RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Workshop Manual

Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 351 of 365

13B-351

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

TEST 9

CONTINUED 1

CASE No. 2: If at least one of these values is equal to or less than - 5 mg/st

– Check the valve clearance.

– Check the level and condition of the engine oil.

– Remove the injector with the largest correction.

– If there is diesel fuel contamination, check the condition of the cylinder concerned (cylinder, piston, valves).

Use an endoscope if possible.

– Only replace the removed injector, and modify the IMA code using command SC002 Enter injector codes

(see Interpretation of commands).

–Apply Part B of this test to confirm the fault finding.

CASE No. 3: If at least one of these values does not stabilise (20 seconds after starting)

– Check the low pressure circuit using Test 4 Low pressure circuit check.

– Check the conformity of the fuel by applying Test 11 Diesel fuel conformity check.

–Apply Part B of this test to confirm the fault finding procedure

CASE No. 4: If all the fuel flow correction values are correct (between - 5 mg/st and + 5 mg/st)

–Apply Part C of this test (Fuel return flow measurement).

IMPORTANT

When removing or refitting injectors, follow the cleanliness and safety instructions (see MR 364 (Mégane II), 370

(Scénic II) or 395 (Laguna II), Mechanical, 13B, Diesel injection, Diesel injector: Removal - Refitting).

Page 352 of 365

13B-352

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

TEST 9

CONTINUED 2

Section B: Confirmation of flow correction fault finding for each injector (individual correction):

Clear the faults and perform a test with the engine idling for at least 5 minutes and fuel temperature > 50°C.

Check that no fault appears on the CLIP diagnostic tool and that the corrective values do not reach ±5mg/

stroke to confirm the repair.

If the customer complaint is still present and the fuel flow correction values are between

-5 mg/stroke and + 5mg/stroke, apply Part A Fuel regulation balance check for each injector (individual)

of this test (Case no.4).

If one or more cylinders has an injector flow correction value in excess of ± 5 mg/stroke, apply Part A Fuel

regulation balance check for each injector (individual) of this test, as one or more injectors may be defective.

Part C: Measuring fuel return flow

1 – Fitting the tool:

This section is only to be carried out if PR063 "Fuel temperature" is higher than 50°C (see step 2 of

section C for this test).

Remove the engine undertray

Disconnect the entire fuel return pipe in accordance with the following procedure (do not remove the clips):

– press the clip,

– pull vertically on the end piece (see arrow in the diagram below) of the fuel return pipe.

IMPORTANT

The end piece is fragile. Be careful not to break it by pulling it too hard. Replace all removed clips

