fuel RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Injection Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 236, PDF Size: 1.32 MB

Page 115 of 236

13B-115

DIESEL INJECTION

Fault finding - Conformity check13B

V10 MR-372-J84-13B150$423.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

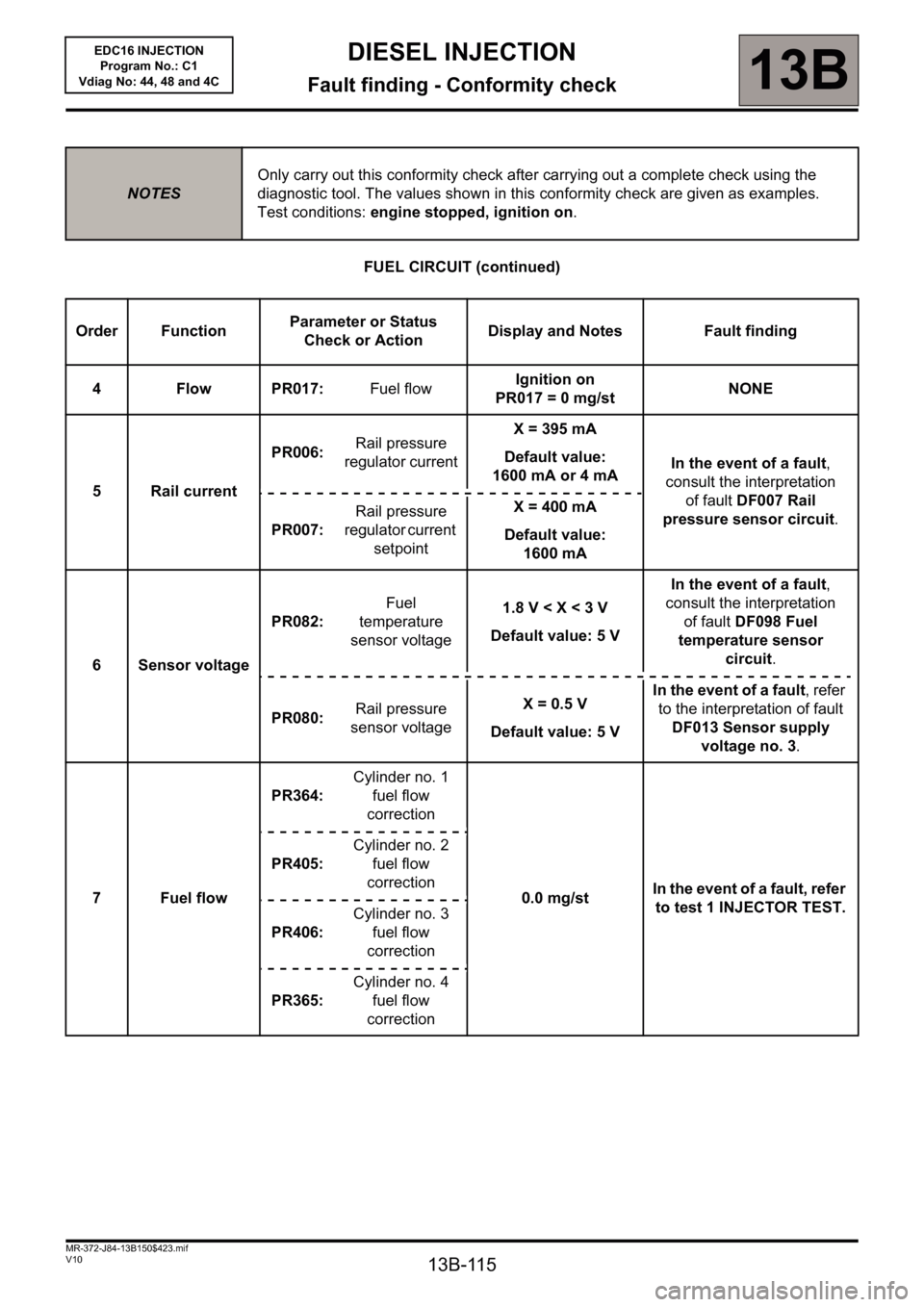

FUEL CIRCUIT (continued)

NOTESOnly carry out this conformity check after carrying out a complete check using the

diagnostic tool. The values shown in this conformity check are given as examples.

Test conditions: engine stopped, ignition on.

Order FunctionParameter or Status

Check or ActionDisplay and Notes Fault finding

4 Flow PR017: Fuel flowIgnition on

PR017= 0mg/stNONE

5 Rail currentPR006: Rail pressure

regulator currentX = 395 mA

Default value:

1600 mA or 4 mAIn the event of a fault,

consult the interpretation

of fault DF007 Rail

pressure sensor circuit.

PR007: Rail pressure

regulator current

setpointX = 400 mA

Default value:

1600 mA

6 Sensor voltagePR082: Fuel

temperature

sensor voltage1.8 V < X < 3 V

Default value: 5 VIn the event of a fault,

consult the interpretation

of fault DF098 Fuel

temperature sensor

circuit.

PR080: Rail pressure

sensor voltageX= 0.5V

Default value: 5 VIn the event of a fault, refer

to the interpretation of fault

DF013 Sensor supply

voltage no. 3.

