weight RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 338 of 365

13B-338

MR-372-J84-13B200$864.mif

V13

13B

DIESEL INJECTION

Fault finding – Tests

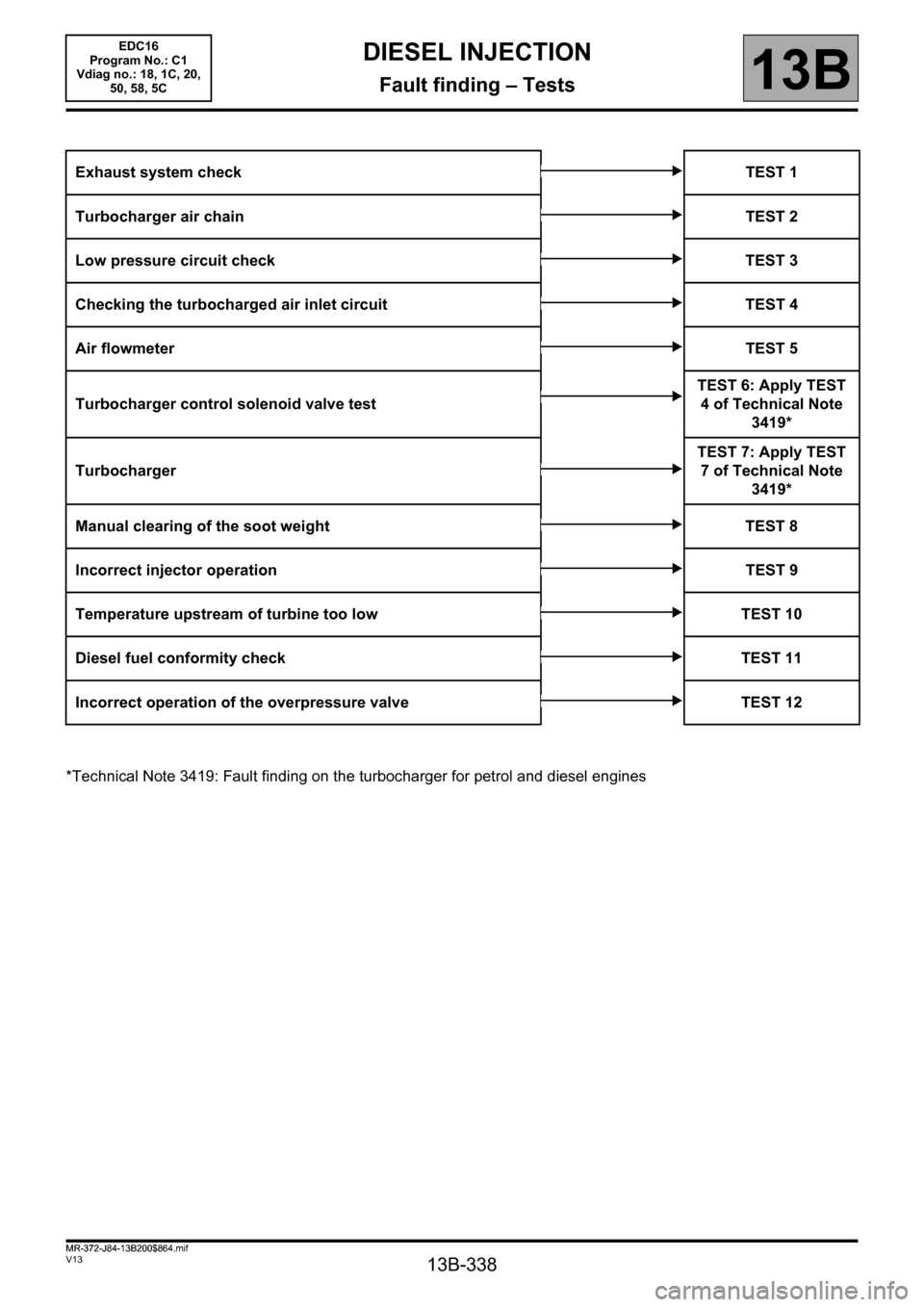

*Technical Note 3419: Fault finding on the turbocharger for petrol and diesel engines Exhaust system checkTEST 1

