heater RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 27 of 365

13B-27

MR-372-J84-13B200$216.mif

V13

13B

DIESEL INJECTION

Fault finding – Fault summary table

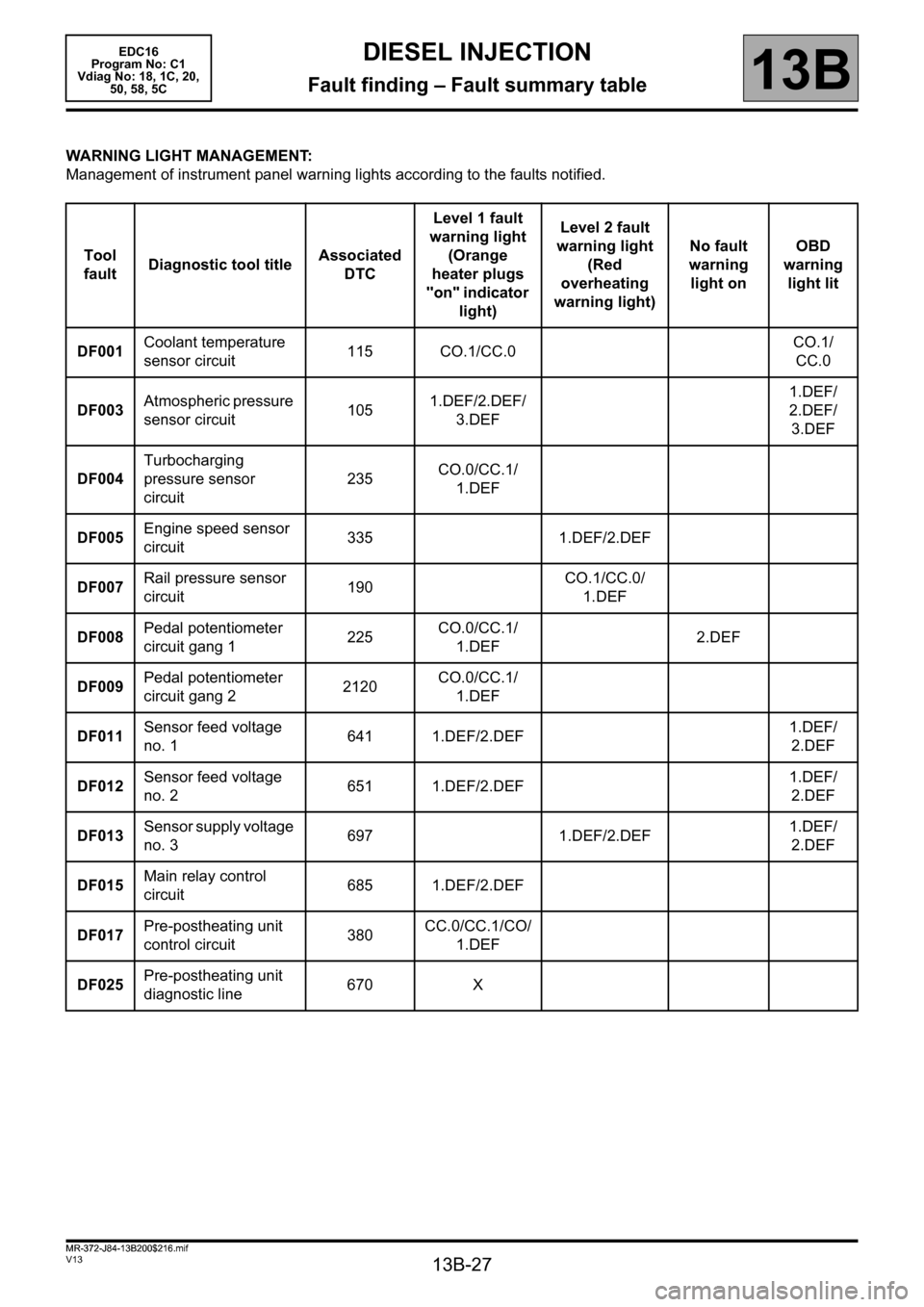

WARNING LIGHT MANAGEMENT:

Management of instrument panel warning lights according to the faults notified.

