ABS RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Injection Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 236, PDF Size: 1.32 MB

Page 159 of 236

13B-159

DIESEL INJECTION

Fault finding - Interpretation of statuses13B

V10 MR-372-J84-13B150$564.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

ET042

(CONTINUED 2)

SPEED

LIMITER

When the driver presses the main switch in the speed limiter position, status ET042

becomes SPEED LIMITER.

If CRUISE CONTROL or INACTIVE appears although the switch was depressed in the

speed limiter position, carry out the following operations:

Check the connections of the cruise control/speed limiter main switch.

Check for + 12 V after ignition on the main switch connector.

– Connection code AP43 of component 1081 (Mégane II).

– Connection code AP43 of component 1546 (Scénic II).

Disconnect the main switch and with it in the rest position, check the insulation between:

– Connection codes AP43 and 3FX of component 1081 (Mégane II).

– Connection codes AP43 and 3PD of component 1081 (Mégane II).

– Connection codes AP43 and 3FX of component 1546 (Scénic II).

– Connection codes AP43 and 3PD of component 1546 (Scénic II).

– Check the continuity between connections AP43 and 3PD of component 1081

(Mégane II) and component 1546 (Scénic II) in the speed limiter position.

– Check the continuity between connections AP43 and 3FX of component 1081

(Mégane II) and component 1546 (Scénic II) in the cruise control position.

If these checks show incorrect values, replace the main switch.

Check the insulation, continuity and the absence of interference resistance on the

following connections:

– Connection code 3FX,

– Connection code 3PD,

between components 1081 and 120 (Mégane II).

between components 1546 and 120 (Scénic II).

Also check the engine management computer connectors.

If there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

Page 160 of 236

13B-160

DIESEL INJECTION

Fault finding - Interpretation of statuses13B

V10 MR-372-J84-13B150$564.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

ET042

(CONTINUED 3)

CRUISE

CONTROL

When the driver presses the main cruise control button, status ET042 becomes CRUISE

CONTROL.

If SPEED LIMITER or INACTIVE appears although the driver pressed the switch in the

cruise control position, carry out the following operations:

Check the connections of the cruise control/speed limiter main switch.

Check for + 12 V APC on the main switch connector.

– Connection code AP43 of component 1081 (Mégane II).

– Connection code AP43 of component 1546 (Scénic II).

Disconnect the switch and when it is in the rest position, check the insulation between:

– Connection codes AP43 and 3FX of component 1081 (Mégane II).

– Connection codes AP43 and 3PD of component 1081 (Mégane II).

– Connection codes AP43 and 3FX of component 1546 (Scénic II).

– Connection codes AP43 and 3PD of component 1546 (Scénic II).

Check the continuity between connections AP43 and 3PD of component 1081

(Mégane II) or component 1546 (Scénic II) in the speed limiter position.

Check the continuity between connections AP43 and 3FX of component 1081

(Mégane II) or component 1546 (Scénic II) in the cruise control position.

If these checks show incorrect values, replace the main switch.

Check the insulation, continuity, and the absence of interference resistance on the

following connections:

– Connection code 3FX,

– Connection code3PD.

Between components 1081 and 120 (Mégane II).

Between components 1546 and 120 (Scénic II).

Also check the engine management computer connectors.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

Page 169 of 236

13B-169

DIESEL INJECTION

Fault finding - Interpretation of statuses13B

V10 MR-372-J84-13B150$564.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

ET405

CONTINUED 1

INACTIVECheck the condition and fitting of the clutch pedal switch.

Remove the clutch pedal switch, check the insulation between tracks 1 and 2 in rest

position.

Repeat this operation with the switch pressed and check the continuity between tracks

1 and 2.

If these two checks are not in order, replace the switch.

Then check the continuity and absence of interference resistance of the following

connection:

Injection computer black 32-track

connector A, track C4Track 1 clutch connector

Check for earth on track 2 of the clutch switch connector.

If the connection or connections are faulty and there is a repair procedure (see

Technical Note 6015A, Electrical wiring repair, Wiring: Precautions for repair),

repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

Page 170 of 236

13B-170

DIESEL INJECTION

Fault finding - Interpretation of statuses13B

V10 MR-372-J84-13B150$564.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

ET415

CRUISE CONTROL/SPEED LIMITER DEACTIVATION

NOTESSpecial notes:

Only perform the tests if the statuses do not correspond with the system programming

functions.

Note:

Cruise control can be activated when the vehicle speed exceeds 18 mph (30 km/h).

Status ET415 shows various factors that cause deactivation of the cruise control/speed limiter function, due to a

driver request or the external environment (e.g. STATUS 1).

