RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Workshop Manual

Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 111 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-111

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-111V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

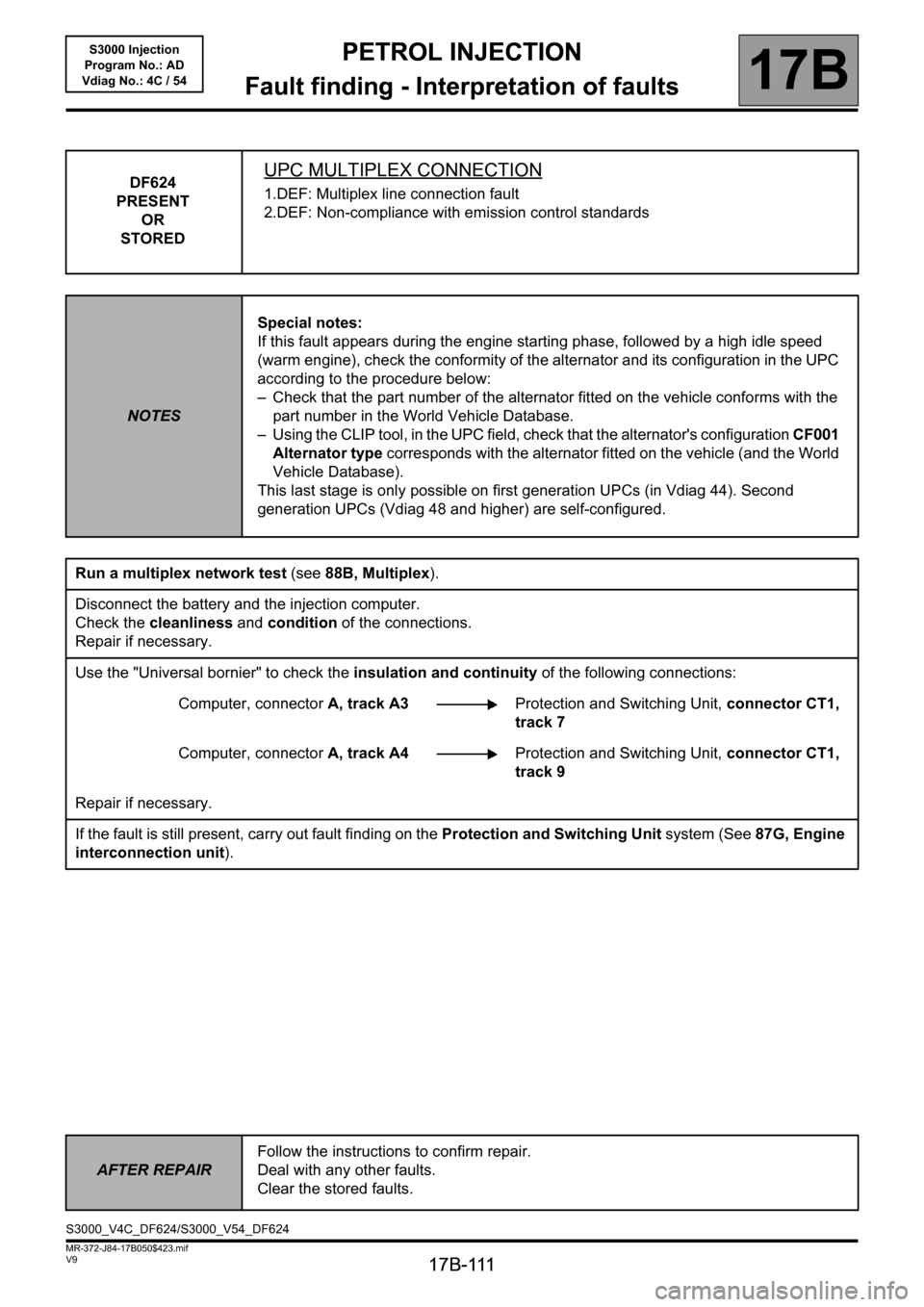

DF624

PRESENT

OR

STOREDUPC MULTIPLEX CONNECTION

1.DEF: Multiplex line connection fault

2.DEF: Non-compliance with emission control standards

NOTESSpecial notes:

If this fault appears during the engine starting phase, followed by a high idle speed

(warm engine), check the conformity of the alternator and its configuration in the UPC

according to the procedure below:

– Check that the part number of the alternator fitted on the vehicle conforms with the

part number in the World Vehicle Database.

– Using the CLIP tool, in the UPC field, check that the alternator's configuration CF001

Alternator type corresponds with the alternator fitted on the vehicle (and the World

Vehicle Database).

This last stage is only possible on first generation UPCs (in Vdiag 44). Second

generation UPCs (Vdiag 48 and higher) are self-configured.

Run a multiplex network test (see88B, Multiplex).

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Computer, connectorA, track A3Protection and Switching Unit, connector CT1,

track 7

Computer, connectorA, track A4Protection and Switching Unit, connector CT1,

track 9

Repair if necessary.

If the fault is still present, carry out fault finding on the Protection and Switching Unit system (See87G, Engine

interconnection unit).

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF624/S3000_V54_DF624

Page 112 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-112V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