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF001Coolant temperature

sensor circuit115 CO.1/CC.0CO.1/

CC.0

DF003Atmospheric pressure

sensor circuit1051.DEF/2.DEF/

3.DEF1.DEF/

2.DEF/

3.DEF

DF004Turbocharging

pressure sensor

circuit235CO.0/CC.1/

1.DEF

DF005Engine speed sensor

circuit335 1.DEF/2.DEF

DF007Rail pressure sensor

circuit190CO.1/CC.0/

1.DEF

DF008Pedal potentiometer

circuit gang 1225CO.0/CC.1/

1.DEF2.DEF

DF009Pedal potentiometer

circuit gang 22120CO.0/CC.1/

1.DEF

DF011Sensor feed voltage

no. 1641 1.DEF/2.DEF1.DEF/

2.DEF

DF012Sensor feed voltage

no. 2651 1.DEF/2.DEF1.DEF/

2.DEF

DF013Sensor supply voltage

no. 3697 1.DEF/2.DEF1.DEF/

2.DEF

DF015Main relay control

circuit685 1.DEF/2.DEF

DF017Pre-postheating unit

control circuit380CC.0/CC.1/CO/

1.DEF

DF025Pre-postheating unit

diagnostic line670 X

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$216.mif

Page 28 of 365

13B-28

MR-372-J84-13B200$216.mif

V13

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

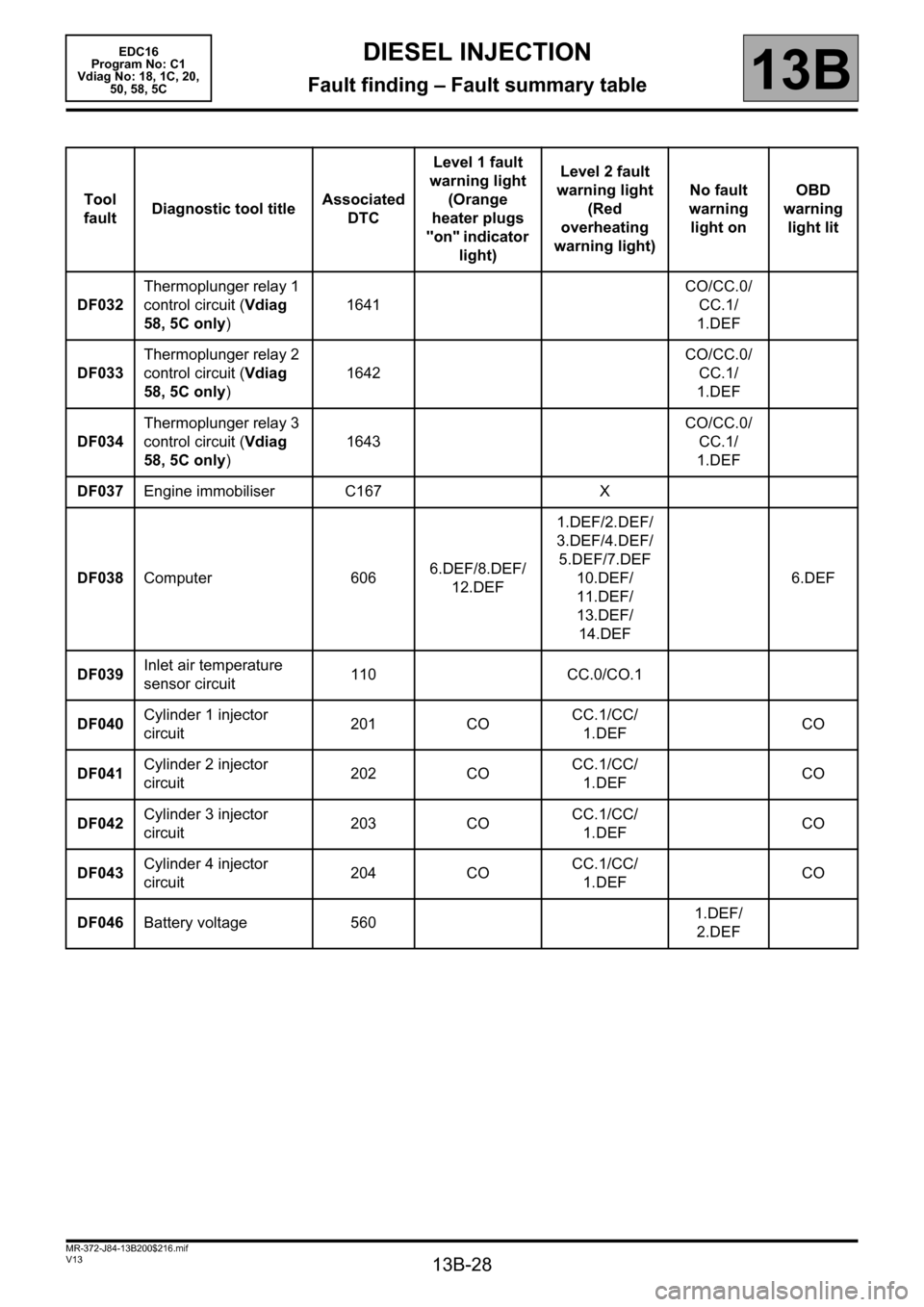

DF032Thermoplunger relay 1

control circuit (Vdiag

58, 5C only)1641CO/CC.0/

CC.1/

1.DEF

DF033Thermoplunger relay 2

control circuit (Vdiag

58, 5C only)1642CO/CC.0/

CC.1/

1.DEF

DF034Thermoplunger relay 3

control circuit (Vdiag