IMPORTANT

Clear the fault memory by running command RZ001 Fault memory to reset this status to NONE.

WITHOUTThis status is present on the diagnostic tool when:

The computer has been reinitialised.

The computer has been reprogrammed.

STATUS 1Traction control request

If the vehicle is fitted with a traction control system, the cruise control function is

deactivated every time the ABS computer calls for traction control.

Status ET415 becomes STATUS 1 when driving with the cruise control active (ET042

Cruise control/Speed limiter: CRUISE CONTROL) and traction control is requested.

This deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ001

“Fault memory”.

If status ET415 becomes STATUS 1 with no traction control request (see 38C, Anti-lock

Braking System).

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

EDC16_V44_ET415/EDC16_V48_ET415/EDC16_V4C_ET415

Page 173 of 236

13B-173

DIESEL INJECTION

Fault finding - Interpretation of statuses13B

V10 MR-372-J84-13B150$564.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

ET415

(CONTINUED 3)

STATUS 6Gear lever in neutral (manual gearbox) or the neutral position (automatic gearbox)

Status ET415 becomes STATUS 6 when driving with the cruise control active (ET042

Cruise control/speed limiter: CRUISE CONTROL) and:

- If the driver puts the gear lever in neutral position on a manual gearbox without

declutching or,

- if the gear lever is in neutral on an automatic gearbox.

This deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ001

Fault memory.

If status ET415 becomes STATUS 6 without shifting the gear lever into neutral on a

manual gearbox without declutching, or into neutral on an automatic transmission, run

fault finding on the ABS computer and check the configuration of the tyre size stored in

the computer. If the configuration is correct, contact the Techline.

STATUS 7Lack of correlation between the request and the vehicle speed

Status ET415 becomes STATUS 7 if the computer detects too great a difference

between the speed requested by the driver and the vehicle speed.

STATUS 7 may occur when driving with the cruise control active (ET042 Cruise control/

speed limiter: CRUISE CONTROL) and on a very uneven surface.

This inconsistency deactivates cruise control.

Reinitialise status ET415 on the injection computer by running command RZ001

Fault memory.

If status ET415 becomes STATUS 7 where the surface is not uneven, contact the

Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

Page 174 of 236

13B-174

DIESEL INJECTION

Fault finding - Interpretation of statuses13B

V10 MR-372-J84-13B150$564.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

ET415

(CONTINUED 4)

STATUS 8Automatic gearbox in defect mode.

Status ET415 becomes STATUS 8, when driving with cruise control active (ET042:

Cruise control/speed limiter: CRUISE CONTROL) and if the automatic transmission

is in defect mode.

This signal is conveyed on the multiplex line and deactivates the cruise control.

Carry out a multiplex network test, then run fault finding on the automatic transmission

computer.

Deal with the present or stored faults (see 23A, Automatic transmission,

Interpretation of faults).

Clear the automatic transmission computer memory by running command RZ001 Fault

memory or RZ007 Fault memory.

Reinitialise ET415 of the injection computer by running command RZ001 Fault

memory or RZ007 Fault memory.

If STATUS 8 remains, contact Techline.

STATUS 9Vehicle speed monitoring

Status ET415 changes to STATUS 9 if the vehicle speed received by the computer is

invalid or absent.

This signal is conveyed on the multiplex line and deactivates the cruise control.

Carry out a multiplex network test, then run fault finding on the ABS computer.

Deal with any present or stored faults (see 38C, Anti-lock braking system,

interpretation of faults).

Reinitialise ET415 of the injection computer by running command RZ001 Fault

memory or RZ007 Fault memory.

