warning RENAULT SCENIC 2009 J84 / 2.G Engine And Peripherals EDC16 Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 273

Page 128 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B -128V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF652

PRESENT

OR

STOREDTURBINE UPSTREAM TEMPERATURE SENSOR CIRCUIT

CC.0 : Short circuit to earth

CO.1 : Short circuit or open circuit to + 12 V

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present:

–ignition is on (CC.0),

–following a road test, engine warm (CO.1).

Special notes:

If the fault is present:

–the EGR function is inhibited,

–particle filter regeneration is inhibited,

–the vehicle performance is reduced,

–the level 1 warning light is illuminated.

Priorities when dealing with a number of faults:

DF011 Sensor voltage supply no. 1

IMPORTANT

The turbine upstream temperature sensor only measures temperatures above

200˚C.

Check the condition of the turbine upstream temperature sensor connector (see Wiring Diagram Technical Note,

Mégane II, Scénic II, component code 1589).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II, Scénic II, component code 120).

If one of the connectors is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V51_DF652

Page 130 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B -130V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF778

PRESENT

OR

STOREDTURBINE UPSTREAM TEMPERATURE CONTROL

1.DEF: Temperature measured too high

2.DEF: Parameter at max limit

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present:

–the engine is started with a speed greater than 1750 rpm and a fuel flow greater than

30 mg/st,

–a road test.

Special notes:

If the fault is present:

–particle filter regeneration is inhibited,

–the vehicle performance is reduced,

–the level 1 warning light is illuminated.

IMPORTANT

This fault can result in a rapid and significant fouling of the particle filter.

Apply TEST 3 Turbocharged air inlet circuit check.

Check the turbine upstream temperature sensor connections.

check the engine management computer connections.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V51_DF778

Page 176 of 273

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

13B - 176V3 MR-372-J84-13B250$630.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

ET014

CHECK COOLING FAN 1

NOTESSpecial notes:

Only perform these tests if the statuses do not correspond with the system

programming functions.

NOTE:

Status ET014 test and status ET022 GMV1 low speed request change their status at the same time.

RUNNING

The low-speed engine fan unit is supplied in three scenarios:

–the engine coolant temperature is above 89 ˚C;

–the air conditioning is operating

–the injection computer has system faults that could lead to the engine overheating.

When the low-speed engine fan is supplied:

–status ET014 GMV 1 test becomes RUNNING status ET022 Low speed GMV

request becomes ACTIVE.

If the low speed GMV does not work (see 87G, engine compartment connection unit).

The low-speed engine fan assembly stops when:

–the engine coolant temperature is below 89 ˚C;

–the air conditioning is not switched on by the driver.

STOPPED

IMPORTANTWARNING

If the UPC does not detect the injection computer frames, the low speed engine

fan is supplied until the battery is completely discharged.

In the event that the low-speed engine fan assembly is faulty, the high-speed

engine fan assembly will then be activated.

AFTER REPAIRCarry out a road test followed by a complete test with the diagnostic tool.

EDC16_V51_ET014

Page 177 of 273

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

13B - 177V3 MR-372-J84-13B250$630.mif

STOPPED

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

ET015

CHECK COOLING FAN 2

NOTESSpecial notes:

Only perform these tests if the statuses do not correspond with the system

programming functions.

NOTE:

Status ET015 GMV 2 test and status ET021 High speed GMV request change their status at the same time.

RUNNING

The engine fan assembly can be supplied when:

–the engine coolant temperature is above 99 ˚C.

–the injection computer has system faults that could lead to the engine overheating.

When the high speed fan is supplied:

–status ET015 GMV 2 test becomes RUNNING and status ET021 High speed GMV

request becomes ACTIVE.

The high-speed engine fan assembly stops when:

–the engine coolant temperature is below 99 ˚C;

IMPORTANTWARNING

If the UPC does not detect the injection computer frames, the low speed engine

fan is supplied until the battery is completely discharged.

In the event that the low-speed engine fan assembly is faulty, the high-speed

engine fan assembly will then be activated.

AFTER REPAIRCarry out a road test followed by a complete test with the diagnostic tool.

EDC16_V51_ET015

Page 178 of 273

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

13B - 178V3 MR-372-J84-13B250$630.mif

INACTIVE

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

ET021

HIGH-SPEED FAN REQUEST

NOTESSpecial notes:

Only perform these tests if the statuses do not correspond with the system

programming functions.

NOTE:

Status ET021 High speed GMV request and status ET015 GMV 2 test change their status at the same time.

