ESP RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 186 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 186

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 186V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET415

CRUISE CONTROL/SPEED LIMITER DEACTIVATION

NOTESSpecial notes:

Only perform the tests if the statuses do not correspond with the system programming

functions.

Note:

Cruise control can be activated when the vehicle speed exceeds 18 mph (30 km/h).

Status ET415 displays the various reasons for deactivation of the cruise control/speed limiter function, which are

due to driver demand or the exterior environment.

IMPORTANT

Clear the fault memory by running command RZ001 "Fault memory", to reset this status to "NONE".

NONEThis status is present on the diagnostic tool when:

The computer has been reinitialised.

The computer has been reprogrammed

STATUS 1Traction control request

If the vehicle is fitted with a traction control system, the cruise control function is

deactivated every time the ABS computer calls for traction control.

Status ET415 becomes STATUS 1 when driving with the cruise control active (ET042

Cruise control/Speed limiter: CRUISE CONTROL) and traction control is requested.

This deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ001

"Fault memory".

If status ET415 becomes STATUS 1 with no traction control request (see 38C, Anti-lock

Braking System).

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool

S3000_V4C_ET415/S3000_V54_ET415

Page 187 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 187

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 187V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET415

(CONTINUED 1)

STATUS 2Brake pedal depressed

The cruise control function is deactivated when the brake pedal is depressed.

Status ET415 becomes STATUS 2 when driving with cruise control active (ET042

Cruise control/Speed limiter: CRUISE CONTROL) and the brake pedal is depressed.

This deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ001

"Fault memory".

If status ET415 becomes STATUS 2 without depressing the brake pedal, consult the

interpretation of statuses ET704 Brake switch no. 1 and ET705 Brake switch no. 2.

STATUS 3Clutch pedal depressed

Manual gearbox ONLY

The cruise control function is deactivated when the gearbox is not coupled to the engine

(clutch pedal depressed).

Status ET415 becomes STATUS 3 when driving with cruise control active (ET042

Cruise control/speed limiter: CRUISE CONTROL) and the clutch pedal is depressed.

This deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ001

"Fault memory".

If status ET415 becomes STATUS 3 without the clutch pedal being depressed, consult

the interpretation of status ET405 Clutch pedal switch.

If the vehicle is fitted with automatic transmission:

Test the multiplex network: check the configuration of the multiplex network in relation to

the vehicle's technical specification, especially the configuration of the automatic

transmission computer (see 88B, Multiplexing)

STATUS 4Cancel button pressed

The cruise control/speed limiter function is deactivated whenever the suspend button is

pressed.

Status ET415 becomes STATUS 4 while driving when:

- Either the cruise control is active.

- Or the speed limiter is active,

- and the driver presses the 0 button.

This action deactivates the Cruise control/Speed limiter.

Reinitialise status ET415 on the injection computer by running command RZ001

"Fault memory".

If status ET415 becomes STATUS 4 without pressing the 0 button, consult the

interpretation of status ET703 Cruise control/speed limiter buttons and run fault

finding on the R/0 control button located on the right-hand side of the steering wheel.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool

Page 195 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 195

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 195V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET566

TYPE 3 DEFECT MODE

NOTESThere must be no present or stored faults.

This status groups the faults for deducing that the system no longer responds to engine or vehicle speed regulation,

but still controls the air flow modulation (throttle servo system operational). It uses the pedal mode reconstructed

by calibration.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET566/S3000_V54_ET566

Page 198 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 198

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 198V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET703

CRUISE CONTROL/SPEED LIMITER BUTTONS

NOTESSpecial notes:

Only perform the tests if the statuses do not correspond with the system programming

functions.

INACTIVEStatus ET703 becomes "INACTIVE" when none of the cruise control/speed limiter

buttons is pressed. These buttons are located on the steering wheel.

If status ET703 does not display "INACTIVE",

●check the condition of the cruise control/speed limiter +/- button and the condition of

its connector,

●check the condition of the cruise control/speed limiter R/0 button and the condition of

its connector.

INCREASEStatus ET703 becomes PLUS when the cruise control/speed limiter + button is pressed.

This button is on the steering wheel, on the left-hand side.