Page 353 of 365

13B-353

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

TEST 9

CONTINUED 3

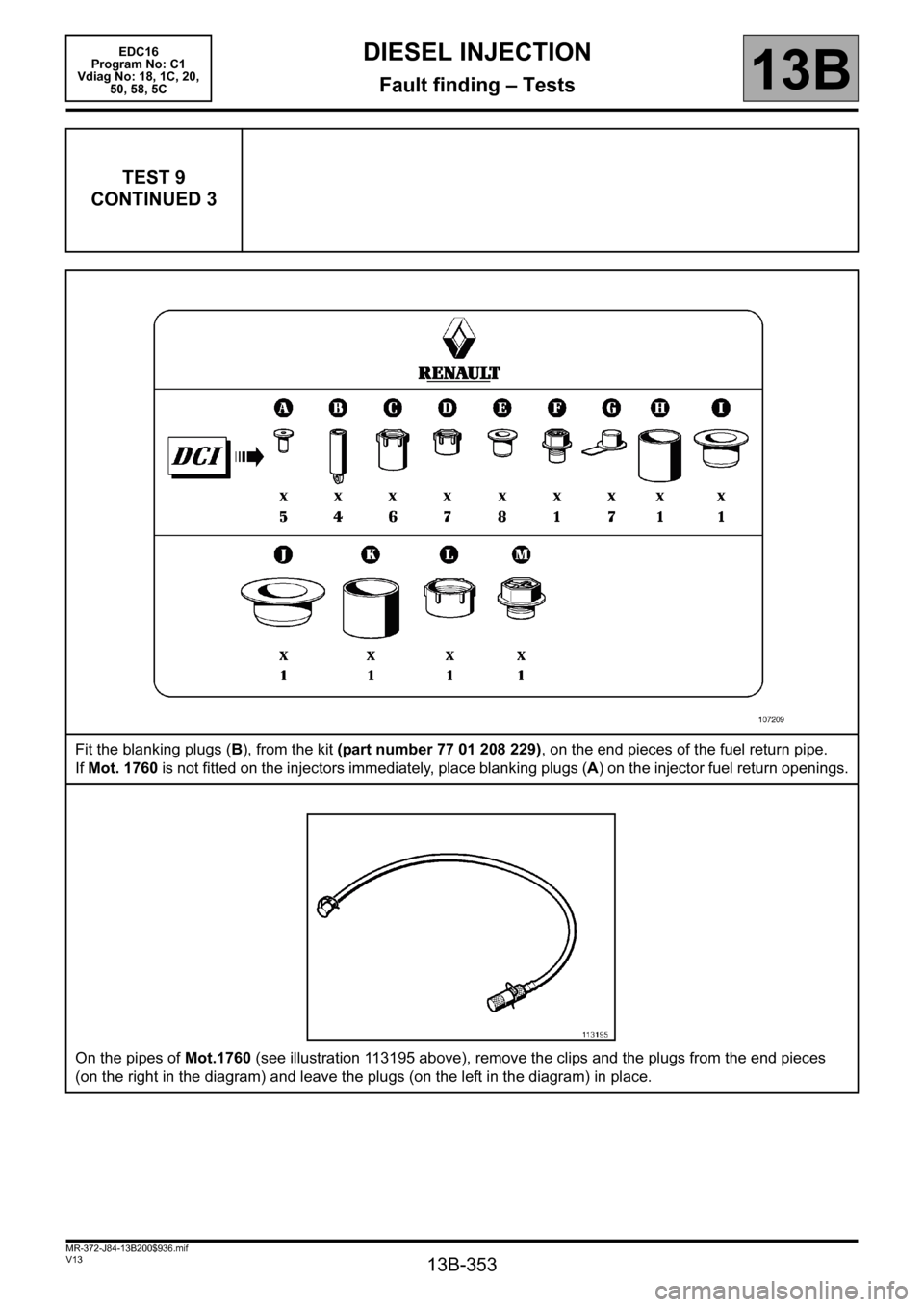

Fit the blanking plugs (B), from the kit (part number 77 01 208 229), on the end pieces of the fuel return pipe.

If Mot. 1760 is not fitted on the injectors immediately, place blanking plugs (A) on the injector fuel return openings.

On the pipes of Mot.1760 (see illustration 113195 above), remove the clips and the plugs from the end pieces

(on the right in the diagram) and leave the plugs (on the left in the diagram) in place.