If STATUS 9 remains, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

Page 181 of 236

13B - 181

DIESEL INJECTION

Fault finding - Parameter summary table13B

V10 MR-372-J84-13B150$611.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

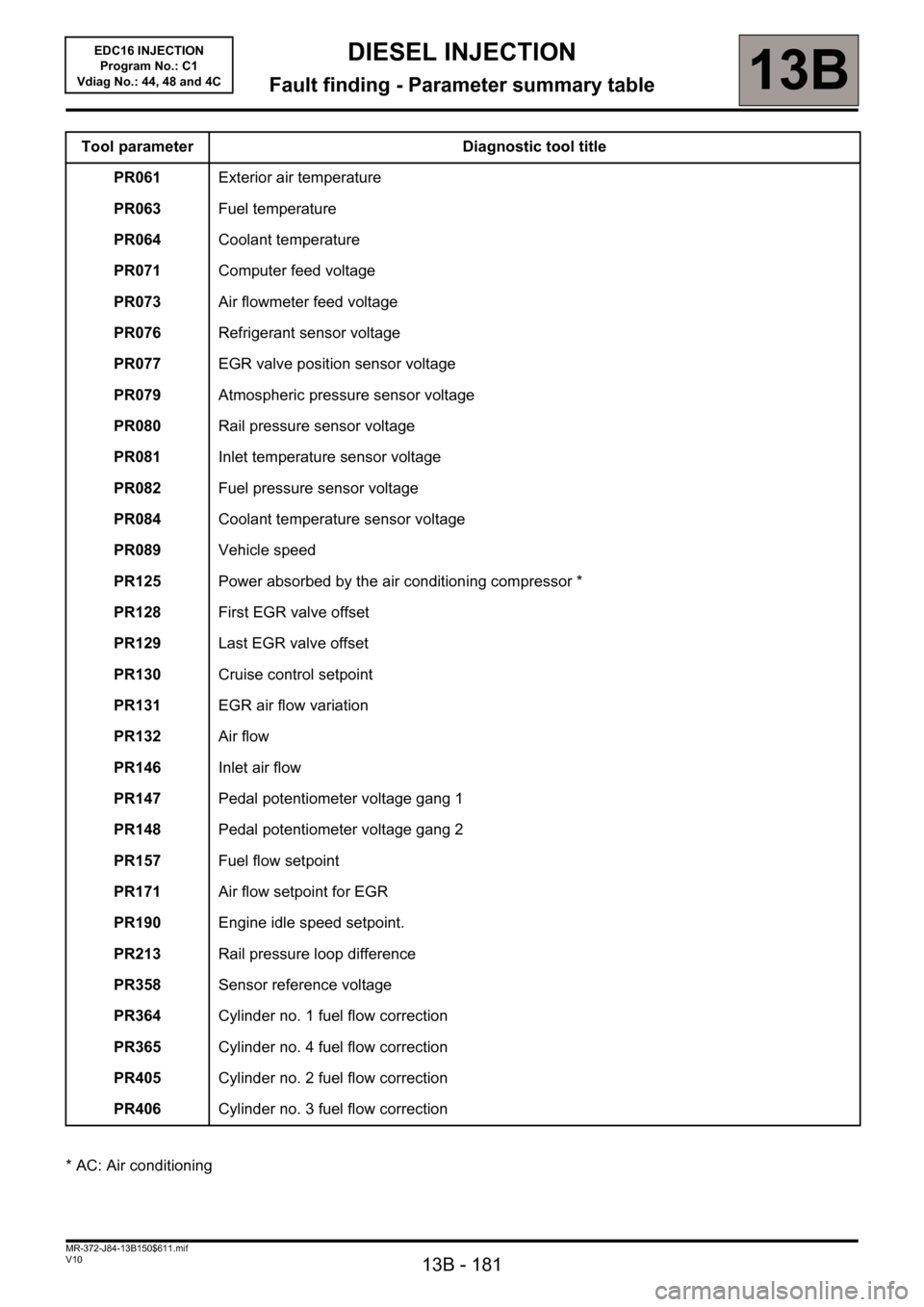

Tool parameter Diagnostic tool title

PR061Exterior air temperature

PR063Fuel temperature

PR064Coolant temperature

PR071Computer feed voltage

PR073Air flowmeter feed voltage

PR076Refrigerant sensor voltage

PR077EGR valve position sensor voltage

PR079Atmospheric pressure sensor voltage

PR080Rail pressure sensor voltage

PR081Inlet temperature sensor voltage

PR082Fuel pressure sensor voltage

PR084Coolant temperature sensor voltage

PR089Vehicle speed

PR125Power absorbed by the air conditioning compressor *

PR128First EGR valve offset

PR129Last EGR valve offset

PR130Cruise control setpoint

PR131EGR air flow variation

PR132Air flow

PR146Inlet air flow

PR147Pedal potentiometer voltage gang 1

PR148Pedal potentiometer voltage gang 2

PR157Fuel flow setpoint

PR171Air flow setpoint for EGR

PR190Engine idle speed setpoint.

PR213Rail pressure loop difference

PR358Sensor reference voltage

PR364Cylinder no. 1 fuel flow correction

PR365Cylinder no. 4 fuel flow correction

PR405Cylinder no. 2 fuel flow correction

PR406Cylinder no. 3 fuel flow correction

* AC: Air conditioning

Page 183 of 236

13B - 183

DIESEL INJECTION

Fault finding - Interpretation of parameters13B

V10 MR-372-J84-13B150$658.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

PR037

REFRIGERANT PRESSURE

NOTESThere must be no present or stored faults.

