weight RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 157 of 365

13B-157

MR-372-J84-13B200$360.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of faults

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

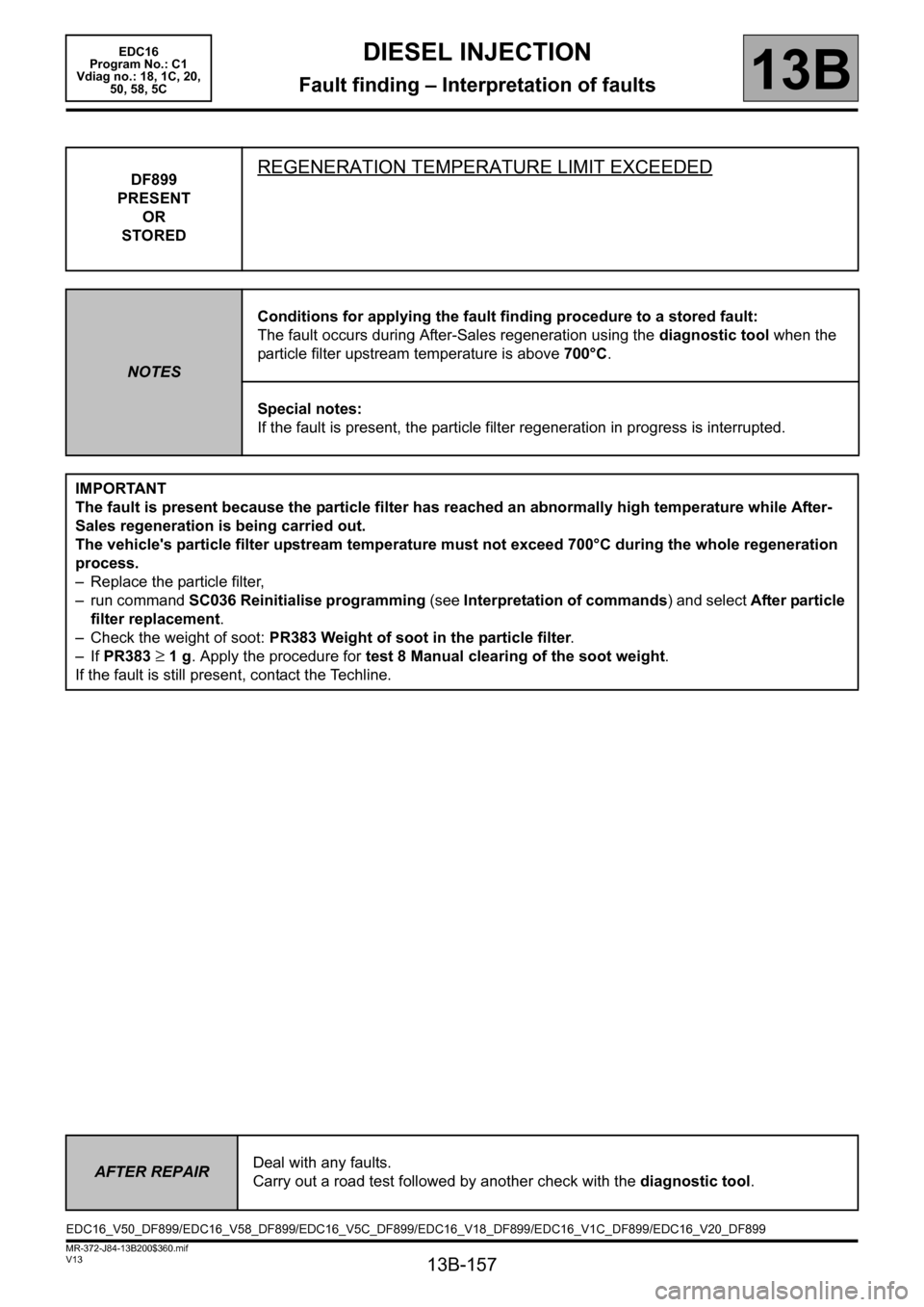

DF899

PRESENT

OR

STOREDREGENERATION TEMPERATURE LIMIT EXCEEDED

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault occurs during After-Sales regeneration using the diagnostic tool when the

particle filter upstream temperature is above 700°C.

Special notes:

If the fault is present, the particle filter regeneration in progress is interrupted.

IMPORTANT

The fault is present because the particle filter has reached an abnormally high temperature while After-

Sales regeneration is being carried out.

The vehicle's particle filter upstream temperature must not exceed 700°C during the whole regeneration

process.

– Replace the particle filter,

– run command SC036 Reinitialise programming (see Interpretation of commands) and select After particle

filter replacement.

– Check the weight of soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply the procedure for test 8 Manual clearing of the soot weight.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V50_DF899/EDC16_V58_DF899/EDC16_V5C_DF899/EDC16_V18_DF899/EDC16_V1C_DF899/EDC16_V20_DF899

Page 159 of 365

13B-159

MR-372-J84-13B200$360.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of faults