58, 5C only)1643CO/CC.0/

CC.1/

1.DEF

DF037Engine immobiliser C167 X

DF038Computer 6066.DEF/8.DEF/

12.DEF1.DEF/2.DEF/

3.DEF/4.DEF/

5.DEF/7.DEF

10.DEF/

11.DEF/

13.DEF/

14.DEF6.DEF

DF039Inlet air temperature

sensor circuit110 CC.0/CO.1

DF040Cylinder 1 injector

circuit201 COCC.1/CC/

1.DEFCO

DF041Cylinder 2 injector

circuit202 COCC.1/CC/

1.DEFCO

DF042Cylinder 3 injector

circuit203 COCC.1/CC/

1.DEFCO

DF043Cylinder 4 injector

circuit204 COCC.1/CC/

1.DEFCO

DF046Battery voltage 5601.DEF/

2.DEF

Page 29 of 365

13B-29

MR-372-J84-13B200$216.mif

V13

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

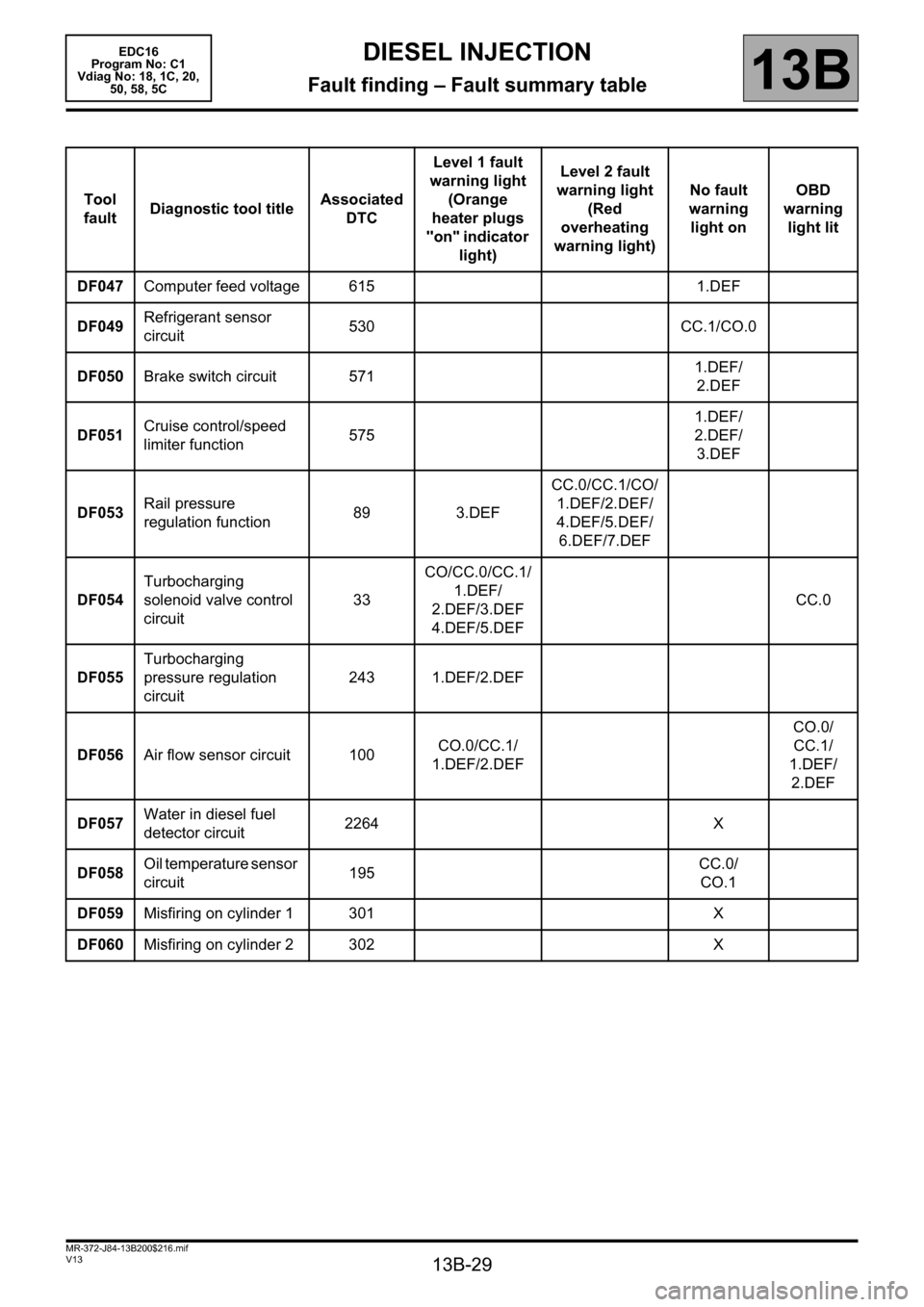

DF047Computer feed voltage 615 1.DEF

DF049Refrigerant sensor

circuit530 CC.1/CO.0

DF050Brake switch circuit 5711.DEF/

2.DEF

DF051Cruise control/speed

limiter function5751.DEF/

2.DEF/

3.DEF

DF053Rail pressure

regulation function89 3.DEFCC.0/CC.1/CO/

1.DEF/2.DEF/

4.DEF/5.DEF/

6.DEF/7.DEF

DF054Turbocharging

solenoid valve control

circuit33CO/CC.0/CC.1/

1.DEF/

2.DEF/3.DEF

4.DEF/5.DEFCC.0

DF055Turbocharging

pressure regulation

circuit243 1.DEF/2.DEF

DF056Air flow sensor circuit 100CO.0/CC.1/

1.DEF/2.DEFCO.0/

CC.1/

1.DEF/

2.DEF

DF057Water in diesel fuel

detector circuit2264 X

DF058Oil temperature sensor