If status ET703 does not display PLUS, check the condition of the cruise control/speed

limiter +/- button, and the condition of its connector. Repair if necessary.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's front airbag (see MR 364 Mechanical, 88C,

Airbag and seat belt pretensioners, Driver's front airbag, Removal - Refitting)

Measure the resistance on the following connection with the "+" button pressed:

Injection computer,

connector A, black, 32-track track D2 "+/-" button track 2.

connector A, black, 32-track track D3 "+/-" button track 1.

If the resistance is not approximately 300 Ω, check the continuity of the connection when

the button is not pressed.

If there is continuity, replace the +/- control button.

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

S3000_V4C_ET703/S3000_V54_ET703

Page 201 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 201

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 201V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

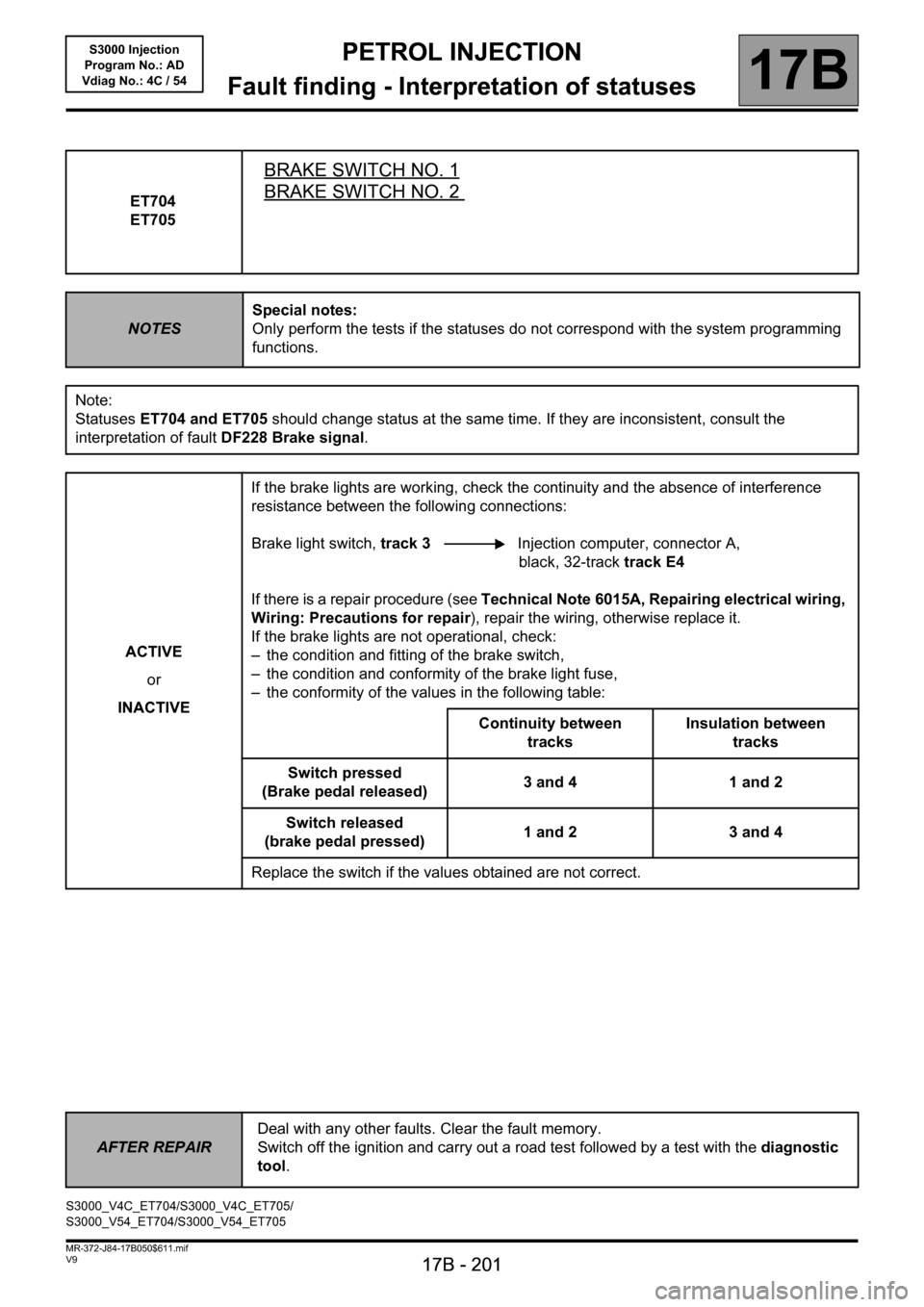

ET704

ET705

BRAKE SWITCH NO. 1

BRAKE SWITCH NO. 2

NOTESSpecial notes:

Only perform the tests if the statuses do not correspond with the system programming

functions.

Note:

Statuses ET704 and ET705 should change status at the same time. If they are inconsistent, consult the

interpretation of fault DF228 Brake signal.

ACTIVE

or

INACTIVEIf the brake lights are working, check the continuity and the absence of interference

resistance between the following connections:

Brake light switch, track 3 Injection computer, connector A,

black, 32-track track E4

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the brake lights are not operational, check:

– the condition and fitting of the brake switch,

– the condition and conformity of the brake light fuse,

– the conformity of the values in the following table:

Continuity between

tracksInsulation between

tracks

Switch pressed

(Brake pedal released)3 and 4 1 and 2

Switch released

(brake pedal pressed)1 and 2 3 and 4

Replace the switch if the values obtained are not correct.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

S3000_V4C_ET704/S3000_V4C_ET705/

S3000_V54_ET704/S3000_V54_ET705

Page 219 of 230

PETROL INJECTION

Fault finding - Test

17B

PETROL INJECTION

Fault finding - Test

17B

17B-219V9 MR-372-J84-17B050$846.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

