check engine light RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 314 of 365

13B-314

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

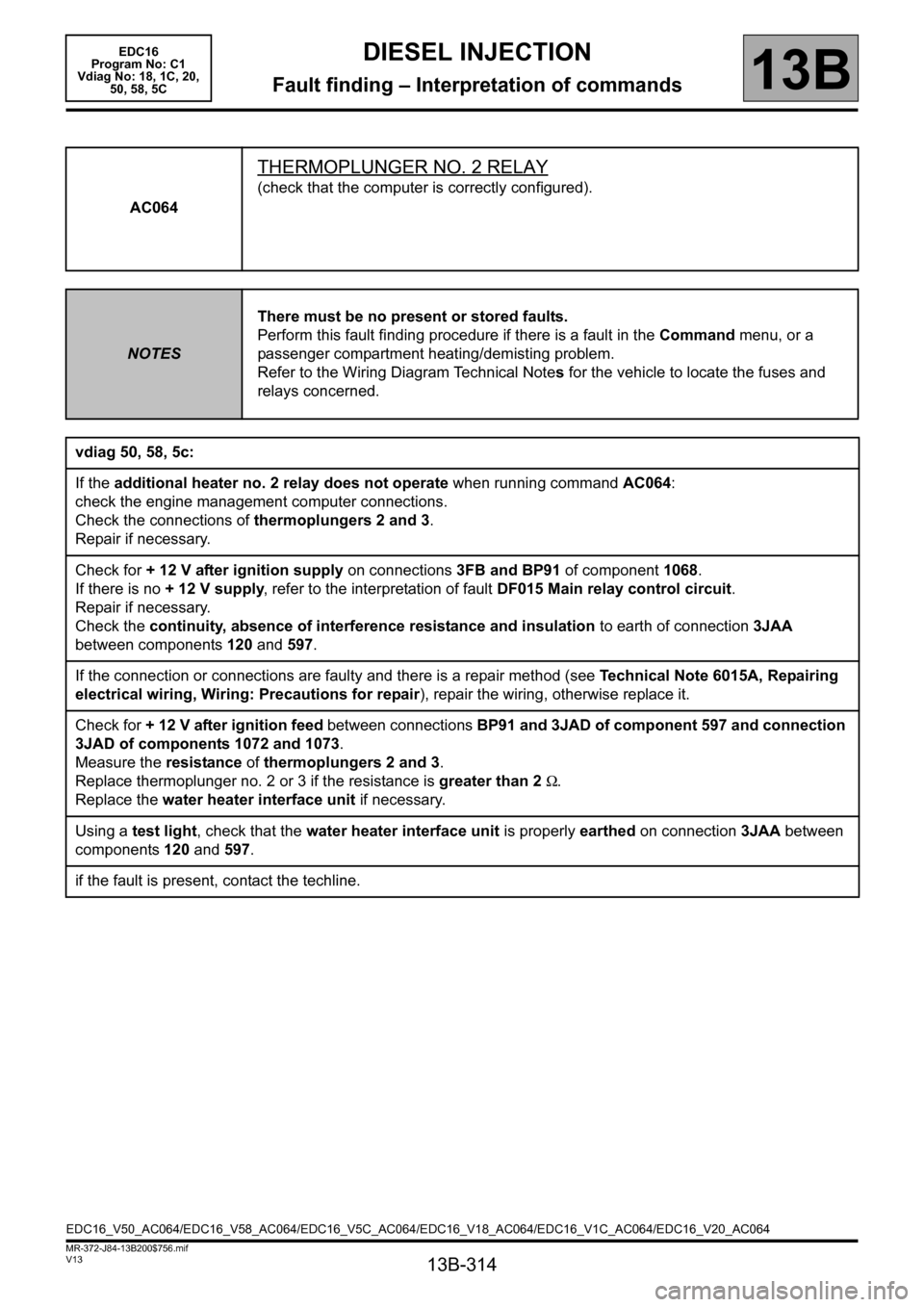

AC064

THERMOPLUNGER NO. 2 RELAY

(check that the computer is correctly configured).

