battery RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 48 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-48

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-48V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF038

PRESENT

COMPUTER

1.DEF: Internal electronic fault

NOTESPriority when dealing with a number of faults:

Deal with the other faults first.

Special note:

–the OBD warning light is lit,

– throttle valve defect mode types 1, 2 or 5 present or stored.

Make sure there is a supply to the injection computer:

– disconnect the battery and the injection computer,

– check the cleanliness and condition of the connections,

– reconnect the battery.

Using the universal bornier, check for + 12 V on the following computer tracks:

–track D1, connector A,

–track M2, connector B.

Repair if necessary.

Check for the injection computer earths:

– disconnect the battery and the injection computer,

– check the cleanliness and condition of the connections,

– reconnect the battery.

Using the Universal bornier, check for earths on the following computer tracks:

–track L1, connector B,

–track M1, connector B,

–track L1, connector C,

–track M1, connector C.

Repair if necessary.

If all the supplies and earths are correct, contact the Techline.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF038P/S3000_V54_DF038P

Page 49 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-49

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-49V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF046

PRESENT

BATTERY VOLTAGE

1.DEF: Abnormal voltage

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with fault DF084 Actuators relay control circuit first

if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present with the engine running.

Special note:

–level 1 fault warning light illuminated.

– throttle valve defect mode types 1 and 2 in the event of undervoltage: vehicle and

engine speed restriction, the ESP and cruise control/speed limiter are deactivated.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the computer connections.

Repair if necessary.

Disconnect the CN and MN connector of the Protection and Switching Unit.

Check the cleanliness and condition of its connections.

Use the Universal bornier to check the continuity of the following connections:

Injection computer, connectorB, track M2Protection and Switching Unit, connector CN,

track 6

Injection computer, connectorB, track D4Protection and Switching Unit, connector MN,

track 5

Repair if necessary.

– clean the battery terminals and all connections to + and the Earth,

– check the battery voltage,

– check the charging circuit (see Technical Note 6014A Checking the charging circuit).

Repair or replace the faulty components, if necessary.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF046P/S3000_V54_DF046P

Page 50 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-50

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-50V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF054

PRESENT

OR

STOREDTURBOCHARGING SOLENOID VALVE CONTROL CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition is switched on or with then engine

running at an engine speed above 600 rpm.

Special note:

–for F4R-Turbo only,

–OBD warning light illuminated.

– Throttle valve defect mode type 6.

Check the cleanliness, condition and fitting of the turbocharging solenoid valve.

Repair if necessary.

If the fault is still present, manipulate the harness to note any change in fault status (present↔ stored).

Look for possible damage to the wiring harness, check the condition and connection of the connectors of the

injection computer and turbocharging solenoid valve.

Repair if necessary.

If the fault is still present, check (with the ignition on) for +12V on track 2 of the turbocharging solenoid valve.

If there is no + 12 V, check the insulation, continuity and the absence of interference resistance on the

following connections:

Injection computer, connectorB, track M2 track 2 of the turbocharging solenoid valve

Main relay

Repair if necessary.

If the fault is still present, disconnect the battery and the injection computer.

Check the insulation, continuity and the absence of interference resistance on the following connections:

Injection computer, connectorC track G4 track 1 of the turbocharging solenoid valve

Repair if necessary.

If the fault is still present, measure the resistance of the turbocharging solenoid valve between tracks 1 and 2.

Replace the turbocharging solenoid valve if the resistance is not 30Ω ±2Ω at 23°C.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF054/S3000_V54_DF054

Page 59 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-59

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-59V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF078

PRESENT

OR

STOREDMOTORISED THROTTLE CONTROL CIRCUIT

1.DEF: Component in bad condition

WARNING

Never drive the vehicle without having confirmed that no faults involving the throttle valve are present.

NOTESPriority when dealing with a number of faults:

If faults DF095 Throttle potentiometer circuit gang 1 or DF096 Throttle

potentiometer circuit gang 2 are present, deal with these first.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present if:

– the engine speed varies,

–the AC027 Motorised throttle command is activated,

– the engine air temperature should be between 5°C and 105°C.

Special note:

–level 1 fault warning light illuminated.

– throttle valve defect mode types 1 and 2: vehicle and engine speed restriction, ESP

and the cruise control/speed limiter are deactivated.

