light RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 2 of 365

13B-2

MR-372-J84-13B200$036.mif

V13

13B

DIESEL INJECTION

Fault finding – Introduction

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this manual):

– Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

– Visu-Schéma (CD-ROM), paper.

Type of diagnostic tools

– CLIP + multiplex line sensor

Special tooling required

3. REMINDERS

Procedure

In order to save energy, the LAGUNA II Phase 2 UCH cuts off the + after ignition feed after 3 minutes.

To run fault finding on a vehicle computer, it is possible to force the + after ignition feed for 1 hour by applying the

following procedure:

– Press the card unlocking button.

– Insert the card into the reader.

– Press the start button (interrupting the timed + after ignition feed mode).

– Press the start button for more than 5 seconds, without conditions for starting being met, until the

immobiliser warning light flashes rapidly (4Hz).

– Connect the diagnostic tool and perform the required operations.

This forced + after ignition feed mode remains active for 1 hour.

Pressing the Start button or removing the card from the card reader cuts off the + after ignition feed but does not

cut off the forced after ignition feed timed mode. As long as one hour has not elapsed the + after ignition feed

function restarts the forced + after ignition feed for the remaining time. Vehicles: MEGANE II ph1 and ph2, SCENIC II ph1

and ph2, LAGUNA II ph 2,

Engine type and suffix: F9Q 758, 759, 804, 803

Function concerned: DIESEL INJECTIONName of computer: BOSCH EDC16 C3

Program No: C1

Vdiag No: 18, 1C, 20, 50, 58, 5C

Special tooling required

Multimeter

Elé. 1590 Computer connection bornier

Or Elé. 1681 Universal bornier

EDC16_V50_PRELI/EDC16_V58_PRELI/EDC16_V5C_PRELI/EDC16_V18_PRELI/EDC16_V1C_PRELI/EDC16_V20_PRELI EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$036.mif

Page 5 of 365

13B-5

MR-372-J84-13B200$036.mif

V13

DIESEL INJECTION

Fault finding – Introduction

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

3. FAULT FINDING PROCEDURE (continued)

3.1 Checking the wiring

Fault finding problems

Disconnecting the connectors and/or manipulating the wiring harness may temporarily remove the cause of a fault.

Visual inspection

Look for damage under the bonnet and in the passenger compartment.

Carefully check the protectors, insulation, and routing of the wiring, as well as the mountings.

Tactile inspection

When manoeuvring the wiring, either use the diagnostic tool to detect a change in status, from "stored" to

"present", or the multimeter to view the status changes.

Make sure that the connectors are properly locked.

Apply light pressure to the connectors.

Twist the wiring harness.

Checking earth insulation

This check is carried out by measuring the voltage (multimeter in voltmeter mode) between the suspect connection

and the 12 V or 5V feed. The correct measured value is 0V.

Checking insulation against + 12 V or + 5 V

This check is carried out by measuring the voltage (multimeter in voltmeter mode) between the suspect connection

and the earth. In the first instance, the earth may be taken on the chassis. The correct measured value is 0V.

Continuity check

A continuity check is carried out by measuring the resistance (multimeter in ohmmeter mode), with the connectors

disconnected at both ends. The expected result is: 1Ω±1Ω for each connection. The line must be fully checked,

and the intermediate connections are only included in the method if this saves time during the fault finding

procedure. The continuity check on the multiplex lines must be carried out on both wires. The measured value

should be 1Ω±1Ω.

Checking the supply

This check may be carried out using a test light (21 W or 5W depending on the maximum authorised charge).

Page 12 of 365

13B-12

MR-372-J84-13B200$108.mif

V13

DIESEL INJECTION

Fault finding – System operation

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

a) The computer:

Determines the value of injection pressure necessary for the engine to operate correctly and then controls the

pressure regulator.

Checks that the pressure value is correct by analysing the value transmitted by the pressure sensor located on the

rail.

It determines the injection timing required to deliver the right quantity of diesel fuel and the moment when injection

should start. Controls each injector electrically and individually after determining these two values.

The flow injected into the engine is determined by:

– the duration of injector control,

– the rail pressure (regulated by the computer),

– the injector opening and closing speed,

– the needle stroke (determined by a constant for the type of injector),

– the nominal hydraulic flow of the injector (specific to each injector).