Page 354 of 365

13B-354

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

TEST 9

CONTINUED 4

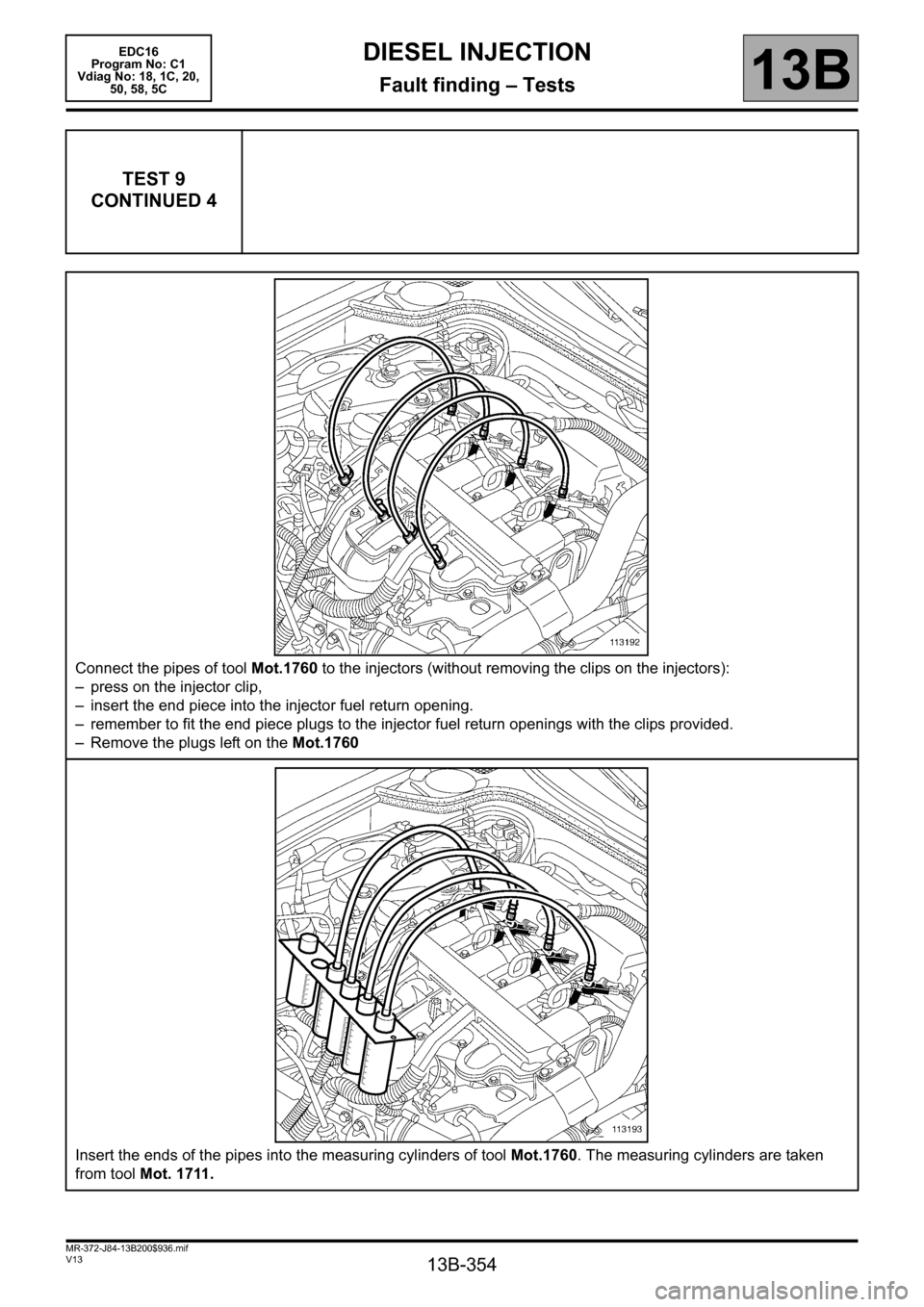

Connect the pipes of tool Mot.1760 to the injectors (without removing the clips on the injectors):

– press on the injector clip,

– insert the end piece into the injector fuel return opening.

– remember to fit the end piece plugs to the injector fuel return openings with the clips provided.

– Remove the plugs left on the Mot.1760

Insert the ends of the pipes into the measuring cylinders of tool Mot.1760. The measuring cylinders are taken

from tool Mot. 1711.

Page 355 of 365

13B-355

MR-372-J84-13B200$936.mif

V13

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Tests13B

2 – Injector return flow balance check:

3 – Removing the tool:

Disconnect the pipe from an injector:

– press on the injector clip,

– pull vertically on the end piece of the pipe of tool Mot.1760, placing a wipe on the end piece to prevent run-off.

Lift the end piece vertically so that the fuel contained in the pipes flows into the measuring cylinders of tool

Mot.1760.

Remove the other 3 pipes using the same procedure.

TEST 9

CONTINUED 5

Does the engine start?

YES

– The injector return pipes must be fitted to the injectors.

– Start the engine.

– Display the Fuel circuit sub-function in the CLIP diagnostic tool.

– Raise the temperature of the engine.

– Read the diesel fuel temperature with PR063 Fuel temperature until a diesel fuel temperature greater than

50°C is reached

– Switch off the engine.

–Fit Mot. 1760 as shown in the installation procedure (see step 1).

– Check the value of the PR038 Rail pressure.

– Ask another Cotech to monitor the rise in fuel in the cans during engine turnover, as one of the cans will fill up

quickly if one of the injectors is leaking.

– Start the engine.

– Accelerate the engine until the pressure in the rail is 550 bar:

* if the engine speed is less than 3000 rpm, maintain this pressure.

* if the engine speed is greater than 3000 rpm, reduce the engine speed until the rail pressure is 500 bar and

maintain this pressure.

– Maintain these conditions for one minute.

– Release the accelerator pedal and maintain the idle speed for 10 seconds.

– Switch off the engine.

– Measure the quantity of fuel contained in each measuring cylinder.

– Replace the injector if the quantity of fuel is more than 50 ml.

– Remove Mot. 1760 as shown in the tool removal procedure (see step 3).

IMPORTANT

Use a cleaning cloth (part number 77 11 211 707) to absorb fuel run-off.NO

Fit Mot. 1760 as shown in the tool fitting procedure.

- Start the vehicle or perform a 15 second starting sequence

(with ignition key).

- Measure the length travelled by the diesel fuel in the pipes of

Mot. 1760.