Check the cleanliness and condition of the throttle valve and its connections.

Manually check that the throttle rotates properly.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connectorB, track M3 track 3 of the motorised throttle

(K4M 766/812 and 813, F4R 770 and 771)

track 4of the motorised throttle

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connectorB track M4 track 5 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 3 of the motorised throttle

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF078/S3000_V54_DF078

Page 62 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-62

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-62V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

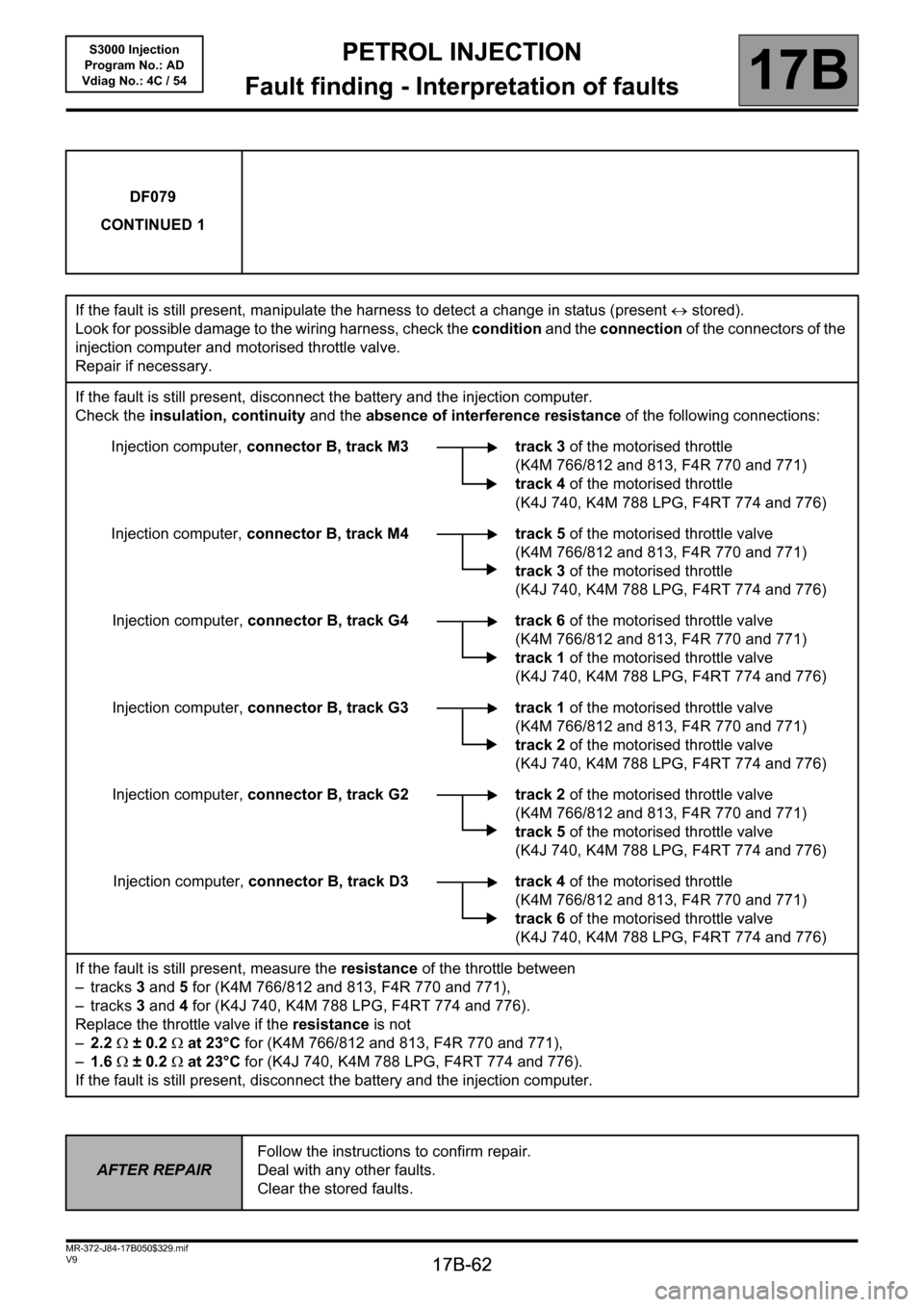

DF079

CONTINUED 1

If the fault is still present, manipulate the harness to detect a change in status (present ↔ stored).