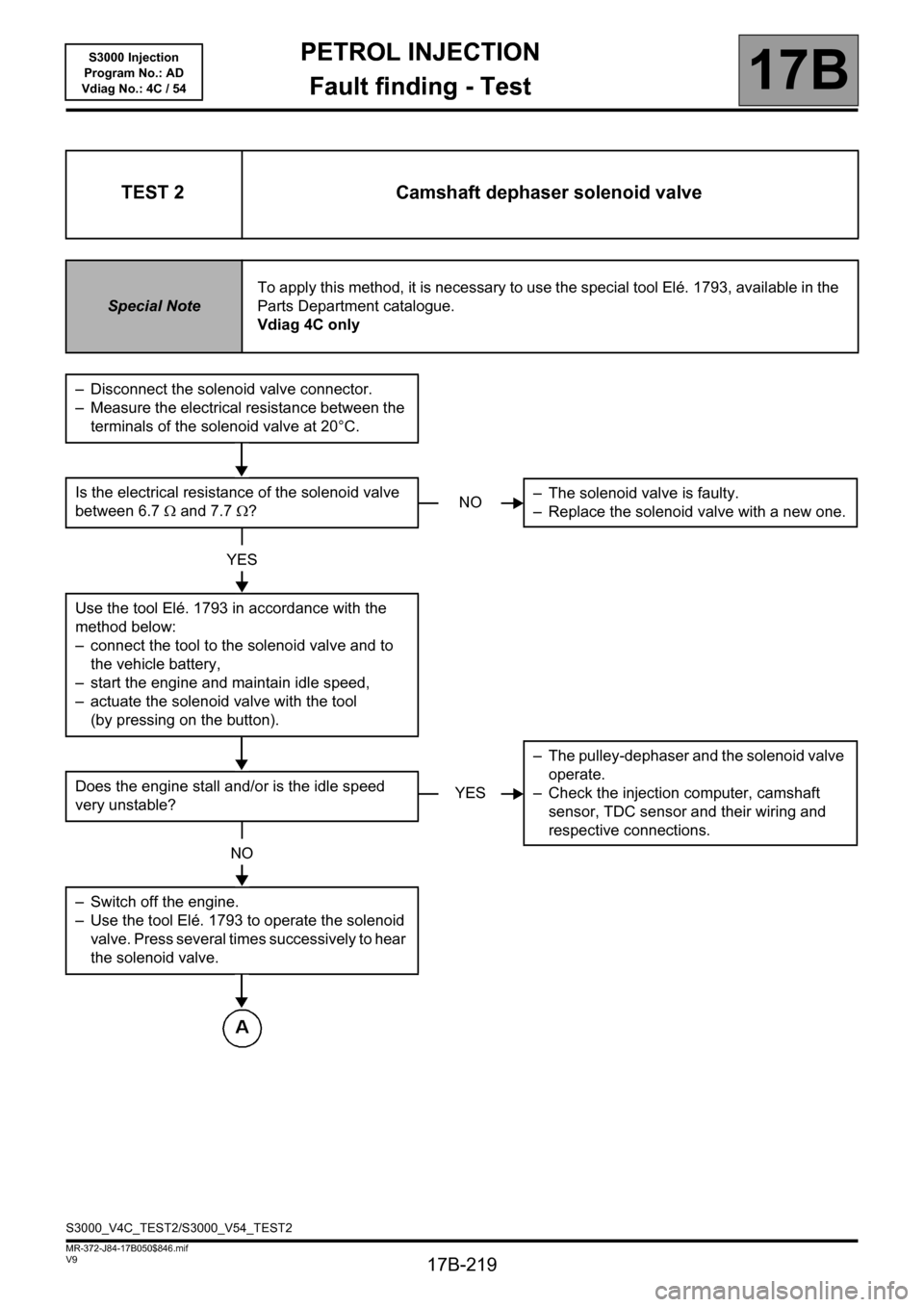

TEST 2 Camshaft dephaser solenoid valve

Special NoteTo apply this method, it is necessary to use the special tool Elé. 1793, available in the

Parts Department catalogue.

Vdiag 4C only

– Disconnect the solenoid valve connector.

– Measure the electrical resistance between the

terminals of the solenoid valve at 20°C.

Is the electrical resistance of the solenoid valve

between 6.7Ω and 7.7Ω?

YES

Use the tool Elé. 1793 in accordance with the

method below:

– connect the tool to the solenoid valve and to

the vehicle battery,

– start the engine and maintain idle speed,

– actuate the solenoid valve with the tool

(by pressing on the button).

Does the engine stall and/or is the idle speed

very unstable?

NO

– Switch off the engine.

– Use the tool Elé. 1793 to operate the solenoid

valve. Press several times successively to hear

the solenoid valve.

NO– The solenoid valve is faulty.

– Replace the solenoid valve with a new one.

YES– The pulley-dephaser and the solenoid valve

operate.

– Check the injection computer, camshaft

sensor, TDC sensor and their wiring and

respective connections.

S3000_V4C_TEST2/S3000_V54_TEST2

Page 221 of 230

PETROL INJECTION

Fault finding - Test

17B

PETROL INJECTION

Fault finding - Test

17B

17B-221V9 MR-372-J84-17B050$846.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