The computer manages:

– idling regulation,

– exhaust gas flow reinjection to the inlet (EGR),

– fuel supply check (advance, flow and rail pressure),

– the fan assembly control,

– the air conditioning (cold loop function),

– the cruise control/speed limiter function,

– pre-post heating control,

– indicator lights control via the multiplex network,

– the operation of the catalysed particle filter.

The high pressure pump is supplied at low pressure by an integrated low pressure pump (transfer pump).

It supplies the rail, the pressure of which is controlled by the fuel flow actuator (MPROP) for charging, and for

discharging by the injector valves. This compensates for pressure drops. The flow actuator allows the high pressure

pump to supply the exact quantity of diesel fuel required to maintain the pressure in the rail. This component

minimises the heat generated and improves engine output.

In order to discharge the rail using the injector valves, the valves are controlled by brief electrical pulses which are:

– short enough not to open the injector (passing through the feedback circuit from the injectors),

– long enough to open the valves and discharge the rail.

Page 13 of 365

13B-13

MR-372-J84-13B200$108.mif

V13

DIESEL INJECTION

Fault finding – System operation

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

Some vehicles have adopted a sensor for detecting water in the diesel fuel, located in the filter. If there is water in

the diesel fuel, the orange "Injection and pre-post heating" warning light will come on.

The system can inject diesel fuel into the engine at a pressure of up to 1600 bar. Before each operation, check that

the injector rail is depressurised and that the fuel temperature is not too high.

You must respect the cleanliness guidelines and safety advice specified in this document for any work on the high

pressure injection system.

Do not remove the internal parts of the pump and injectors. Only the flow actuator, the diesel temperature sensor

and the Venturi tube can be replaced.

For safety reasons, do not loosen high pressure pipe unions when the engine is running.

It is not possible to remove the pressure sensor from the fuel rail because this may cause circuit contamination

faults. If the pressure sensor fails, the pressure sensor, the rail and the five high pressure pipes must be replaced.

Do not remove an injection pump pulley marked with the number 070 575. If the pump needs to be replaced, replace

the pulley.

Supplying any system component directly with +12V is prohibited.

Ultrasonic decoking and cleaning are prohibited.

Never start the engine unless the battery is connected correctly.

Disconnect the injection computer when carrying out any welding work on the vehicle.

b)The connections between the vehicle's various computers are multiplexed.

The electronic system fitted in this vehicle is multiplexed. This system enables dialogue between the various vehicle

computers. As a result:

– the activation of the fault warning lights on the instrument panel is performed by the multiplex network, with the

vehicle speed sensor on the gearbox deactivated,

– vehicle faults are displayed by the multiplex network,

– the vehicle speed sensor on the gearbox is not needed.

The vehicle speed signal on the instrument panel is transmitted by the ABS computer via a wire connection, then

sent out on the multiplex network by the instrument panel. The vehicle speed signal is used mainly by the injection

computer and the airbag computer.WARNING

The engine must not operate with:

– Diesel fuel containing more than 10% diester.

– petrol, even in tiny quantities.

Page 17 of 365

13B-17

MR-372-J84-13B200$108.mif

V13

DIESEL INJECTION

Fault finding – System operation

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

If regeneration whilst driving has not been possible, the driver should request After-Sales regeneration in the

following cases:

– the soot weight is greater than 56 g for Vdiag 18.

– the soot weight is greater than 59 g or the number of failed regenerations is greater than 10 for Vdiag 1C

and 20.

This regeneration is carried out in the workshop. It is essential to follow the instructions described in the

interpretation of commands SC017 Particle filter regeneration. To carry out regeneration safely (see Te c h n i c a l

Note 5040A, Recommendations for particle filter regeneration).

Warning light management:

Instrument panel display

The computer manages the data display on the instrument panel relating to engine operation. This involves six

functions:

– the pre-postheating warning light,

– the coolant temperature warning light or warning message;

– the level 1 fault warning light (non-critical fault),

– the level 2 fault warning light (emergency stop),

– the OBD warning light (European On Board Diagnostic),

– particle filter warning message or light.

These six functions are represented by 4 or 5 warning lights and/or messages displayed by the trip computer.

In addition, for vehicles fitted with a voice synthesiser the illumination of some warning lights may be accompanied

by a spoken message (refer to the Driver's Handbook for the vehicle concerned).

A 3 second visual inspection (automatic test procedure managed by the instrument panel) is carried out by the

injection computer when the ignition is switched on.

Orange pre-post heating/non-critical fault SERVICE warning light (level 1)

This light is used both as an in-operation indicator light and as a system fault indicator:

– Continuously lit with + after ignition feed:

Indicates plug preheating (this light goes out when preheating is complete and the engine is able to start).