Look for possible damage to the wiring harness, check the condition and the connection of the connectors of the

injection computer and motorised throttle valve.

Repair if necessary.

If the fault is still present, disconnect the battery and the injection computer.

Check the insulation, continuity and the absence of interference resistance of the following connections:

Injection computer, connector B, track M3 track 3 of the motorised throttle

(K4M 766/812 and 813, F4R 770 and 771)

track 4of the motorised throttle

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track M4 track 5 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 3 of the motorised throttle

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track G4 track 6 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 1 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track G3 track 1 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 2 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track G2 track 2 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 5 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track D3 track 4of the motorised throttle

(K4M 766/812 and 813, F4R 770 and 771)

track 6 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

If the fault is still present, measure the resistance of the throttle between

– tracks3 and 5 for (K4M 766/812 and 813, F4R 770 and 771),

– tracks3 and 4 for (K4J 740, K4M 788 LPG, F4RT 774 and 776).

Replace the throttle valve if the resistance is not

–2.2Ω ±0.2Ω at 23°C for (K4M 766/812 and 813, F4R 770 and 771),

–1.6Ω ±0.2Ω at 23°C for (K4J 740, K4M 788 LPG, F4RT 774 and 776).

If the fault is still present, disconnect the battery and the injection computer.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

Page 64 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-64

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-64V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Interpretation of faults