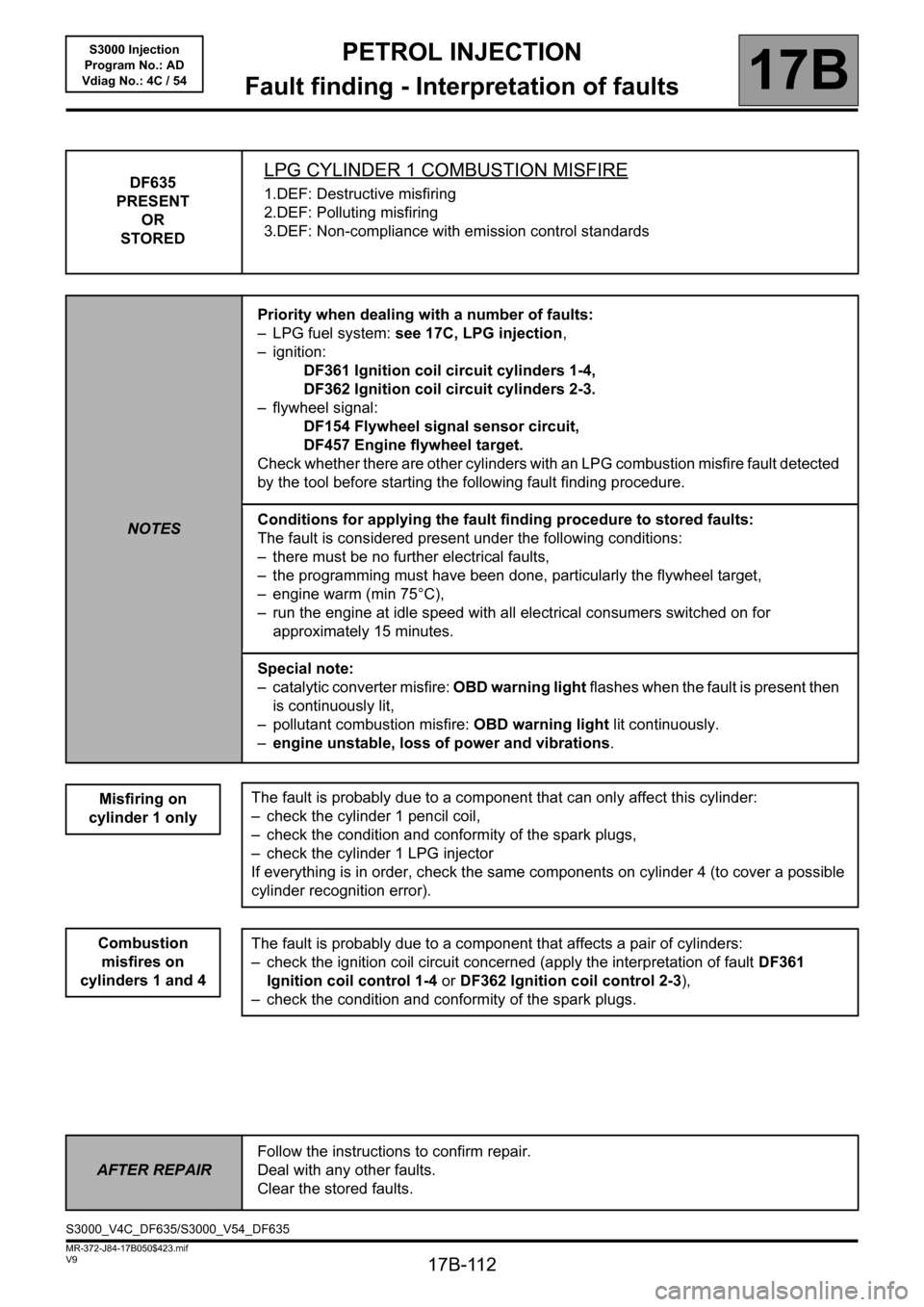

DF635

PRESENT

OR

STOREDLPG CYLINDER 1 COMBUSTION MISFIRE

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– LPG fuel system: see 17C, LPG injection,

– ignition:

DF361 Ignition coil circuit cylinders 1-4,

DF362 Ignition coil circuit cylinders 2-3.

– flywheel signal:

DF154 Flywheel signal sensor circuit,

DF457 Engine flywheel target.

Check whether there are other cylinders with an LPG combustion misfire fault detected

by the tool before starting the following fault finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– the programming must have been done, particularly the flywheel target,

– engine warm (min 75°C),

– run the engine at idle speed with all electrical consumers switched on for

approximately 15 minutes.

Special note:

– catalytic converter misfire: OBD warning light flashes when the fault is present then

is continuously lit,

– pollutant combustion misfire: OBD warning light lit continuously.

–engine unstable, loss of power and vibrations.

Misfiring on

cylinder 1 only

Combustion

misfires on

cylinders 1 and 4

The fault is probably due to a component that can only affect this cylinder:

– check the cylinder 1 pencil coil,

– check the condition and conformity of the spark plugs,

– check the cylinder 1 LPG injector

If everything is in order, check the same components on cylinder 4 (to cover a possible

cylinder recognition error).

The fault is probably due to a component that affects a pair of cylinders:

– check the ignition coil circuit concerned (apply the interpretation of fault DF361

Ignition coil control 1-4 or DF362 Ignition coil control 2-3),

– check the condition and conformity of the spark plugs.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF635/S3000_V54_DF635

Page 113 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-113V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