NOTESThere must be no present or stored faults.

Perform this fault finding procedure if there is a fault in the Command menu, or a

passenger compartment heating/demisting problem.

Refer to the Wiring Diagram Technical Notes for the vehicle to locate the fuses and

relays concerned.

vdiag 50, 58, 5c:

If the additional heater no. 2 relay does not operate when running command AC064:

check the engine management computer connections.

Check the connections of thermoplungers 2 and 3.

Repair if necessary.

Check for + 12 V after ignition supply on connections 3FB and BP91 of component 1068.

If there is no + 12 V supply, refer to the interpretation of fault DF015 Main relay control circuit.

Repair if necessary.

Check the continuity, absence of interference resistance and insulation to earth of connection 3JAA

between components 120 and 597.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check for + 12 V after ignition feed between connections BP91 and 3JAD of component 597 and connection

3JAD of components 1072 and 1073.

Measure the resistance of thermoplungers 2 and 3.

Replace thermoplunger no. 2 or 3 if the resistance is greater than 2 Ω.

Replace the water heater interface unit if necessary.

Using a test light, check that the water heater interface unit is properly earthed on connection 3JAA between

components 120 and 597.

if the fault is present, contact the techline.

EDC16_V50_AC064/EDC16_V58_AC064/EDC16_V5C_AC064/EDC16_V18_AC064/EDC16_V1C_AC064/EDC16_V20_AC064

Page 317 of 365

13B-317

MR-372-J84-13B200$792.mif

V13

13B

DIESEL INJECTION

Fault finding – Customer complaints

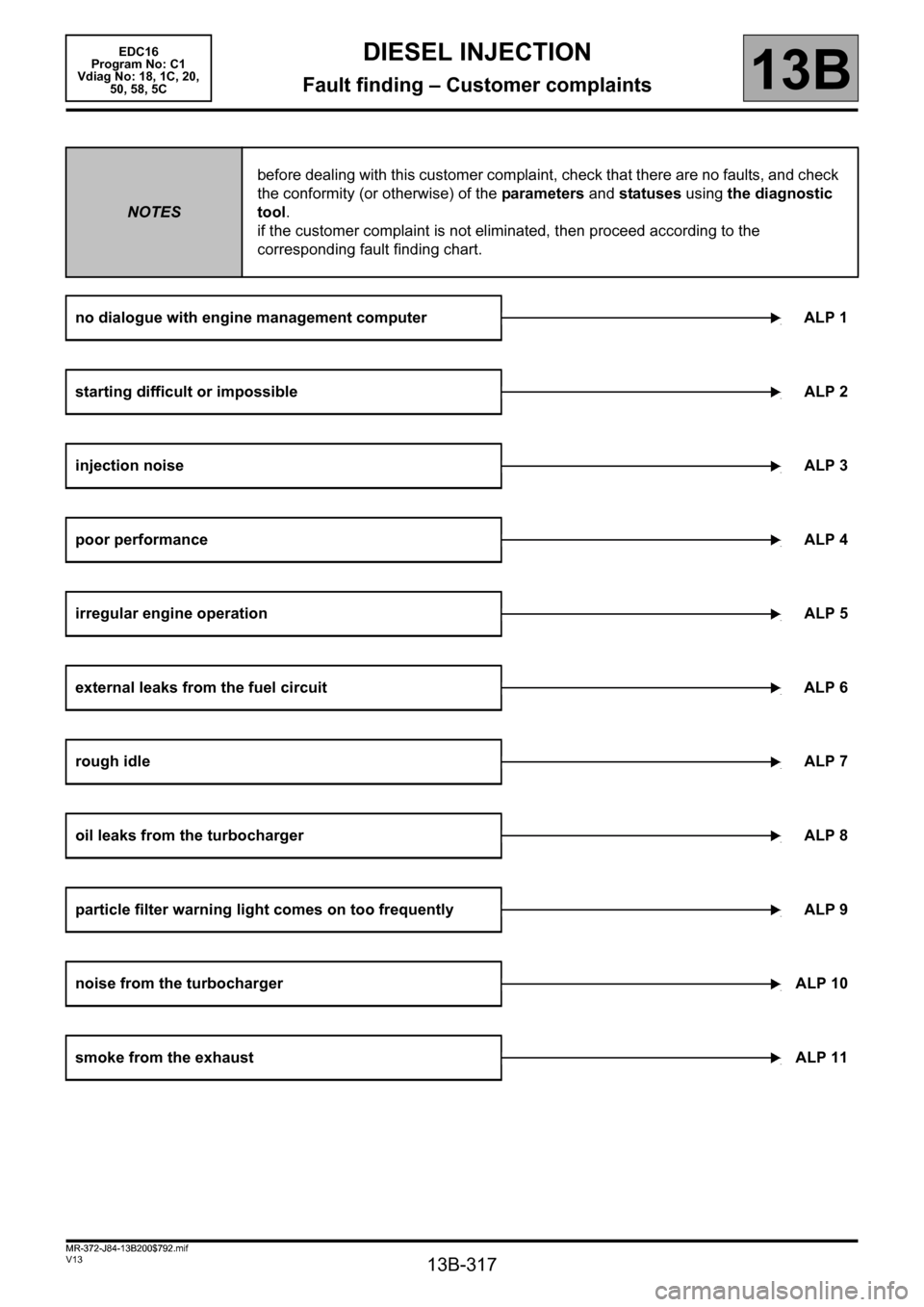

NOTESbefore dealing with this customer complaint, check that there are no faults, and check

the conformity (or otherwise) of the parameters and statuses using the diagnostic

tool.

if the customer complaint is not eliminated, then proceed according to the

corresponding fault finding chart.

no dialogue with engine management computer ALP 1

starting difficult or impossibleALP 2

injection noiseALP 3

poor performanceALP 4

irregular engine operationALP 5

external leaks from the fuel circuit ALP 6

rough idleALP 7

oil leaks from the turbochargerALP 8

particle filter warning light comes on too frequently ALP 9

noise from the turbochargerALP 10

smoke from the exhaustALP 11

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$792.mif

Page 320 of 365

13B-320

MR-372-J84-13B200$828.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Fault Finding Chart13B