Replace the injector if the length travelled by the fuel is more than

10 cm compared with the average of the other three injectors.

Page 356 of 365

13B-356

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

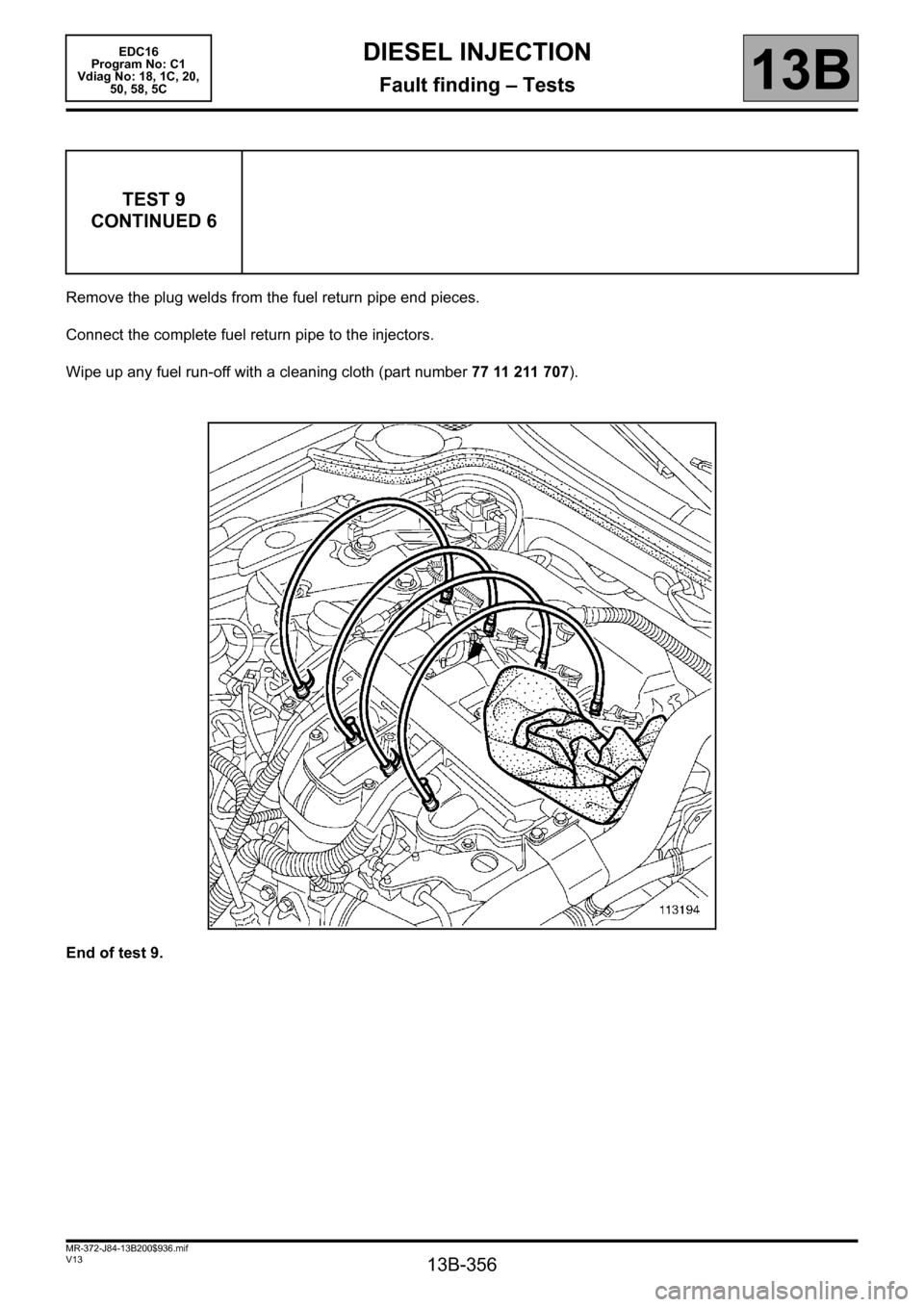

Remove the plug welds from the fuel return pipe end pieces.

Connect the complete fuel return pipe to the injectors.

Wipe up any fuel run-off with a cleaning cloth (part number 77 11 211 707).

End of test 9.