circuit195CC.0/

CO.1

DF059Misfiring on cylinder 1 301 X

DF060Misfiring on cylinder 2 302 X

Page 30 of 365

13B-30

MR-372-J84-13B200$216.mif

V13

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

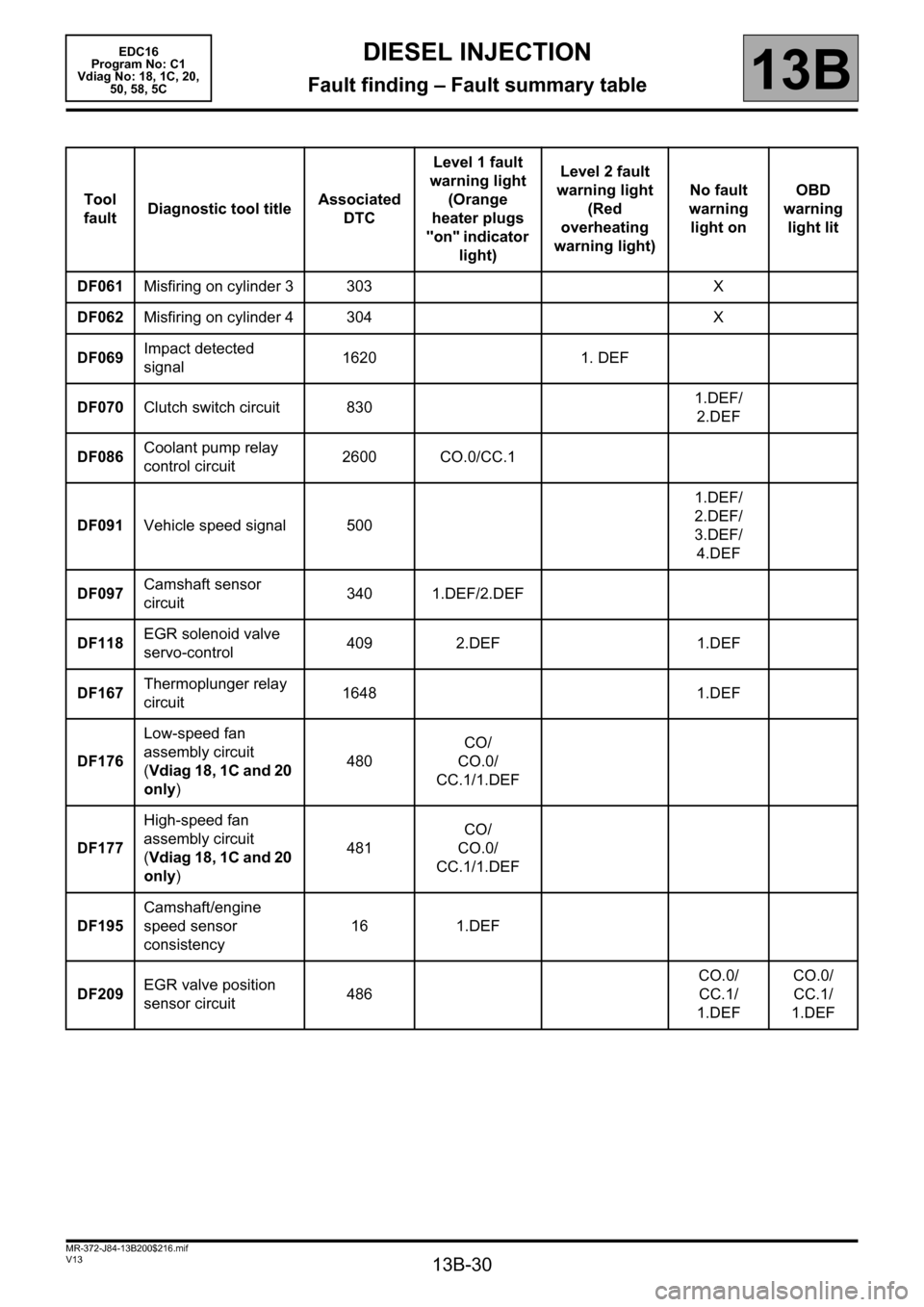

DF061Misfiring on cylinder 3 303 X

DF062Misfiring on cylinder 4 304 X

DF069Impact detected

signal1620 1. DEF

DF070Clutch switch circuit 8301.DEF/

2.DEF

DF086Coolant pump relay

control circuit2600 CO.0/CC.1

DF091Vehicle speed signal 5001.DEF/

2.DEF/

3.DEF/

4.DEF

DF097Camshaft sensor

circuit340 1.DEF/2.DEF

DF118EGR solenoid valve

servo-control409 2.DEF 1.DEF

DF167Thermoplunger relay

circuit1648 1.DEF

DF176 Low-speed fan

assembly circuit

(Vdiag 18, 1C and 20

only)480CO/

CO.0/

CC.1/1.DEF

DF177 High-speed fan

assembly circuit

(Vdiag 18, 1C and 20

only)481CO/

CO.0/

CC.1/1.DEF

DF195Camshaft/engine

speed sensor

consistency16 1.DEF

DF209EGR valve position

sensor circuit486CO.0/

CC.1/

1.DEFCO.0/

CC.1/

1.DEF

Page 31 of 365

13B-31

MR-372-J84-13B200$216.mif

V13

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

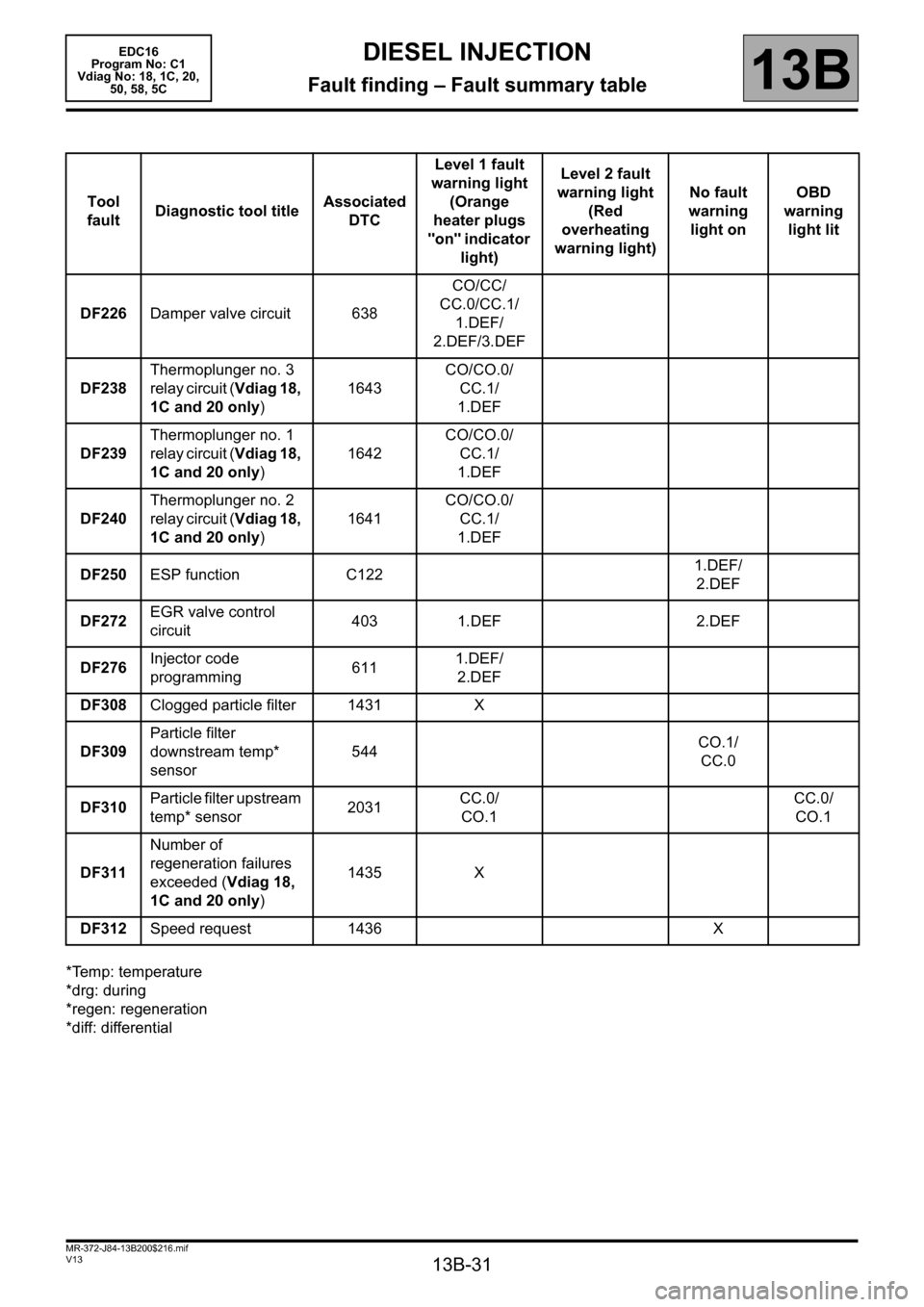

*Temp: temperature

*drg: during

*regen: regeneration

*diff: differentialTool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF226Damper valve circuit 638CO/CC/