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

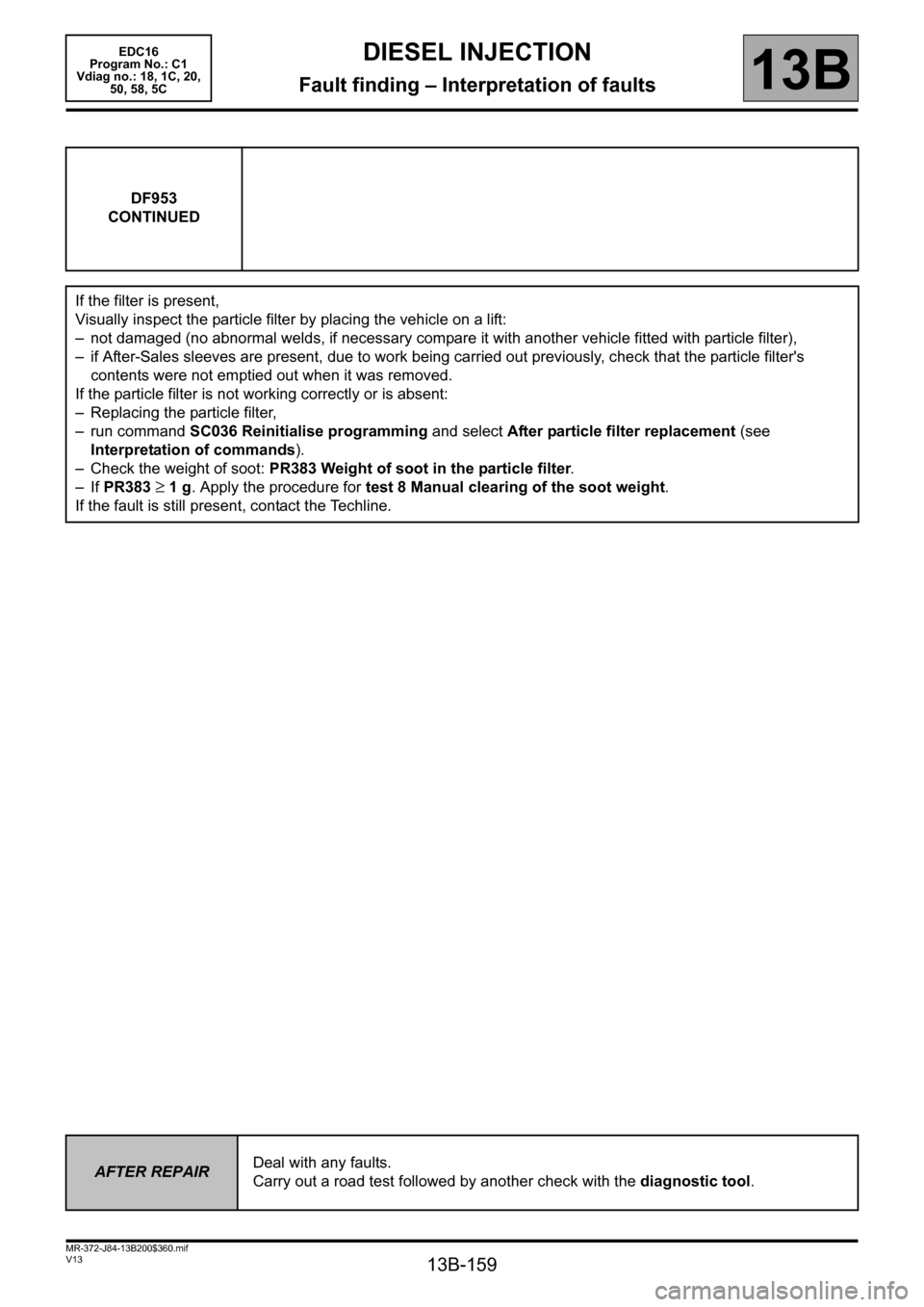

DF953

CONTINUED

If the filter is present,

Visually inspect the particle filter by placing the vehicle on a lift:

– not damaged (no abnormal welds, if necessary compare it with another vehicle fitted with particle filter),

– if After-Sales sleeves are present, due to work being carried out previously, check that the particle filter's

contents were not emptied out when it was removed.

If the particle filter is not working correctly or is absent:

– Replacing the particle filter,

– run command SC036 Reinitialise programming and select After particle filter replacement (see

Interpretation of commands).

– Check the weight of soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply the procedure for test 8 Manual clearing of the soot weight.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

Page 209 of 365

13B-209

MR-372-J84-13B200$540.mif

V13

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Interpretation of statuses13B