7 Fuel flowPR364:Cylinder no. 1

fuel flow

correction

0.0 mg/stIn the event of a fault, refer

to test 1 INJECTOR TEST. PR405:Cylinder no. 2

fuel flow

correction

PR406:Cylinder no. 3

fuel flow

correction

PR365:Cylinder no. 4

fuel flow

correction

Page 133 of 236

13B-133

DIESEL INJECTION

Fault finding - Conformity check13B

V10 MR-372-J84-13B150$423.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

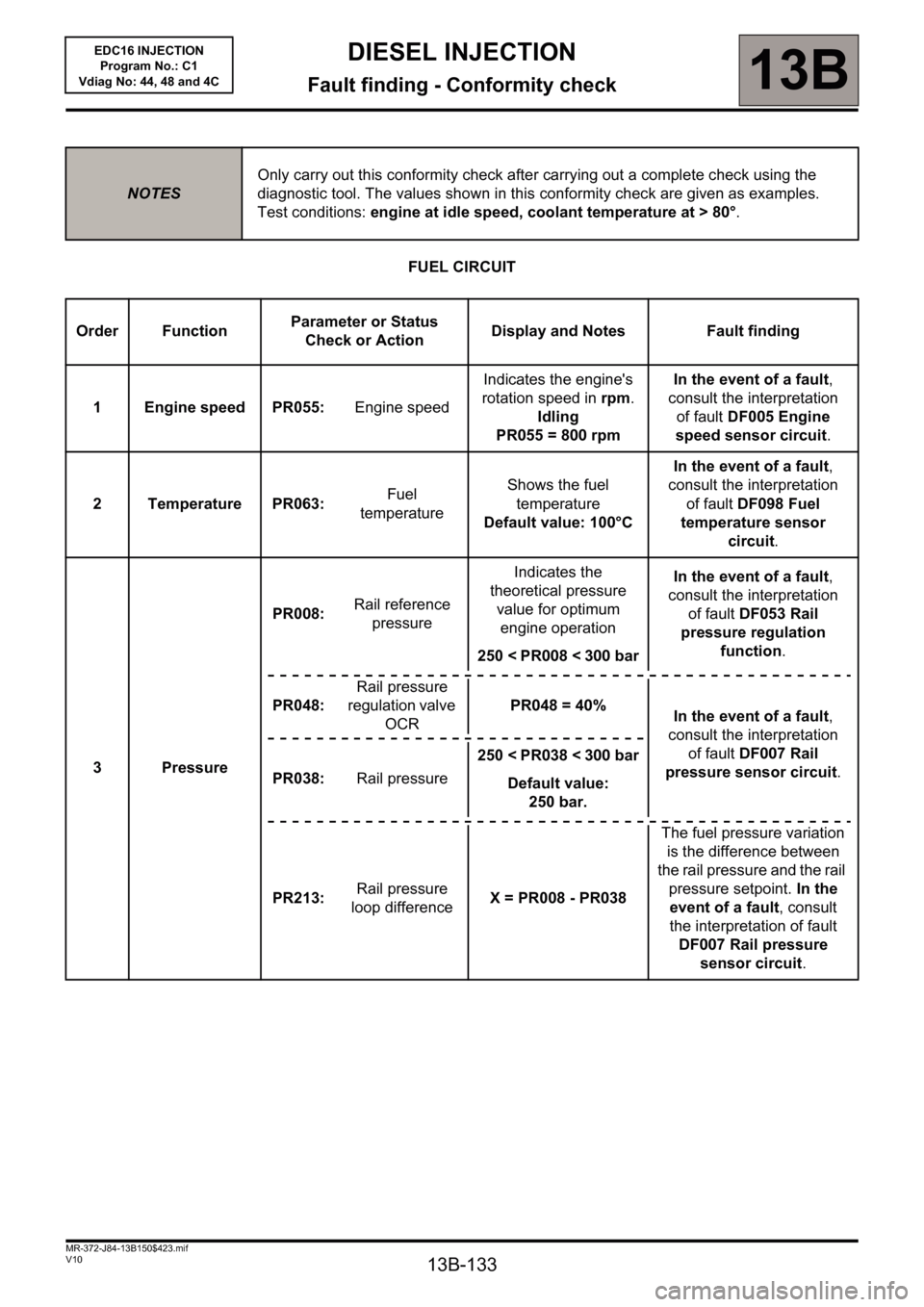

FUEL CIRCUIT

NOTESOnly carry out this conformity check after carrying out a complete check using the

diagnostic tool. The values shown in this conformity check are given as examples.

Test conditions: engine at idle speed, coolant temperature at > 80°.

Order FunctionParameter or Status

Check or ActionDisplay and Notes Fault finding

1 Engine speed PR055: Engine speedIndicates the engine's

rotation speed in rpm.

Idling

PR055 = 800 rpmIn the event of a fault,

consult the interpretation

of fault DF005 Engine

speed sensor circuit.

2 Temperature PR063: Fuel

temperatureShows the fuel

temperature

Default value: 100°CIn the event of a fault,

consult the interpretation

of fault DF098 Fuel

temperature sensor

circuit.

3PressurePR008: Rail reference

pressureIndicates the

theoretical pressure

value for optimum

engine operation

250< PR008< 300barIn the event of a fault,

consult the interpretation

of fault DF053 Rail

pressure regulation

function.

PR048:Rail pressure

regulation valve

OCRPR048 = 40%

In the event of a fault,

consult the interpretation

of fault DF007 Rail

pressure sensor circuit.

PR038: Rail pressure250< PR038< 300bar

Default value:

250 bar.

PR213: Rail pressure

loop differenceX = PR008 - PR038The fuel pressure variation

is the difference between

the rail pressure and the rail

pressure setpoint. In the

event of a fault, consult

the interpretation of fault

DF007 Rail pressure

sensor circuit.