CC.0/CC.1/

1.DEF/

2.DEF/3.DEF

DF238Thermoplunger no. 3

relay circuit (Vdiag 18,

1C and 20 only)1643CO/CO.0/

CC.1/

1.DEF

DF239 Thermoplunger no. 1

relay circuit (Vdiag 18,

1C and 20 only)1642CO/CO.0/

CC.1/

1.DEF

DF240Thermoplunger no. 2

relay circuit (Vdiag 18,

1C and 20 only)1641CO/CO.0/

CC.1/

1.DEF

DF250ESP function C1221.DEF/

2.DEF

DF272EGR valve control

circuit403 1.DEF 2.DEF

DF276Injector code

programming6111.DEF/

2.DEF

DF308Clogged particle filter 1431 X

DF309Particle filter

downstream temp*

sensor544CO.1/

CC.0

DF310Particle filter upstream

temp* sensor2031CC.0/

CO.1CC.0/

CO.1

DF311 Number of

regeneration failures

exceeded (Vdiag 18,

1C and 20 only)1435 X

DF312Speed request 1436 X

Page 32 of 365

13B-32

MR-372-J84-13B200$216.mif

V13

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

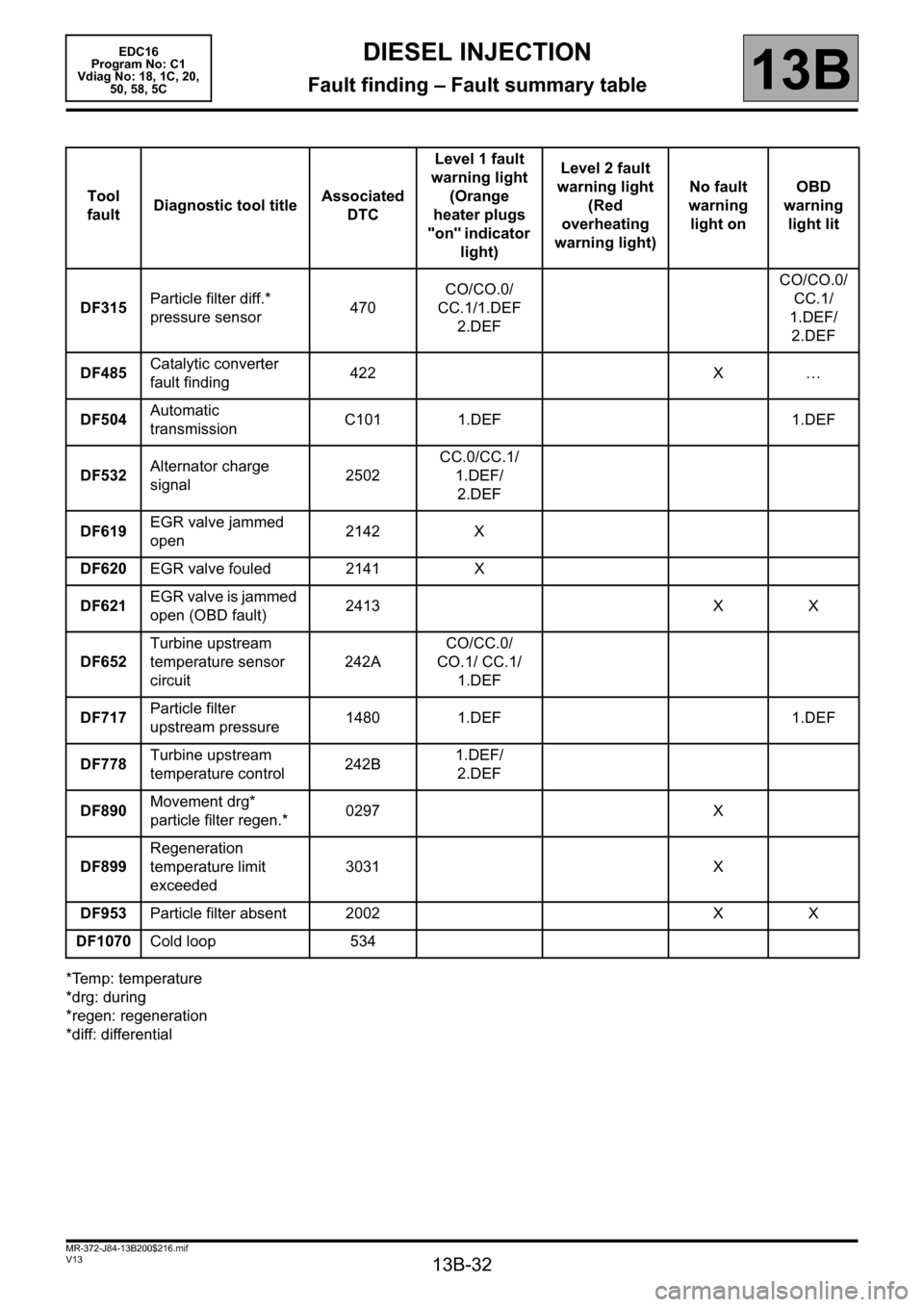

*Temp: temperature

*drg: during

*regen: regeneration

*diff: differentialTool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF315Particle filter diff.*

pressure sensor 470CO/CO.0/

CC.1/1.DEF

2.DEFCO/CO.0/

CC.1/

1.DEF/

2.DEF

DF485Catalytic converter

fault finding422 X …

DF504Automatic

transmissionC101 1.DEF 1.DEF

DF532Alternator charge

signal2502CC.0/CC.1/

1.DEF/

2.DEF

DF619EGR valve jammed

open2142 X

DF620EGR valve fouled 2141 X

DF621EGR valve is jammed

open (OBD fault)2413 X X

DF652Turbine upstream

temperature sensor

circuit242ACO/CC.0/

CO.1/ CC.1/

1.DEF

DF717Particle filter

upstream pressure1480 1.DEF 1.DEF

DF778Turbine upstream

temperature control242B1.DEF/

2.DEF

DF890Movement drg*

particle filter regen.*0297 X

DF899Regeneration

temperature limit

exceeded 3031 X

DF953Particle filter absent 2002 X X

DF1070Cold loop 534

Page 57 of 365

13B-57

MR-372-J84-13B200$252.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of faults

