RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Workshop Manual

Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 171 of 431

13B-171

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

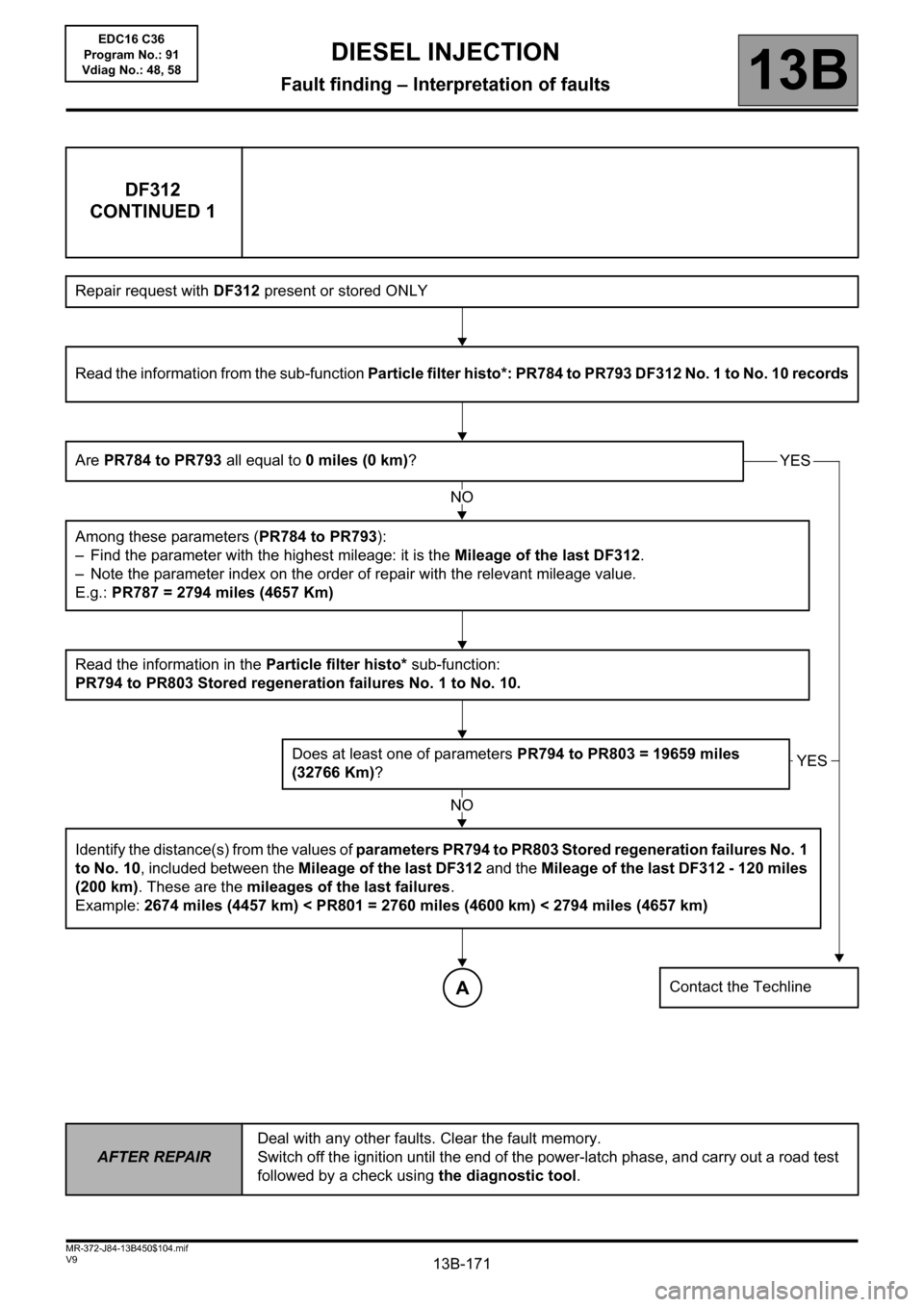

DF312

CONTINUED 1

Repair request with DF312 present or stored ONLY

Read the information from the sub-function Particle filter histo*: PR784 to PR793 DF312 No. 1 to No. 10 records

Are PR784 to PR793 all equal to 0 miles (0 km)?

Among these parameters (PR784 to PR793):

– Find the parameter with the highest mileage: it is the Mileage of the last DF312.

– Note the parameter index on the order of repair with the relevant mileage value.

E.g.: PR787 = 2794 miles (4657 Km)

Read the information in the Particle filter histo* sub-function:

PR794 to PR803 Stored regeneration failures No. 1 to No. 10.

Does at least one of parameters PR794 to PR803 = 19659 miles

(32766 Km)?