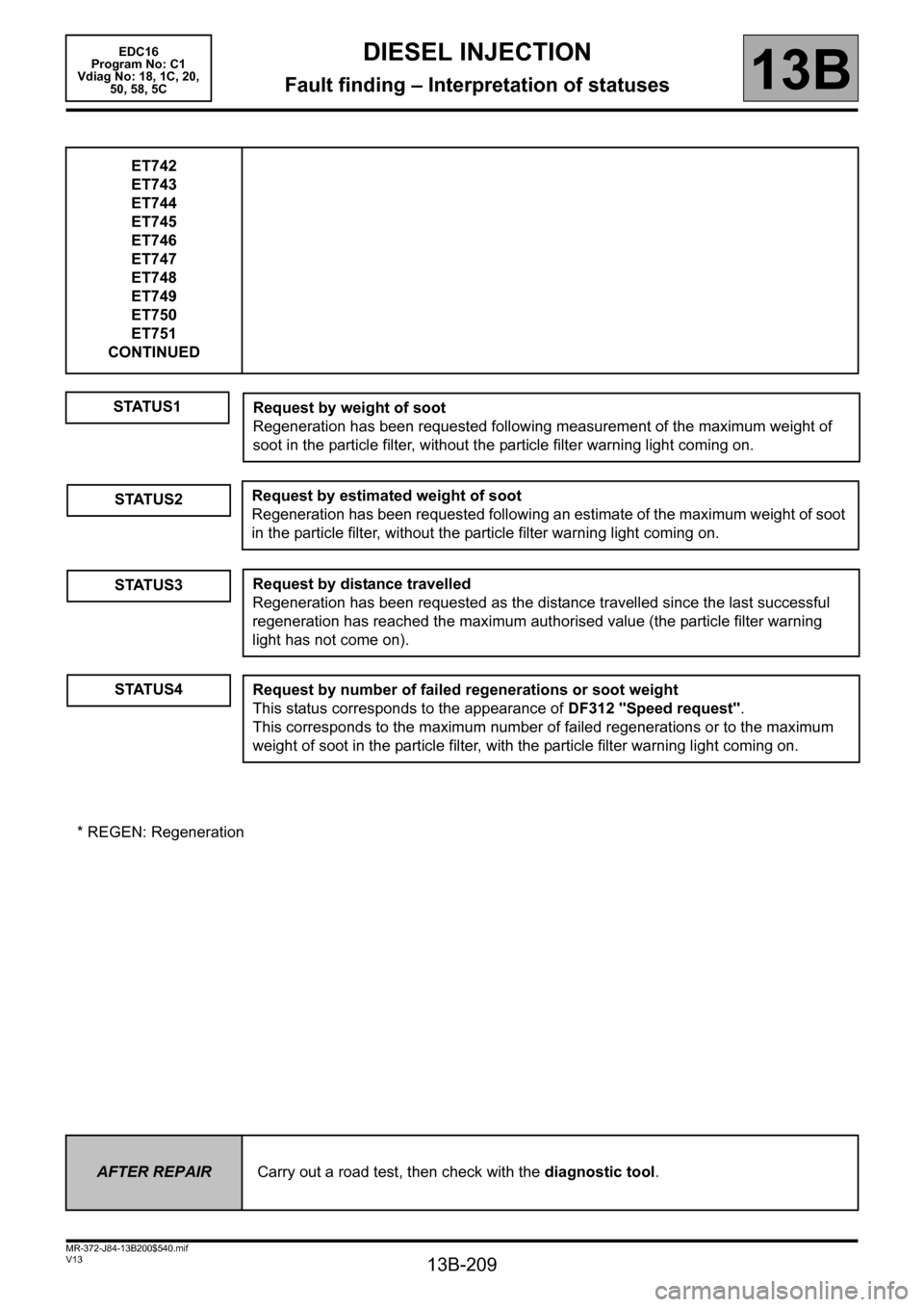

ET742

ET743

ET744

ET745

ET746

ET747

ET748

ET749

ET750

ET751

CONTINUED

STATUS1

Request by weight of soot

Regeneration has been requested following measurement of the maximum weight of

soot in the particle filter, without the particle filter warning light coming on.

STATUS2Request by estimated weight of soot

Regeneration has been requested following an estimate of the maximum weight of soot

in the particle filter, without the particle filter warning light coming on.

STATUS3Request by distance travelled

Regeneration has been requested as the distance travelled since the last successful

regeneration has reached the maximum authorised value (the particle filter warning

light has not come on).

STATUS4Request by number of failed regenerations or soot weight

This status corresponds to the appearance of DF312 "Speed request".

This corresponds to the maximum number of failed regenerations or to the maximum

weight of soot in the particle filter, with the particle filter warning light coming on.

* REGEN: Regeneration

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 212 of 365

13B-212

MR-372-J84-13B200$576.mif

V13

DIESEL INJECTION

Fault finding – Parameter summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