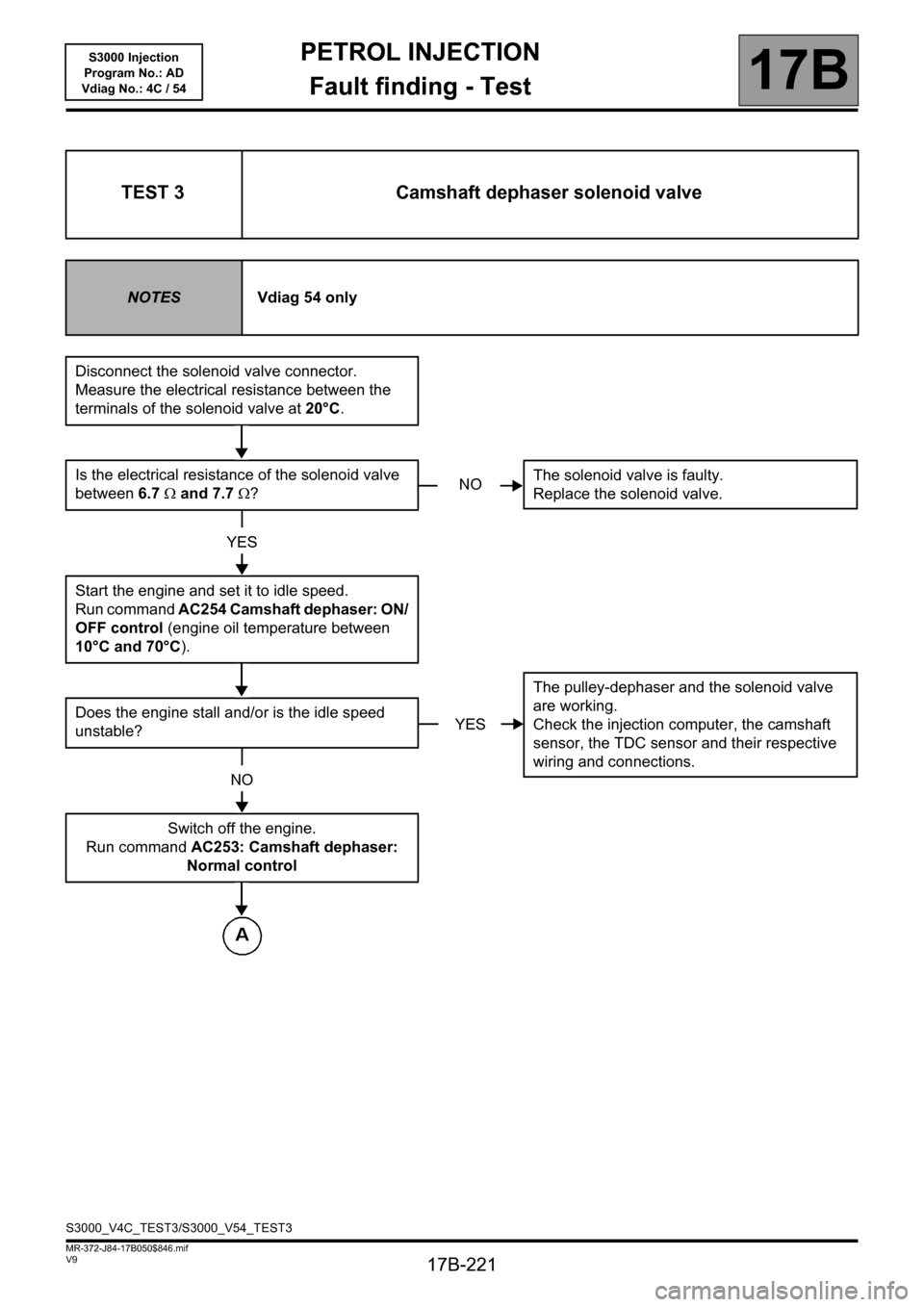

TEST 3 Camshaft dephaser solenoid valve

NOTESVdiag 54 only

Disconnect the solenoid valve connector.

Measure the electrical resistance between the

terminals of the solenoid valve at 20°C.

Is the electrical resistance of the solenoid valve

between 6.7 Ω and 7.7 Ω?

YES

Start the engine and set it to idle speed.

Run command AC254 Camshaft dephaser: ON/

OFF control (engine oil temperature between

10°C and 70°C).

Does the engine stall and/or is the idle speed

unstable?

NO

Switch off the engine.

Run command AC253: Camshaft dephaser:

Normal control

NOThe solenoid valve is faulty.

Replace the solenoid valve.

YESThe pulley-dephaser and the solenoid valve

are working.

Check the injection computer, the camshaft

sensor, the TDC sensor and their respective

wiring and connections.

S3000_V4C_TEST3/S3000_V54_TEST3

Page 228 of 230

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-228

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-228V9 MR-372-J84-17B050$940.mif

S3000 Injection

Program No.: AD

Vdiag No.:4C / 54

ALP 2 The engine will not start

NOTESFollow ALP 2 after a complete check with the diagnostic tool.

WARNING

Never drive the vehicle without checking first that there are no throttle valve

faults.

If the starter motor does not engage, there may be an engine immobiliser fault.

Carry out fault finding on the UCH (see87B, Passenger Compartment Connection Unit).

Check the condition of the battery.

Check the cleanliness, condition and tightness of the battery terminals.

Check that the battery is correctly earthed to the vehicle bodywork.