ACTIVE

The injection computer requests the activation of the high speed GMV when:

–the engine coolant temperature is above 99 ˚C.

–the injection computer has system faults that could lead to the engine overheating.

When the high speed fan is supplied:

–status ET021 High speed GMV request becomes RUNNING and status ET015

GMV 2 test becomes ACTIVE.

The high-speed engine fan assembly stops when:

–the engine coolant temperature is below 99 ˚C;

–no fault which could cause engine overheating is present in the injection

system.

IMPORTANTWARNING

If the UPC does not detect the injection computer frames, the low speed engine

fan is supplied until the battery is completely discharged.

In the event that the low-speed engine fan assembly is faulty, the high-speed

engine fan assembly will then be activated.

AFTER REPAIRCarry out a road test followed by a complete test with the diagnostic tool.

EDC16_V51_ET021

Page 179 of 273

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

13B - 179V3 MR-372-J84-13B250$630.mif

INACTIVE

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

ET022

LOW SPEED GMV CONTROL

NOTESSpecial notes:

Only perform these tests if the statuses do not correspond with the system

programming functions.

NOTE:

Status ET022 Low speed GMV request and status ET014 GMV 1 test change their status at the same time.

ACTIVE

The injection computer requests the activation of the low speed GMV when:

–the engine coolant temperature is above 89 ˚C;

–the injection computer has system faults that could lead to the engine overheating,

–the air conditioning is switched on by the driver.

When the high speed fan is supplied:

–status ET022 Low speed GMV request becomes ACTIVE and status ET014 GMV

1 test becomes RUNNING.

The low-speed engine fan assembly stops when:

–the engine coolant temperature is below 89 ˚C;

–no fault which could cause engine overheating is present in the injection

system.

–the air conditioning is not switched on by the driver.

IMPORTANTWARNING

If the UPC does not detect the injection computer frames, the low speed engine

fan is supplied until the battery is completely discharged.

In the event that the low-speed engine fan assembly is faulty, the high-speed

engine fan assembly will then be activated.

AFTER REPAIRCarry out a road test followed by a complete test with the diagnostic tool.

EDC16_V51_ET022

Page 191 of 273

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

13B - 191V3 MR-372-J84-13B250$630.mif

COMPLETED

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

ET238

SYNCHRONISATION

NOTESSpecial notes:

Only perform these tests if the statuses do not correspond with the system

programming functions.

WARNING

Synchronisation is carried out during the engine starting phase. This is established between the camshaft position

sensor and the TDC sensor.

Once this synchronisation has been carried out, it enables the computer to identify cylinder no. 1 and to calculate

the precise position of the cylinder's Top Dead Centre.

NOT PERFORMED

When the engine is stopped but the ignition switched on, cylinder no. 1 is no longer

indicated.

Status ET238 is NOT DONE; synchronisation between the crankshaft and the camshaft

has not been carried out.

Synchronisation is carried out during the engine starting phase.

Cylinder No. 1 is indicated and synchronisation will be performed once the engine is

started.

Status ET238 is DONE.

If after several attempts to start the engine, status ET238 remains NOT DONE, refer to

the interpretation of the following faults:

–DF005 Engine speed sensor circuit.

–DF097 Camshaft sensor circuit.

If the engine does still not start, consult the Customer complaints section, ALP2

Starting faults.

AFTER REPAIRSwitch off the ignition and carry out a road test followed by a test with the diagnostic tool

EDC16_V51_ET238

Page 210 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -210V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

SC002

ENTER INJECTOR CODES

NOTESThis command should be run after the injectors have been replaced and only if the

vehicle has been configured with IMA.

(ET104 USE OF INJECTOR CODES to YES).

If this command is not performed, the DF276 INJECTOR CODE PROGRAMMING

fault will be present.

WARNING

The letters J and Q, and figures 0 and 9 are not used in IMA coding.

If these characters are used the entry will be invalid.

Cylinder no. 1 is the cylinder located at the engine flywheel end.

Procedure to be followed:

–Read the 6-character alphanumeric codes etched on the upper section of the injector bodies.

–Use command SC002.

–Select the cylinder number for the cylinder concerned in the Desired, column, then confirm.

–Enter the injector code displayed for the cylinder.

–Enter the new codes for each cylinder, then confirm.

–When the command is completed, the modified codes appear in the Current column.

–Check that the codes correspond to those read earlier.

–If the codes entered appear in neither the Current column nor the Desired column, check the codes read and

make sure the data has been entered correctly,

The possible confusions are:

digit "1" with the letter "I"

figure 8 with the letter B

figure 5 with the letter S

–Exit fault finding mode.