Turbocharger air chainTEST 2

Low pressure circuit check TEST 3

Checking the turbocharged air inlet circuit TEST 4

Air flowmeterTEST 5

Turbocharger control solenoid valve testTEST 6: Apply TEST

4 of Technical Note

3419*

TurbochargerTEST 7: Apply TEST

7 of Technical Note

3419*

Manual clearing of the soot weight TEST 8

Incorrect injector operation TEST 9

Temperature upstream of turbine too low TEST 10

Diesel fuel conformity check TEST 11

Incorrect operation of the overpressure valve TEST 12

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$864.mif

Page 340 of 365

13B-340

MR-372-J84-13B200$900.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Tests13B

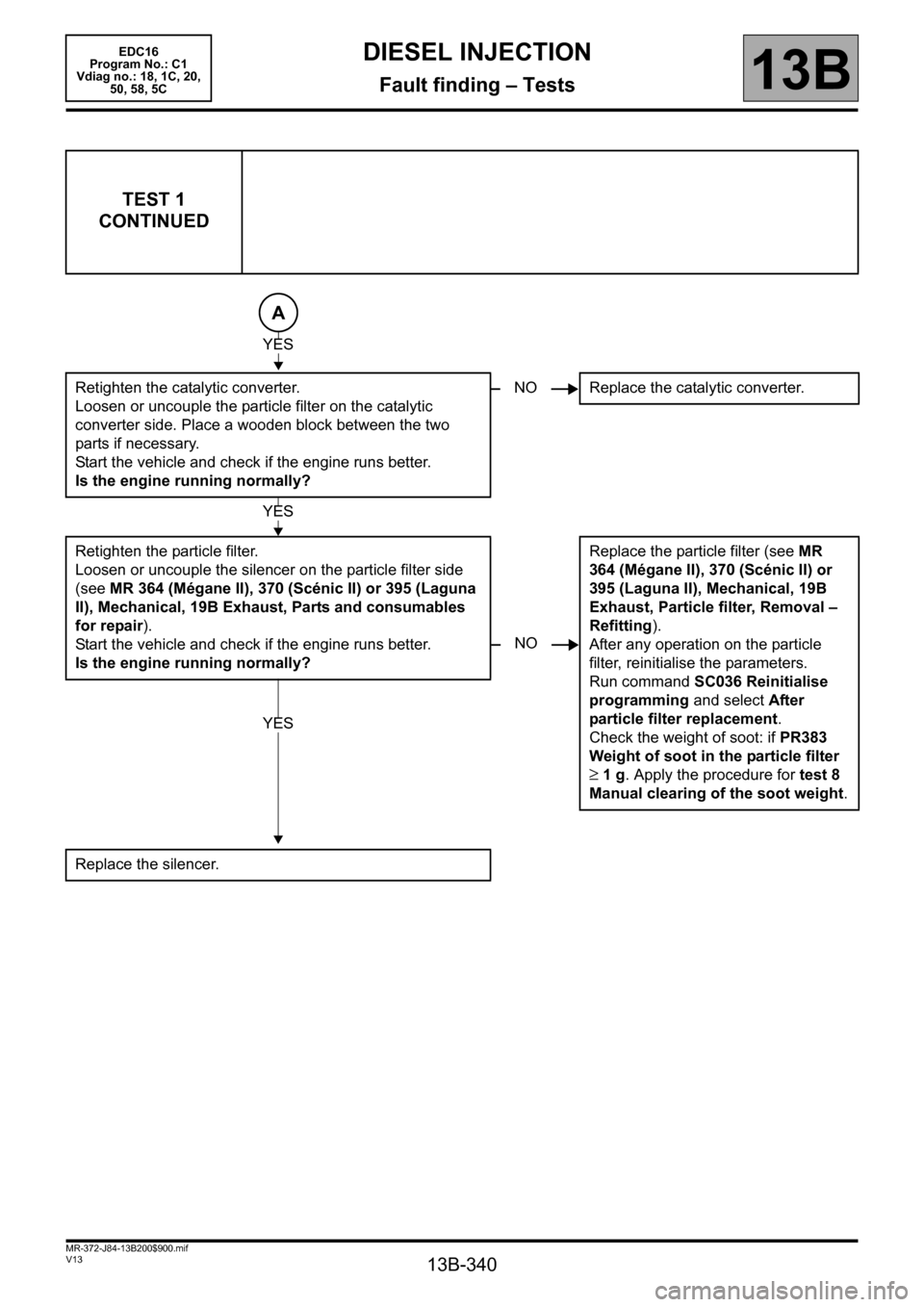

TEST 1

CONTINUED

Retighten the catalytic converter.

Loosen or uncouple the particle filter on the catalytic

converter side. Place a wooden block between the two

parts if necessary.