Page 134 of 236

13B-134

DIESEL INJECTION

Fault finding - Conformity check13B

V10 MR-372-J84-13B150$423.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

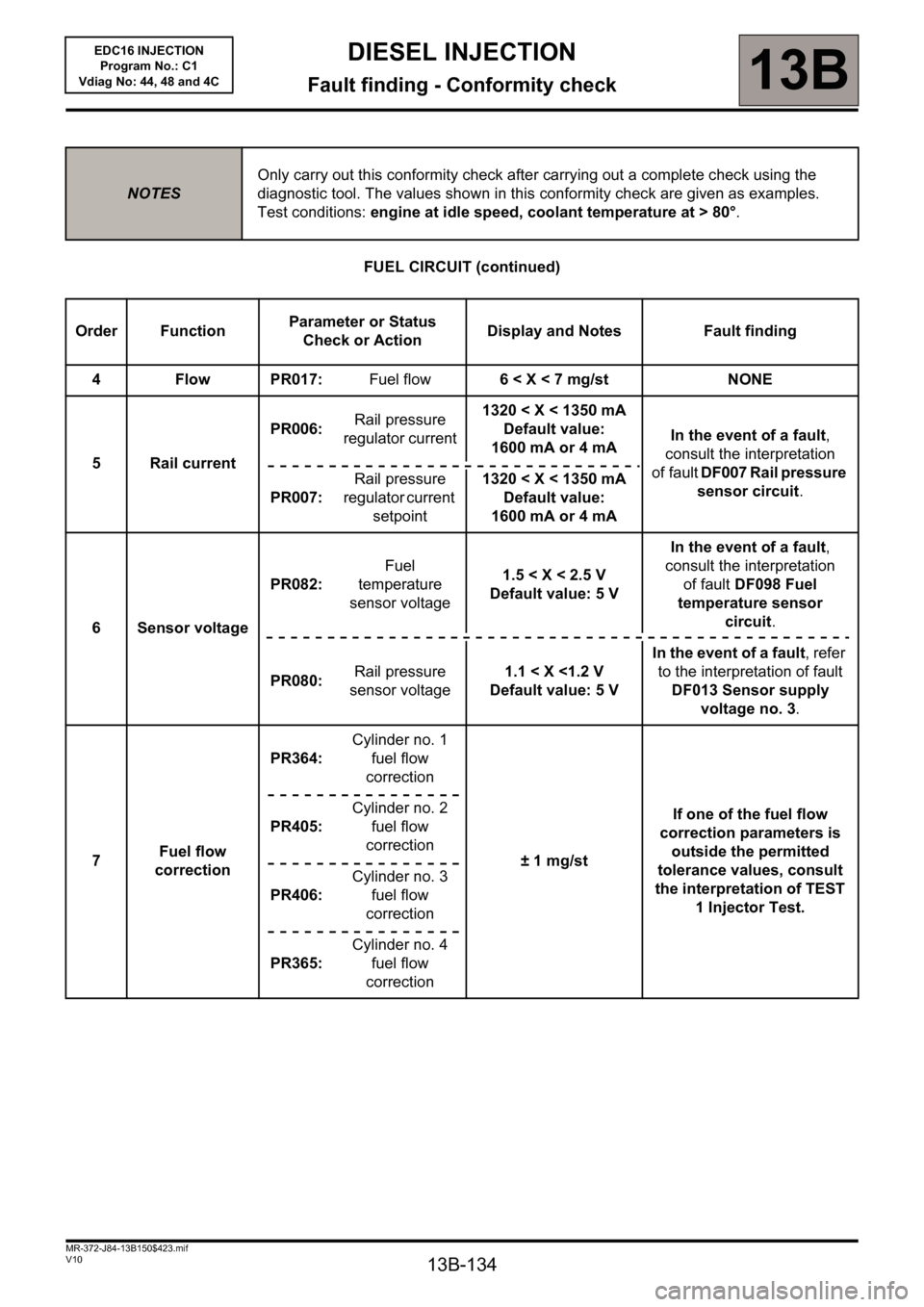

FUEL CIRCUIT (continued)

NOTESOnly carry out this conformity check after carrying out a complete check using the

diagnostic tool. The values shown in this conformity check are given as examples.

Test conditions: engine at idle speed, coolant temperature at > 80°.

Order FunctionParameter or Status

Check or ActionDisplay and Notes Fault finding

4FlowPR017: Fuel flow6 < X < 7 mg/st NONE

5 Rail currentPR006: Rail pressure

regulator current1320 < X < 1350 mA

Default value:

1600 mA or 4 mAIn the event of a fault,

consult the interpretation

of fault DF007 Rail pressure

sensor circuit.

PR007: Rail pressure

regulator current

setpoint1320 < X < 1350 mA

Default value:

1600 mA or 4 mA

6 Sensor voltagePR082: Fuel

temperature

sensor voltage1.5

consult the interpretation

of fault DF098 Fuel

temperature sensor

circuit.

PR080: Rail pressure

sensor voltage1.1 < X <1.2 V

Default value: 5 VIn the event of a fault, refer

to the interpretation of fault

DF013 Sensor supply

voltage no. 3.

7 Fuel flow

correctionPR364: Cylinder no. 1

fuel flow

correction

± 1 mg/stIf one of the fuel flow

correction parameters is

outside the permitted

tolerance values, consult

the interpretation of TEST

1 Injector Test. PR405: Cylinder no. 2

fuel flow

correction

PR406: Cylinder no. 3

fuel flow

correction

PR365: Cylinder no. 4

fuel flow

correction

Page 180 of 236

13B - 180

DIESEL INJECTION

Fault finding - Parameter summary table13B

V10 MR-372-J84-13B150$611.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4CDIESEL INJECTION