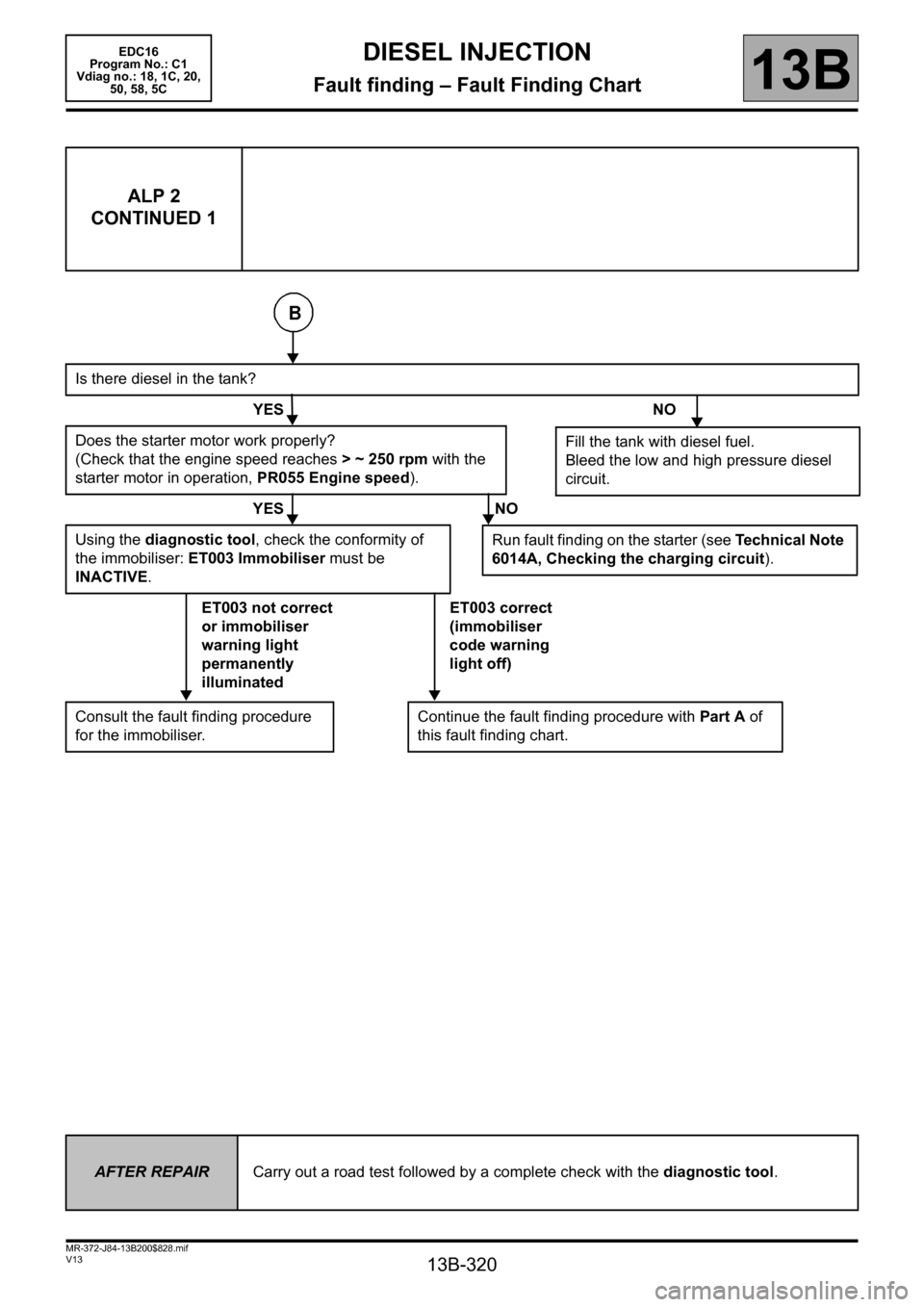

ALP 2

CONTINUED 1

Is there diesel in the tank?

YES NO

Does the starter motor work properly?

(Check that the engine speed reaches >~250rpm with the

starter motor in operation, PR055 Engine speed).

YES NO

Using the diagnostic tool, check the conformity of

the immobiliser: ET003 Immobiliser must be

INACTIVE.

ET003 not correct

or immobiliser

warning light

permanently

illuminatedET003 correct

(immobiliser

code warning

light off)

Consult the fault finding procedure

for the immobiliser.Continue the fault finding procedure with Part A of

this fault finding chart.

Fill the tank with diesel fuel.

Bleed the low and high pressure diesel

circuit.

Run fault finding on the starter (see Technical Note

6014A, Checking the charging circuit).

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 322 of 365

13B-322

MR-372-J84-13B200$828.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Fault Finding Chart13B