TEST 9

CONTINUED 6

Page 357 of 365

13B-357

MR-372-J84-13B200$936.mif

V13

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Tests13B

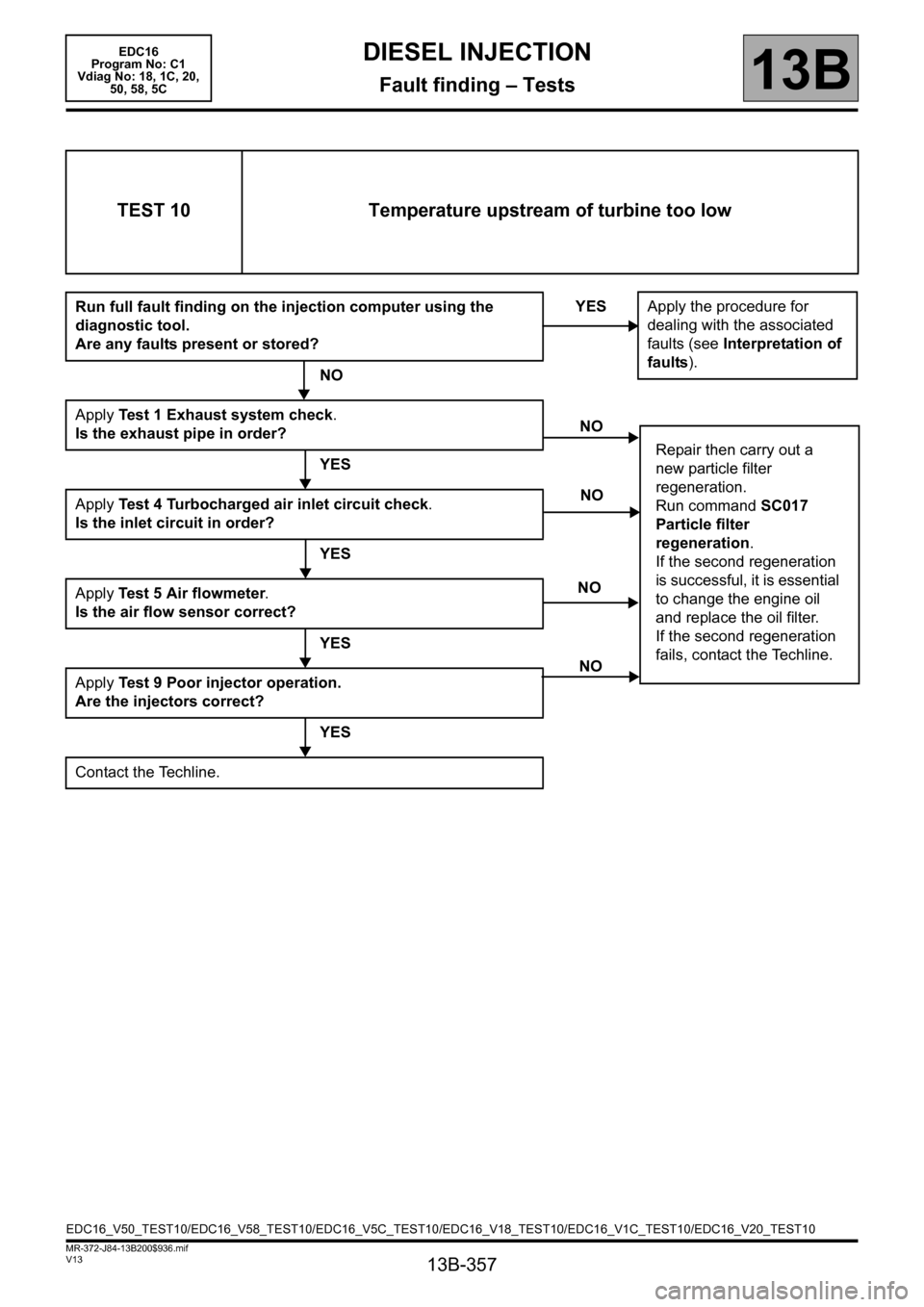

TEST 10 Temperature upstream of turbine too low

Run full fault finding on the injection computer using the

diagnostic tool.

Are any faults present or stored?

NO

Apply Test 1 Exhaust system check.

Is the exhaust pipe in order?

YES

Apply Test 4 Turbocharged air inlet circuit check.

Is the inlet circuit in order?

YES

Apply Test 5 Air flowmeter.

Is the air flow sensor correct?

YES

Apply Test 9 Poor injector operation.

Are the injectors correct?

YES

Contact the Techline.YES

Apply the procedure for

dealing with the associated

faults (see Interpretation of

faults).

NO

Repair then carry out a

new particle filter

regeneration.