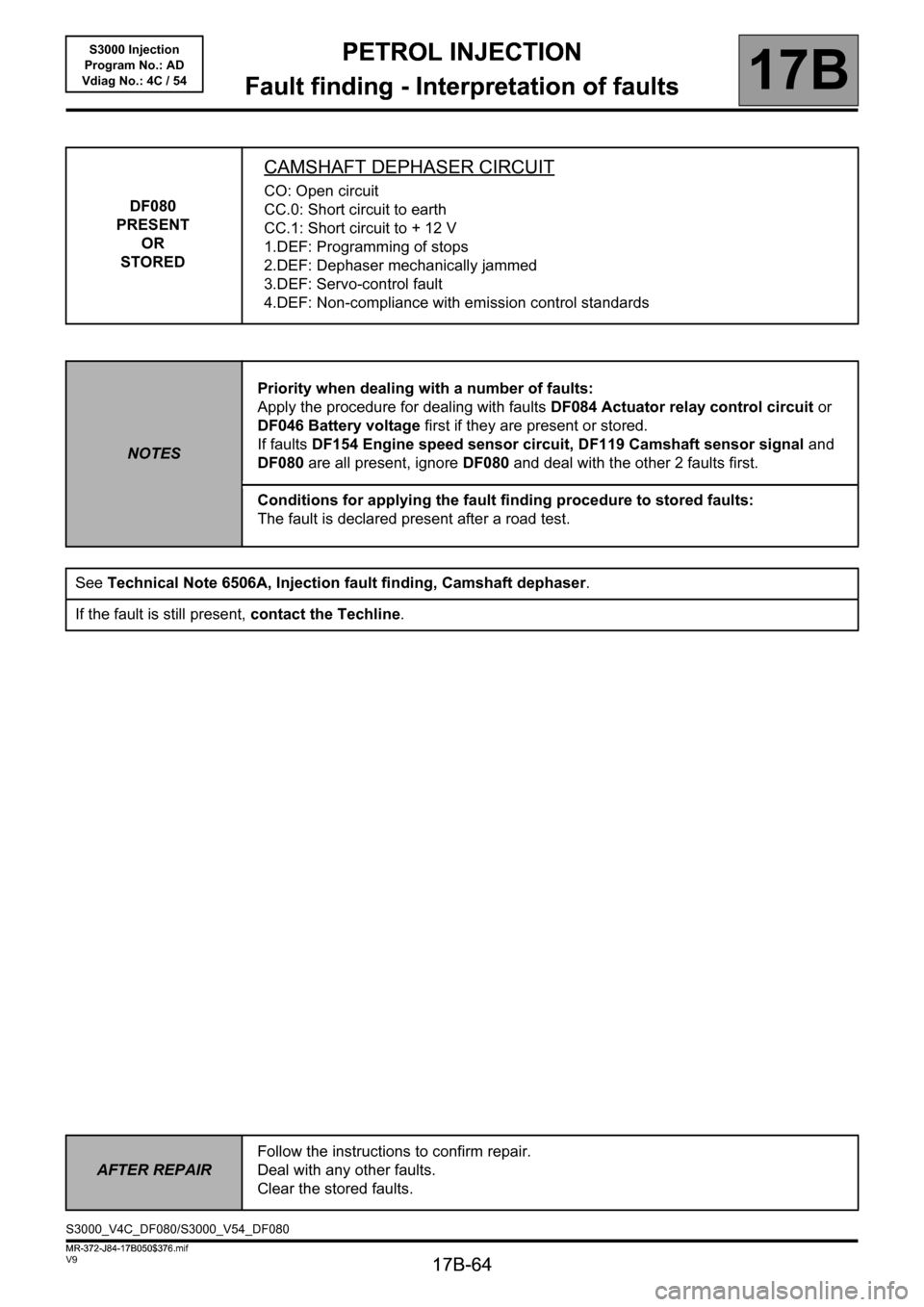

DF080

PRESENT

OR

STORED

CAMSHAFT DEPHASER CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short circuit to + 12 V

1.DEF: Programming of stops

2.DEF: Dephaser mechanically jammed

3.DEF: Servo-control fault

4.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with faults DF084 Actuator relay control circuit or

DF046 Battery voltage first if they are present or stored.

If faults DF154 Engine speed sensor circuit, DF119 Camshaft sensor signal and

DF080 are all present, ignore DF080 and deal with the other 2 faults first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after a road test.

See Technical Note 6506A, Injection fault finding, Camshaft dephaser.

If the fault is still present, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF080/S3000_V54_DF080

MR-372-J84-17B050$376.mif

Page 65 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-65

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-65V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