Perform this fault finding procedure after an inconsistency is displayed in the

Parameters menu or after a customer complaint (no air conditioning, etc.).

Step 1

– Start the engine, switch on the air conditioning and increase the engine speed to 1,500 rpm:

– Display PR037 Refrigerant pressure in the Cold loop function on the diagnostic tool:

If the pressure is greater than ~27bar, go to step 2.

If the pressure does not rise, or remains below normal:

– Ensure that the air conditioning compressor and the relay are operating correctly.

– Check the conformity of the refrigerant pressure sensor by comparing* the value displayed by the tool (PR192)

with the reading given by the charging station high pressure gauge.

If the pressure difference = ±1.5bar, (or 1500 mbar):

Check the continuity and the absence of interference resistance on the connections between:

Injection computer, grey 24-track connector C,

track C3Track A of the refrigerant pressure sensor

Injection computer, brown 48-track connector

B, track F1Track C of the refrigerant pressure sensor

Injection computer, brown 48-track connector

B, track F3Track B of the refrigerant pressure sensor

If these connections are not faulty, replace the refrigerant pressure sensor.

If there is no difference, the refrigerant pressure sensor is correct: go to step 2.

Step 2

– Perform fault finding on the air conditioning.

*Note:

The diagnostic tool displays the absolute pressure, the charging station high pressure gauge displays the relative

pressure.

The normal difference between the two is equal to atmospheric pressure, i.e. ~1,000mbar.

AFTER REPAIRRepeat the conformity check from the start.

EDC16_V44_PR037/EDC16_V48_PR037/EDC16_V4C_PR037

Page 184 of 236

13B - 184

DIESEL INJECTION

Fault finding - Interpretation of parameters13B

V10 MR-372-J84-13B150$658.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

PR038

RAIL PRESSURE

NOTESPerform this fault finding procedure:

– after the interpretation of fault DF053 Rail pressure regulation function,

– after an inconsistency for PR038 noted in the Parameters menu,

– after the interpretation of the fault finding procedure for AC011 Rail pressure

regulator,

– following a customer complaint (starting faults, poor performance, stalling, etc.).

Check the continuity and the absence of interference resistance on the following connections:

Injection computer, brown 48-track connector

B, track G3Track 2 of the rail pressure sensor connector

Injection computer brown 48-track

connector B, track A4Track 3 of the rail pressure sensor connector

Injection computer, brown 48-track connector

B, track C4Track 1 of the rail pressure sensor connector

If all these connections are correct, check for fuel pressure sensor power supply:

+ 5 V Track 3 of the rail pressure sensor connector

Earth Track 1 of the rail pressure sensor connector

Repair if necessary.

Check the sealing of the low and high-pressure diesel circuits (visual inspections, odour) pump housing,

overpressure valve, pipes, rail and injector unions, injector wells, etc.

If all of the previous checks are correct, switch the ignition on, wait for more than 1 minute and display PR038 Rail

pressure.

If the value is less than 50 bar, the rail pressure sensor is correct. If it is greater than this value, replace the rail

pressure sensor and tighten it to 35 ± 5 Nm.

AFTER REPAIRRepeat the conformity check from the start.

EDC16_V44_PR038/EDC16_V48_PR038/EDC16_V4C_PR038

Page 186 of 236

13B - 186

DIESEL INJECTION

Fault finding - Interpretation of parameters13B

V10 MR-372-J84-13B150$658.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

PR063

FUEL TEMPERATURE

NOTESThere must be no present or stored faults.

NOTE

In the event of a relatively low outside temperature, the difference between the

fuel temperature and the engine temperature after cold starting may be greater

than 30 °C.

Check in the Fuel circuit tab in PR063 Fuel temperature that the value displayed is not the recovery value 100 °C.

If it is, check the fuel temperature sensor:

Check that the fuel temperature sensor is in good condition:

Repair if necessary.

Check the continuity and the absence of interference resistance on the following lines:

Brown 48-track connector B, track H2 Track 1 fuel temperature sensor

Grey 32-track connector C, track F1 Track 2 fuel temperature sensor

If the temperature read is inconsistent, check that the sensor follows the resistance as a function of temperature

calibration curve (NTC) correctly.

Replace the fuel pressure and temperature sensor if the resistance is not:

2,051 ± 123Ω at 25 °C

810 ± 47Ω at 50 °C

309 ± 17Ω at 80 °C

Replace the fuel temperature sensor if it is incorrect (an incorrect sensor is often the result of an electric shock).

AFTER REPAIRRepeat the conformity check from the start.

EDC16_V44_PR063/EDC16_V48_PR063/EDC16_V4C_PR063