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

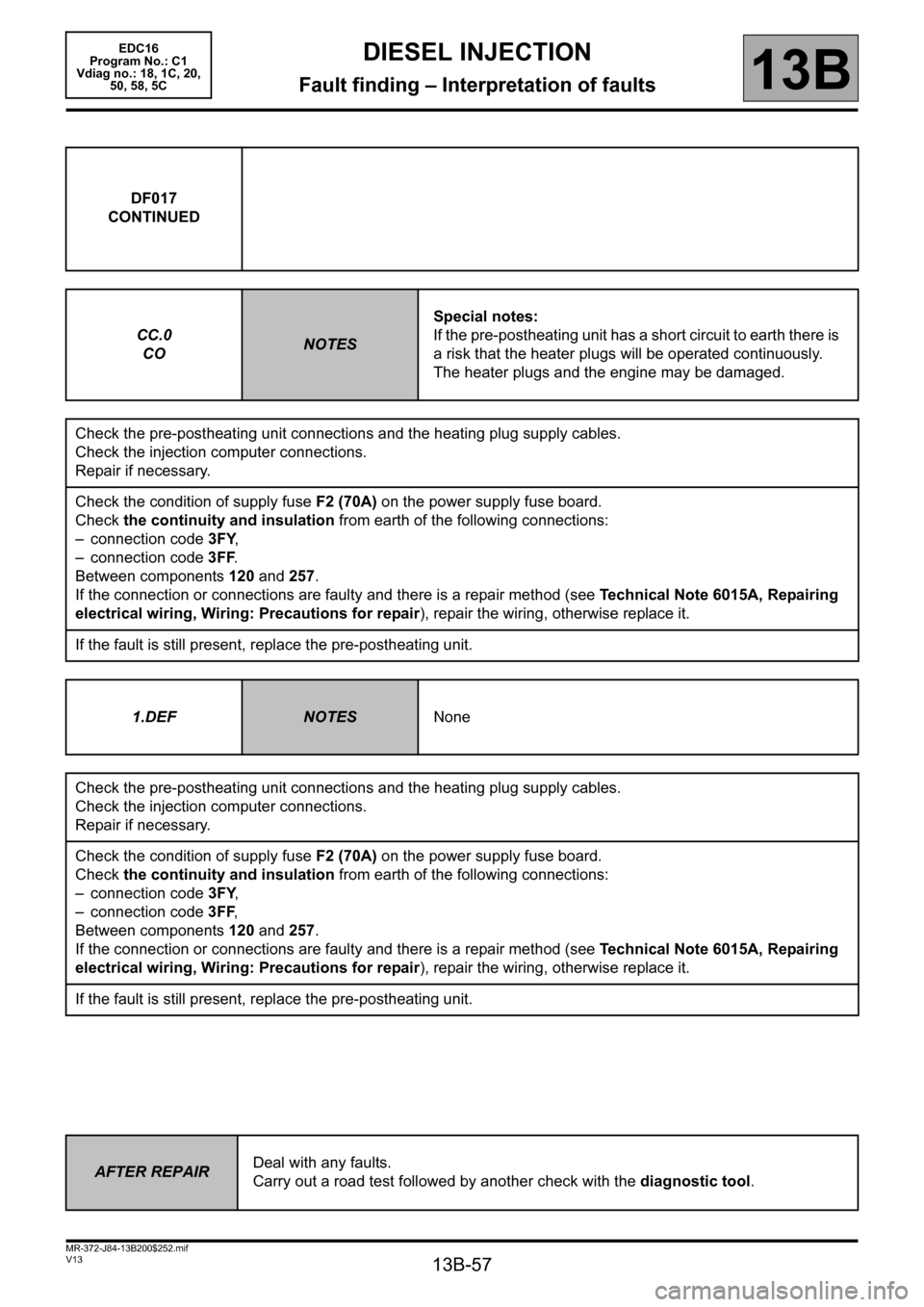

DF017

CONTINUED

CC.0

CO

NOTESSpecial notes:

If the pre-postheating unit has a short circuit to earth there is

a risk that the heater plugs will be operated continuously.

The heater plugs and the engine may be damaged.

Check the pre-postheating unit connections and the heating plug supply cables.

Check the injection computer connections.

Repair if necessary.

Check the condition of supply fuse F2 (70A) on the power supply fuse board.

Check the continuity and insulation from earth of the following connections:

– connection code3FY,

– connection code 3FF.

Between components 120 and 257.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the pre-postheating unit.

1.DEF

NOTESNone

Check the pre-postheating unit connections and the heating plug supply cables.

Check the injection computer connections.

Repair if necessary.

Check the condition of supply fuse F2 (70A) on the power supply fuse board.