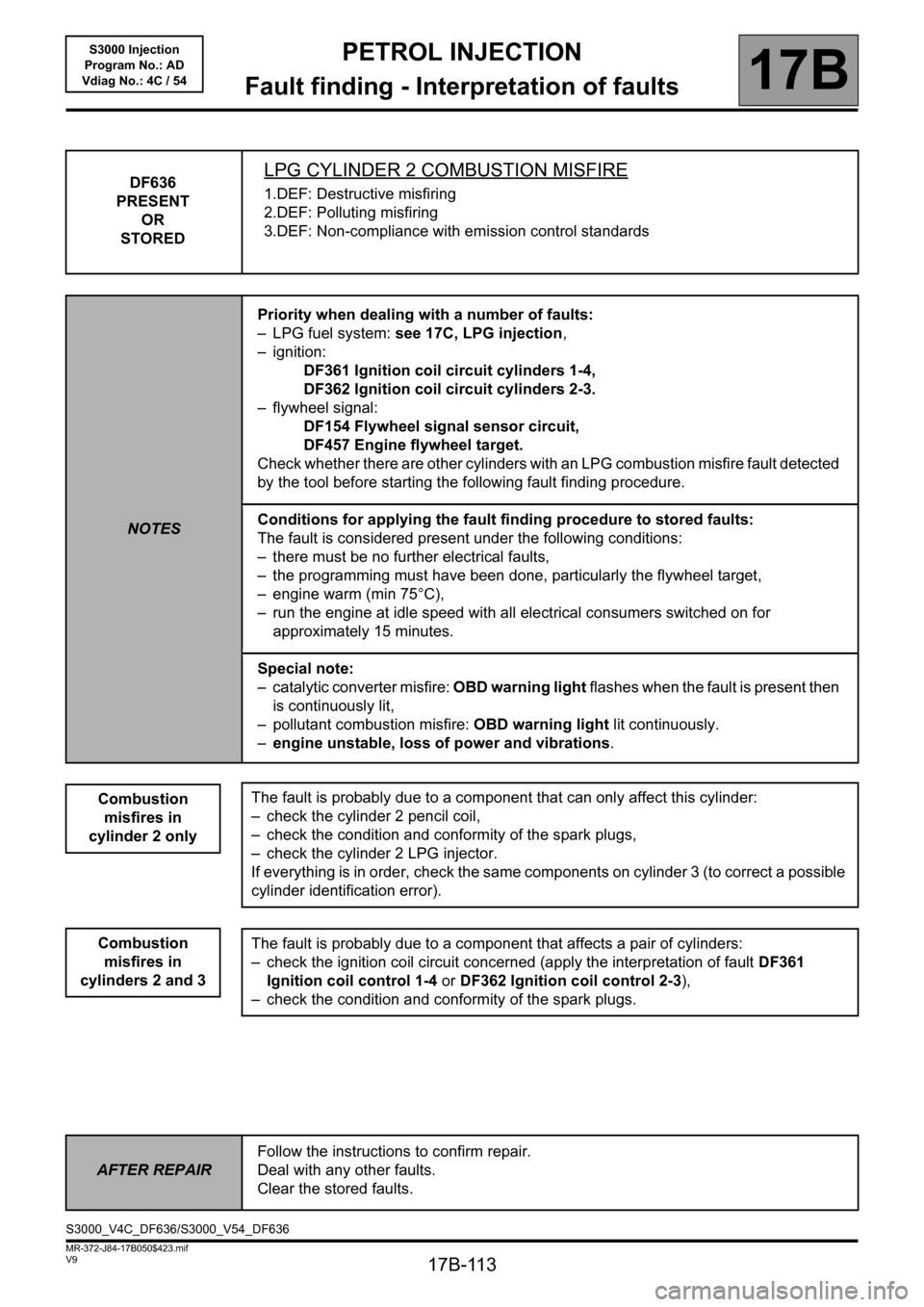

DF636

PRESENT

OR

STOREDLPG CYLINDER 2 COMBUSTION MISFIRE

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– LPG fuel system: see 17C, LPG injection,

– ignition:

DF361 Ignition coil circuit cylinders 1-4,

DF362 Ignition coil circuit cylinders 2-3.

– flywheel signal:

DF154 Flywheel signal sensor circuit,

DF457 Engine flywheel target.

Check whether there are other cylinders with an LPG combustion misfire fault detected

by the tool before starting the following fault finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– the programming must have been done, particularly the flywheel target,

– engine warm (min 75°C),

– run the engine at idle speed with all electrical consumers switched on for

approximately 15 minutes.

Special note:

– catalytic converter misfire: OBD warning light flashes when the fault is present then

is continuously lit,

– pollutant combustion misfire: OBD warning light lit continuously.

–engine unstable, loss of power and vibrations.

Combustion

misfires in

cylinder 2 only

Combustion

misfires in

cylinders 2 and 3

The fault is probably due to a component that can only affect this cylinder:

– check the cylinder 2 pencil coil,

– check the condition and conformity of the spark plugs,

– check the cylinder 2 LPG injector.

If everything is in order, check the same components on cylinder 3 (to correct a possible

cylinder identification error).

The fault is probably due to a component that affects a pair of cylinders:

– check the ignition coil circuit concerned (apply the interpretation of fault DF361

Ignition coil control 1-4 or DF362 Ignition coil control 2-3),

– check the condition and conformity of the spark plugs.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF636/S3000_V54_DF636

Page 114 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-114V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

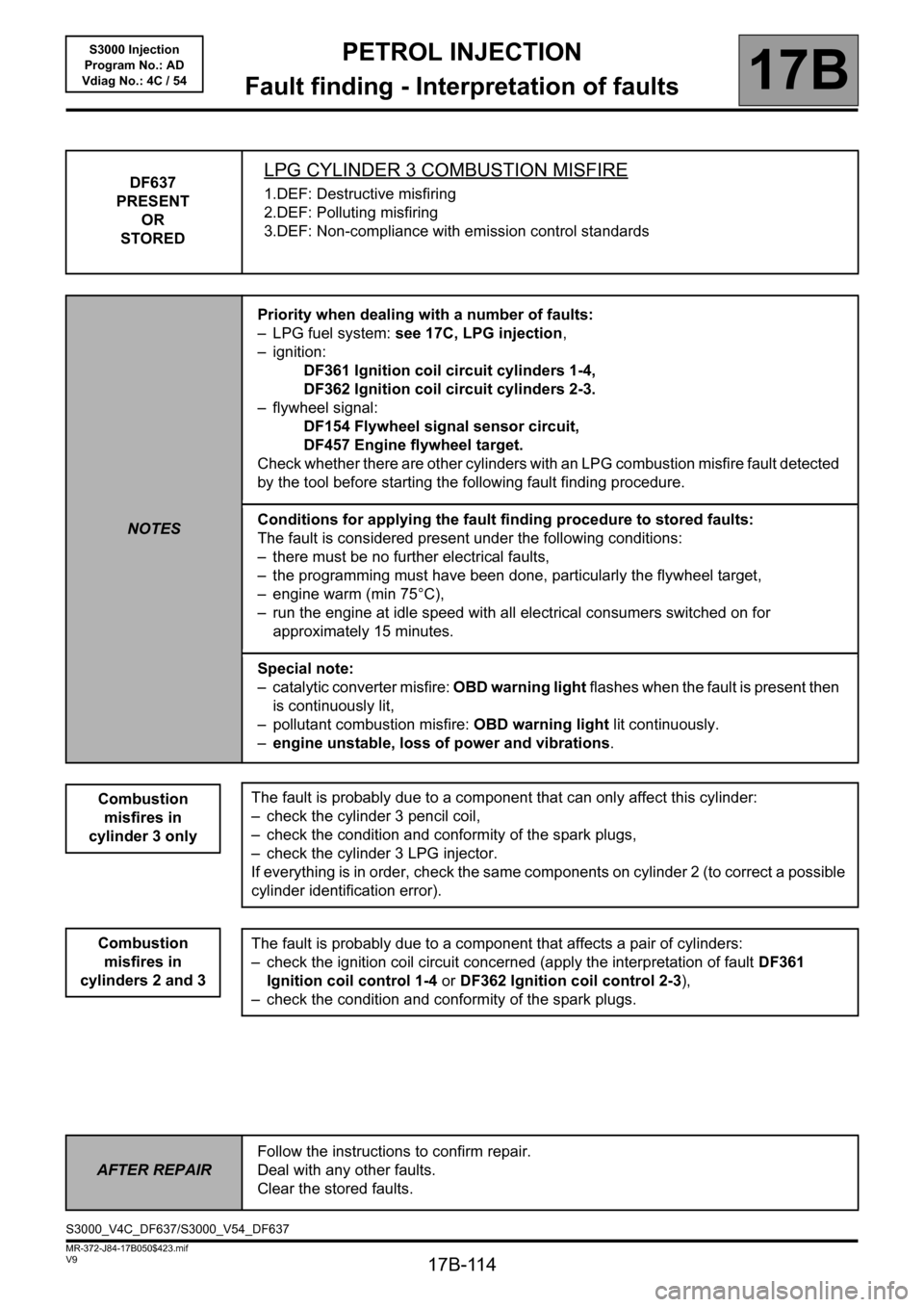

DF637

PRESENT

OR

STOREDLPG CYLINDER 3 COMBUSTION MISFIRE

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– LPG fuel system: see 17C, LPG injection,

– ignition:

DF361 Ignition coil circuit cylinders 1-4,

DF362 Ignition coil circuit cylinders 2-3.

