working properly.

Introduction

1-Check the sealing of the high pressure air circuit:

Pipes not joined or pierced, pressure sensor disconnected or poorly fitted (seal present), intercooler pierced.

To test the intercooler: stabilise the engine speed between 3,500 and 4,000 rpm with the vehicle stopped and

check that there are no leaks.

Check the resistance of the turbocharging limitation solenoid valve between tracks 1 and 2.

Replace the solenoid valve if its resistance is not 15.4 Ω ± 0.7 at 20˚C.

Check the injection computer connections.

Check for continuity and make sure there is no interference resistance on the following connection:

Injection computer grey 32-track connector C,

track E1Track 1 turbocharging solenoid valve

Repair if necessary.

Check for the presence of + 12 V after relay on track 2 of the turbocharging solenoid valve.

2 - Turbocharger control circuit check

–With the engine stopped, make sure that the control rod is in the resting position.

–Start the engine and make sure that the control rod actuates to the upper stop.

–(when the engine is switched off, the control rod should return to the rest position)

–If the control rod does not move correctly, carry out the following checks:

1) Vacuum pressure command check:

–Disconnect the solenoid valve inlet hose and connect it to a pressure gauge.

–Start the engine and run it at a stable idle speed.

–If the vacuum pressure does not reach 800 mbar ± 100: check the vacuum pressure circuit from the vacuum

pump.

–Stop the engine, reconnect the inlet hoses and go to step no. 2.

2) Solenoid valve control check:

–Disconnect the solenoid valve outlet hose.

–Start the engine and run it at a stable idle speed.

–Place your hand on the solenoid valve and block the outlet union with your thumb.

–If you notice no solenoid valve vibration, check the operation of the computer output (step 5). Solenoid valve

operation check:

–Connect the pressure gauge to the solenoid valve outlet union.

–Start the engine and run it at a stable idle speed.

If the vacuum pressure does not reach 800 mbar ± 100, replace the solenoid valve.

EDC16_V51_AC004

Page 217 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -217V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

* Opening cyclic ratio signalAC004

CONTINUED

Turbocharger control circuit check (continued)

4) Turbocharger operation check:

a) Connect a vacuum pump to the hose connected to the turbocharger control diaphragm.

Apply a negative pressure of 800 ± 100 mbar:

If there is a leak, replace the turbocharger (diaphragm included).

b) Check the control rod movement and setting (see MR 364, Mechanics, 12B, Turbocharging).

If the control rod is sticking, replace the turbocharger.

c) Engine cold and stopped:

Remove the turbocharger inlet duct and check that the compressor turns freely on the axis.

d) If the fault persists:

Check that the exhaust manifold is not leaking.

Check that the exhaust is not blocked.

Carry out the necessary repairs.

5) Computer output stage check: (solenoid valve connected).

This operation can only be carried out if the checks indicated in step no. 2 are not conclusive.

Either with the voltmeter: Connect the voltmeter earth lead on track 2 of the solenoid valve and the positive

lead on track 1.

Clear any solenoid valve fault then run command AC004:

●The voltmeter should display ten cycles of two successive voltages ~ = battery voltage X opening cycle ratio*

in process.

that is: ~ 2.5 V (opening cyclic ratio* of 20%) then ~ 8.7 V (opening cyclic ratio* of 70%).

Or with the oscilloscope (at 5 V range/division and 1 ms/div time base): Connect the earth lead of the

oscilloscope to the battery earth and the positive test pin to track 2 of the solenoid valve.

Clear any solenoid valve faults, then run command AC004:

●the oscilloscope should display a square wave signal of 12.5 V in amplitude at a frequency of 140 Hz

(with an opening cyclic ratio* passing from ~ 20 to ~ 70%).

If the measurement is correct, replace the solenoid valve.

If the measurement does not show any control or continuous voltage, contact the Techline.