Check the continuity and insulation from earth of the following connections:

– connection code3FY,

– connection code 3FF,

Between components 120 and 257.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the pre-postheating unit.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

Page 58 of 365

13B-58

MR-372-J84-13B200$252.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of faults

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

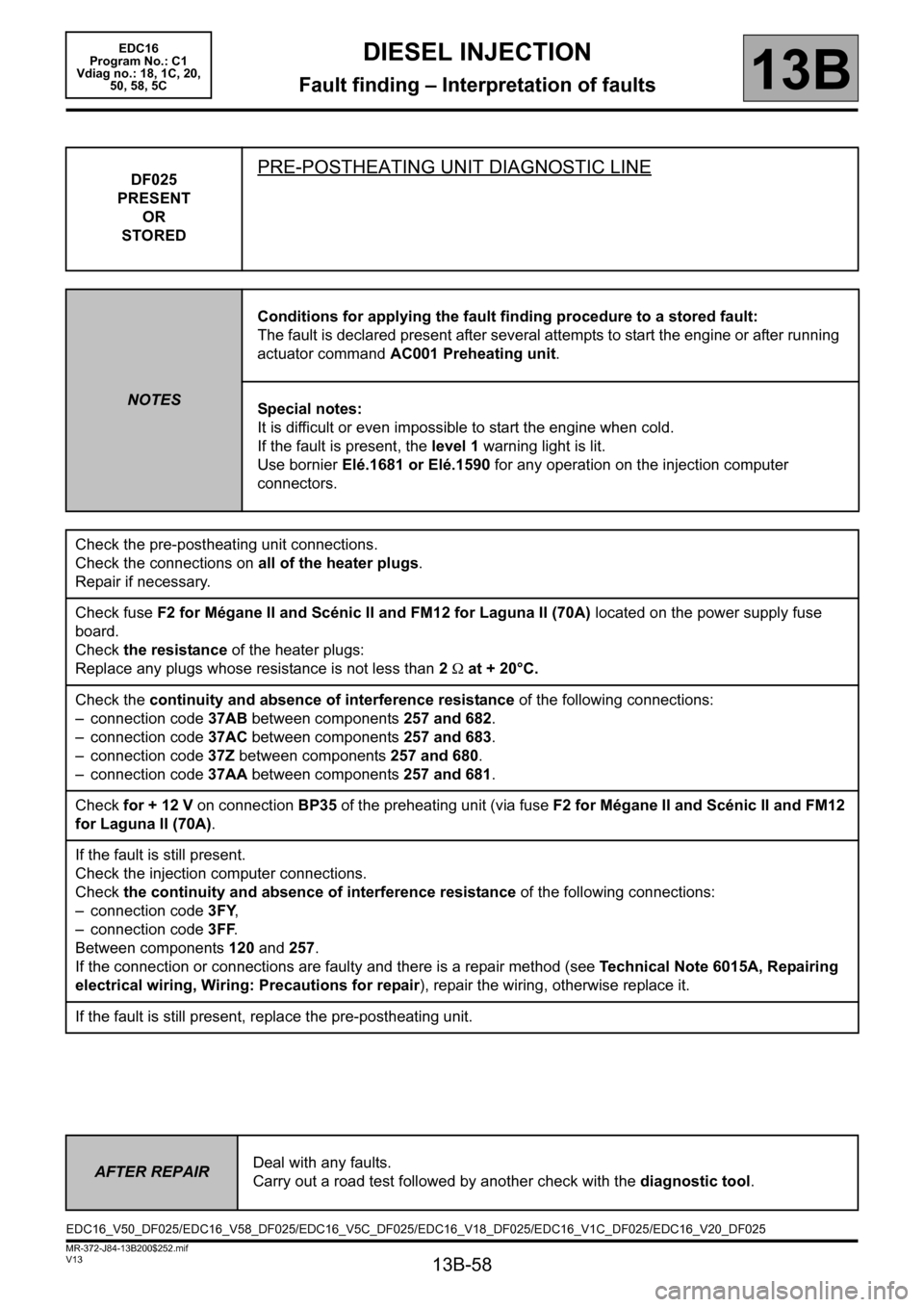

DF025

PRESENT

OR

STOREDPRE-POSTHEATING UNIT DIAGNOSTIC LINE

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after several attempts to start the engine or after running

actuator command AC001 Preheating unit.

Special notes:

It is difficult or even impossible to start the engine when cold.

If the fault is present, the level 1 warning light is lit.

Use bornier Elé.1681 or Elé.1590 for any operation on the injection computer

connectors.

Check the pre-postheating unit connections.

Check the connections on all of the heater plugs.

Repair if necessary.

Check fuse F2 for Mégane II and Scénic II and FM12 for Laguna II (70A) located on the power supply fuse

board.

Check the resistance of the heater plugs:

Replace any plugs whose resistance is not less than 2 Ω at + 20°C.

Check the continuity and absence of interference resistance of the following connections:

– connection code 37AB between components 257 and 682.

– connection code 37AC between components 257 and 683.

– connection code 37Z between components 257 and 680.

– connection code 37AA between components 257 and 681.

Check for + 12 V on connection BP35 of the preheating unit (via fuse F2 for Mégane II and Scénic II and FM12

for Laguna II (70A).

If the fault is still present.

Check the injection computer connections.

Check the continuity and absence of interference resistance of the following connections:

– connection code3FY,

– connection code 3FF.

Between components 120 and 257.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the pre-postheating unit.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V50_DF025/EDC16_V58_DF025/EDC16_V5C_DF025/EDC16_V18_DF025/EDC16_V1C_DF025/EDC16_V20_DF025

Page 59 of 365

13B-59

MR-372-J84-13B200$252.mif

V13

13B

DIESEL INJECTION

Fault finding – Interpretation of faults

DF032

PRESENT

OR

STOREDTHERMOPLUNGER 1 RELAY CONTROL CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1 : Short circuit to + 12 V

1.DEF: Inconsistent signal

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after:

– the ignition is switched on,

– with the engine running,

– actuator command AC063 Thermoplunger no. 1 relay.

If faults DF033 “Thermoplunger relay 2 control circuit” and DF034

“Thermoplunger relay 3 control circuit” appear, ignore them and go straight to

configuration CF030 “Thermoplunger configuration”.

Special notes:

Use bornier Elé. 1681 for all operations on the engine management computer

connectors.

check the engine management computer connections.

Check the thermoplunger connections, component code 898.

Repair if necessary.

Check for + 12 V after ignition supply on connections BP27 and BP35 of component 1550.

If there is no + 12 V supply, refer to the interpretation of fault DF015 Main relay control circuit.

Repair if necessary.

Check the continuity and absence of interference resistance of connection 3JA between components 120

and 1550.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Using a test light, check the supply by running command AC063 Thermoplunger no. 1 relay on connection 3JB

between components 898 and 1550.

Measure the resistance of the thermoplunger, component code 898.