Fault finding - Parameter summary table

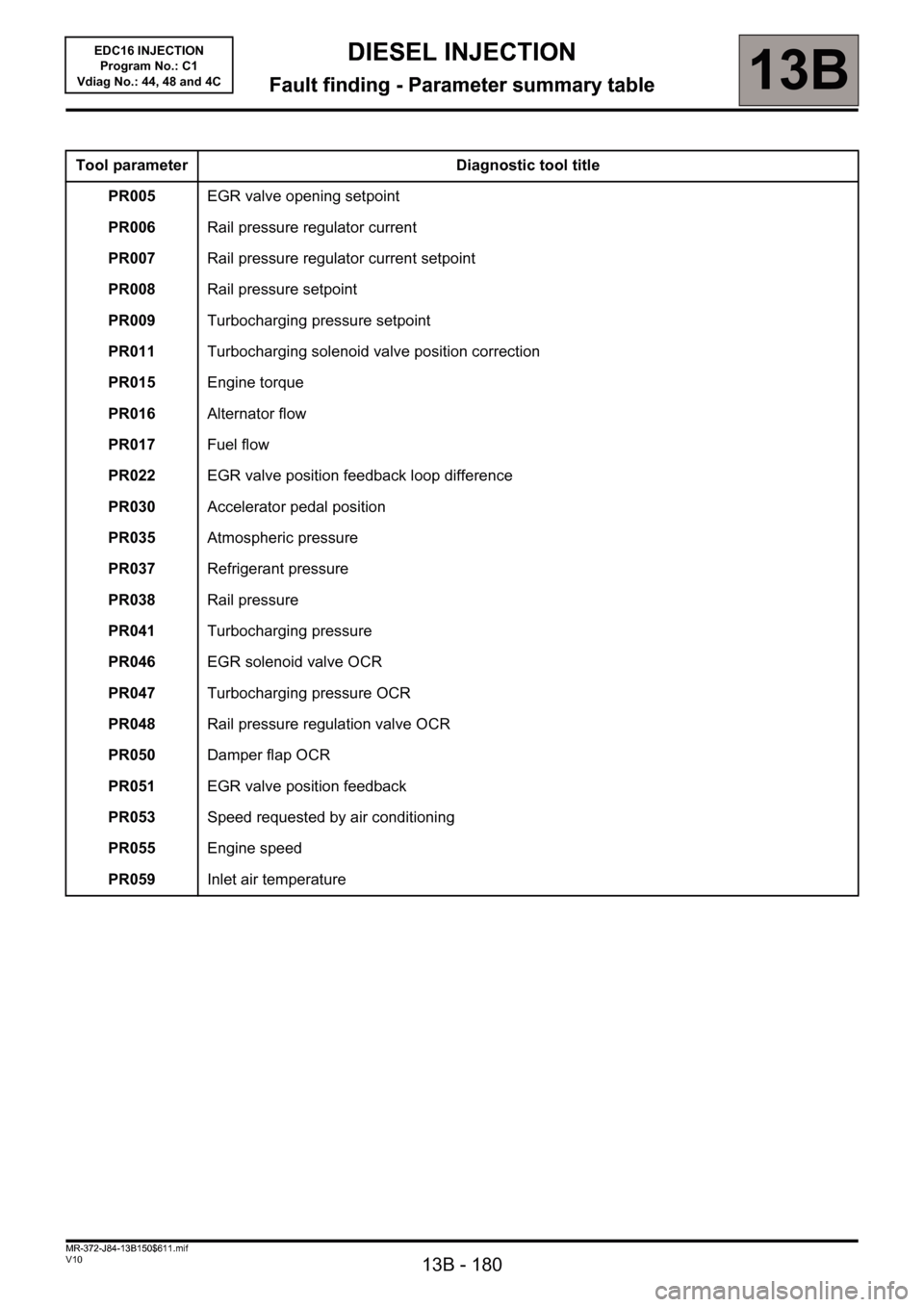

Tool parameter Diagnostic tool title

PR005EGR valve opening setpoint

PR006Rail pressure regulator current

PR007Rail pressure regulator current setpoint

PR008Rail pressure setpoint

PR009Turbocharging pressure setpoint

PR011Turbocharging solenoid valve position correction

PR015Engine torque

PR016Alternator flow

PR017Fuel flow

PR022EGR valve position feedback loop difference

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR041Turbocharging pressure

PR046EGR solenoid valve OCR

PR047Turbocharging pressure OCR

PR048Rail pressure regulation valve OCR

PR050Damper flap OCR

PR051EGR valve position feedback

PR053Speed requested by air conditioning

PR055Engine speed

PR059Inlet air temperature

MR-372-J84-13B150$611.mif

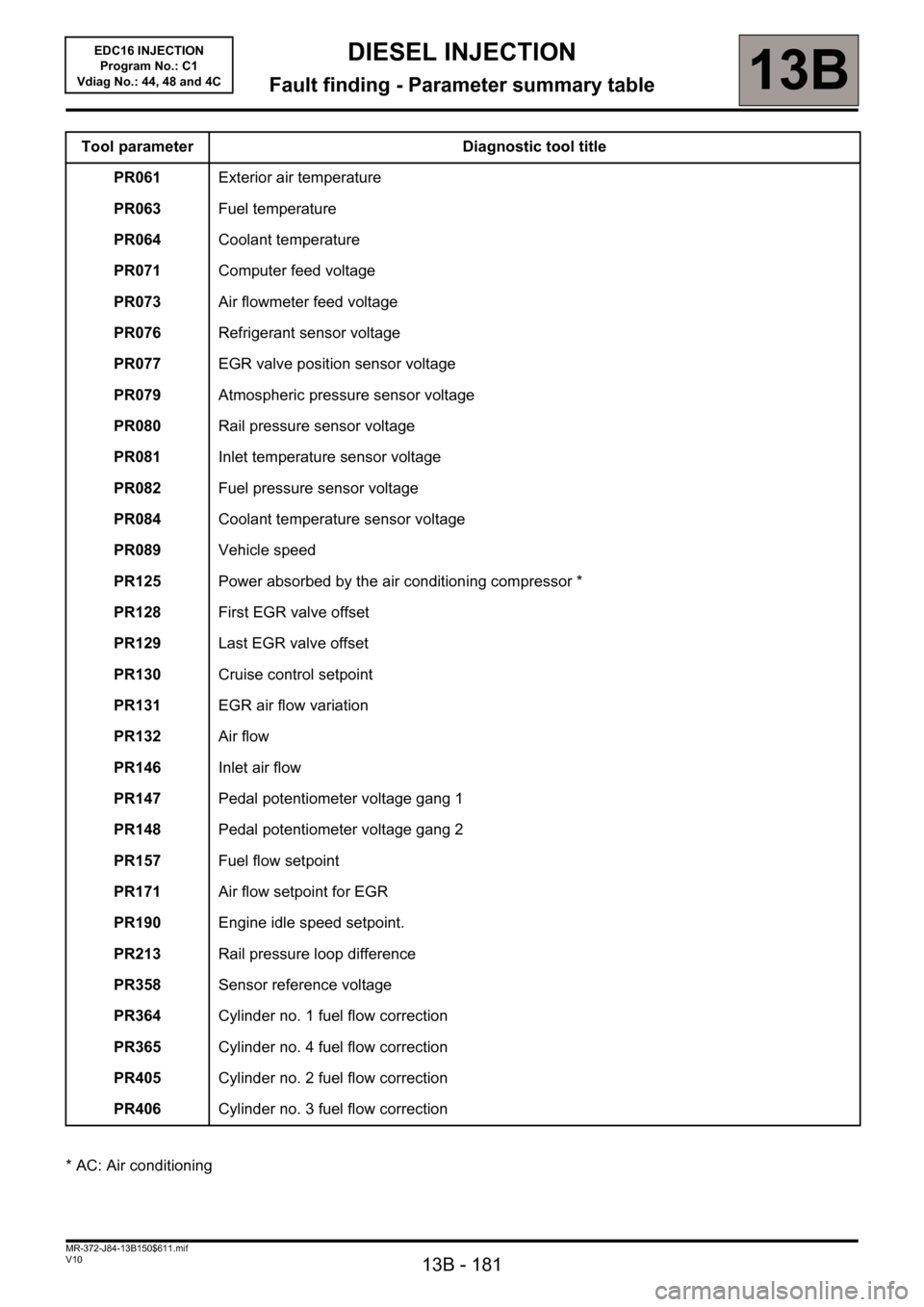

Page 181 of 236

13B - 181

DIESEL INJECTION

Fault finding - Parameter summary table13B

V10 MR-372-J84-13B150$611.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

Tool parameter Diagnostic tool title

PR061Exterior air temperature

PR063Fuel temperature

PR064Coolant temperature

PR071Computer feed voltage

PR073Air flowmeter feed voltage

PR076Refrigerant sensor voltage

PR077EGR valve position sensor voltage

PR079Atmospheric pressure sensor voltage

PR080Rail pressure sensor voltage

PR081Inlet temperature sensor voltage

PR082Fuel pressure sensor voltage

PR084Coolant temperature sensor voltage

PR089Vehicle speed

PR125Power absorbed by the air conditioning compressor *

PR128First EGR valve offset

PR129Last EGR valve offset

PR130Cruise control setpoint

PR131EGR air flow variation

PR132Air flow

PR146Inlet air flow

PR147Pedal potentiometer voltage gang 1

PR148Pedal potentiometer voltage gang 2

PR157Fuel flow setpoint

PR171Air flow setpoint for EGR

PR190Engine idle speed setpoint.