–Switch off the ignition and wait for 1 min.

–Switch the ignition back on and check for faults.

–DF276 INJECTOR CODE PROGRAMMING should be stored.

If fault DF276 is still present, the command has not been performed correctly.

Start the procedure again and follow the instructions.

If the codes are still not recognised, check whether the computer's standby has been correctly set:

Switch off the ignition and wait for 1 min.

If the warning light flashes when the ignition is switched off, the computer has not been put on standby and the

command will be ignored.

If all these checks still do not enable the command to be confirmed, contact the Techline.

EDC16_V51_SC002

Page 226 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -226V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

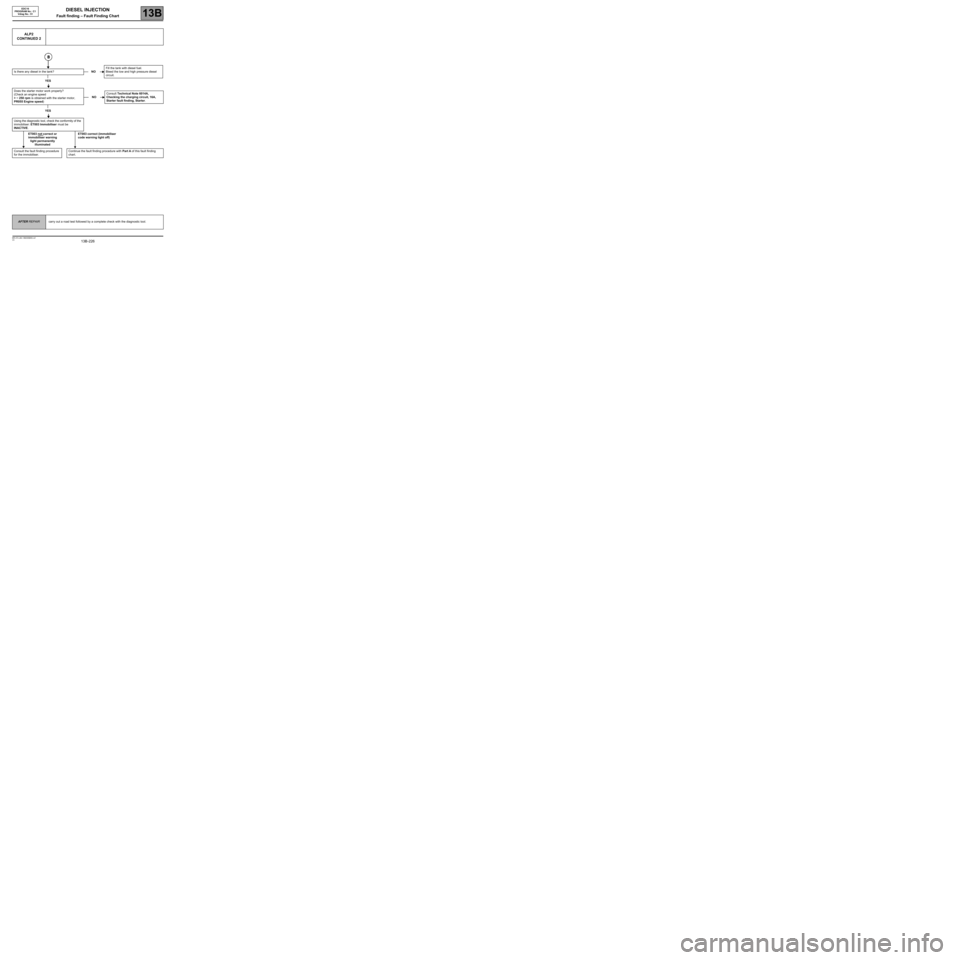

ALP2

CONTINUED 2

Is there any diesel in the tank?

YES

Does the starter motor work properly?

(Check an engine speed

> ~ 250 rpm is obtained with the starter motor,

PR055 Engine speed)

YES

Using the diagnostic tool, check the conformity of the

immobiliser: ET003 Immobiliser must be

INACTIVE.

ET003 not

correct or

immobiliser warning

light permanently

illuminatedET003 correct (immobiliser

code warning light off)

Consult the fault finding procedure

for the immobiliser.

NOFill the tank with diesel fuel.

Bleed the low and high pressure diesel

circuit.

NOConsult Technical Note 6014A,

Checking the charging circuit, 16A,

Starter fault finding, Starter.

Continue the fault finding procedure with Part A of this fault finding

chart.

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.