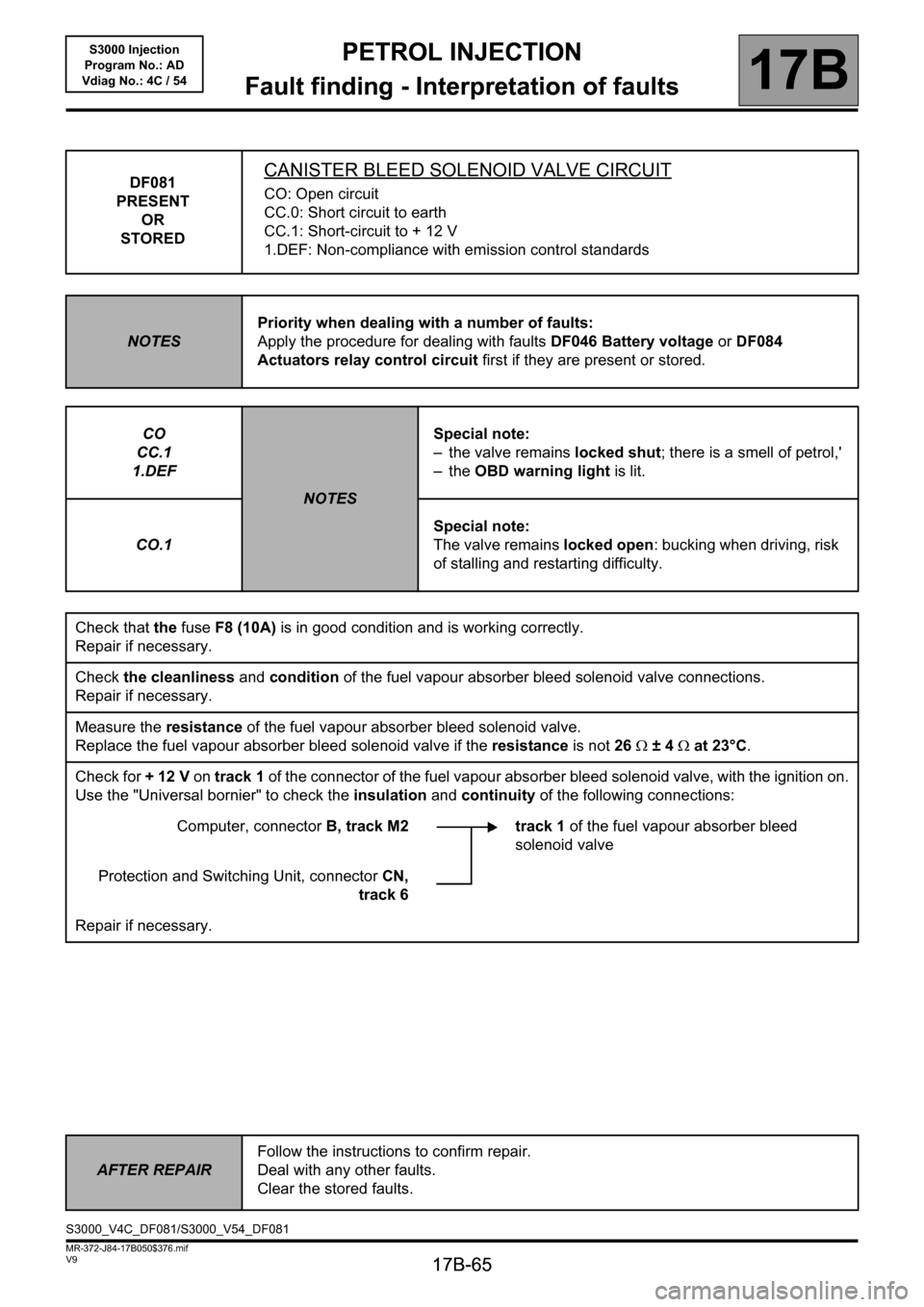

DF081

PRESENT

OR

STOREDCANISTER BLEED SOLENOID VALVE CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with faults DF046 Battery voltage or DF084

Actuators relay control circuit first if they are present or stored.

CO

CC.1

1.DEF

NOTESSpecial note:

– the valve remains locked shut; there is a smell of petrol,'

–the OBD warning light is lit.

CO.1Special note:

The valve remains locked open: bucking when driving, risk

of stalling and restarting difficulty.

Check that the fuseF8 (10A) is in good condition and is working correctly.

Repair if necessary.

Check the cleanliness and condition of the fuel vapour absorber bleed solenoid valve connections.

Repair if necessary.

Measure the resistance of the fuel vapour absorber bleed solenoid valve.

Replace the fuel vapour absorber bleed solenoid valve if the resistance is not 26Ω ±4Ω at 23°C.

Check for + 12 V on track 1 of the connector of the fuel vapour absorber bleed solenoid valve, with the ignition on.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Computer, connectorB, track M2 track 1 of the fuel vapour absorber bleed

solenoid valve

Protection and Switching Unit, connectorCN,

track 6

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF081/S3000_V54_DF081

Page 66 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-66

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-66V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF081

CONTINUED

Disconnect the battery.

Disconnect the computer. Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity on the following connection:

Computer, connectorC, track E1 track 2 of the petrol vapour absorber bleed

solenoid valve

Repair if necessary.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

Page 67 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-67

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-67V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