– Continuously lit accompanied by the message Check injection or Electronic fault:

Indicates a level 1 fault (involving operation of the injection system in defect mode).

The driver should carry out repairs as soon as possible. IMPORTANT

The particle filter must be replaced after a period of time which largely depends on the grade of engine oil used.

This information is provided in the vehicle's Driver's handbook.

After replacing the particle filter, it is essential to reconfigure certain parameters in the computer (see SC036

Reinitialise programming).

Page 18 of 365

13B-18

MR-372-J84-13B200$108.mif

V13

DIESEL INJECTION

Fault finding – System operation

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

Temperature warning light/red EMERGENCY STOP (level 2)

This indicator light is used both as an in-operation indicator light and as a system fault warning light. It lights up for

3 seconds after the ignition is switched on (automatic test procedure managed by the instrument panel):

– Continuously or intermittently lit, accompanied by the message Engine overheating:

Indicates engine overheating (the driver is free to choose whether or not to stop the vehicle).

–For Vdiag 50, 58 and 5C: continuously lit, accompanied by the message faulty injection:

Indicates a level 2 fault (in this case, the injection is automatically cut after a few seconds).

The driver should carry out repairs as soon as possible.

–For Vdiag 18, 1C and 20: continuously lit, accompanied by the message Injection fault: stop the engine and by

a bleep, this indicates a level 2 fault.

In that case, the vehicle must be stopped immediately (when traffic conditions allow).

The driver should carry out repairs as soon as possible.

ORANGE OBD excess pollution warning light

An engine symbol accompanied by the message Check emission control.

This warning light comes on if the system has one or more OBD faults.

This warning light is used to alert the driver of any injection faults that could lead to excessive pollution, or if the

EOBD system has been deactivated.

The injection computer requests illumination of the OBD warning light for a present fault only after three consecutive

driving cycles.

If it flashes, reduce the engine speed until the flashing stops.

The driver should carry out repairs as soon as possible.

The 3 second visual inspection when the ignition is switched on (automatic test procedure managed by the

instrument panel) is carried out by the injection computer.