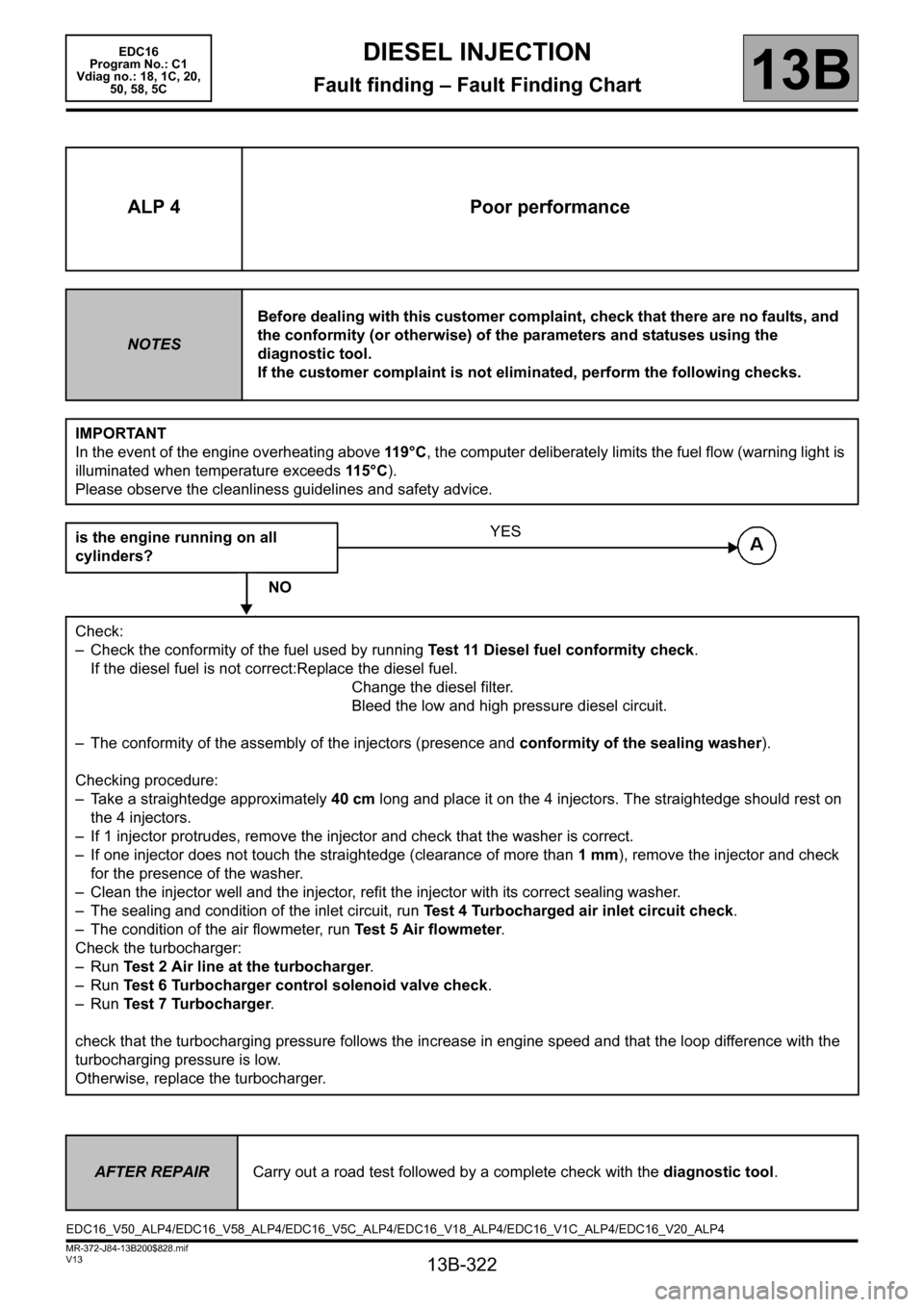

ALP 4 Poor performance

NOTESBefore dealing with this customer complaint, check that there are no faults, and

the conformity (or otherwise) of the parameters and statuses using the

diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT

In the event of the engine overheating above 119°C, the computer deliberately limits the fuel flow (warning light is

illuminated when temperature exceeds 115 ° C).

Please observe the cleanliness guidelines and safety advice.

is the engine running on all

cylinders?

NO

Check:

– Check the conformity of the fuel used by running Test 11 Diesel fuel conformity check.

If the diesel fuel is not correct:Replace the diesel fuel.

Change the diesel filter.

Bleed the low and high pressure diesel circuit.