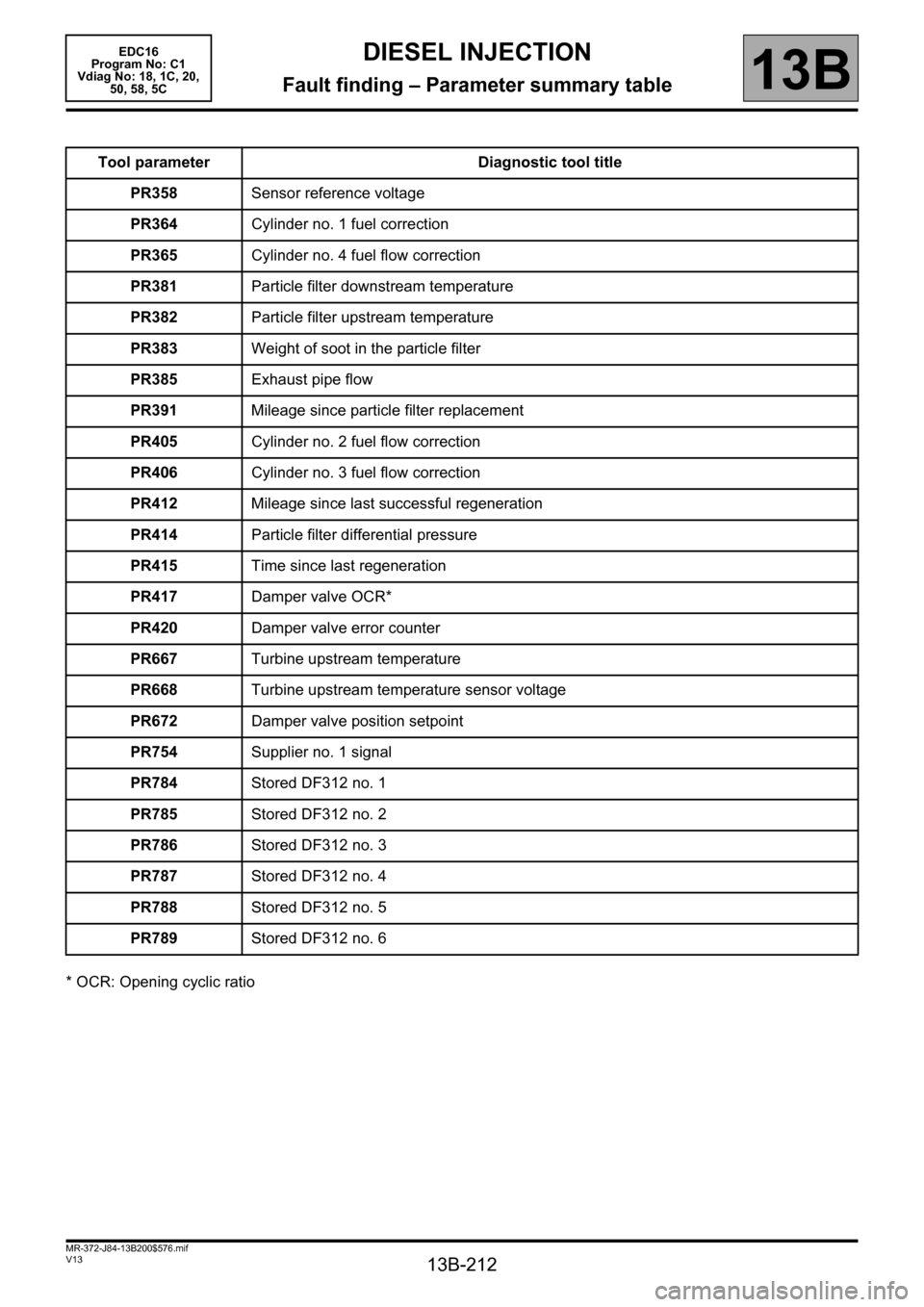

* OCR: Opening cyclic ratioTool parameter Diagnostic tool title

PR358Sensor reference voltage

PR364Cylinder no. 1 fuel correction

PR365Cylinder no. 4 fuel flow correction

PR381Particle filter downstream temperature

PR382Particle filter upstream temperature

PR383Weight of soot in the particle filter

PR385Exhaust pipe flow

PR391Mileage since particle filter replacement

PR405Cylinder no. 2 fuel flow correction

PR406Cylinder no. 3 fuel flow correction

PR412Mileage since last successful regeneration

PR414Particle filter differential pressure

PR415Time since last regeneration

PR417Damper valve OCR*

PR420Damper valve error counter

PR667Turbine upstream temperature

PR668Turbine upstream temperature sensor voltage

PR672Damper valve position setpoint

PR754Supplier no. 1 signal

PR784Stored DF312 no. 1

PR785Stored DF312 no. 2

PR786Stored DF312 no. 3

PR787Stored DF312 no. 4

PR788Stored DF312 no. 5

PR789Stored DF312 no. 6

Page 213 of 365

13B-213

MR-372-J84-13B200$576.mif

V13

DIESEL INJECTION

Fault finding – Parameter summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

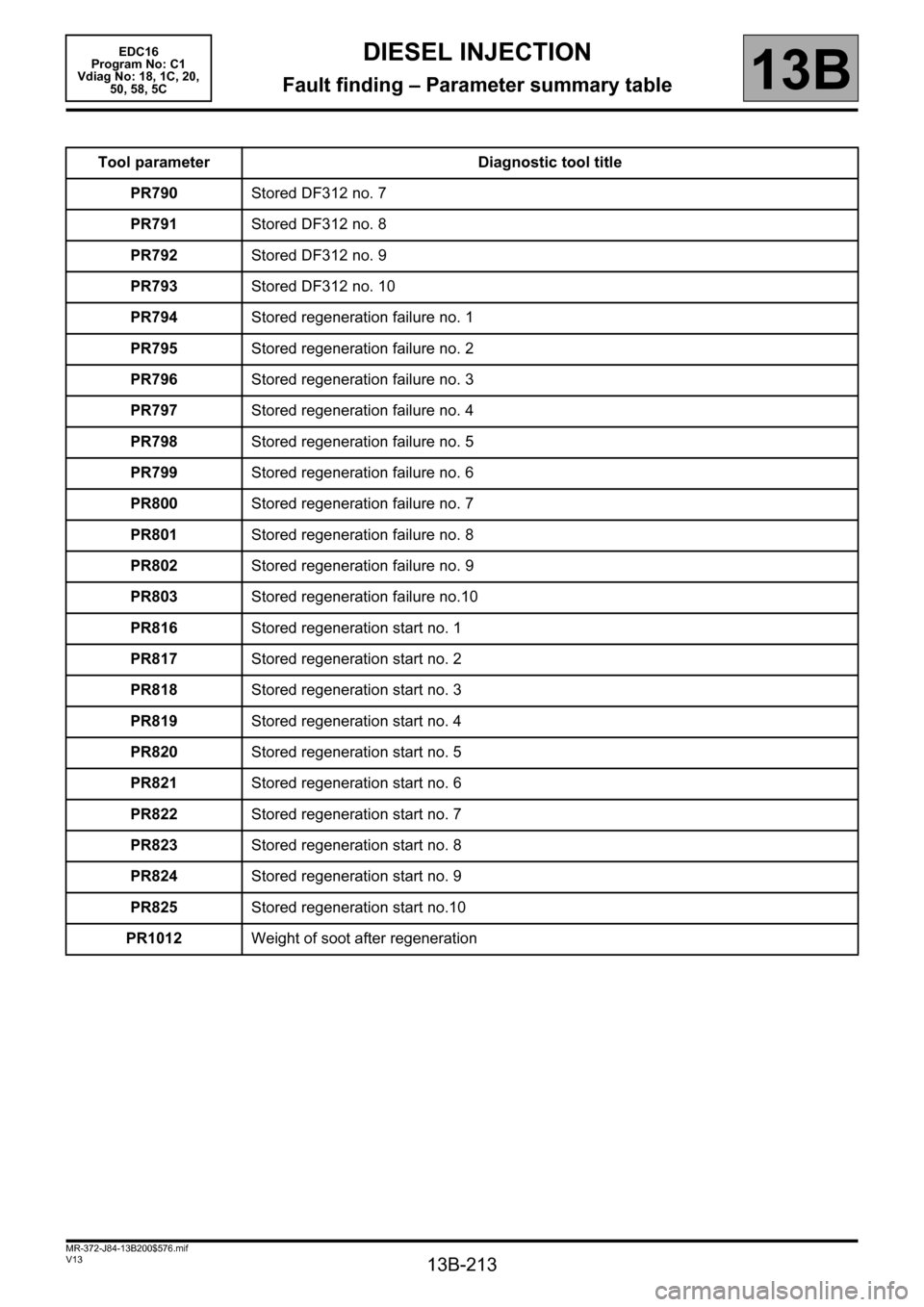

Tool parameter Diagnostic tool title

PR790Stored DF312 no. 7

PR791Stored DF312 no. 8

PR792Stored DF312 no. 9

PR793Stored DF312 no. 10

PR794Stored regeneration failure no. 1

PR795Stored regeneration failure no. 2

PR796Stored regeneration failure no. 3

PR797Stored regeneration failure no. 4

PR798Stored regeneration failure no. 5

PR799Stored regeneration failure no. 6

PR800Stored regeneration failure no. 7

PR801Stored regeneration failure no. 8

PR802Stored regeneration failure no. 9

PR803Stored regeneration failure no.10

PR816Stored regeneration start no. 1

PR817Stored regeneration start no. 2

PR818Stored regeneration start no. 3

PR819Stored regeneration start no. 4

PR820Stored regeneration start no. 5

PR821Stored regeneration start no. 6

PR822Stored regeneration start no. 7

PR823Stored regeneration start no. 8

PR824Stored regeneration start no. 9

PR825Stored regeneration start no.10

PR1012Weight of soot after regeneration

Page 270 of 365

13B-270

MR-372-J84-13B200$648.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of parameters