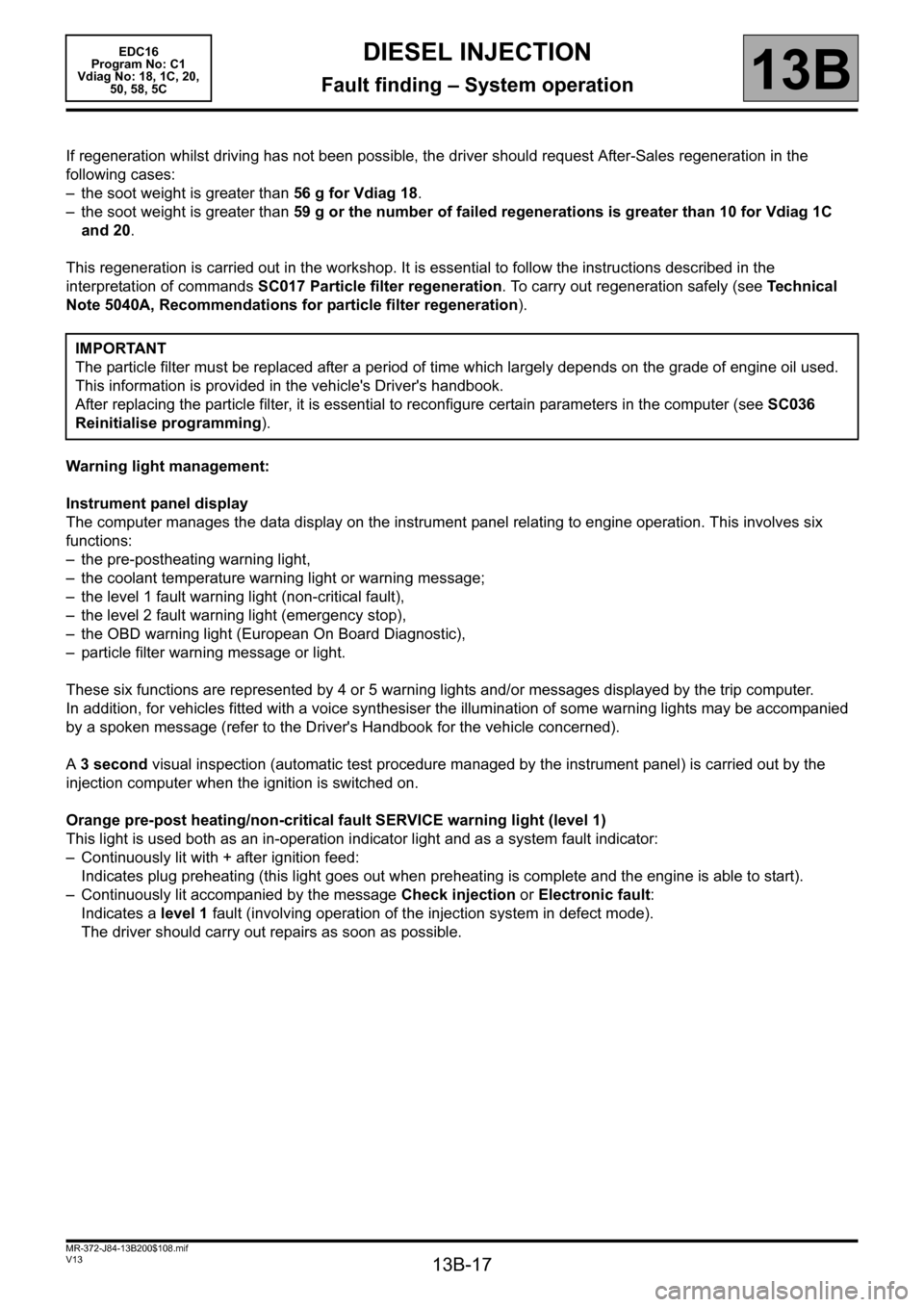

Special particle filter ORANGE warning light or warning message (depending on instrument panel)

– Vdiag 50, 58, 5C:

This warning light or message is used to warn the driver that the particle filter is clogged or a significant number of

failed regenerations while driving due to driving conditions not being favourable for regeneration.

Table of thresholds:

EnginePR383 Weight of soot in the

particle filterPR848 Number of failed

regenerations

Scénic II Mégane IIScénic II Mégane II

F9Q804 Vdiag 5035 35 3

F9Q803 Vdiag 58 and 5C50

7

F9Q804 Vdiag 58 and 5C58 50 7

Page 19 of 365

13B-19

MR-372-J84-13B200$108.mif

V13

DIESEL INJECTION

Fault finding – System operation

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

– Vdiag 18, 1C, 20:

This warning light or message is used to warn the driver that the particle filter is loaded with particles. This happens

when the soot weight is greater than 46 g or the number of failed regenerations is greater than:

– 8 for Vdiag 18.

– 6 for Vdiag 1C and 20.

The driver must then drive as soon as possible at an average speed of 48 mph (80 km/h) subject to the road

conditions and authorised speed limits.

EOBD management. (European On Board Diagnostic):

The OBD (On Board Diagnostic) system permits the detection of any faults relating to the vehicle emission control

system (OBD EURO IV emission control standards being exceeded).

This system should be active for the entire life of the vehicle.

1. OBD fault display conditions

An OBD fault will be detected after 3 driving cycles and the following parameters will be saved in the computer:

– engine load,

– vehicle speed

– air temperature

– coolant temperature,

– turbocharging pressure,

– rail pressure,

– air flow,

– distance travelled in miles by the vehicle since activation of the OBD warning light.

It allows the driver to know whether the vehicle has a fault directly linked to the emission control system.

Page 20 of 365

13B-20

MR-372-J84-13B200$108.mif

V13

DIESEL INJECTION

Fault finding – System operation

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

2. System faults displayed by the OBD

Only a few faults are displayed by the OBD system:

– DF001 Coolant temperature sensor circuit.

– DF003 Atmospheric pressure sensor circuit.

– DF011 Sensor supply voltage no. 1.

– DF012 Sensor supply voltage no. 2.

– DF013 Sensor supply voltage no. 3.

– DF038 Computer in 6.DEF EEPROM fault.

– DF040 Cylinder 1 injector circuit in CO Open circuit.

– DF041 Cylinder 2 injector circuit in CO Open circuit.

– DF042 Cylinder 3 injector circuit in CO Open circuit.

– DF043 Cylinder 4 injector circuit in CO Open circuit.

– DF054 Turbocharging solenoid valve control circuit in CC.0 Short circuit to earth.

– DF056 Air flowmeter circuit.

– DF209 EGR valve position sensor circuit.

– DF310 Particle filter upstream temp.* sensor.