Start the vehicle and check if the engine runs better.

Is the engine running normally?Replace the catalytic converter.

Retighten the particle filter.

Loosen or uncouple the silencer on the particle filter side

(see MR 364 (Mégane II), 370 (Scénic II) or 395 (Laguna

II), Mechanical, 19B Exhaust, Parts and consumables

for repair).

Start the vehicle and check if the engine runs better.

Is the engine running normally?Replace the particle filter (see MR

364 (Mégane II), 370 (Scénic II) or

395 (Laguna II), Mechanical, 19B

Exhaust, Particle filter, Removal –

Refitting).

After any operation on the particle

filter, reinitialise the parameters.

Run command SC036 Reinitialise

programming and select After

particle filter replacement.

Check the weight of soot: if PR383

Weight of soot in the particle filter

≥ 1 g. Apply the procedure for test 8

Manual clearing of the soot weight.

Replace the silencer.

A

YES

NO

YES

NO

YES

Page 348 of 365

13B-348

MR-372-J84-13B200$900.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Tests13B

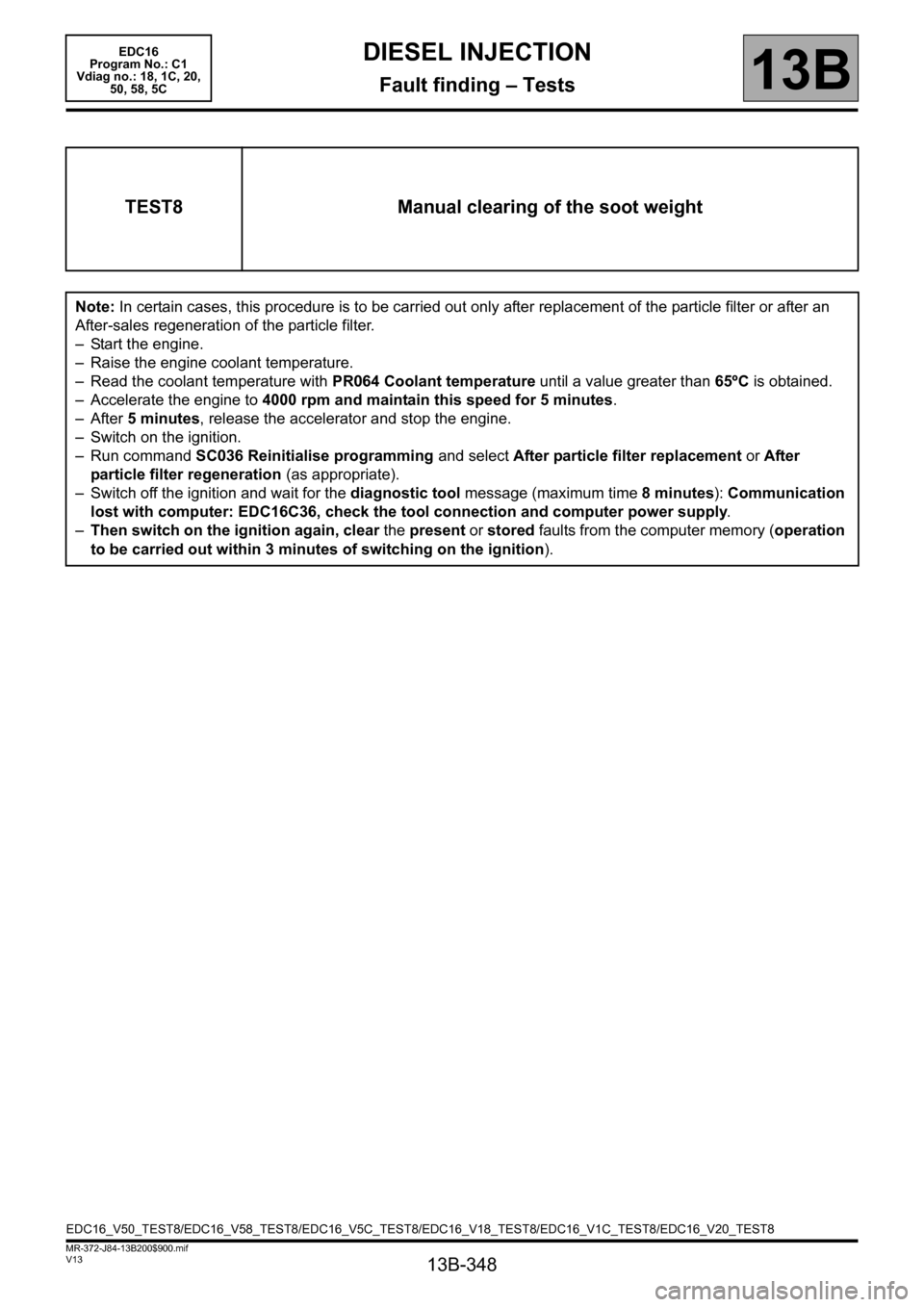

TEST8 Manual clearing of the soot weight

Note: In certain cases, this procedure is to be carried out only after replacement of the particle filter or after an