Run command SC017

Particle filter

regeneration.

If the second regeneration

is successful, it is essential

to change the engine oil

and replace the oil filter.

If the second regeneration

fails, contact the Techline.

NO

NO

NO

EDC16_V50_TEST10/EDC16_V58_TEST10/EDC16_V5C_TEST10/EDC16_V18_TEST10/EDC16_V1C_TEST10/EDC16_V20_TEST10

Page 358 of 365

13B-358

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

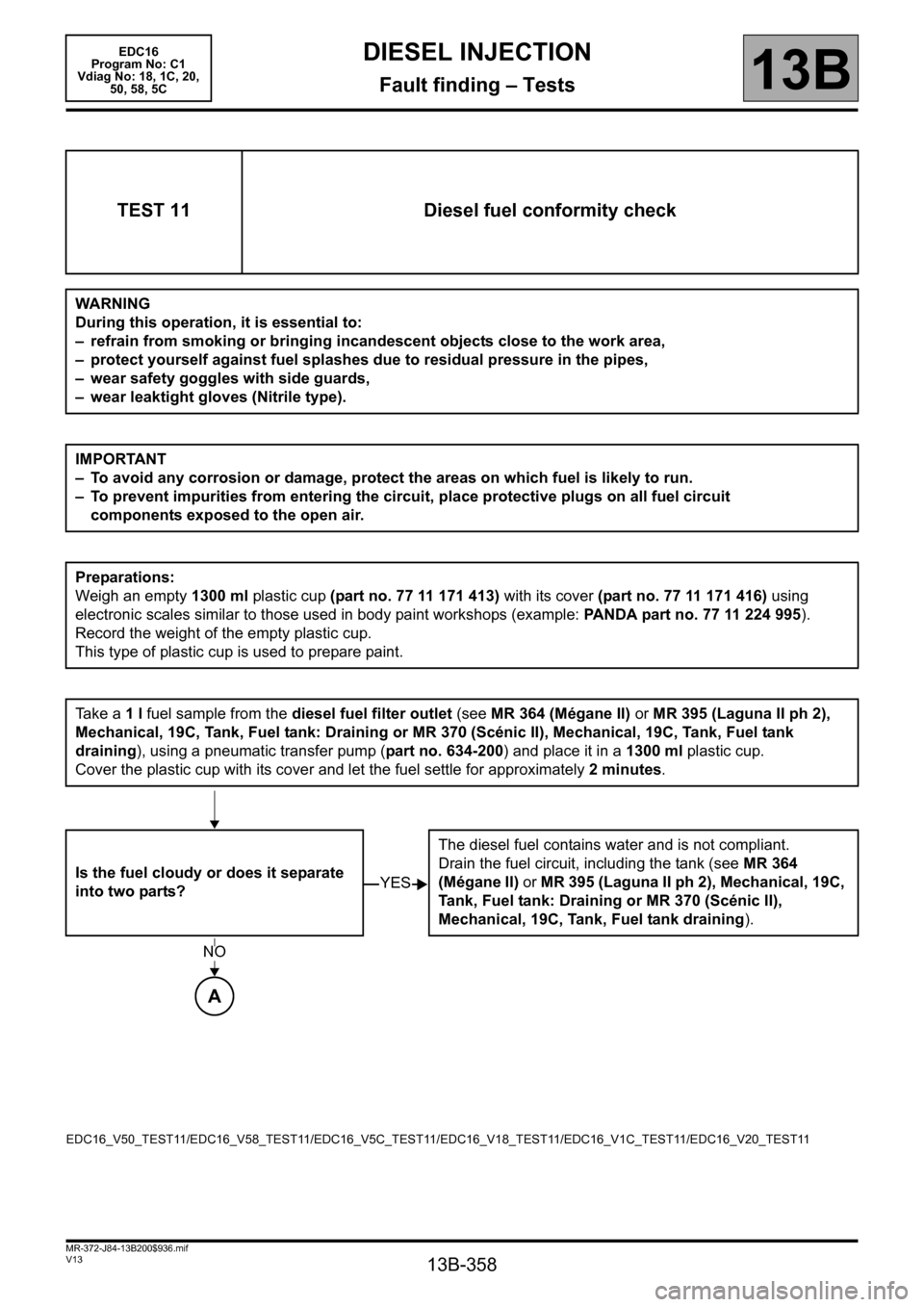

TEST 11 Diesel fuel conformity check

WARNING

During this operation, it is essential to:

– refrain from smoking or bringing incandescent objects close to the work area,

– protect yourself against fuel splashes due to residual pressure in the pipes,

– wear safety goggles with side guards,

– wear leaktight gloves (Nitrile type).