– flywheel signal:

DF154 Flywheel signal sensor circuit,

DF457 Engine flywheel target.

Check whether there are other cylinders with an LPG combustion misfire fault detected

by the tool before starting the following fault finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– the programming must have been done, particularly the flywheel target,

– engine warm (min 75°C),

– run the engine at idle speed with all electrical consumers switched on for

approximately 15 minutes.

Special note:

– catalytic converter misfire: OBD warning light flashes when the fault is present then

is continuously lit,

– pollutant combustion misfire: OBD warning light lit continuously.

–engine unstable, loss of power and vibrations.

Combustion

misfires in

cylinder 3 only

Combustion

misfires in

cylinders 2 and 3

The fault is probably due to a component that can only affect this cylinder:

– check the cylinder 3 pencil coil,

– check the condition and conformity of the spark plugs,

– check the cylinder 3 LPG injector.

If everything is in order, check the same components on cylinder 2 (to correct a possible

cylinder identification error).

The fault is probably due to a component that affects a pair of cylinders:

– check the ignition coil circuit concerned (apply the interpretation of fault DF361

Ignition coil control 1-4 or DF362 Ignition coil control 2-3),

– check the condition and conformity of the spark plugs.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF637/S3000_V54_DF637

Page 115 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-115V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

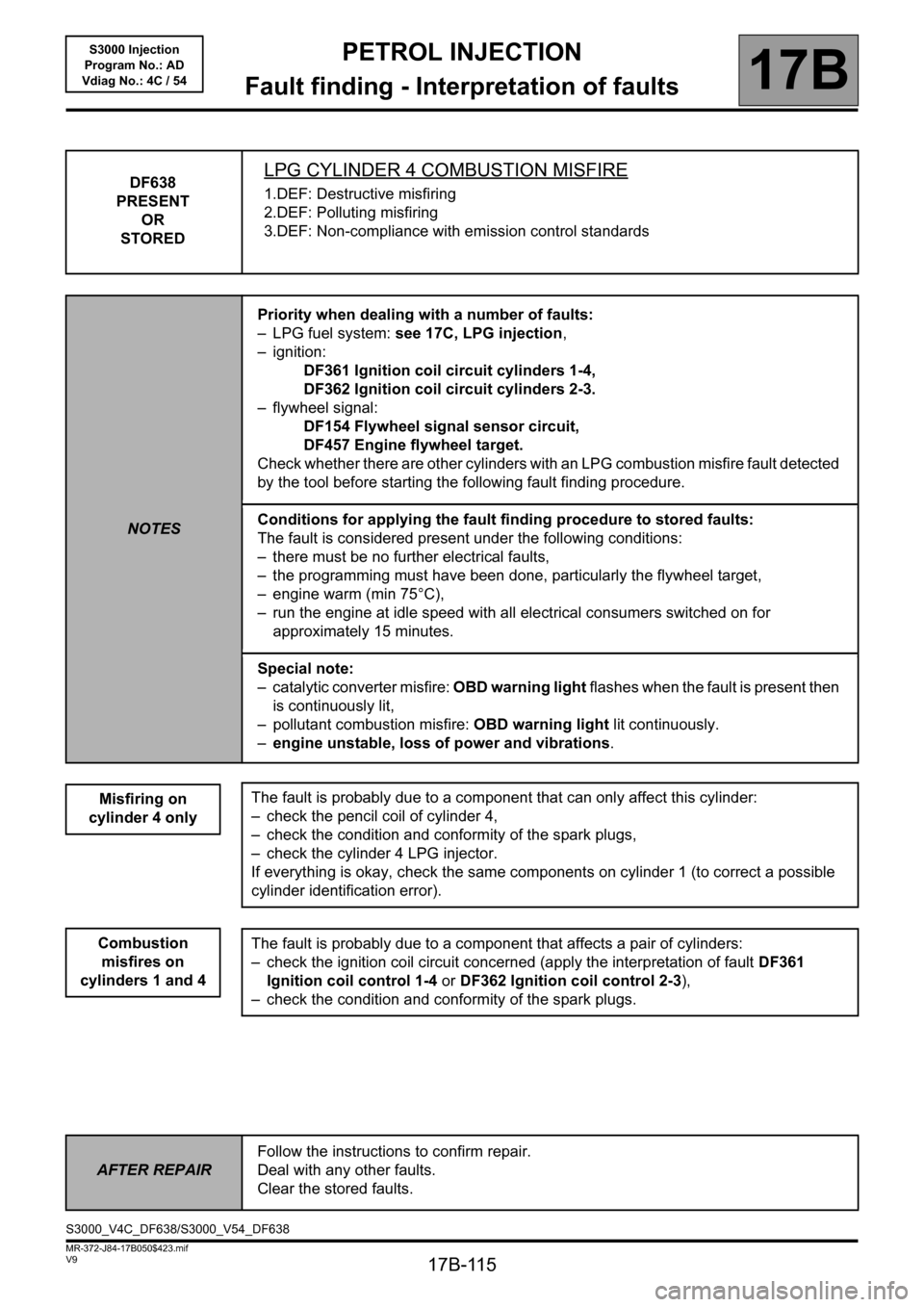

DF638

PRESENT

OR

STOREDLPG CYLINDER 4 COMBUSTION MISFIRE

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– LPG fuel system: see 17C, LPG injection,

– ignition:

DF361 Ignition coil circuit cylinders 1-4,

DF362 Ignition coil circuit cylinders 2-3.

– flywheel signal:

DF154 Flywheel signal sensor circuit,

DF457 Engine flywheel target.

Check whether there are other cylinders with an LPG combustion misfire fault detected

by the tool before starting the following fault finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– the programming must have been done, particularly the flywheel target,

– engine warm (min 75°C),

– run the engine at idle speed with all electrical consumers switched on for

approximately 15 minutes.