Page 228 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -228V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

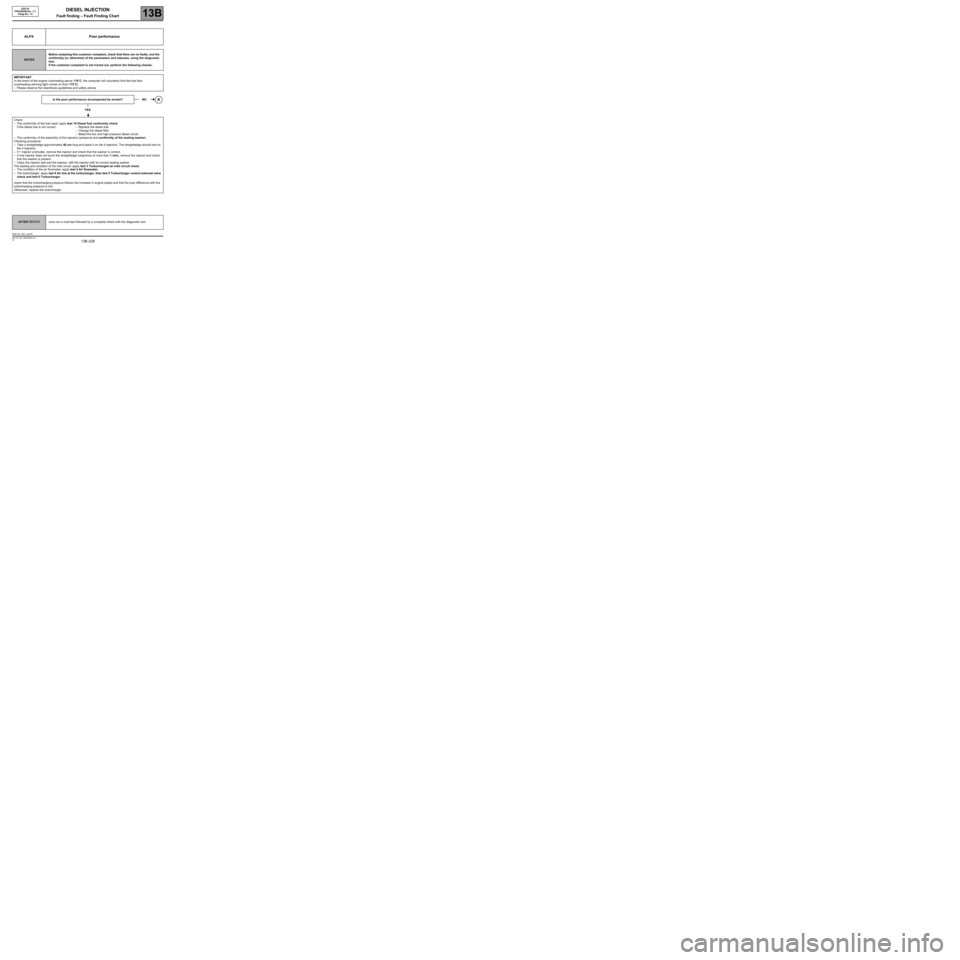

ALP4 Poor performance

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not ironed out, perform the following checks:

IMPORTANT

In the event of the engine overheating above 119˚C, the computer will voluntarily limit the fuel flow

(overheating warning light comes on from 115˚C).

–Please observe the cleanliness guidelines and safety advice.

Is the poor performance accompanied by smoke?

YES

Check:

–The conformity of the fuel used: apply test 10 Diesel fuel conformity check.

If the diesel fuel is not correct: – Replace the diesel fuel.

–Change the diesel filter.

–Bleed the low and high pressure diesel circuit.

–The conformity of the assembly of the injectors (presence and conformity of the sealing washer).

Checking procedure:

–Take a straightedge approximately 40 cm long and place it on the 4 injectors. The straightedge should rest on

the 4 injectors.

–If 1 injector protrudes, remove the injector and check that the washer is correct.

–If one injector does not touch the straightedge (clearance of more than 1 mm), remove the injector and check

that the washer is present.

–Clean the injector well and the injector, refit the injector with its correct sealing washer.

The sealing and condition of the inlet circuit: apply test 3 Turbocharged air inlet circuit check.

–The condition of the air flowmeter: apply test 4 Air flowmeter.

–The turbocharger: apply test 9 Air line at the turbocharger, then test 5 Turbocharger control solenoid valve

check and test 6 Turbocharger.

check that the turbocharging pressure follows the increase in engine speed and that the loop difference with the

turbocharging pressure is low.

Otherwise, replace the turbocharger.

NO

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V51_ALP4