IMPORTANT

– To avoid any corrosion or damage, protect the areas on which fuel is likely to run.

– To prevent impurities from entering the circuit, place protective plugs on all fuel circuit

components exposed to the open air.

Preparations:

Weigh an empty 1300 ml plastic cup (part no. 77 11 171 413) with its cover (part no. 77 11 171 416) using

electronic scales similar to those used in body paint workshops (example: PANDA part no. 77 11 224 995).

Record the weight of the empty plastic cup.

This type of plastic cup is used to prepare paint.

Ta k e a 1 l fuel sample from the diesel fuel filter outlet (see MR 364 (Mégane II) or MR 395 (Laguna II ph 2),

Mechanical, 19C, Tank, Fuel tank: Draining or MR 370 (Scénic II), Mechanical, 19C, Tank, Fuel tank

draining), using a pneumatic transfer pump (part no. 634-200) and place it in a 1300 ml plastic cup.

Cover the plastic cup with its cover and let the fuel settle for approximately 2 minutes.

Is the fuel cloudy or does it separate

into two parts?The diesel fuel contains water and is not compliant.

Drain the fuel circuit, including the tank (see MR 364

(Mégane II) or MR 395 (Laguna II ph 2), Mechanical, 19C,

Tank, Fuel tank: Draining or MR 370 (Scénic II),

Mechanical, 19C, Tank, Fuel tank draining).

YES

NO

A

EDC16_V50_TEST11/EDC16_V58_TEST11/EDC16_V5C_TEST11/EDC16_V18_TEST11/EDC16_V1C_TEST11/EDC16_V20_TEST11

Page 359 of 365

13B-359

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

TEST 11

CONTINUED

Weigh the diesel fuel and note the fuel weight after subtracting the weight of the empty plastic cup and its cover.

Does the fuel weight fall between the minimum and maximum weights given in the table below?

Calculated weight (g.)

Fuel temperature

(°C)

Min. weight Max. weight

821 846 13

821 846 14

820 845 15

819 844 16

819 844 17

818 843 18

817 842 19

816 841 20

816 841 21

815 840 22

814 839 23

814 839 24

813 838 25

Check the fuel temperature by immersing a thermometer in the plastic cup.

End of test.The fuel is not correct.

If the fuel weight is less than the minimum value then there is petrol in the

diesel fuel.

If the fuel weight is greater than the maximum value then there is oil in the

diesel fuel.

Drain the fuel circuit, including the tank (see MR 364 (Mégane II) or MR 395

(Laguna II ph 2), Mechanical, 19C, Tank, Fuel tank: Draining or MR 370

(Scénic II), Mechanical, 19C, Tank, Fuel tank draining).

Note:

If the weight measured reaches the limit values, the measurement can be performed with a 2230 ml

(part no. 77 11 171 414) plastic cup with a cover (part no. 77 11 171 417):

– Carry out a quick test drive in order to mix the fuel and then take a sample of 2 litres of fuel.

– Perform the test again and check the results by multiplying the limit values by 2.

Contact the Techline if you have doubts or problems with the customer.