– DF315 Particle filter diff.* pressure sensor.

– DF504 Automatic transmission.

– DF621 EGR valve jammed open.

– DF717 Particle filter upstream pressure.

– DF953 Particle filter absent.

Some repair operations require programming to ensure that certain engine components function correctly.

Follow the programming procedures (see Replacement of components), if replacing the exhaust gas

recirculation valve or an injector.

3. OBD fault clearing conditions

An OBD fault is cleared in several steps.

The fault present in the diagnostic tool will only be stored (after a repair operation) after the vehicle has been

driven 3 times.

The OBD warning light will only go out after these 3 trips.

The instrument panel warning light coming on does not automatically mean that the system has a fault.

In order for the OBD fault and display parameters to be cleared from the computer, the system requires

40 engine heating cycles.

An engine heating cycle is a driving cycle during which:

– the engine coolant temperature reaches at least 71.1°C,

– the engine coolant temperature varies by 22.2°C in relation to the engine starting temperature.

If one of these conditions is not fulfilled, the OBD fault will still be present or stored on the injection

computer.

* diff: differential

* temp: temperature

Page 21 of 365

13B-21

MR-372-J84-13B200$144.mif

V13

13B

DIESEL INJECTION

Fault finding – Replacement of components

COMPUTER REPLACEMENT OR REPROGRAMMING

Two operations must be performed when replacing or reprogramming the computer:

SC003 Save computer data and SC001 Enter saved data.

– Run command SC003 Save computer data before replacing or reprogramming the computer. This enables

certain data to be saved in the diagnostic tool so that the new computer* can be reconfigured like the old one.

The saved data includes: injector codes, EGR programming, specific data for particle filter operation and vehicle

options.

– Run command SC001 Write saved data after replacing or reprogramming the computer. This command

enables the data (saved by the command SC003 Save computer data) to be rewritten in the new computer*.

If you cannot establish dialogue with the computer being replaced: you will not be able to save anything.

After replacing the computer:

– Manually enter the IMA codes for each injector by reading the code on each injector (see 13B, Diesel injection,

Replacement of components, Injector replacement).

– Enter the data specific to particle filter operation by running SC036 Reinitialise programming and select After

replacing the injection computer with no save option.

Exhaust gas recirculation valve data is programmed automatically the 1st time the new computer is switched on*.

* New computer or reprogrammed computer.

Specific to the cruise control/speed limiter operation to be carried out before reprogramming of the

computer:

Before reprogramming the injection computer, move the main cruise control/speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational.

The procedure for resetting the function is as follows:

– Vehicle ignition on.

– Position the cruise control/speed limiter switch in the rest position (the computer then detects the rest position).

– Position the cruise control/speed limiter switch in the Cruise control position to activate the Cruise control

function.

– Position the cruise control/speed limiter switch in the Speed limiter position to activate the Speed limiter function. IMPORTANT

– Switch on the diagnostic tool (mains or cigarette lighter supply).

– Connect a battery charger.

– Cut off all the electrical consumers (lights, interior lighting, air conditioning, radio CD, etc.).

– Wait for the engine to cool (engine coolant temperature < 60° and air temperature < 50°).

– For Vdiags 50, 58, 5C, during (re)programming of the computer, the engine fan assemblies are actuated

automatically.

– For Vdiags 18, 1C, 20, during (re)programming of the computer, the instrument panel screen displays

“Oil pressure fault”.

– Ignore this message and do not take any action in connection with it.