PR213Rail pressure loop difference

PR358Sensor reference voltage

PR364Cylinder no. 1 fuel flow correction

PR365Cylinder no. 4 fuel flow correction

PR405Cylinder no. 2 fuel flow correction

PR406Cylinder no. 3 fuel flow correction

* AC: Air conditioning

Page 184 of 236

13B - 184

DIESEL INJECTION

Fault finding - Interpretation of parameters13B

V10 MR-372-J84-13B150$658.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

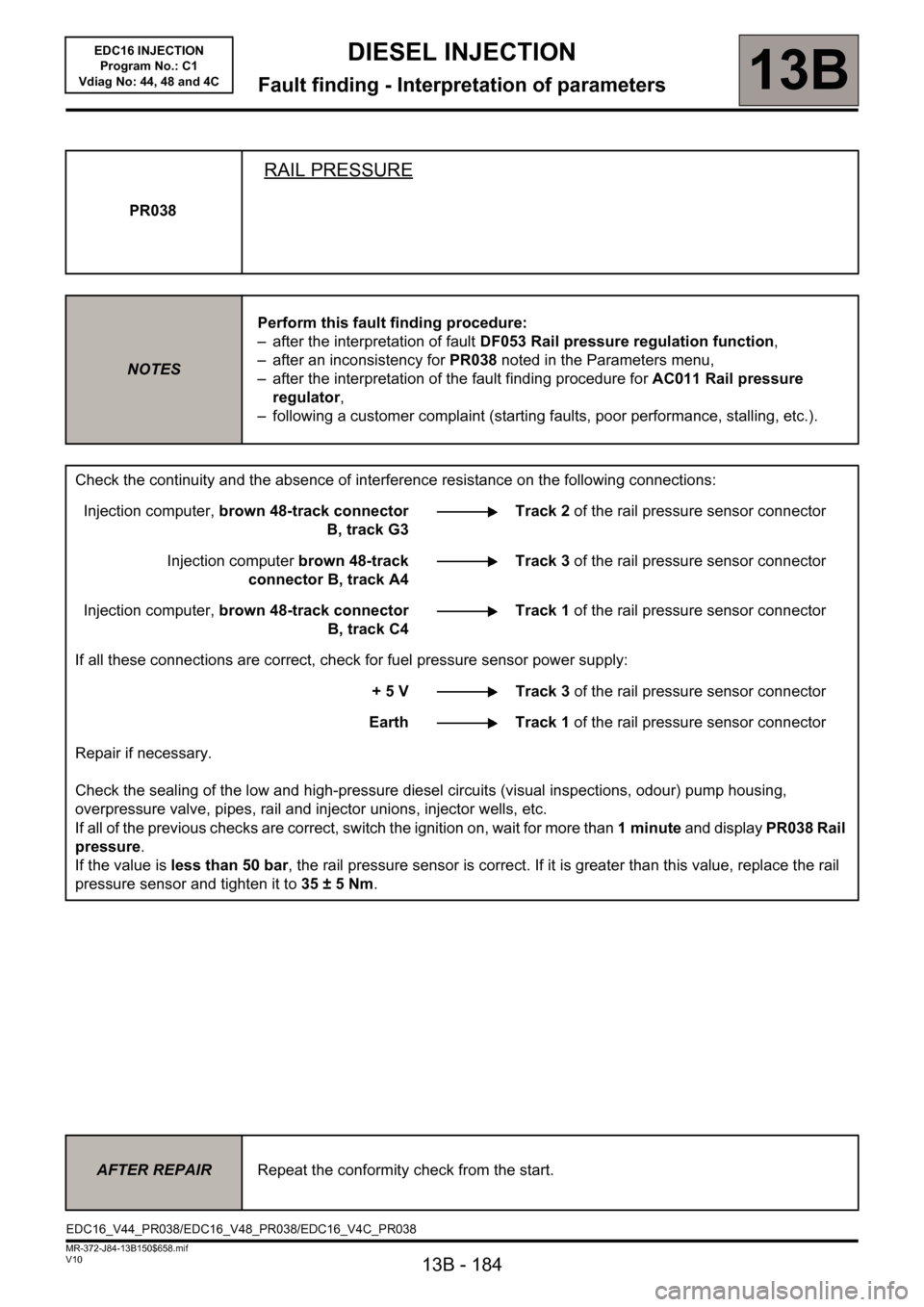

PR038

RAIL PRESSURE

NOTESPerform this fault finding procedure:

– after the interpretation of fault DF053 Rail pressure regulation function,

– after an inconsistency for PR038 noted in the Parameters menu,

– after the interpretation of the fault finding procedure for AC011 Rail pressure

regulator,

– following a customer complaint (starting faults, poor performance, stalling, etc.).

Check the continuity and the absence of interference resistance on the following connections:

Injection computer, brown 48-track connector

B, track G3Track 2 of the rail pressure sensor connector

Injection computer brown 48-track

connector B, track A4Track 3 of the rail pressure sensor connector

Injection computer, brown 48-track connector

B, track C4Track 1 of the rail pressure sensor connector

If all these connections are correct, check for fuel pressure sensor power supply:

+ 5 V Track 3 of the rail pressure sensor connector

Earth Track 1 of the rail pressure sensor connector

Repair if necessary.

Check the sealing of the low and high-pressure diesel circuits (visual inspections, odour) pump housing,

overpressure valve, pipes, rail and injector unions, injector wells, etc.

If all of the previous checks are correct, switch the ignition on, wait for more than 1 minute and display PR038 Rail

pressure.

If the value is less than 50 bar, the rail pressure sensor is correct. If it is greater than this value, replace the rail

pressure sensor and tighten it to 35 ± 5 Nm.

AFTER REPAIRRepeat the conformity check from the start.