Special note:

– catalytic converter misfire: OBD warning light flashes when the fault is present then

is continuously lit,

– pollutant combustion misfire: OBD warning light lit continuously.

–engine unstable, loss of power and vibrations.

Misfiring on

cylinder 4 only

Combustion

misfires on

cylinders 1 and 4

The fault is probably due to a component that can only affect this cylinder:

– check the pencil coil of cylinder 4,

– check the condition and conformity of the spark plugs,

– check the cylinder 4 LPG injector.

If everything is okay, check the same components on cylinder 1 (to correct a possible

cylinder identification error).

The fault is probably due to a component that affects a pair of cylinders:

– check the ignition coil circuit concerned (apply the interpretation of fault DF361

Ignition coil control 1-4 or DF362 Ignition coil control 2-3),

– check the condition and conformity of the spark plugs.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF638/S3000_V54_DF638

Page 116 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-116

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-116V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

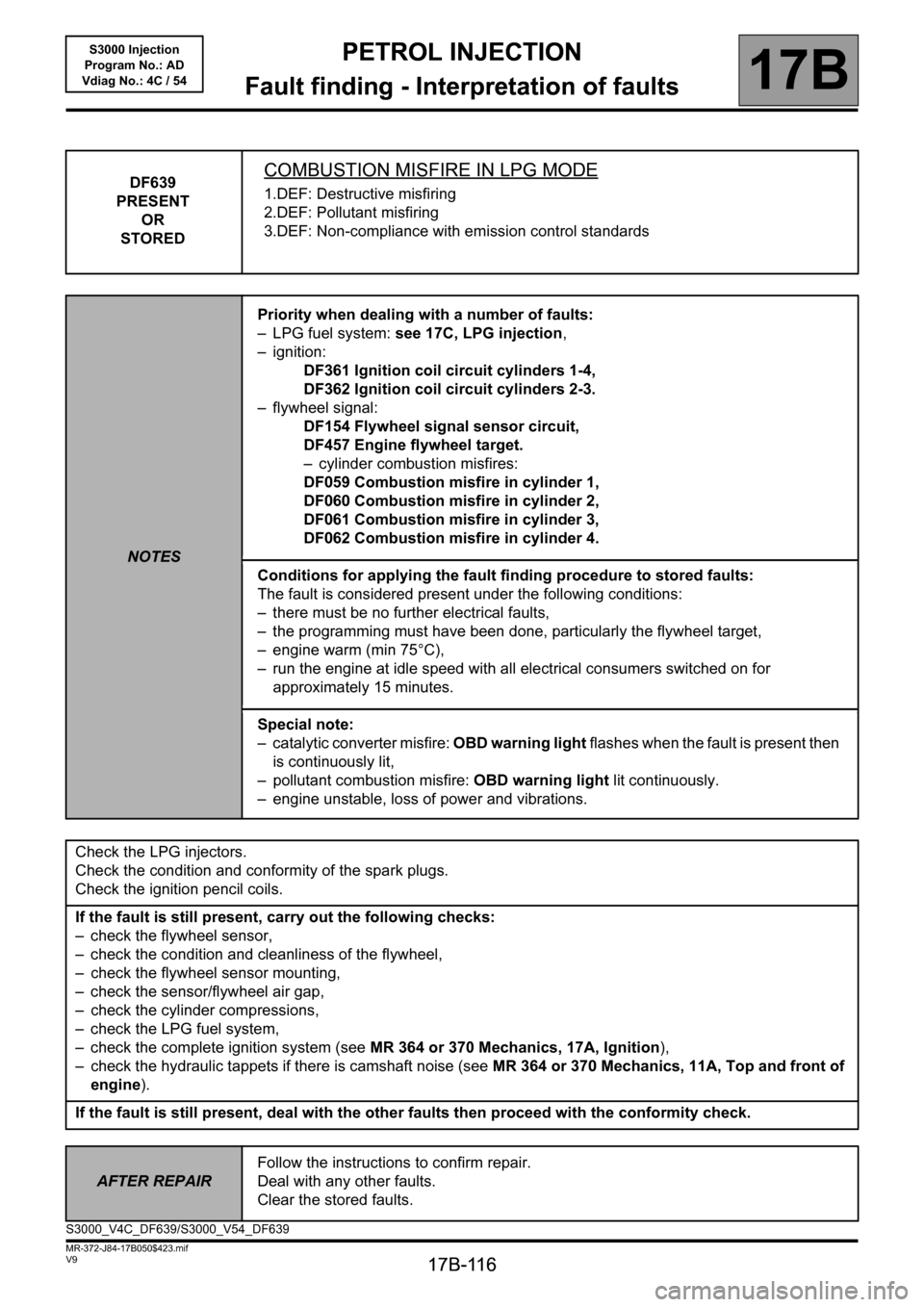

DF639

PRESENT

OR

STOREDCOMBUSTION MISFIRE IN LPG MODE

1.DEF: Destructive misfiring

2.DEF: Pollutant misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– LPG fuel system: see 17C, LPG injection,

– ignition:

DF361 Ignition coil circuit cylinders 1-4,

DF362 Ignition coil circuit cylinders 2-3.

– flywheel signal:

DF154 Flywheel signal sensor circuit,

DF457 Engine flywheel target.

– cylinder combustion misfires:

DF059 Combustion misfire in cylinder 1,

DF060 Combustion misfire in cylinder 2,

DF061 Combustion misfire in cylinder 3,

DF062 Combustion misfire in cylinder 4.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– the programming must have been done, particularly the flywheel target,

– engine warm (min 75°C),

– run the engine at idle speed with all electrical consumers switched on for

approximately 15 minutes.

Special note:

– catalytic converter misfire: OBD warning light flashes when the fault is present then

is continuously lit,

– pollutant combustion misfire: OBD warning light lit continuously.

– engine unstable, loss of power and vibrations.

Check the LPG injectors.

Check the condition and conformity of the spark plugs.

Check the ignition pencil coils.

If the fault is still present, carry out the following checks:

– check the flywheel sensor,

– check the condition and cleanliness of the flywheel,

– check the flywheel sensor mounting,

– check the sensor/flywheel air gap,

– check the cylinder compressions,

– check the LPG fuel system,

– check the complete ignition system (see MR 364 or 370 Mechanics, 17A, Ignition),

– check the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of

engine).