Identify the distance(s) from the values of parameters PR794 to PR803 Stored regeneration failures No. 1

to No. 10, included between the Mileage of the last DF312 and the Mileage of the last DF312 - 120 miles

(200 km). These are the mileages of the last failures.

Example: 2674 miles (4457 km) < PR801 = 2760 miles (4600 km) < 2794 miles (4657 km)

Contact the Techline

YES

YES

NO

NO

A

EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 172 of 431

13B-172

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

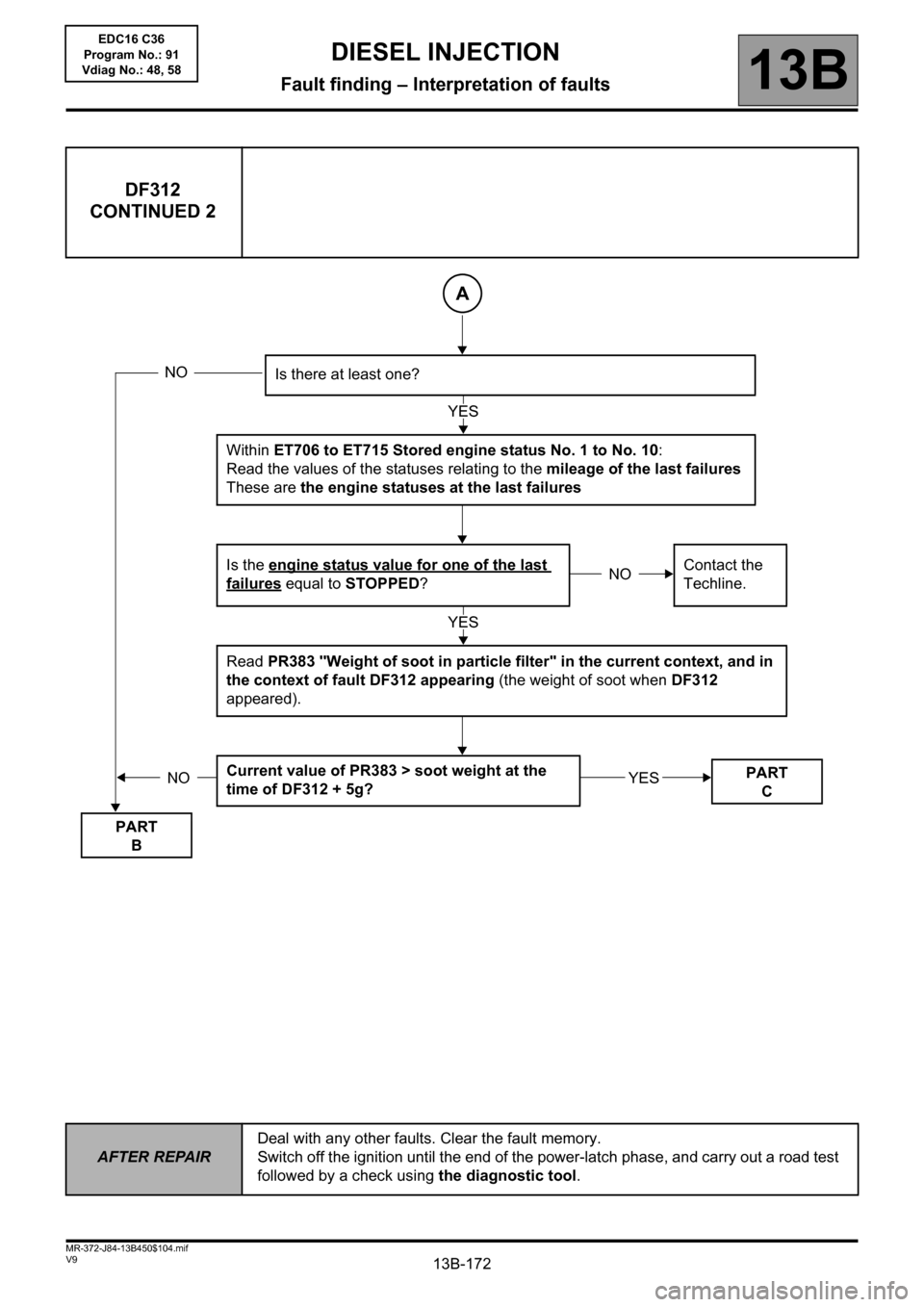

DF312

CONTINUED 2

Is there at least one?

Within ET706 to ET715 Stored engine status No. 1 to No. 10:

Read the values of the statuses relating to the mileage of the last failures

These are the engine statuses at the last failures

Is the engine status value for one of the last

failures equal to STOPPED?Contact the

Techline.