EDC16_V44_PR038/EDC16_V48_PR038/EDC16_V4C_PR038

Page 186 of 236

13B - 186

DIESEL INJECTION

Fault finding - Interpretation of parameters13B

V10 MR-372-J84-13B150$658.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

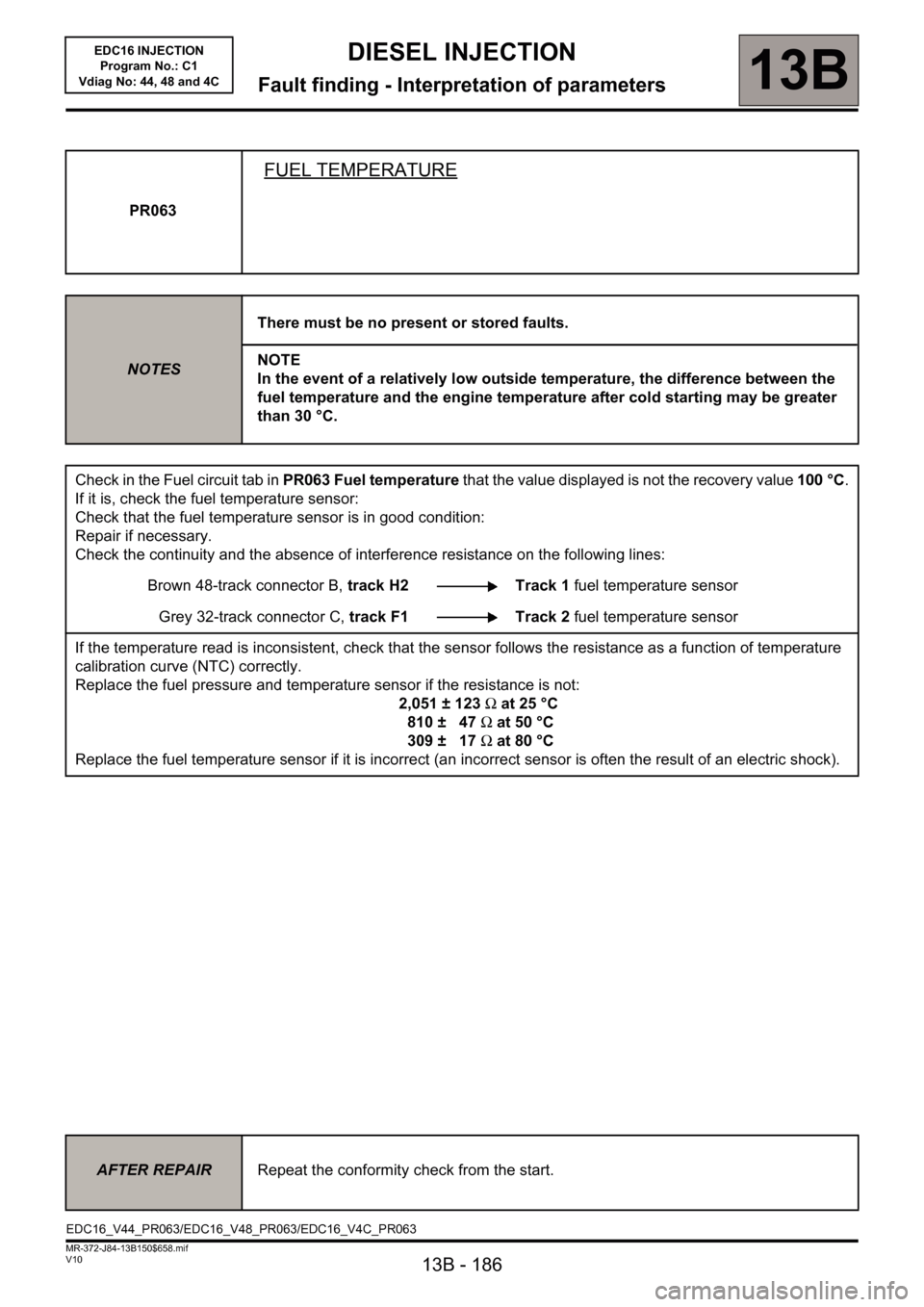

PR063

FUEL TEMPERATURE

NOTESThere must be no present or stored faults.

NOTE

In the event of a relatively low outside temperature, the difference between the

fuel temperature and the engine temperature after cold starting may be greater

than 30 °C.

Check in the Fuel circuit tab in PR063 Fuel temperature that the value displayed is not the recovery value 100 °C.

If it is, check the fuel temperature sensor:

Check that the fuel temperature sensor is in good condition:

Repair if necessary.

Check the continuity and the absence of interference resistance on the following lines:

Brown 48-track connector B, track H2 Track 1 fuel temperature sensor

Grey 32-track connector C, track F1 Track 2 fuel temperature sensor

If the temperature read is inconsistent, check that the sensor follows the resistance as a function of temperature

calibration curve (NTC) correctly.

Replace the fuel pressure and temperature sensor if the resistance is not:

2,051 ± 123Ω at 25 °C

810 ± 47Ω at 50 °C

309 ± 17Ω at 80 °C

Replace the fuel temperature sensor if it is incorrect (an incorrect sensor is often the result of an electric shock).

AFTER REPAIRRepeat the conformity check from the start.

EDC16_V44_PR063/EDC16_V48_PR063/EDC16_V4C_PR063

Page 199 of 236

13B - 199

DIESEL INJECTION

Fault finding - Interpretation of commands13B

V10 MR-372-J84-13B150$752.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

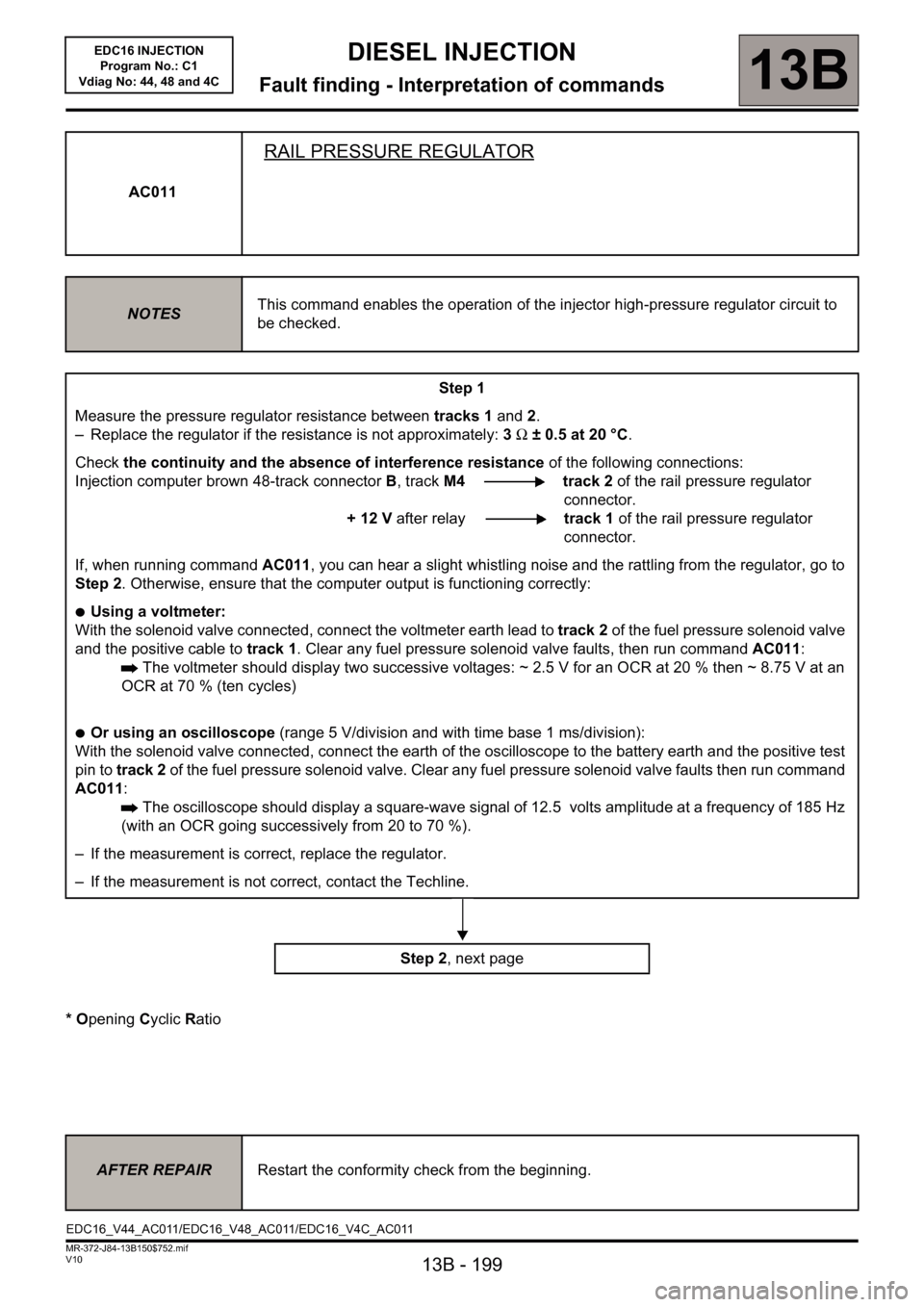

* Opening Cyclic Ratio AC011

RAIL PRESSURE REGULATOR

NOTESThis command enables the operation of the injector high-pressure regulator circuit to

be checked.