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

PR383

WEIGHT OF SOOT IN PARTICLE FILTER

PARAMETER

DEFINITIONThis parameter indicates the weight of soot in the particle filter in g.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C.

Vdiag 50, 58, 5c:

PR383 < 45 g.

If the weight is greater than 45 g:

Refer to the interpretation of fault DF315 Particle filter differential pressure sensor.

Vdiag 18, 1c, 20:

PR383 < 56 g.

If the weight is greater than 56 g:

Refer to the interpretation of fault DF315 Particle filter differential pressure sensor.

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

EDC16_V50_PR383/EDC16_V58_PR383/EDC16_V5C_PR383/EDC16_V18_PR383/EDC16_V1C_PR383/EDC16_V20_PR383

Page 290 of 365

13B-290

MR-372-J84-13B200$684.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of parameters

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

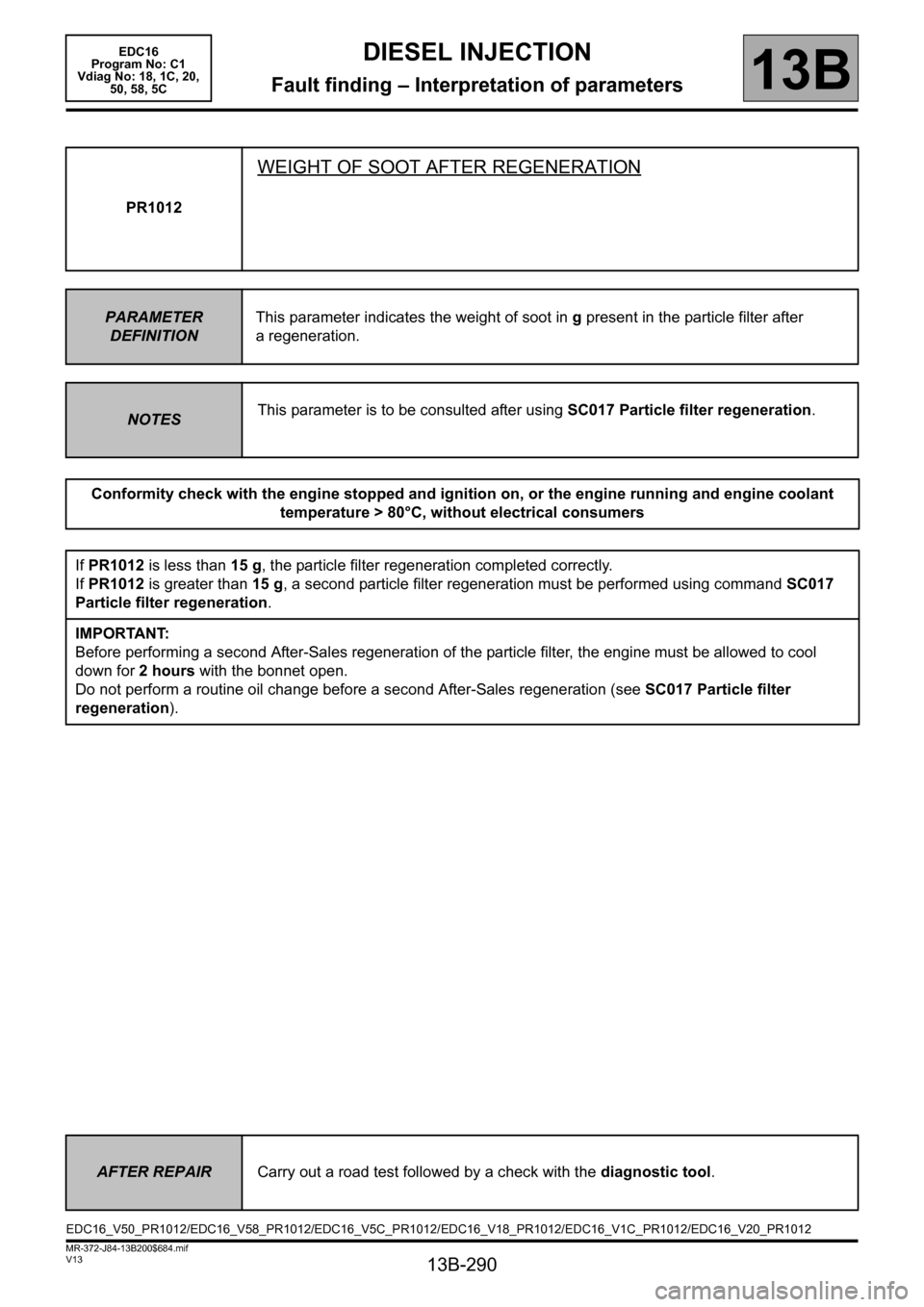

PR1012

WEIGHT OF SOOT AFTER REGENERATION

PARAMETER

DEFINITIONThis parameter indicates the weight of soot in g present in the particle filter after

a regeneration.

NOTESThis parameter is to be consulted after using SC017 Particle filter regeneration.

Conformity check with the engine stopped and ignition on, or the engine running and engine coolant

temperature > 80°C, without electrical consumers

If PR1012 is less than 15 g, the particle filter regeneration completed correctly.