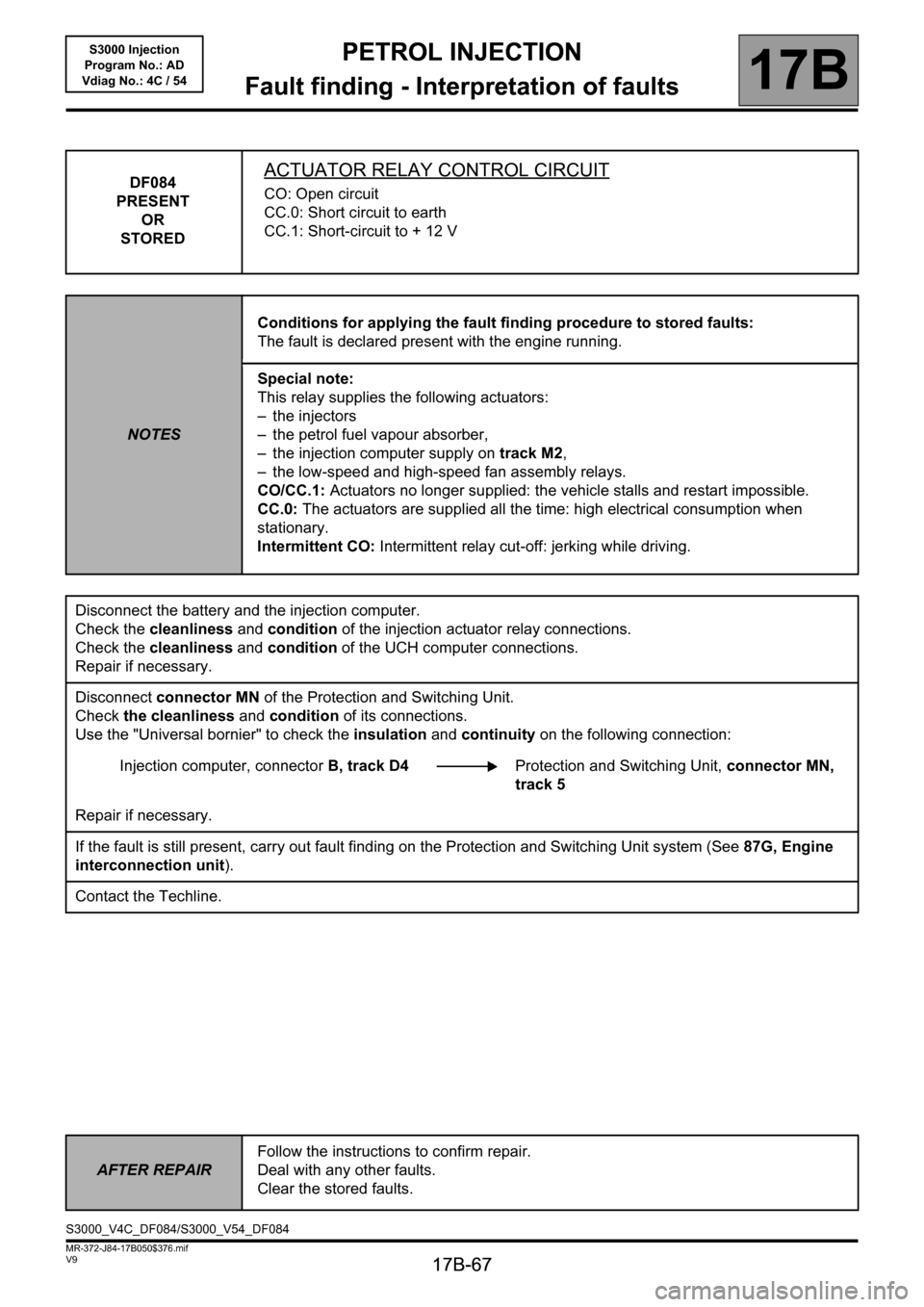

DF084

PRESENT

OR

STOREDACTUATOR RELAY CONTROL CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present with the engine running.

Special note:

This relay supplies the following actuators:

– the injectors

– the petrol fuel vapour absorber,

– the injection computer supply on track M2,

– the low-speed and high-speed fan assembly relays.

CO/CC.1: Actuators no longer supplied: the vehicle stalls and restart impossible.

CC.0: The actuators are supplied all the time: high electrical consumption when

stationary.

Intermittent CO: Intermittent relay cut-off: jerking while driving.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the injection actuator relay connections.

Check the cleanliness and condition of the UCH computer connections.

Repair if necessary.

Disconnect connector MN of the Protection and Switching Unit.

Check the cleanliness and condition of its connections.

Use the "Universal bornier" to check the insulation and continuity on the following connection:

Injection computer, connectorB, track D4Protection and Switching Unit, connector MN,

track 5

Repair if necessary.

If the fault is still present, carry out fault finding on the Protection and Switching Unit system (See87G, Engine

interconnection unit).

Contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF084/S3000_V54_DF084

Page 68 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-68

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-68V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

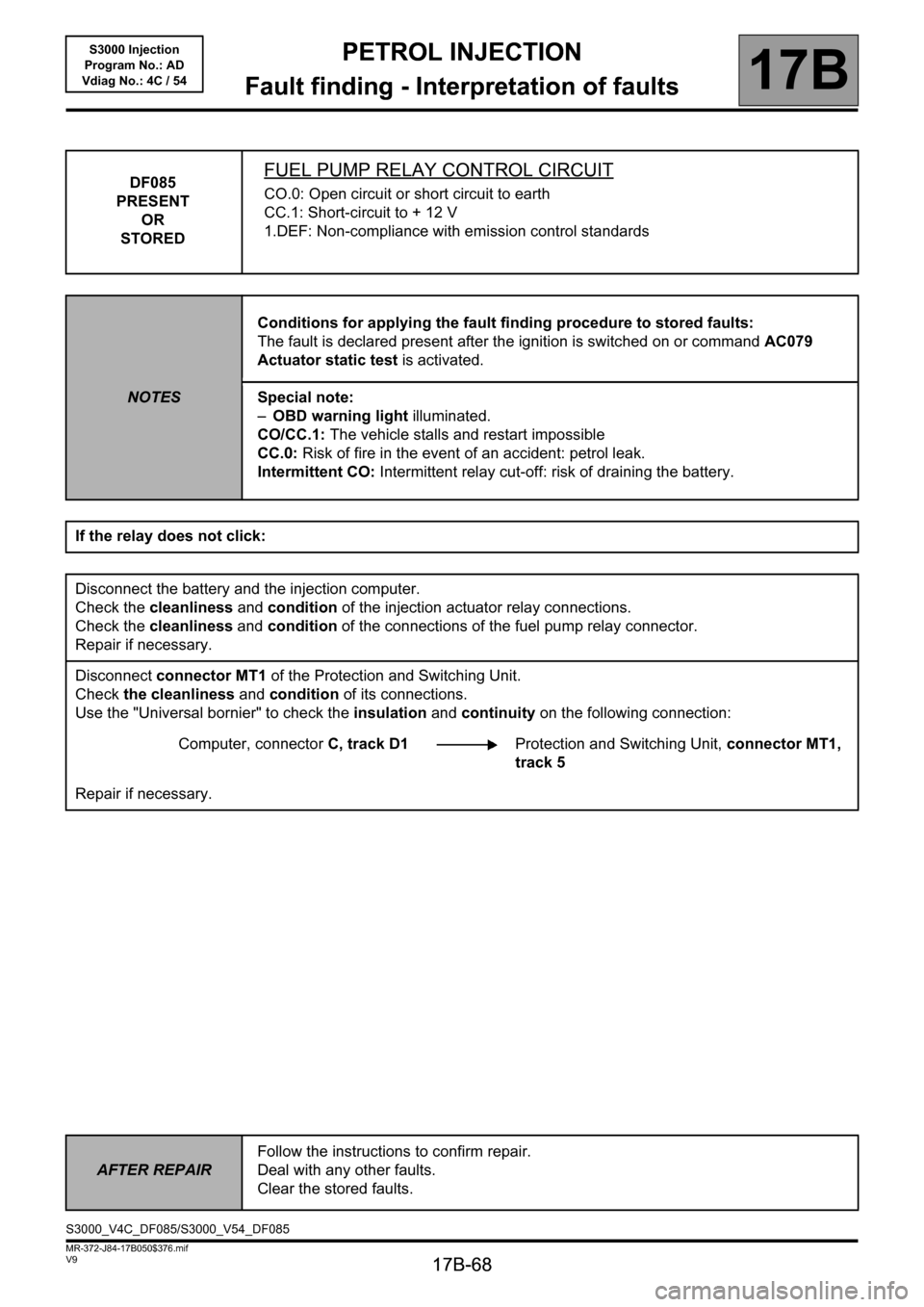

DF085

PRESENT

OR

STOREDFUEL PUMP RELAY CONTROL CIRCUIT

CO.0: Open circuit or short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition is switched on or command AC079

Actuator static test is activated.

Special note:

–OBD warning light illuminated.

CO/CC.1: The vehicle stalls and restart impossible

CC.0: Risk of fire in the event of an accident: petrol leak.

Intermittent CO: Intermittent relay cut-off: risk of draining the battery.

If the relay does not click:

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the injection actuator relay connections.

Check the cleanliness and condition of the connections of the fuel pump relay connector.

Repair if necessary.

Disconnect connector MT1 of the Protection and Switching Unit.

Check the cleanliness and condition of its connections.

Use the "Universal bornier" to check the insulation and continuity on the following connection:

Computer, connectorC, track D1Protection and Switching Unit, connector MT1,

track 5

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF085/S3000_V54_DF085