Step 1

Measure the pressure regulator resistance between tracks 1 and 2.

– Replace the regulator if the resistance is not approximately: 3Ω ± 0.5 at 20 °C.

Check the continuity and the absence of interference resistance of the following connections:

Injection computer brown 48-track connectorB, trackM4 track 2 of the rail pressure regulator

connector.

+ 12 V after relaytrack 1 of the rail pressure regulator

connector.

If, when running command AC011, you can hear a slight whistling noise and the rattling from the regulator, go to

Step 2. Otherwise, ensure that the computer output is functioning correctly:

●Using a voltmeter:

With the solenoid valve connected, connect the voltmeter earth lead to track 2 of the fuel pressure solenoid valve

and the positive cable to track 1. Clear any fuel pressure solenoid valve faults, then run command AC011:

The voltmeter should display two successive voltages: ~ 2.5 V for an OCR at 20 % then ~ 8.75 V at an

OCR at 70 % (ten cycles)

●Or using an oscilloscope (range 5 V/division and with time base 1 ms/division):

With the solenoid valve connected, connect the earth of the oscilloscope to the battery earth and the positive test

pin to track 2 of the fuel pressure solenoid valve. Clear any fuel pressure solenoid valve faults then run command

AC011:

The oscilloscope should display a square-wave signal of 12.5 volts amplitude at a frequency of 185 Hz

(with an OCR going successively from 20 to 70 %).

– If the measurement is correct, replace the regulator.

– If the measurement is not correct, contact the Techline.

Step 2, next page

AFTER REPAIRRestart the conformity check from the beginning.

EDC16_V44_AC011/EDC16_V48_AC011/EDC16_V4C_AC011

Page 205 of 236

13B-205

MR-372-J84-13B150$846.mif

V10

DIESEL INJECTION

Fault finding - Fault finding chart13B

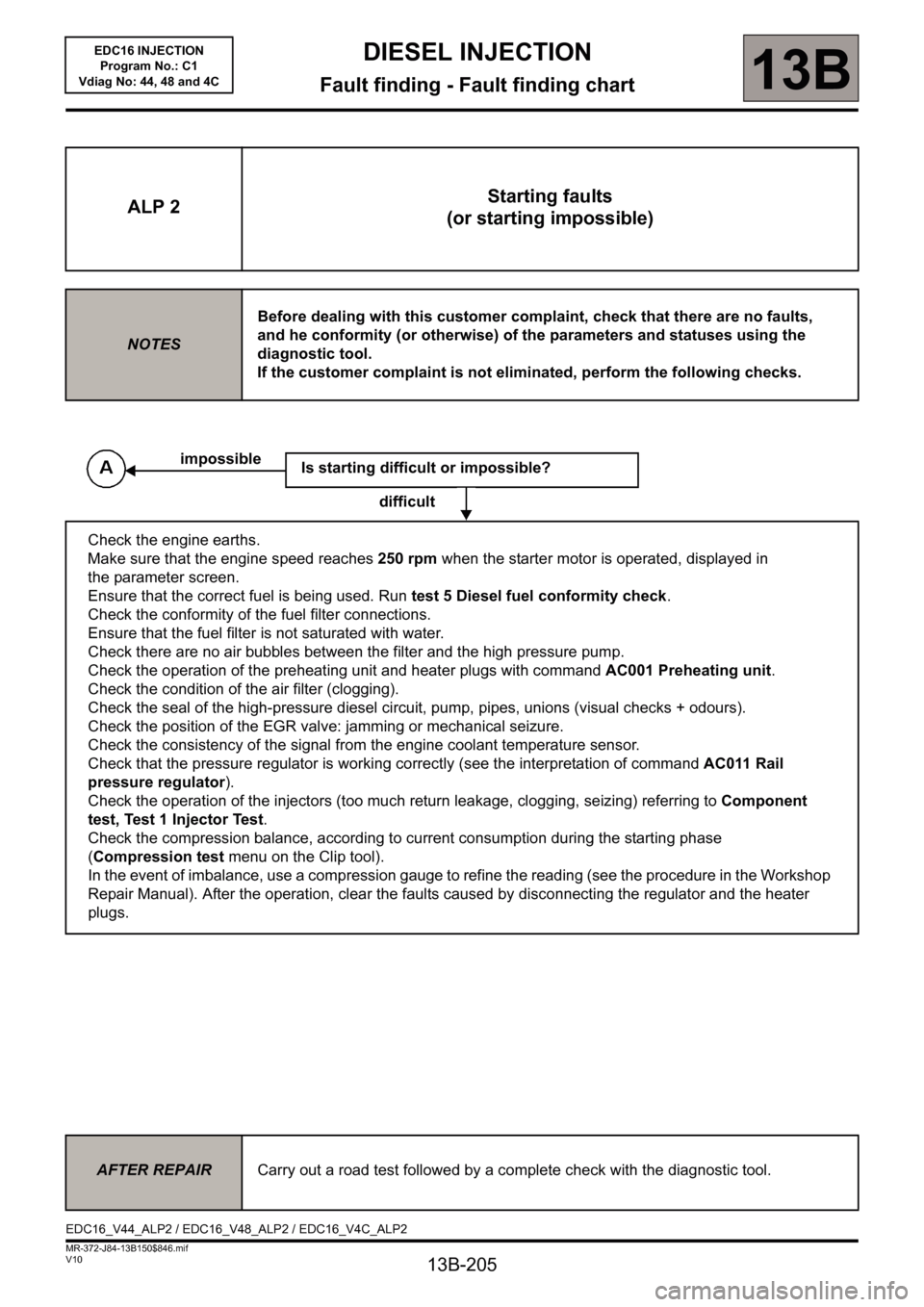

ALP 2Starting faults

(or starting impossible)

NOTESBefore dealing with this customer complaint, check that there are no faults,

and he conformity (or otherwise) of the parameters and statuses using the

diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

Is starting difficult or impossible?

difficult

Check the engine earths.