Page 224 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -224V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

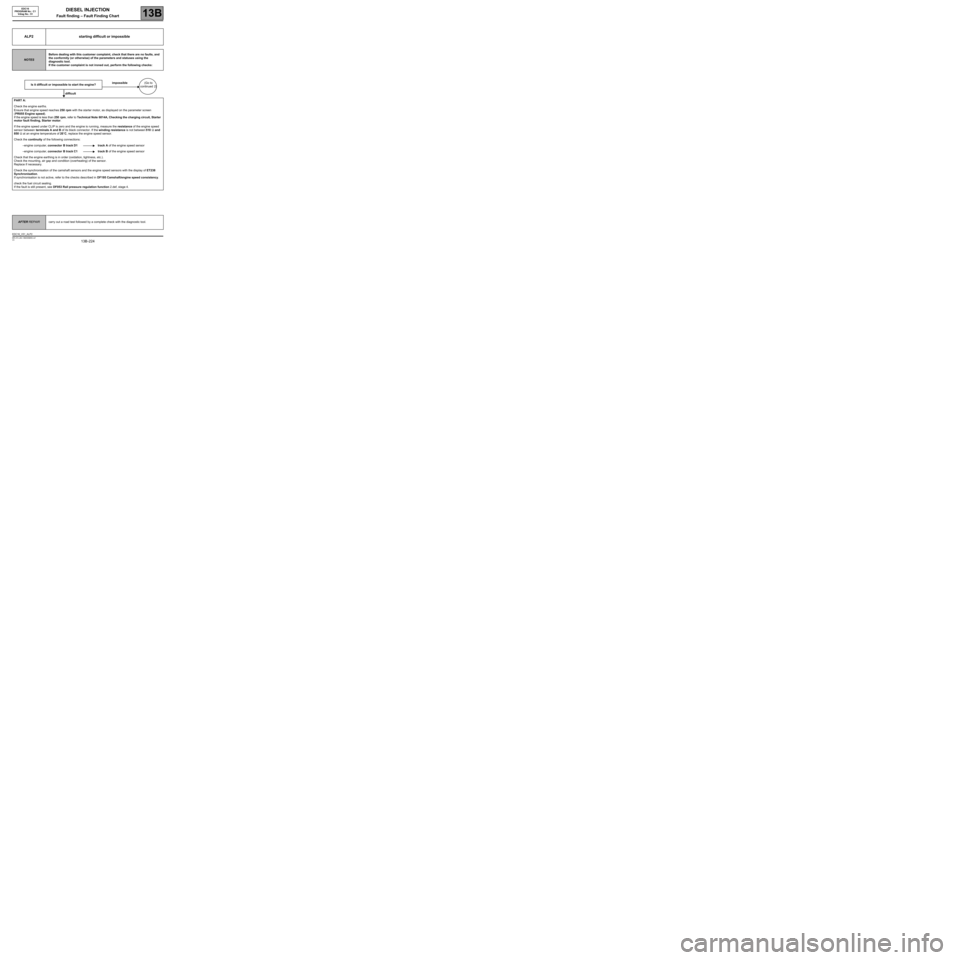

ALP2 starting difficult or impossible

NOTESBefore dealing with this customer complaint, check that there are no faults, and

the conformity (or otherwise) of the parameters and statuses using the

diagnostic tool.

If the customer complaint is not ironed out, perform the following checks:

Is it difficult or impossible to start the engine?impossible(Go to

continued 2)

difficult

PART A:

Check the engine earths.

Ensure that engine speed reaches 250 rpm with the starter motor, as displayed on the parameter screen

(PR055 Engine speed).

If the engine speed is less than 250 rpm, refer to Technical Note 6014A, Checking the charging circuit, Starter

motor fault finding, Starter motor.

If the engine speed under CLIP is zero and the engine is running, measure the resistance of the engine speed

sensor between terminals A and B of its black connector. If the winding resistance is not between 510 Ω and

850 Ω at an engine temperature of 20˚C, replace the engine speed sensor.

Check the continuity of the following connections:

–engine computer, connector B track D1 track A of the engine speed sensor

–engine computer, connector B track C1 track B of the engine speed sensor

Check that the engine earthing is in order (oxidation, tightness, etc.).

Check the mounting, air gap and condition (overheating) of the sensor.

Replace if necessary.

Check the synchronisation of the camshaft sensors and the engine speed sensors with the display of ET238

Synchronisation.