If PR1012 is greater than 15 g, a second particle filter regeneration must be performed using command SC017

Particle filter regeneration.

IMPORTANT:

Before performing a second After-Sales regeneration of the particle filter, the engine must be allowed to cool

down for 2 hours with the bonnet open.

Do not perform a routine oil change before a second After-Sales regeneration (see SC017 Particle filter

regeneration).

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

EDC16_V50_PR1012/EDC16_V58_PR1012/EDC16_V5C_PR1012/EDC16_V18_PR1012/EDC16_V1C_PR1012/EDC16_V20_PR1012

Page 296 of 365

13B-296

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

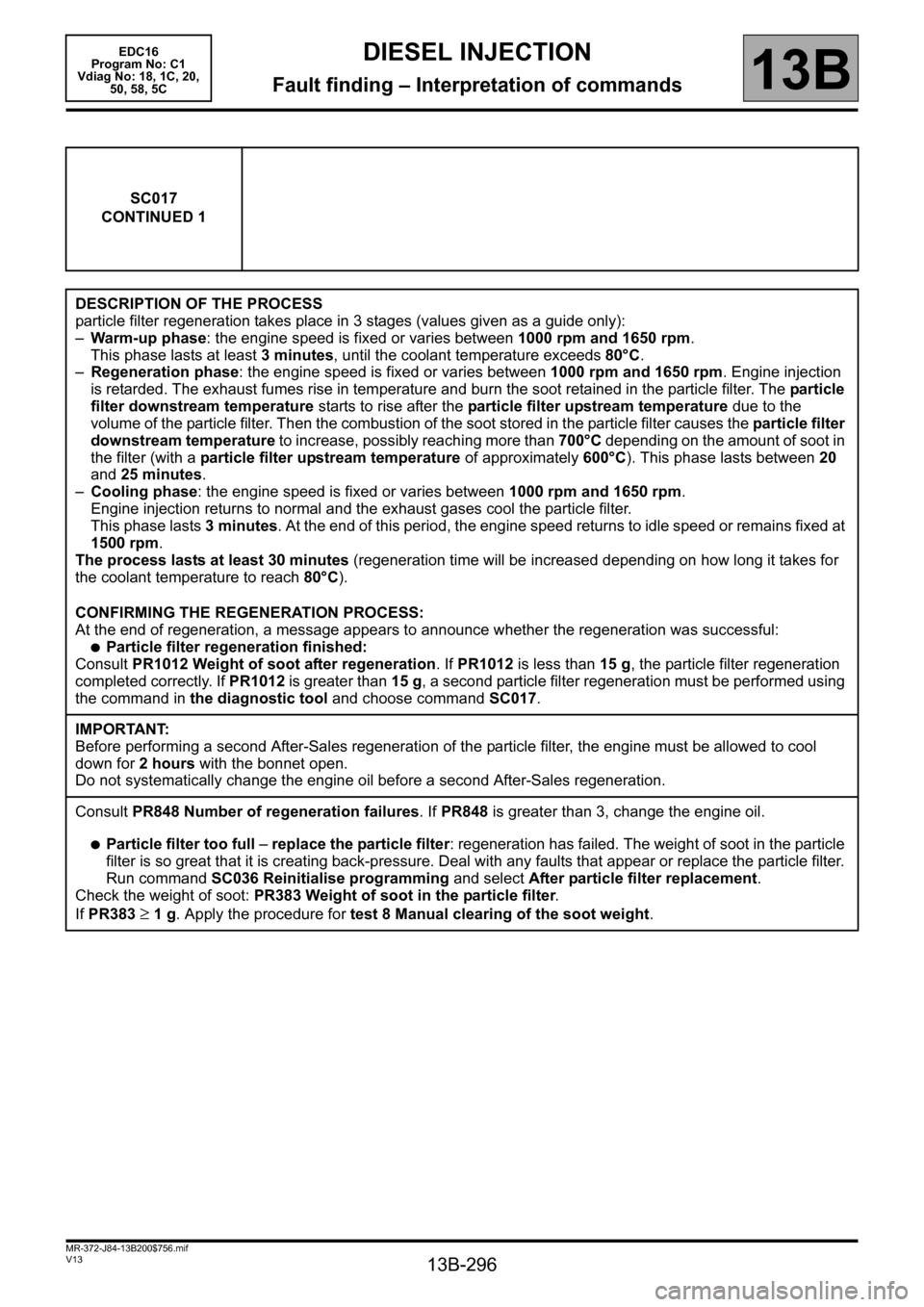

SC017

CONTINUED 1

DESCRIPTION OF THE PROCESS

particle filter regeneration takes place in 3 stages (values given as a guide only):

–Warm-up phase: the engine speed is fixed or varies between 1000 rpm and 1650 rpm.

This phase lasts at least 3 minutes, until the coolant temperature exceeds 80°C.

–Regeneration phase: the engine speed is fixed or varies between 1000 rpm and 1650 rpm. Engine injection

is retarded. The exhaust fumes rise in temperature and burn the soot retained in the particle filter. The particle

filter downstream temperature starts to rise after the particle filter upstream temperature due to the

volume of the particle filter. Then the combustion of the soot stored in the particle filter causes the particle filter

downstream temperature to increase, possibly reaching more than 700°C depending on the amount of soot in

the filter (with a particle filter upstream temperature of approximately 600°C). This phase lasts between 20

and 25 minutes.

–Cooling phase: the engine speed is fixed or varies between 1000 rpm and 1650 rpm.

Engine injection returns to normal and the exhaust gases cool the particle filter.

This phase lasts 3 minutes. At the end of this period, the engine speed returns to idle speed or remains fixed at

1500 rpm.

The process lasts at least 30 minutes (regeneration time will be increased depending on how long it takes for

the coolant temperature to reach 80°C).