Replace the thermoplunger, component code 898 if the resistance is greater than 2 Ω.

Replace the water heater interface unit if necessary.

Using a test light, check that the water heater interface unit is properly earthed by running command AC063

Thermoplunger no. 1 relay on connection 3JA between components 120 and 1550.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V50_DF032/EDC16_V58_DF032/EDC16_V5C_DF032EDC16

Program No.: C1

Vdiag No.: 50, 58, 5C

Page 60 of 365

13B-60

MR-372-J84-13B200$252.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of faults

EDC16

Program No.: C1

Vdiag No.: 50, 58, 5C

13B

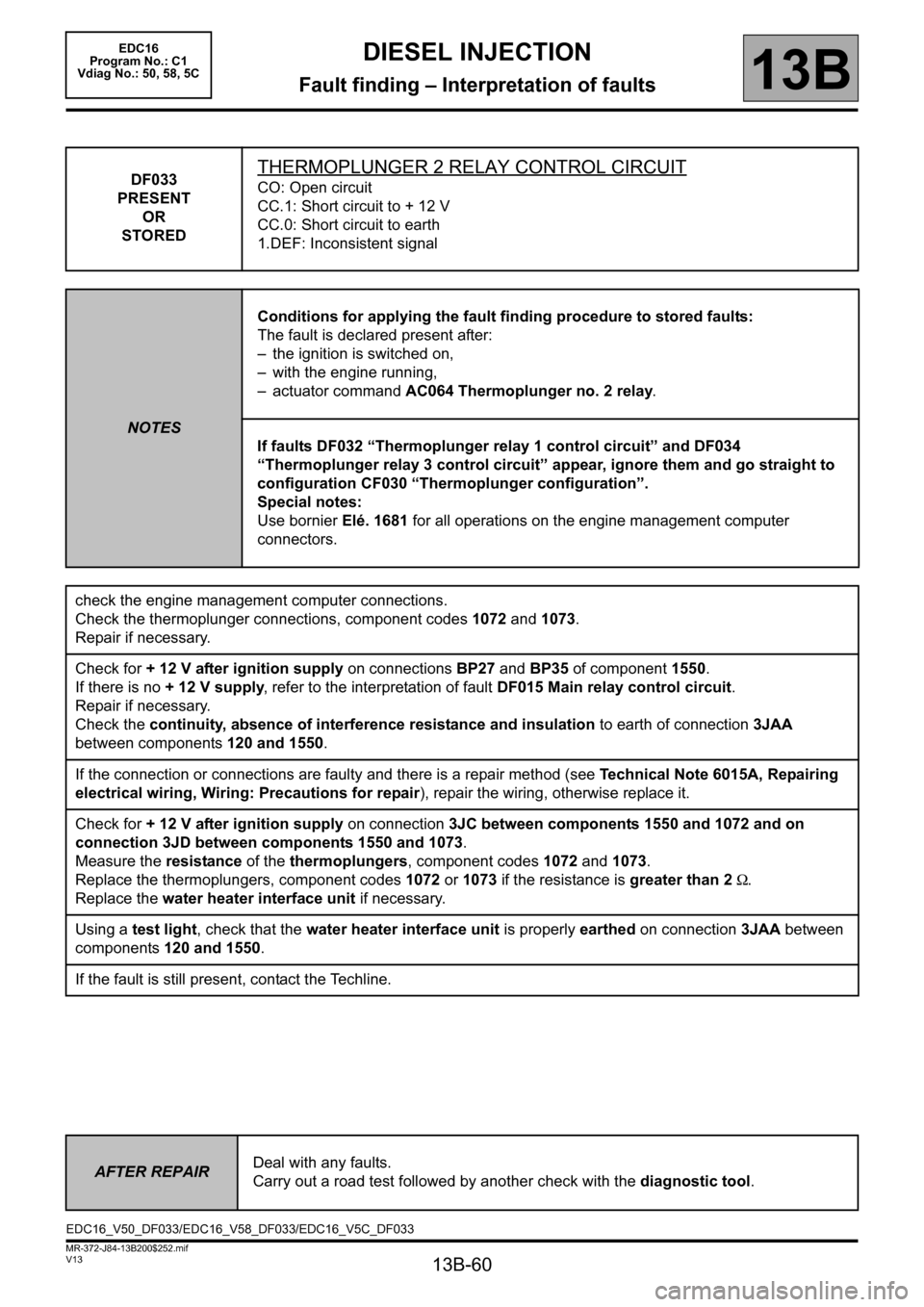

DF033

PRESENT

OR

STOREDTHERMOPLUNGER 2 RELAY CONTROL CIRCUIT

CO: Open circuit

CC.1: Short circuit to + 12 V

CC.0: Short circuit to earth

1.DEF: Inconsistent signal

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after:

– the ignition is switched on,

– with the engine running,

– actuator command AC064 Thermoplunger no. 2 relay.

If faults DF032 “Thermoplunger relay 1 control circuit” and DF034

“Thermoplunger relay 3 control circuit” appear, ignore them and go straight to

configuration CF030 “Thermoplunger configuration”.

Special notes:

Use bornier Elé. 1681 for all operations on the engine management computer

connectors.

check the engine management computer connections.

Check the thermoplunger connections, component codes 1072 and 1073.

Repair if necessary.

Check for + 12 V after ignition supply on connections BP27 and BP35 of component 1550.

If there is no + 12 V supply, refer to the interpretation of fault DF015 Main relay control circuit.

Repair if necessary.

Check the continuity, absence of interference resistance and insulation to earth of connection 3JAA

between components 120 and 1550.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check for + 12 V after ignition supply on connection 3JC between components 1550 and 1072 and on

connection 3JD between components 1550 and 1073.

Measure the resistance of the thermoplungers, component codes 1072 and 1073.

Replace the thermoplungers, component codes 1072 or 1073 if the resistance is greater than 2 Ω.

Replace the water heater interface unit if necessary.

Using a test light, check that the water heater interface unit is properly earthed on connection 3JAA between

components 120 and 1550.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V50_DF033/EDC16_V58_DF033/EDC16_V5C_DF033