Make sure that the engine speed reaches 250 rpm when the starter motor is operated, displayed in

the parameter screen.

Ensure that the correct fuel is being used. Run test 5 Diesel fuel conformity check.

Check the conformity of the fuel filter connections.

Ensure that the fuel filter is not saturated with water.

Check there are no air bubbles between the filter and the high pressure pump.

Check the operation of the preheating unit and heater plugs with command AC001 Preheating unit.

Check the condition of the air filter (clogging).

Check the seal of the high-pressure diesel circuit, pump, pipes, unions (visual checks + odours).

Check the position of the EGR valve: jamming or mechanical seizure.

Check the consistency of the signal from the engine coolant temperature sensor.

Check that the pressure regulator is working correctly (see the interpretation of command AC011 Rail

pressure regulator).

Check the operation of the injectors (too much return leakage, clogging, seizing) referring to Component

test, Test 1 Injector Test.

Check the compression balance, according to current consumption during the starting phase

(Compression test menu on the Clip tool).

In the event of imbalance, use a compression gauge to refine the reading (see the procedure in the Workshop

Repair Manual). After the operation, clear the faults caused by disconnecting the regulator and the heater

plugs.

impossible

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V44_ALP2 / EDC16_V48_ALP2 / EDC16_V4C_ALP2

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

Page 206 of 236

13B-206

MR-372-J84-13B150$846.mif

V10

DIESEL INJECTION

Fault finding - Fault finding chart13B

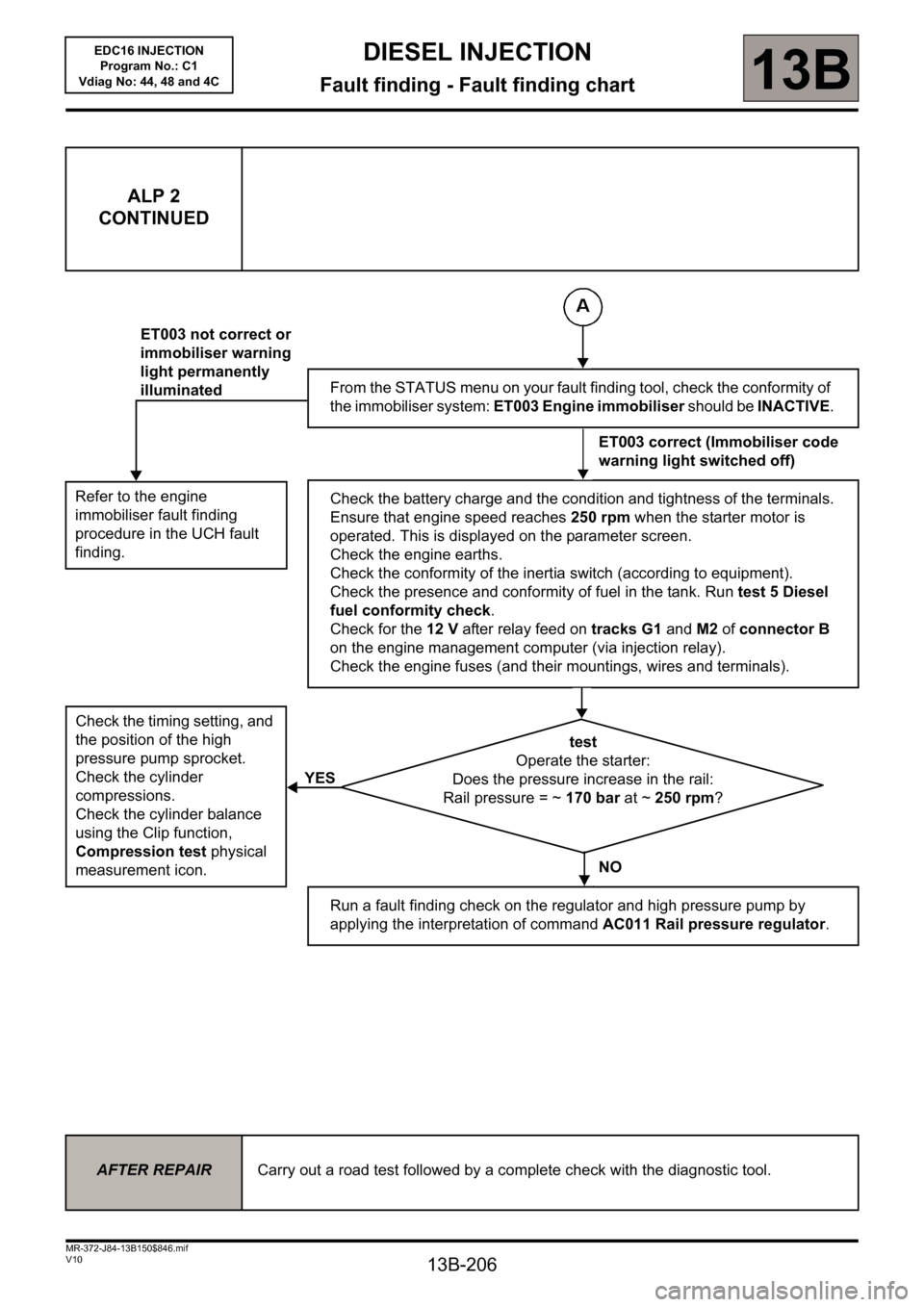

ALP 2

CONTINUED

Refer to the engine

immobiliser fault finding

procedure in the UCH fault

finding.

Check the timing setting, and

the position of the high

pressure pump sprocket.

Check the cylinder

compressions.

Check the cylinder balance

using the Clip function,

Compression test physical

measurement icon.

ET003 not correct or

immobiliser warning

light permanently

illuminated

YESFrom the STATUS menu on your fault finding tool, check the conformity of

the immobiliser system: ET003 Engine immobiliser should be INACTIVE.

ET003 correct (Immobiliser code

warning light switched off)

Check the battery charge and the condition and tightness of the terminals.

Ensure that engine speed reaches 250 rpm when the starter motor is

operated. This is displayed on the parameter screen.

Check the engine earths.

Check the conformity of the inertia switch (according to equipment).

Check the presence and conformity of fuel in the tank. Run test 5 Diesel

fuel conformity check.

Check for the 12 V after relay feed on tracks G1 and M2 of connector B

on the engine management computer (via injection relay).

Check the engine fuses (and their mountings, wires and terminals).

test

Operate the starter:

Does the pressure increase in the rail:

Rail pressure = ~ 170 bar at ~ 250 rpm?

NO

Run a fault finding check on the regulator and high pressure pump by

applying the interpretation of command AC011 Rail pressure regulator.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C