Check that the + battery leads are correctly connected.

Check that the starter motor is properly connected.

Check the starter is working properly (see Technical Note 6014A Checking the charging circuit).

Check the condition and conformity of the spark plugs.

Check the mounting, cleanliness and condition of the flywheel signal sensor.

Check the flywheel signal sensor air gap.

Check the condition of the flywheel.

Check that the air filter is not clogged.

Check that the air inlet circuit is not blocked.

Check that there is fuel in the tank (fuel sender fault).

Check that the tank vent is not blocked.

Check that the fuel is of the correct type.

Check that there are no leaks in the fuel system, from the tank to the injectors.

Check that there are no kinked hoses (especially after a removal operation).

Check the fuel flow rate and pressure.

Check the sealing of the injectors, and that they are working properly.

Check that the exhaust system is not blocked and the catalytic converter not clogged.

Check the timing setting.

Check the cylinder compressions.

Check the hydraulic tappets if there is camshaft noise.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ALP2/S3000_V54_ALP2

Page 229 of 230

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-229

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-229V9 MR-372-J84-17B050$940.mif

S3000 Injection

Program No.: AD

Vdiag No.:4C / 54

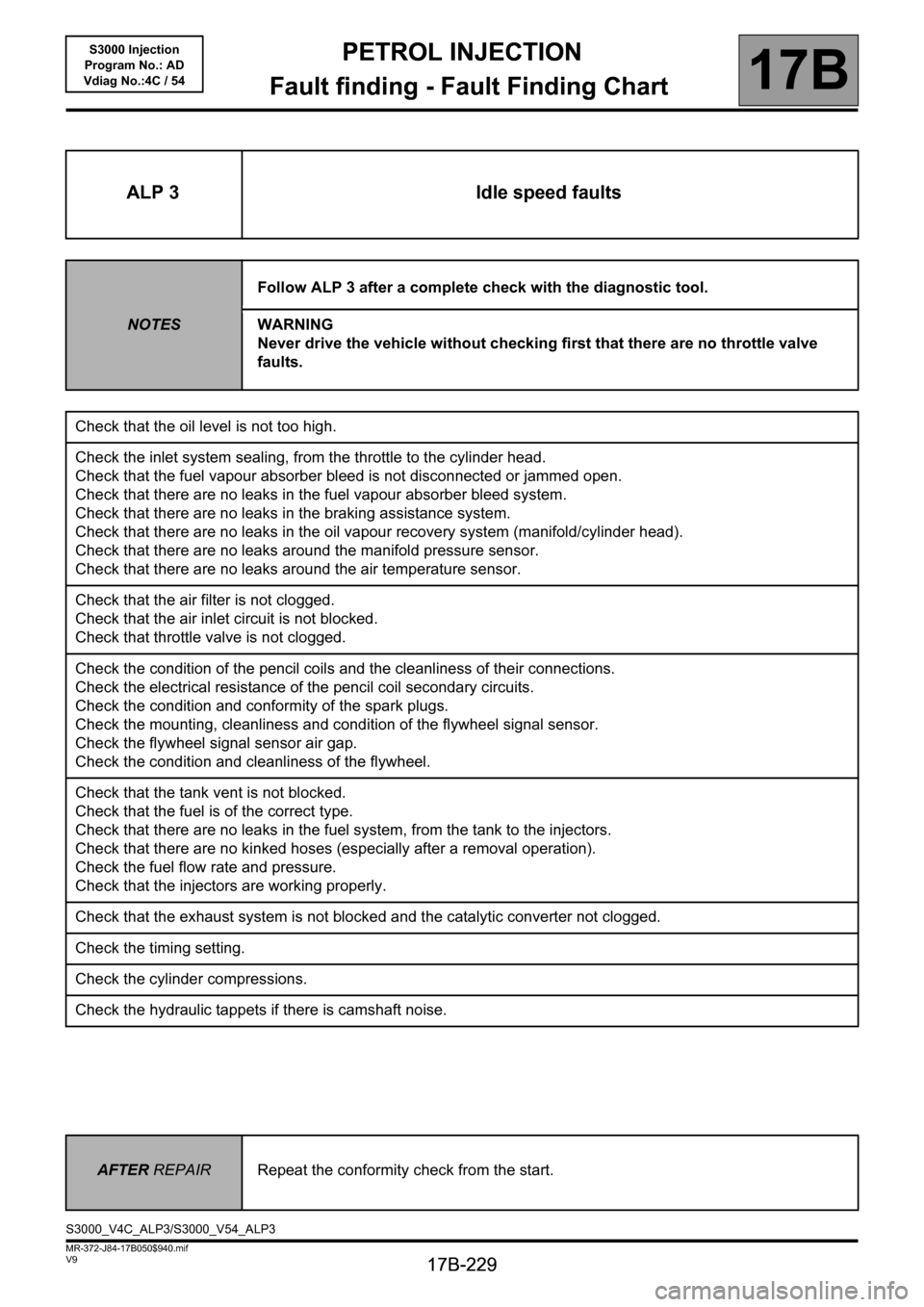

ALP 3 Idle speed faults

NOTESFollow ALP 3 after a complete check with the diagnostic tool.

WARNING

Never drive the vehicle without checking first that there are no throttle valve

faults.

Check that the oil level is not too high.

Check the inlet system sealing, from the throttle to the cylinder head.