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF639/S3000_V54_DF639

Page 117 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-117

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-117V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

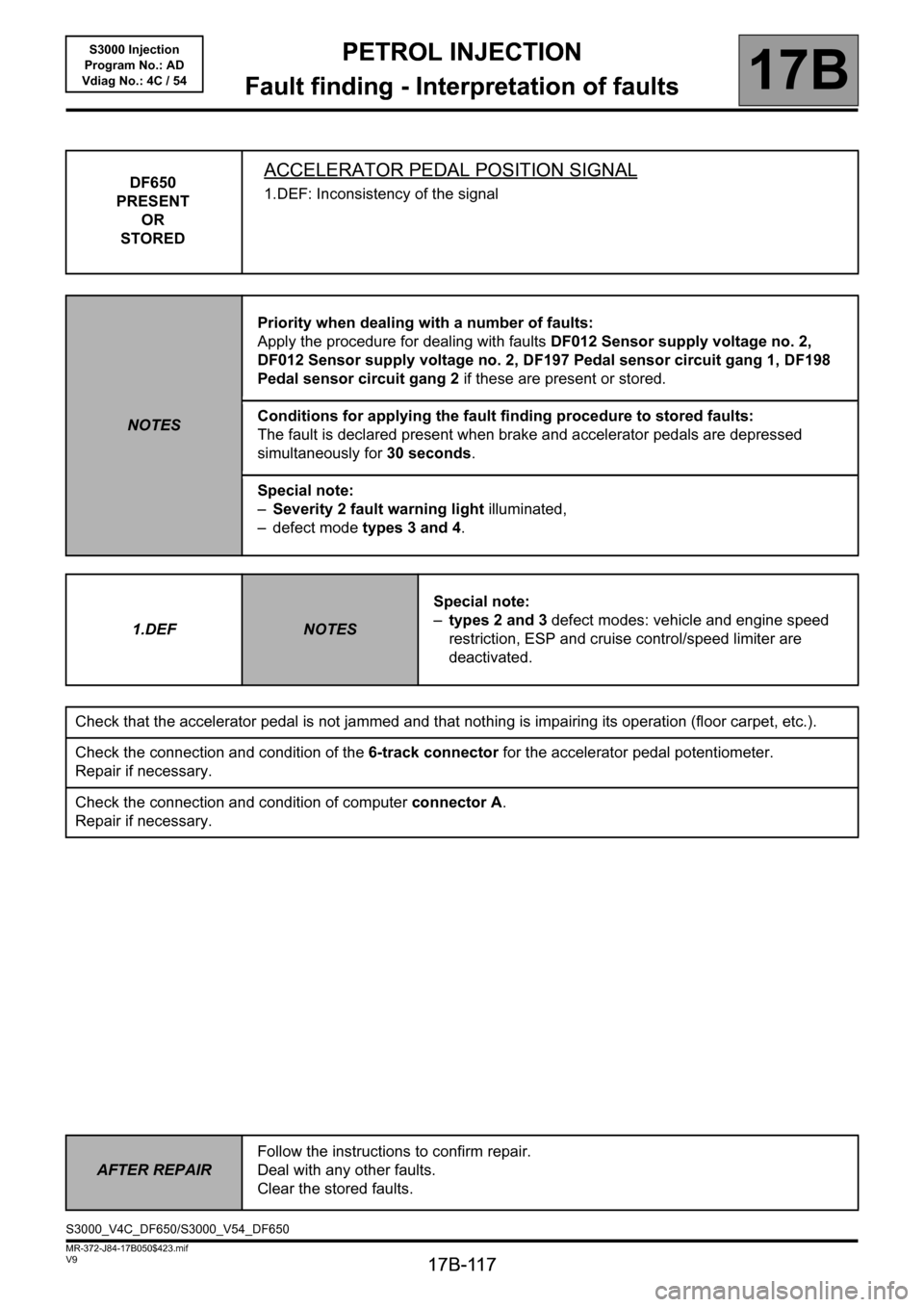

DF650

PRESENT

OR

STOREDACCELERATOR PEDAL POSITION SIGNAL

1.DEF: Inconsistency of the signal

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with faults DF012 Sensor supply voltage no. 2,

DF012 Sensor supply voltage no. 2, DF197 Pedal sensor circuit gang 1, DF198

Pedal sensor circuit gang 2 if these are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present when brake and accelerator pedals are depressed

simultaneously for 30 seconds.

Special note:

–Severity 2 fault warning light illuminated,

– defect mode types 3 and 4.

1.DEF

NOTESSpecial note:

–types 2 and 3 defect modes: vehicle and engine speed

restriction, ESP and cruise control/speed limiter are

deactivated.

Check that the accelerator pedal is not jammed and that nothing is impairing its operation (floor carpet, etc.).

Check the connection and condition of the 6-track connector for the accelerator pedal potentiometer.

Repair if necessary.

Check the connection and condition of computer connector A.

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF650/S3000_V54_DF650

Page 118 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-118

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-118V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