If synchronisation is not active, refer to the checks described in DF195 Camshaft/engine speed consistency.

check the fuel circuit sealing.

If the fault is still present, see DF053 Rail pressure regulation function 2.def, stage 4.

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V51_ALP2

Page 226 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -226V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

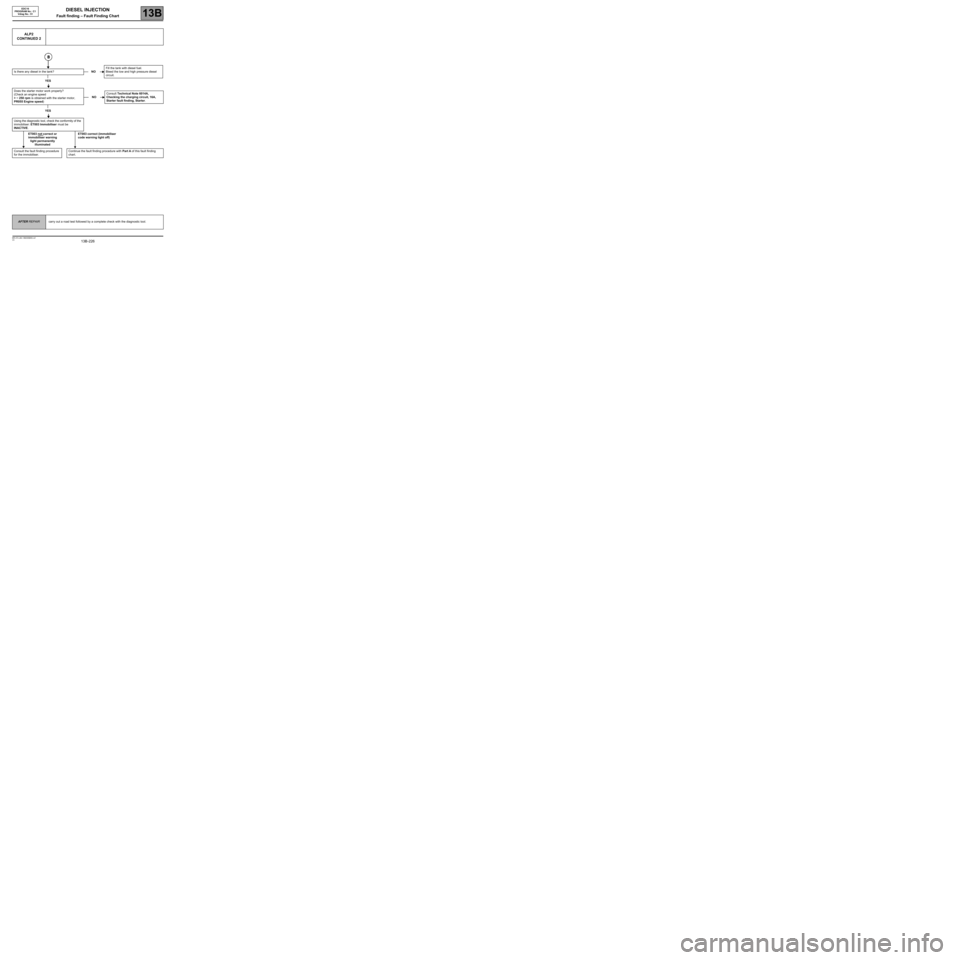

ALP2

CONTINUED 2

Is there any diesel in the tank?

YES

Does the starter motor work properly?

(Check an engine speed

> ~ 250 rpm is obtained with the starter motor,

PR055 Engine speed)

YES

Using the diagnostic tool, check the conformity of the

immobiliser: ET003 Immobiliser must be

INACTIVE.

ET003 not

correct or

immobiliser warning

light permanently

illuminatedET003 correct (immobiliser

code warning light off)

Consult the fault finding procedure

for the immobiliser.

NOFill the tank with diesel fuel.

Bleed the low and high pressure diesel

circuit.

NOConsult Technical Note 6014A,

Checking the charging circuit, 16A,

Starter fault finding, Starter.

Continue the fault finding procedure with Part A of this fault finding

chart.

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.