– The conformity of the assembly of the injectors (presence and conformity of the sealing washer).

Checking procedure:

– Take a straightedge approximately 40 cm long and place it on the 4 injectors. The straightedge should rest on

the 4 injectors.

– If 1 injector protrudes, remove the injector and check that the washer is correct.

– If one injector does not touch the straightedge (clearance of more than 1 mm), remove the injector and check

for the presence of the washer.

– Clean the injector well and the injector, refit the injector with its correct sealing washer.

– The sealing and condition of the inlet circuit, run Test 4 Turbocharged air inlet circuit check.

– The condition of the air flowmeter, run Test 5 Air flowmeter.

Check the turbocharger:

–Run Test 2 Air line at the turbocharger.

–Run Test 6 Turbocharger control solenoid valve check.

–Run Test 7 Turbocharger.

check that the turbocharging pressure follows the increase in engine speed and that the loop difference with the

turbocharging pressure is low.

Otherwise, replace the turbocharger.

YES

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V50_ALP4/EDC16_V58_ALP4/EDC16_V5C_ALP4/EDC16_V18_ALP4/EDC16_V1C_ALP4/EDC16_V20_ALP4

Page 331 of 365

13B-331

MR-372-J84-13B200$828.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Fault Finding Chart13B

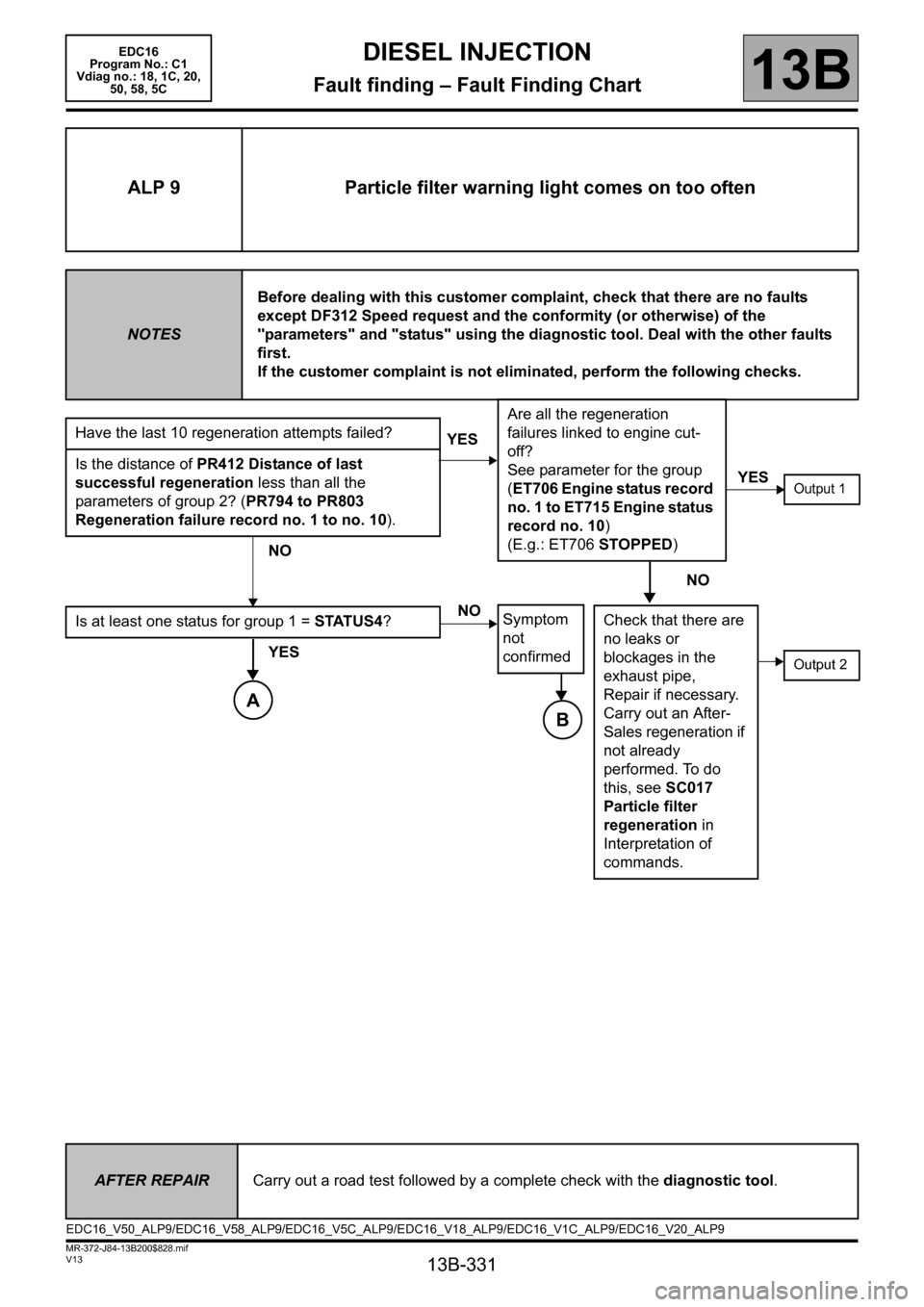

ALP 9 Particle filter warning light comes on too often

NOTESBefore dealing with this customer complaint, check that there are no faults

except DF312 Speed request and the conformity (or otherwise) of the

"parameters" and "status" using the diagnostic tool. Deal with the other faults

first.

If the customer complaint is not eliminated, perform the following checks.

Have the last 10 regeneration attempts failed?

Is the distance of PR412 Distance of last

successful regeneration less than all the

parameters of group 2? (PR794 to PR803

Regeneration failure record no. 1 to no. 10).

NO

Is at least one status for group 1 = STATUS4?

YES

YESAre all the regeneration

failures linked to engine cut-

off?

See parameter for the group

(ET706 Engine status record

no. 1 to ET715 Engine status

record no. 10)

(E.g.: ET706 STOPPED)

NO

Symptom

not

confirmed

YESOutput 1

NO

Check that there are

no leaks or

blockages in the

exhaust pipe,

Repair if necessary.

Carry out an After-

Sales regeneration if

not already

performed. To do

this, see SC017

Particle filter

regeneration in

Interpretation of

commands.

Output 2

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V50_ALP9/EDC16_V58_ALP9/EDC16_V5C_ALP9/EDC16_V18_ALP9/EDC16_V1C_ALP9/EDC16_V20_ALP9