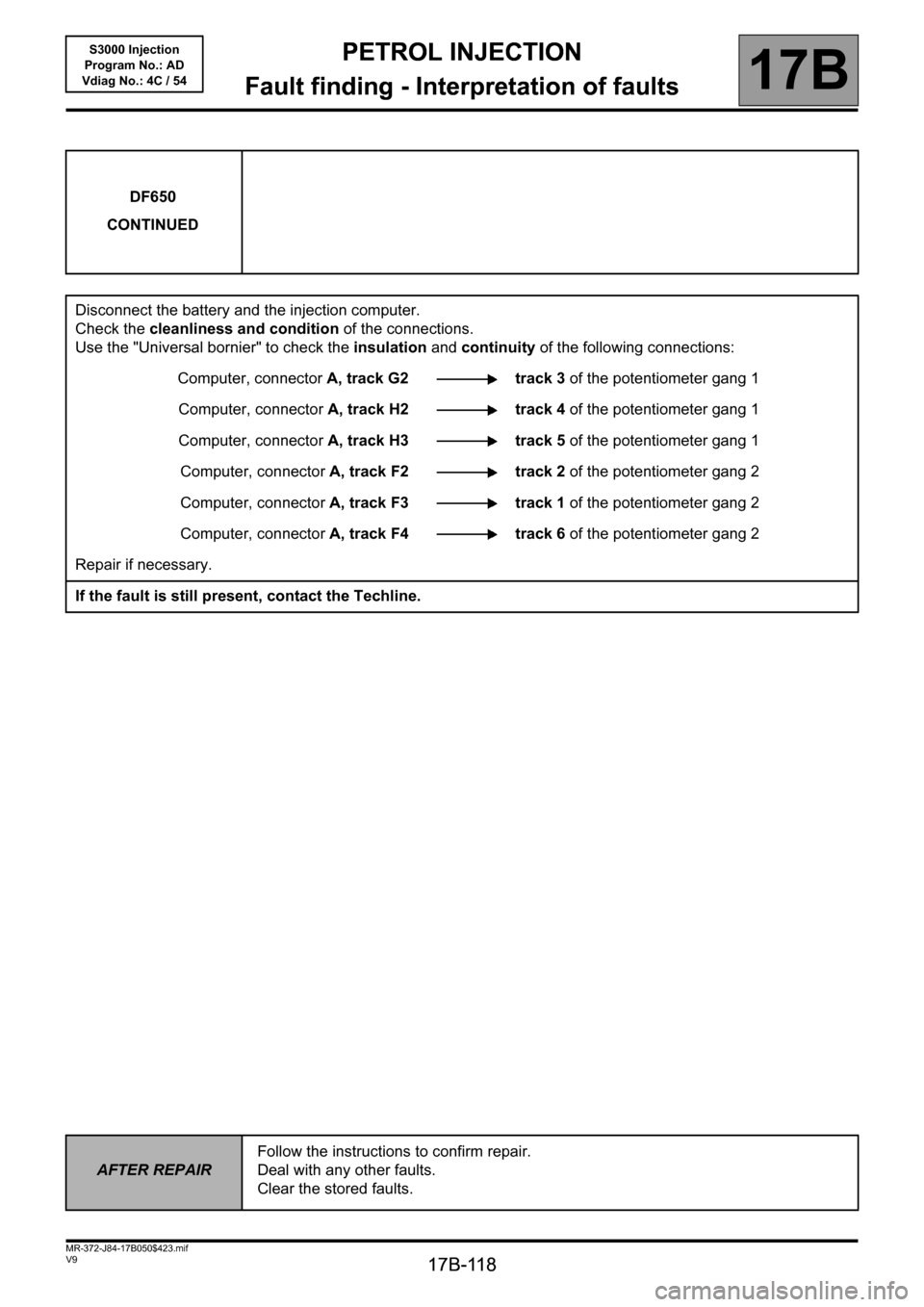

DF650

CONTINUED

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Computer, connectorA, track G2 track 3 of the potentiometer gang 1

Computer, connectorA, track H2 track 4 of the potentiometer gang 1

Computer, connectorA, track H3 track 5 of the potentiometer gang 1

Computer, connectorA, track F2 track 2 of the potentiometer gang 2

Computer, connectorA, track F3 track 1 of the potentiometer gang 2

Computer, connectorA, track F4 track 6 of the potentiometer gang 2

Repair if necessary.

If the fault is still present, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

Page 119 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-119

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-119V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

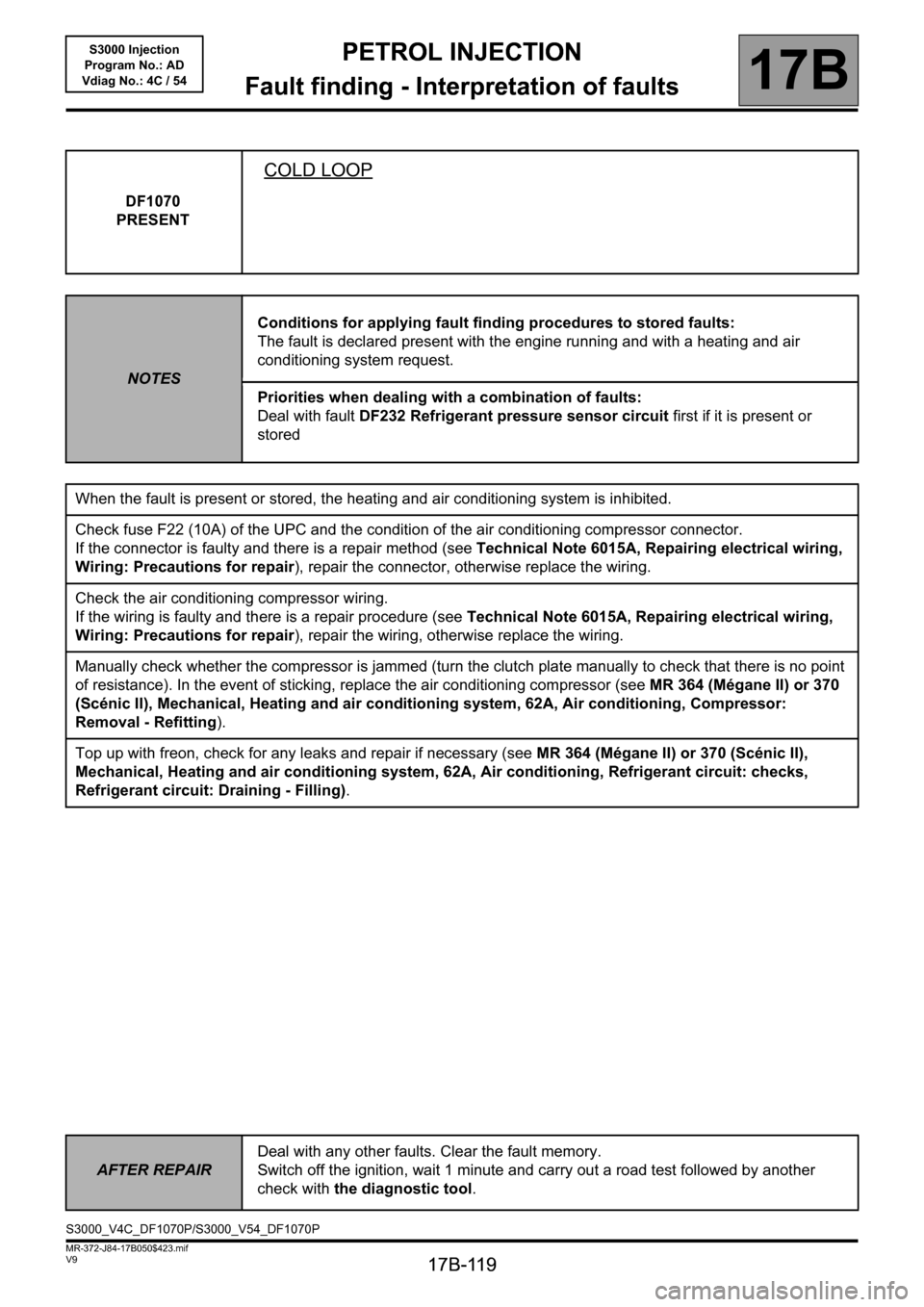

DF1070

PRESENT

COLD LOOP

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present with the engine running and with a heating and air

conditioning system request.