After-sales regeneration of the particle filter.

– Start the engine.

– Raise the engine coolant temperature.

– Read the coolant temperature with PR064 Coolant temperature until a value greater than 65ºC is obtained.

– Accelerate the engine to 4000 rpm and maintain this speed for 5 minutes.

–After 5 minutes, release the accelerator and stop the engine.

– Switch on the ignition.

– Run command SC036 Reinitialise programming and select After particle filter replacement or After

particle filter regeneration (as appropriate).

– Switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes): Communication

lost with computer: EDC16C36, check the tool connection and computer power supply.

–Then switch on the ignition again, clear the present or stored faults from the computer memory (operation

to be carried out within 3 minutes of switching on the ignition).

EDC16_V50_TEST8/EDC16_V58_TEST8/EDC16_V5C_TEST8/EDC16_V18_TEST8/EDC16_V1C_TEST8/EDC16_V20_TEST8

Page 358 of 365

13B-358

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

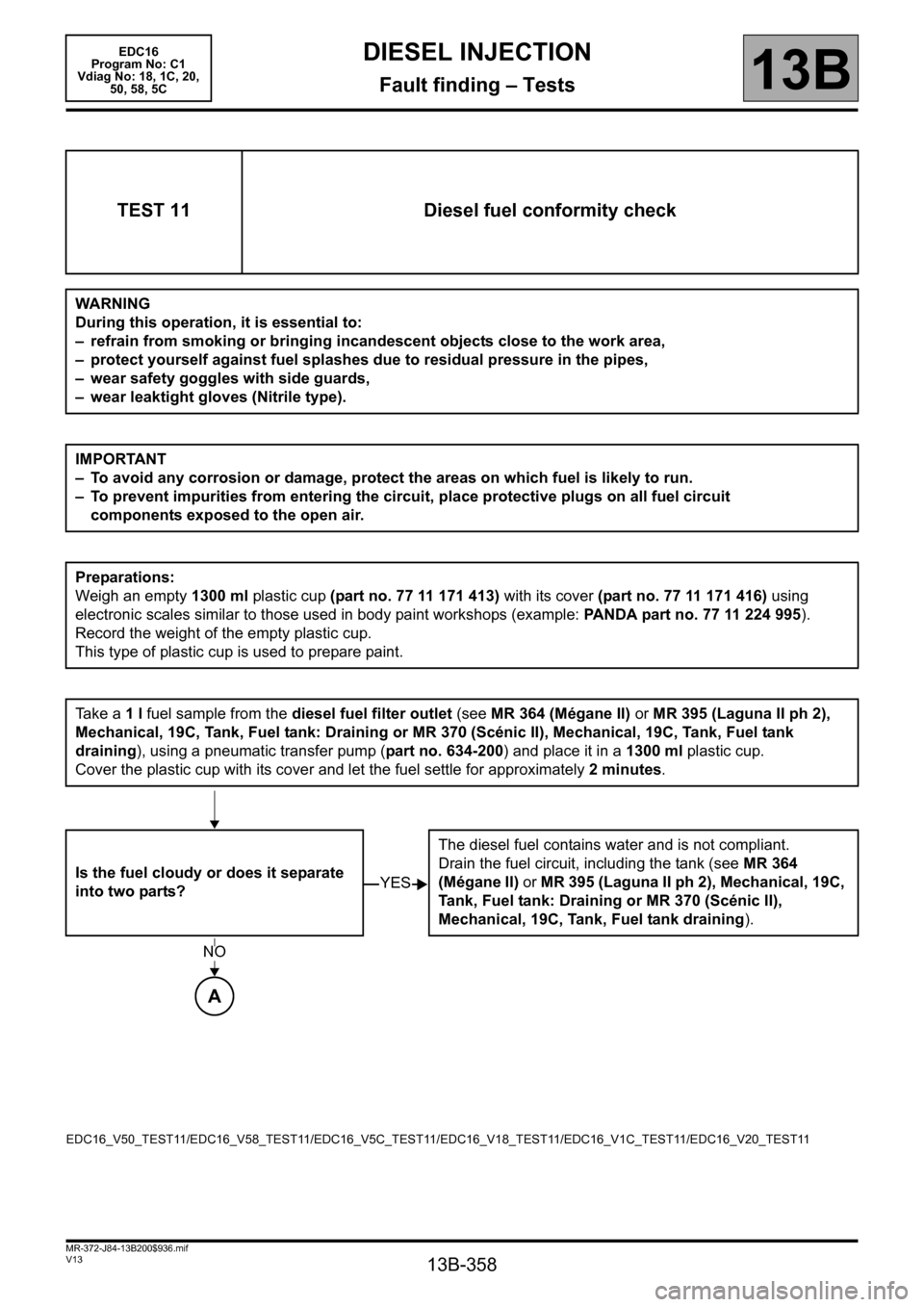

TEST 11 Diesel fuel conformity check

WARNING

During this operation, it is essential to:

– refrain from smoking or bringing incandescent objects close to the work area,

– protect yourself against fuel splashes due to residual pressure in the pipes,

– wear safety goggles with side guards,

– wear leaktight gloves (Nitrile type).

IMPORTANT

– To avoid any corrosion or damage, protect the areas on which fuel is likely to run.

– To prevent impurities from entering the circuit, place protective plugs on all fuel circuit

components exposed to the open air.

Preparations:

Weigh an empty 1300 ml plastic cup (part no. 77 11 171 413) with its cover (part no. 77 11 171 416) using

electronic scales similar to those used in body paint workshops (example: PANDA part no. 77 11 224 995).

Record the weight of the empty plastic cup.

This type of plastic cup is used to prepare paint.

Ta k e a 1 l fuel sample from the diesel fuel filter outlet (see MR 364 (Mégane II) or MR 395 (Laguna II ph 2),

Mechanical, 19C, Tank, Fuel tank: Draining or MR 370 (Scénic II), Mechanical, 19C, Tank, Fuel tank