Check that the fuel vapour absorber bleed is not disconnected or jammed open.

Check that there are no leaks in the fuel vapour absorber bleed system.

Check that there are no leaks in the braking assistance system.

Check that there are no leaks in the oil vapour recovery system (manifold/cylinder head).

Check that there are no leaks around the manifold pressure sensor.

Check that there are no leaks around the air temperature sensor.

Check that the air filter is not clogged.

Check that the air inlet circuit is not blocked.

Check that throttle valve is not clogged.

Check the condition of the pencil coils and the cleanliness of their connections.

Check the electrical resistance of the pencil coil secondary circuits.

Check the condition and conformity of the spark plugs.

Check the mounting, cleanliness and condition of the flywheel signal sensor.

Check the flywheel signal sensor air gap.

Check the condition and cleanliness of the flywheel.

Check that the tank vent is not blocked.

Check that the fuel is of the correct type.

Check that there are no leaks in the fuel system, from the tank to the injectors.

Check that there are no kinked hoses (especially after a removal operation).

Check the fuel flow rate and pressure.

Check that the injectors are working properly.

Check that the exhaust system is not blocked and the catalytic converter not clogged.

Check the timing setting.

Check the cylinder compressions.

Check the hydraulic tappets if there is camshaft noise.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ALP3/S3000_V54_ALP3

Page 230 of 230

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-230

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-230V9 MR-372-J84-17B050$940.mif