CONFIRMING THE REGENERATION PROCESS:

At the end of regeneration, a message appears to announce whether the regeneration was successful:

●Particle filter regeneration finished:

Consult PR1012 Weight of soot after regeneration. If PR1012 is less than 15 g, the particle filter regeneration

completed correctly. If PR1012 is greater than 15 g, a second particle filter regeneration must be performed using

the command in the diagnostic tool and choose command SC017.

IMPORTANT:

Before performing a second After-Sales regeneration of the particle filter, the engine must be allowed to cool

down for 2 hours with the bonnet open.

Do not systematically change the engine oil before a second After-Sales regeneration.

Consult PR848 Number of regeneration failures. If PR848 is greater than 3, change the engine oil.

●Particle filter too full – replace the particle filter: regeneration has failed. The weight of soot in the particle

filter is so great that it is creating back-pressure. Deal with any faults that appear or replace the particle filter.

Run command SC036 Reinitialise programming and select After particle filter replacement.

Check the weight of soot: PR383 Weight of soot in the particle filter.

If PR383

≥ 1 g. Apply the procedure for test 8 Manual clearing of the soot weight.

Page 297 of 365

13B-297

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

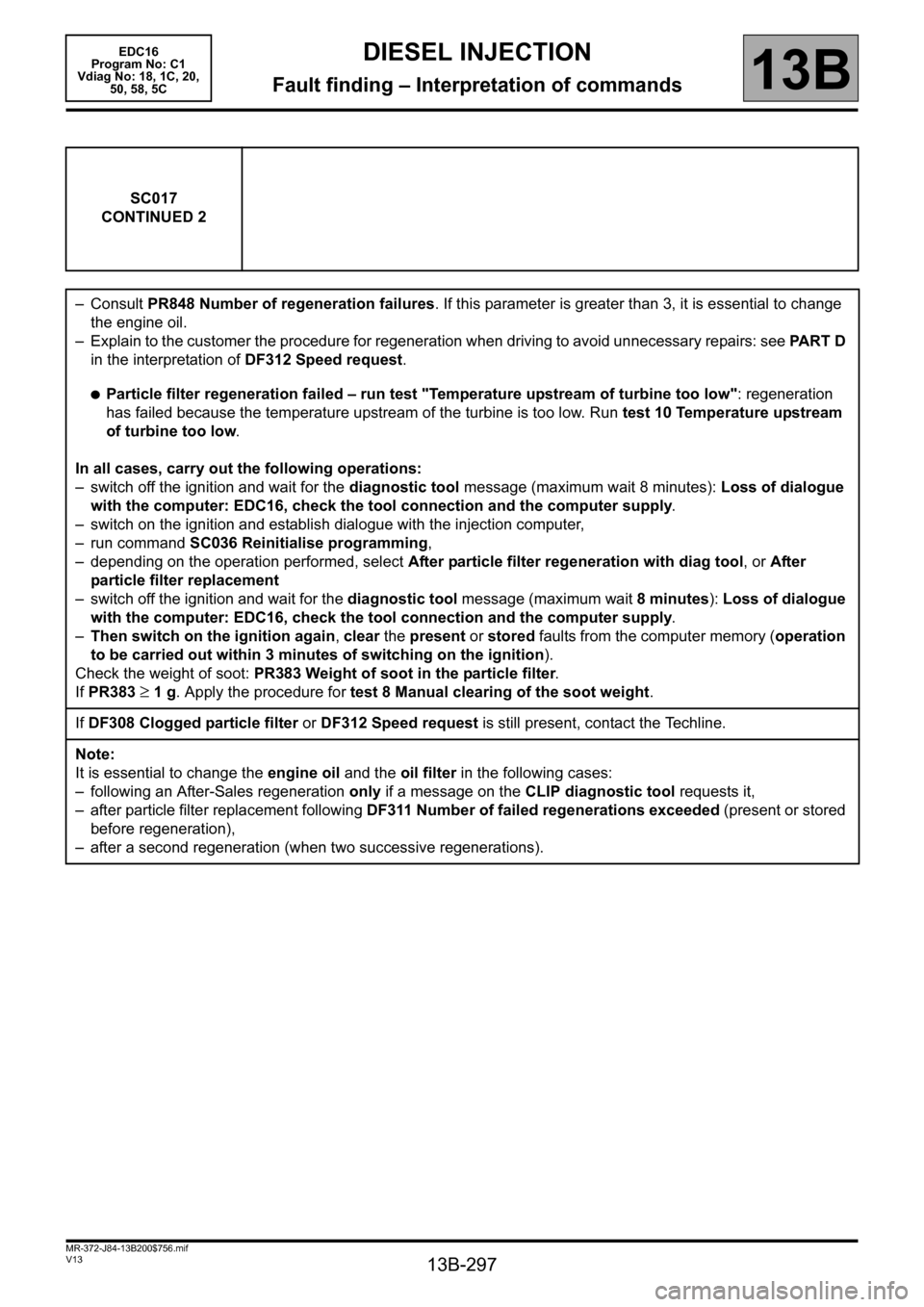

SC017

CONTINUED 2

–Consult PR848 Number of regeneration failures. If this parameter is greater than 3, it is essential to change

the engine oil.

– Explain to the customer the procedure for regeneration when driving to avoid unnecessary repairs: see PART D

in the interpretation of DF312 Speed request.

●Particle filter regeneration failed – run test "Temperature upstream of turbine too low": regeneration

has failed because the temperature upstream of the turbine is too low. Run test 10 Temperature upstream

of turbine too low.

In all cases, carry out the following operations:

– switch off the ignition and wait for the diagnostic tool message (maximum wait 8 minutes): Loss of dialogue

with the computer: EDC16, check the tool connection and the computer supply.

– switch on the ignition and establish dialogue with the injection computer,

– run command SC036 Reinitialise programming,

– depending on the operation performed, select After particle filter regeneration with diag tool, or After

particle filter replacement

– switch off the ignition and wait for the diagnostic tool message (maximum wait 8 minutes): Loss of dialogue

with the computer: EDC16, check the tool connection and the computer supply.