Read PR383 "Weight of soot in particle filter" in the current context, and in

the context of fault DF312 appearing (the weight of soot when DF312

appeared).

Current value of PR383 > soot weight at the

time of DF312 + 5g?

A

YES

NO

NO

YES

PART

B

NOYESPART

C

EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 173 of 431

13B-173

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

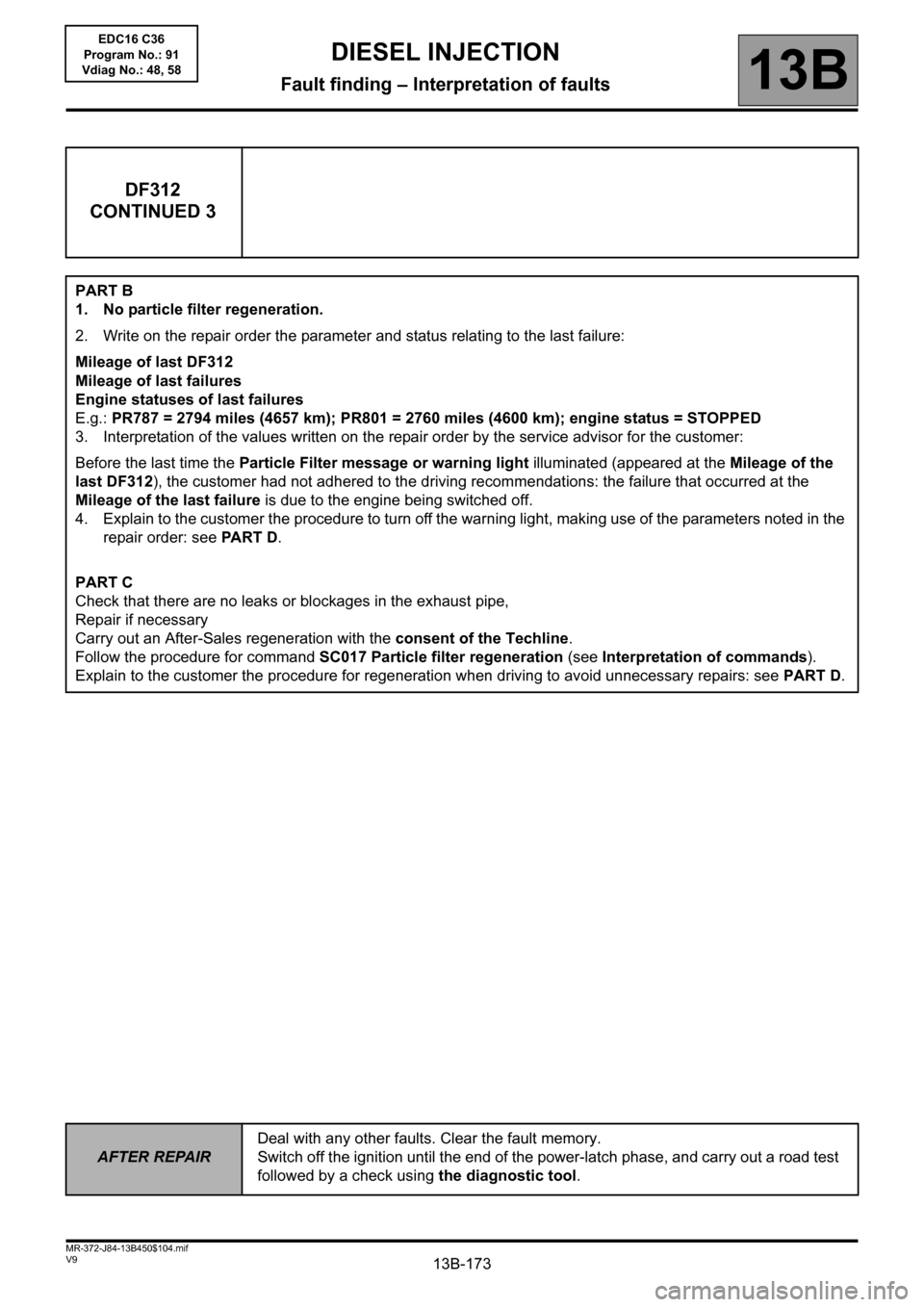

DF312

CONTINUED 3

PART B

1. No particle filter regeneration.

2. Write on the repair order the parameter and status relating to the last failure:

Mileage of last DF312

Mileage of last failures

Engine statuses of last failures

E.g.: PR787 = 2794 miles (4657 km); PR801 = 2760 miles (4600 km); engine status = STOPPED

3. Interpretation of the values written on the repair order by the service advisor for the customer:

Before the last time the Particle Filter message or warning light illuminated (appeared at the Mileage of the

last DF312), the customer had not adhered to the driving recommendations: the failure that occurred at the

Mileage of the last failure is due to the engine being switched off.