S3000 Injection

Program No.: AD

Vdiag No.:4C / 54

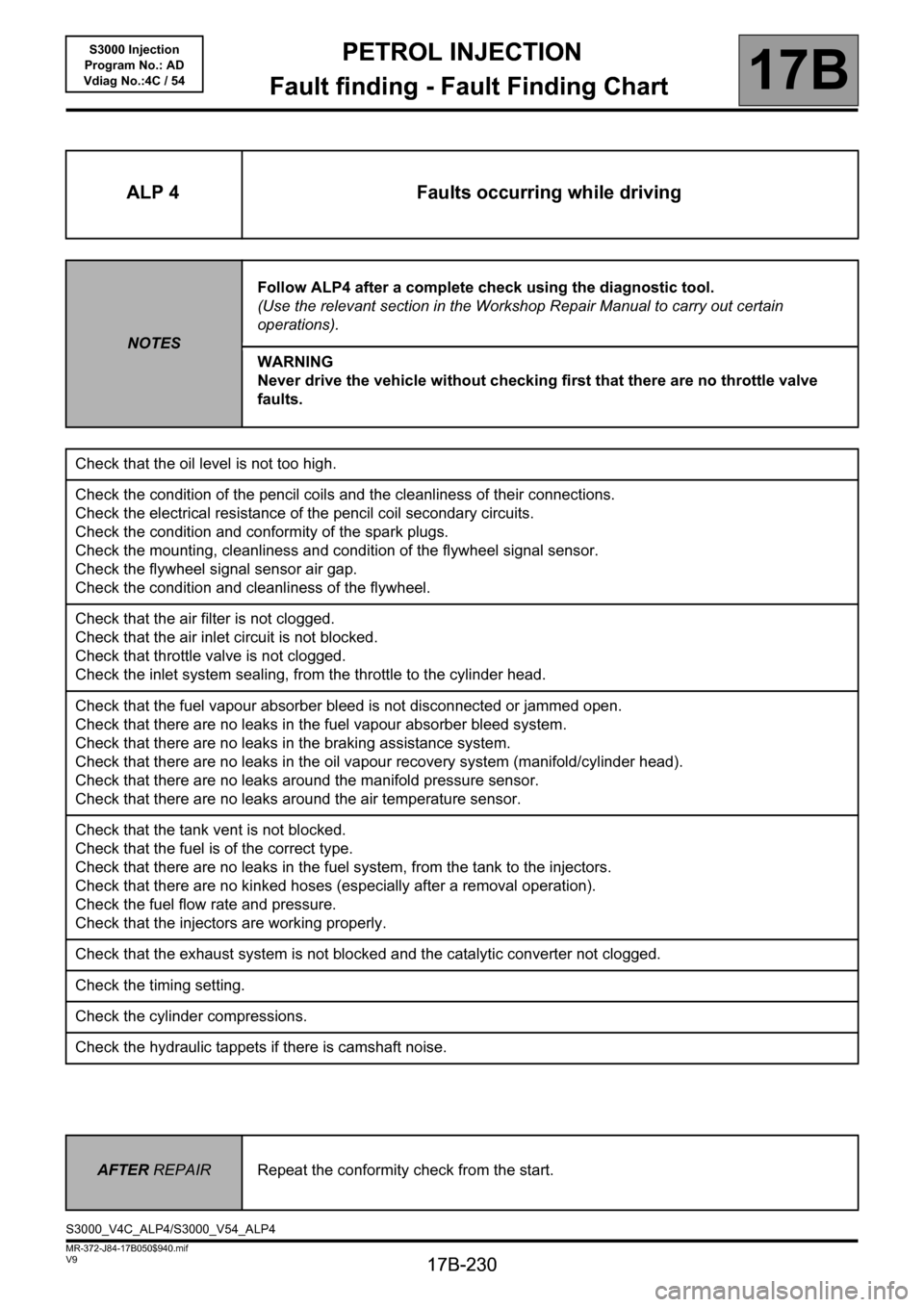

ALP 4 Faults occurring while driving

NOTESFollow ALP4 after a complete check using the diagnostic tool.

(Use the relevant section in the Workshop Repair Manual to carry out certain

operations).

WARNING

Never drive the vehicle without checking first that there are no throttle valve

faults.

Check that the oil level is not too high.

Check the condition of the pencil coils and the cleanliness of their connections.

Check the electrical resistance of the pencil coil secondary circuits.

Check the condition and conformity of the spark plugs.

Check the mounting, cleanliness and condition of the flywheel signal sensor.

Check the flywheel signal sensor air gap.

Check the condition and cleanliness of the flywheel.

Check that the air filter is not clogged.

Check that the air inlet circuit is not blocked.

Check that throttle valve is not clogged.

Check the inlet system sealing, from the throttle to the cylinder head.

Check that the fuel vapour absorber bleed is not disconnected or jammed open.

Check that there are no leaks in the fuel vapour absorber bleed system.

Check that there are no leaks in the braking assistance system.

Check that there are no leaks in the oil vapour recovery system (manifold/cylinder head).

Check that there are no leaks around the manifold pressure sensor.

Check that there are no leaks around the air temperature sensor.

Check that the tank vent is not blocked.

Check that the fuel is of the correct type.

Check that there are no leaks in the fuel system, from the tank to the injectors.

Check that there are no kinked hoses (especially after a removal operation).

Check the fuel flow rate and pressure.

Check that the injectors are working properly.

Check that the exhaust system is not blocked and the catalytic converter not clogged.

Check the timing setting.

Check the cylinder compressions.

Check the hydraulic tappets if there is camshaft noise.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ALP4/S3000_V54_ALP4