–Then switch on the ignition again, clear the present or stored faults from the computer memory (operation

to be carried out within 3 minutes of switching on the ignition).

Check the weight of soot: PR383 Weight of soot in the particle filter.

If PR383

≥ 1 g. Apply the procedure for test 8 Manual clearing of the soot weight.

If DF308 Clogged particle filter or DF312 Speed request is still present, contact the Techline.

Note:

It is essential to change the engine oil and the oil filter in the following cases:

– following an After-Sales regeneration only if a message on the CLIP diagnostic tool requests it,

– after particle filter replacement following DF311 Number of failed regenerations exceeded (present or stored

before regeneration),

– after a second regeneration (when two successive regenerations).

Page 298 of 365

13B-298

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

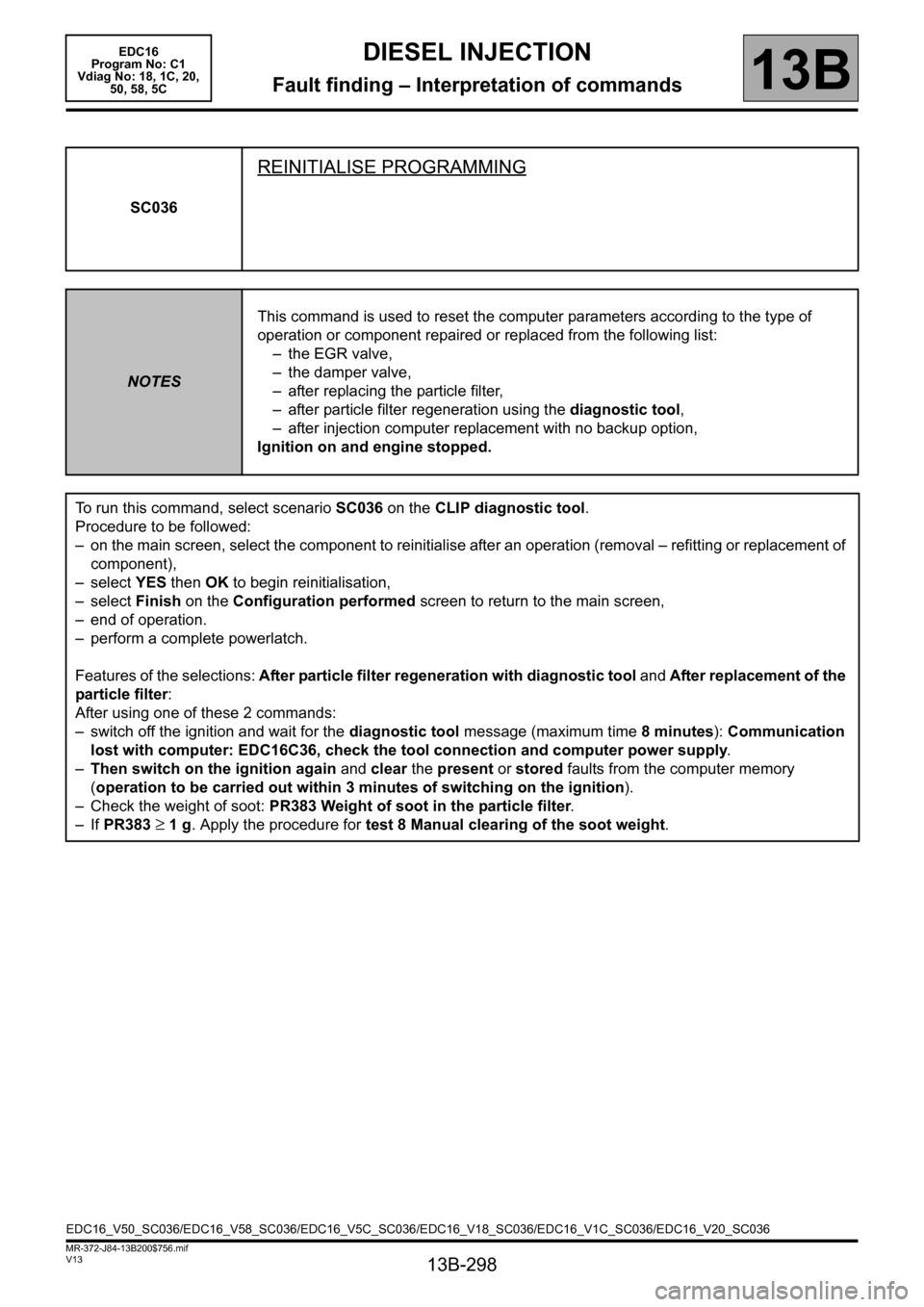

SC036

REINITIALISE PROGRAMMING

NOTESThis command is used to reset the computer parameters according to the type of

operation or component repaired or replaced from the following list:

– the EGR valve,

– the damper valve,

– after replacing the particle filter,

– after particle filter regeneration using the diagnostic tool,

– after injection computer replacement with no backup option,

Ignition on and engine stopped.

To run this command, select scenario SC036 on the CLIP diagnostic tool.

Procedure to be followed:

– on the main screen, select the component to reinitialise after an operation (removal – refitting or replacement of

component),

–select YES then OK to begin reinitialisation,

–select Finish on the Configuration performed screen to return to the main screen,

– end of operation.

– perform a complete powerlatch.

Features of the selections: After particle filter regeneration with diagnostic tool and After replacement of the

particle filter:

After using one of these 2 commands:

– switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes): Communication

lost with computer: EDC16C36, check the tool connection and computer power supply.

–Then switch on the ignition again and clear the present or stored faults from the computer memory

(operation to be carried out within 3 minutes of switching on the ignition).

– Check the weight of soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply the procedure for test 8 Manual clearing of the soot weight.

EDC16_V50_SC036/EDC16_V58_SC036/EDC16_V5C_SC036/EDC16_V18_SC036/EDC16_V1C_SC036/EDC16_V20_SC036