Priorities when dealing with a combination of faults:

Deal with fault DF232 Refrigerant pressure sensor circuit first if it is present or

stored

When the fault is present or stored, the heating and air conditioning system is inhibited.

Check fuse F22 (10A) of the UPC and the condition of the air conditioning compressor connector.

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the air conditioning compressor wiring.

If the wiring is faulty and there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Manually check whether the compressor is jammed (turn the clutch plate manually to check that there is no point

of resistance). In the event of sticking, replace the air conditioning compressor (see MR 364 (Mégane II) or 370

(Scénic II), Mechanical, Heating and air conditioning system, 62A, Air conditioning, Compressor:

Removal - Refitting).

Top up with freon, check for any leaks and repair if necessary (see MR 364 (Mégane II) or 370 (Scénic II),

Mechanical, Heating and air conditioning system, 62A, Air conditioning, Refrigerant circuit: checks,

Refrigerant circuit: Draining - Filling).

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

S3000_V4C_DF1070P/S3000_V54_DF1070P

Page 120 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-120

PETROL INJECTION

Fault finding - Conformity check

17B

17B-120V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Conformity check

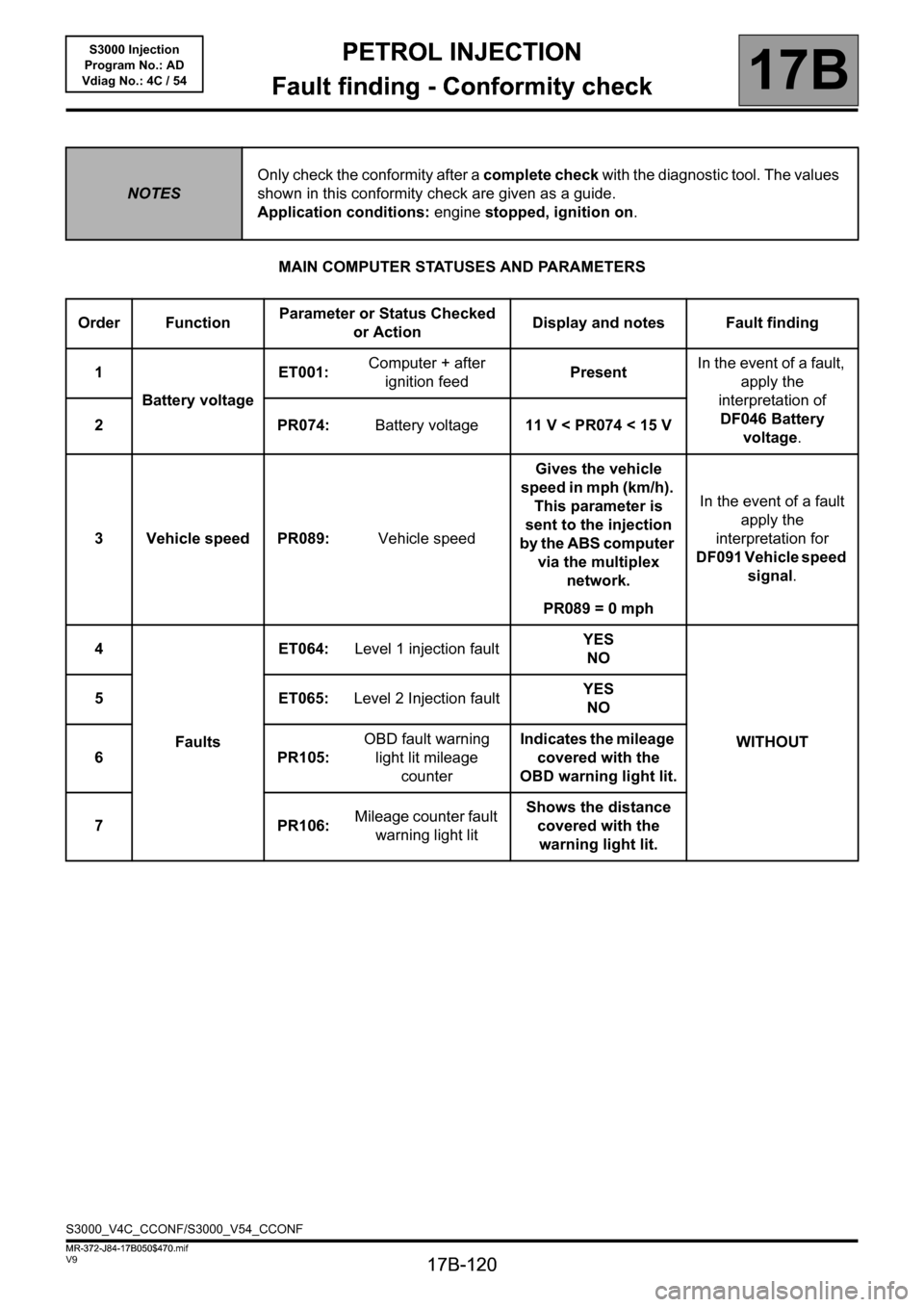

MAIN COMPUTER STATUSES AND PARAMETERS

NOTESOnly check the conformity after a complete check with the diagnostic tool. The values

shown in this conformity check are given as a guide.

Application conditions: engine stopped, ignition on.

Order FunctionParameter or Status Checked

or ActionDisplay and notes Fault finding

1

Battery voltageET001:Computer + after

ignition feedPresentIn the event of a fault,

apply the

interpretation of

DF046 Battery

voltage. 2 PR074:Battery voltage11 V < PR074 < 15 V

3 Vehicle speed PR089:Vehicle speedGives the vehicle

speed in mph (km/h).

This parameter is

sent to the injection

by the ABS computer

via the multiplex

network.

PR089= 0mphIn the event of a fault

apply the

interpretation for

DF091 Vehicle speed

signal.

4

FaultsET064:Level 1 injection faultYES

NO

WITHOUT 5ET065:Level 2 Injection faultYES

NO

6 PR105:OBD fault warning

light lit mileage

counterIndicates the mileage

covered with the

OBD warning light lit.

7 PR106:Mileage counter fault

warning light litShows the distance

covered with the

warning light lit.

S3000_V4C_CCONF/S3000_V54_CCONF

MR-372-J84-17B050$470.mif