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$144.mif

Page 27 of 365

13B-27

MR-372-J84-13B200$216.mif

V13

13B

DIESEL INJECTION

Fault finding – Fault summary table

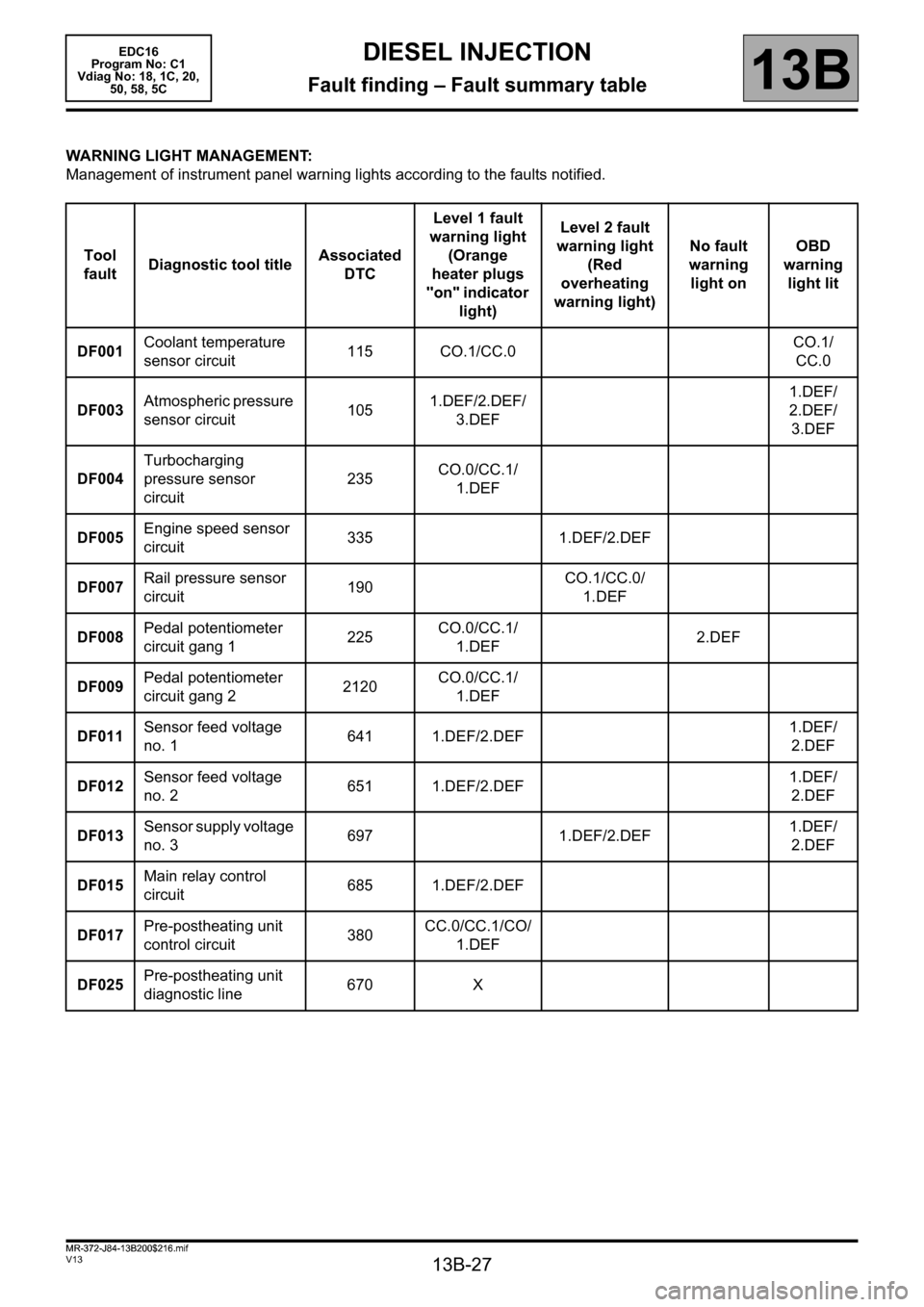

WARNING LIGHT MANAGEMENT:

Management of instrument panel warning lights according to the faults notified.

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF001Coolant temperature

sensor circuit115 CO.1/CC.0CO.1/

CC.0

DF003Atmospheric pressure

sensor circuit1051.DEF/2.DEF/

3.DEF1.DEF/

2.DEF/

3.DEF

DF004Turbocharging

pressure sensor

circuit235CO.0/CC.1/

1.DEF

DF005Engine speed sensor

circuit335 1.DEF/2.DEF

DF007Rail pressure sensor

circuit190CO.1/CC.0/

1.DEF

DF008Pedal potentiometer

circuit gang 1225CO.0/CC.1/

1.DEF2.DEF

DF009Pedal potentiometer

circuit gang 22120CO.0/CC.1/

1.DEF

DF011Sensor feed voltage

no. 1641 1.DEF/2.DEF1.DEF/

2.DEF

DF012Sensor feed voltage

no. 2651 1.DEF/2.DEF1.DEF/

2.DEF

DF013Sensor supply voltage

no. 3697 1.DEF/2.DEF1.DEF/

2.DEF

DF015Main relay control

circuit685 1.DEF/2.DEF

DF017Pre-postheating unit

control circuit380CC.0/CC.1/CO/

1.DEF

DF025Pre-postheating unit

diagnostic line670 X

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$216.mif