A

B

Page 335 of 365

13B-335

MR-372-J84-13B200$828.mif

V13

DIESEL INJECTION

Fault finding – Fault Finding Chart

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

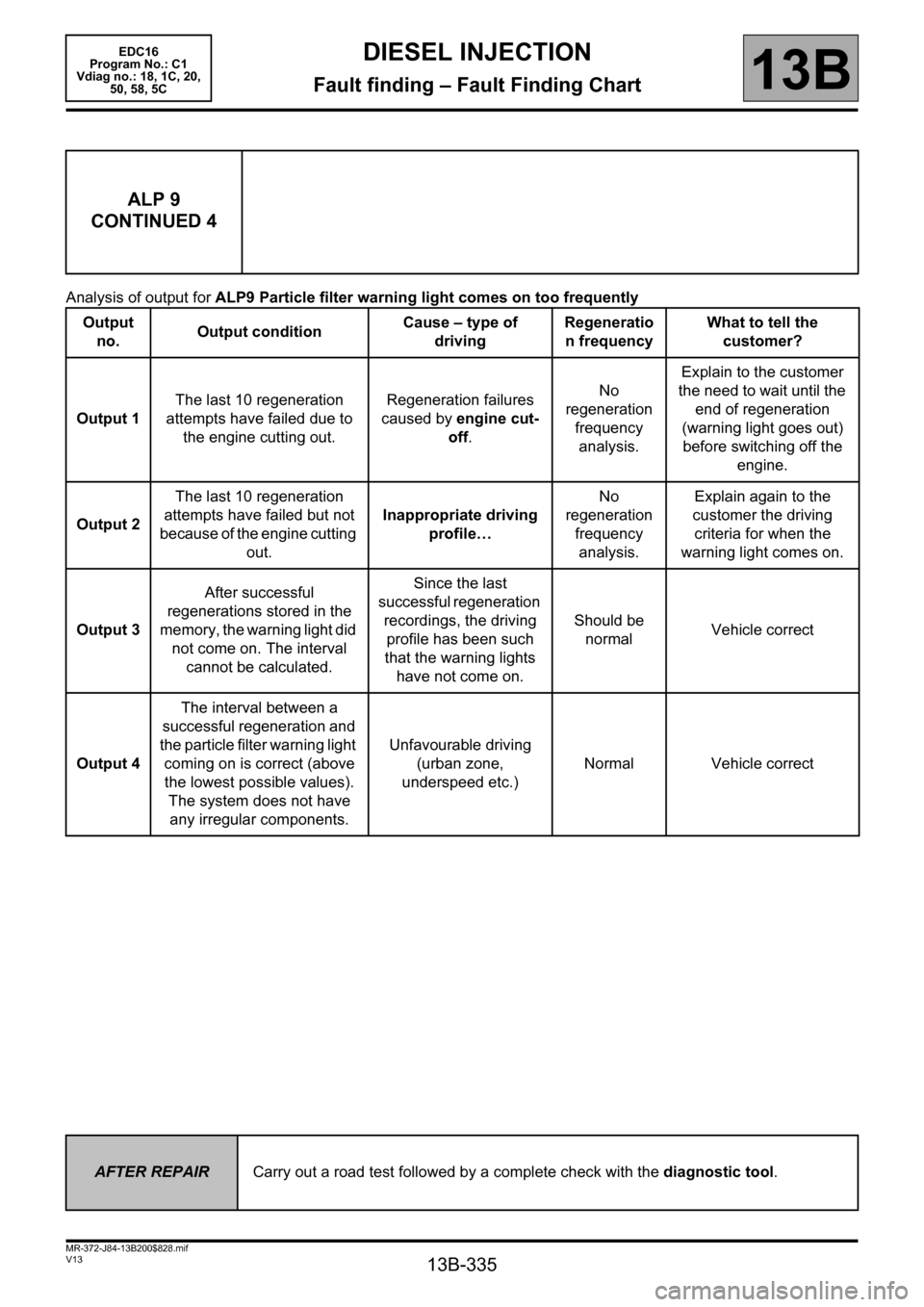

Analysis of output for ALP9 Particle filter warning light comes on too frequently

ALP 9

CONTINUED 4

Output

no. Output conditionCause – type of

drivingRegeneratio

n frequencyWhat to tell the

customer?

Output 1The last 10 regeneration

attempts have failed due to

the engine cutting out.Regeneration failures

caused by engine cut-

off.No

regeneration

frequency

analysis.Explain to the customer

the need to wait until the

end of regeneration

(warning light goes out)

before switching off the

engine.

Output 2The last 10 regeneration

attempts have failed but not

because of the engine cutting

out.Inappropriate driving

profile…No

regeneration

frequency

analysis.Explain again to the

customer the driving

criteria for when the

warning light comes on.

Output 3After successful

regenerations stored in the

memory, the warning light did

not come on. The interval

cannot be calculated.Since the last

successful regeneration

recordings, the driving

profile has been such

that the warning lights

have not come on.Should be

normalVehicle correct

Output 4The interval between a

successful regeneration and

the particle filter warning light

coming on is correct (above

the lowest possible values).

The system does not have

any irregular components.Unfavourable driving

(urban zone,

underspeed etc.)Normal Vehicle correct

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.