A

YESNO

Page 360 of 365

13B-360

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

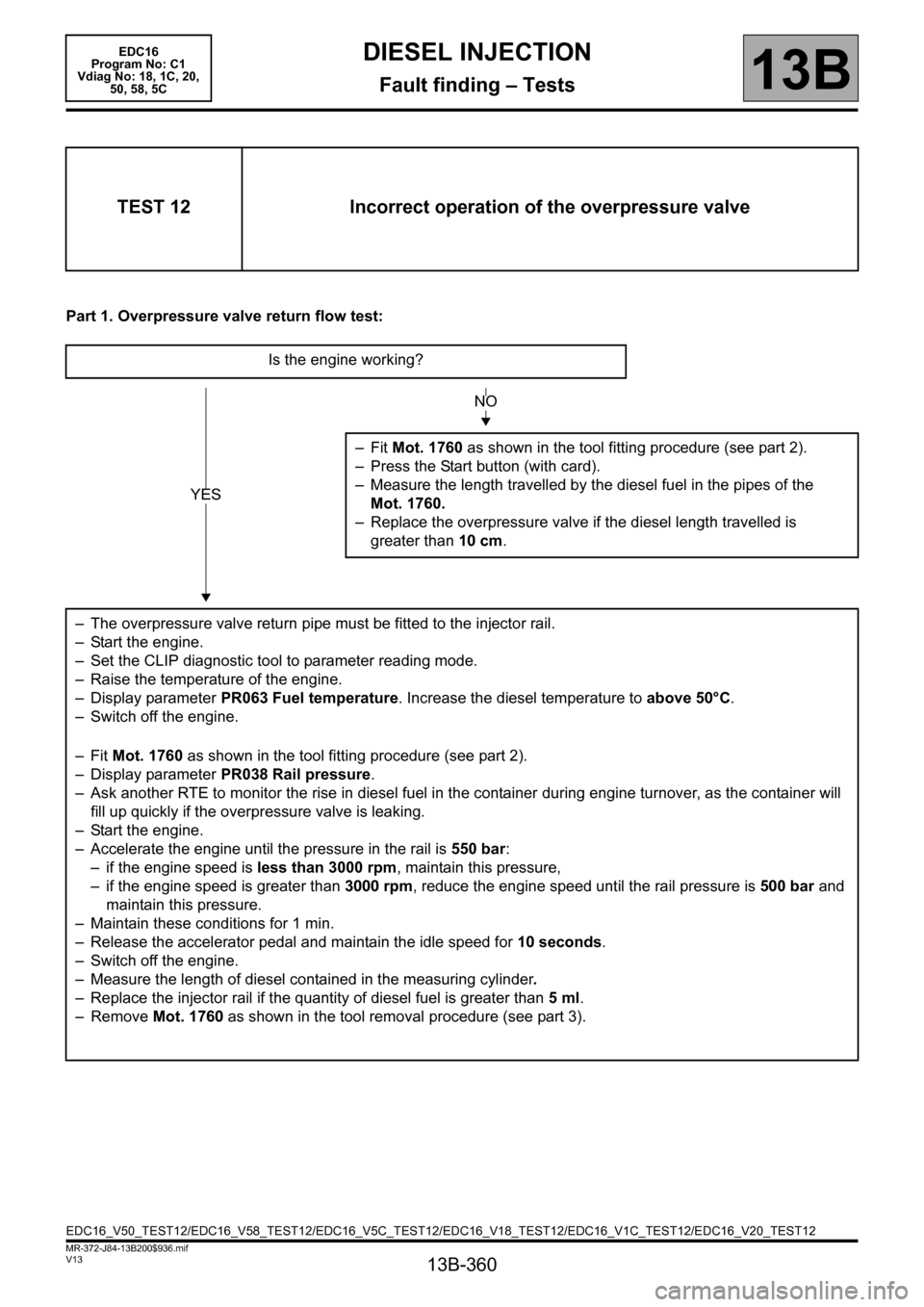

Part 1. Overpressure valve return flow test:

TEST 12 Incorrect operation of the overpressure valve

Is the engine working?

–Fit Mot. 1760 as shown in the tool fitting procedure (see part 2).

– Press the Start button (with card).

– Measure the length travelled by the diesel fuel in the pipes of the

Mot. 1760.

– Replace the overpressure valve if the diesel length travelled is

greater than 10 cm.

– The overpressure valve return pipe must be fitted to the injector rail.

– Start the engine.

– Set the CLIP diagnostic tool to parameter reading mode.

– Raise the temperature of the engine.

– Display parameter PR063 Fuel temperature. Increase the diesel temperature to above 50°C.

– Switch off the engine.

–Fit Mot. 1760 as shown in the tool fitting procedure (see part 2).

– Display parameter PR038 Rail pressure.

– Ask another RTE to monitor the rise in diesel fuel in the container during engine turnover, as the container will

fill up quickly if the overpressure valve is leaking.

– Start the engine.

– Accelerate the engine until the pressure in the rail is 550 bar:

– if the engine speed is less than 3000 rpm, maintain this pressure,

– if the engine speed is greater than 3000 rpm, reduce the engine speed until the rail pressure is 500 bar and

maintain this pressure.

– Maintain these conditions for 1 min.

– Release the accelerator pedal and maintain the idle speed for 10 seconds.

– Switch off the engine.

– Measure the length of diesel contained in the measuring cylinder.

– Replace the injector rail if the quantity of diesel fuel is greater than 5ml.

– Remove Mot. 1760 as shown in the tool removal procedure (see part 3).

YES

NO

EDC16_V50_TEST12/EDC16_V58_TEST12/EDC16_V5C_TEST12/EDC16_V18_TEST12/EDC16_V1C_TEST12/EDC16_V20_TEST12