draining), using a pneumatic transfer pump (part no. 634-200) and place it in a 1300 ml plastic cup.

Cover the plastic cup with its cover and let the fuel settle for approximately 2 minutes.

Is the fuel cloudy or does it separate

into two parts?The diesel fuel contains water and is not compliant.

Drain the fuel circuit, including the tank (see MR 364

(Mégane II) or MR 395 (Laguna II ph 2), Mechanical, 19C,

Tank, Fuel tank: Draining or MR 370 (Scénic II),

Mechanical, 19C, Tank, Fuel tank draining).

YES

NO

A

EDC16_V50_TEST11/EDC16_V58_TEST11/EDC16_V5C_TEST11/EDC16_V18_TEST11/EDC16_V1C_TEST11/EDC16_V20_TEST11

Page 359 of 365

13B-359

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

TEST 11

CONTINUED

Weigh the diesel fuel and note the fuel weight after subtracting the weight of the empty plastic cup and its cover.

Does the fuel weight fall between the minimum and maximum weights given in the table below?

Calculated weight (g.)

Fuel temperature

(°C)

Min. weight Max. weight

821 846 13

821 846 14

820 845 15

819 844 16

819 844 17

818 843 18

817 842 19

816 841 20

816 841 21

815 840 22

814 839 23

814 839 24

813 838 25

Check the fuel temperature by immersing a thermometer in the plastic cup.

End of test.The fuel is not correct.

If the fuel weight is less than the minimum value then there is petrol in the

diesel fuel.

If the fuel weight is greater than the maximum value then there is oil in the

diesel fuel.

Drain the fuel circuit, including the tank (see MR 364 (Mégane II) or MR 395

(Laguna II ph 2), Mechanical, 19C, Tank, Fuel tank: Draining or MR 370

(Scénic II), Mechanical, 19C, Tank, Fuel tank draining).

Note:

If the weight measured reaches the limit values, the measurement can be performed with a 2230 ml

(part no. 77 11 171 414) plastic cup with a cover (part no. 77 11 171 417):

– Carry out a quick test drive in order to mix the fuel and then take a sample of 2 litres of fuel.

– Perform the test again and check the results by multiplying the limit values by 2.

Contact the Techline if you have doubts or problems with the customer.

A

YESNO