4. Explain to the customer the procedure to turn off the warning light, making use of the parameters noted in the

repair order: see PA R T D.

PART C

Check that there are no leaks or blockages in the exhaust pipe,

Repair if necessary

Carry out an After-Sales regeneration with the consent of the Techline.

Follow the procedure for command SC017 Particle filter regeneration (see Interpretation of commands).

Explain to the customer the procedure for regeneration when driving to avoid unnecessary repairs: see PART D.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 174 of 431

13B-174

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

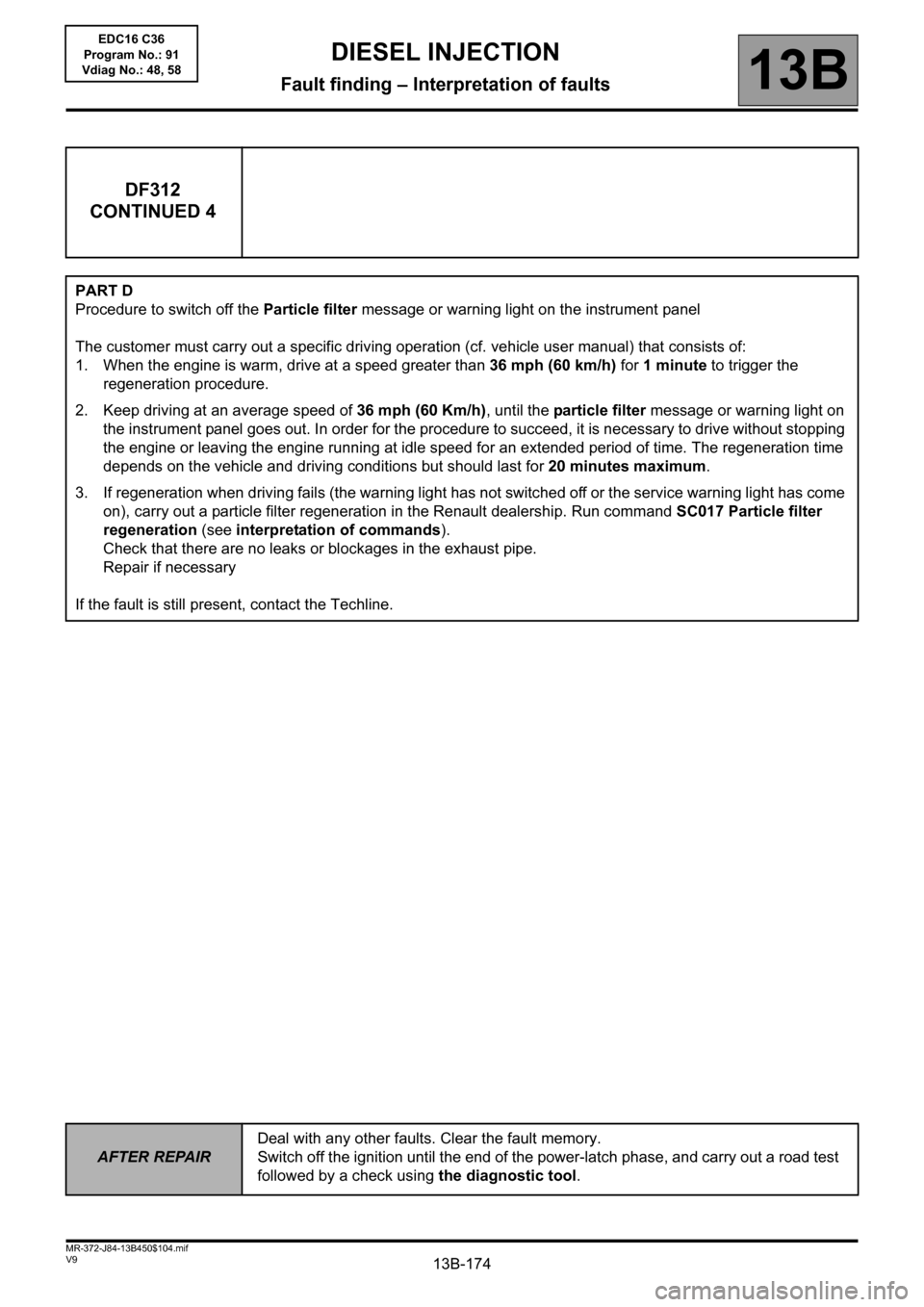

DF312

CONTINUED 4

PART D

Procedure to switch off the Particle filter message or warning light on the instrument panel

The customer must carry out a specific driving operation (cf. vehicle user manual) that consists of:

1. When the engine is warm, drive at a speed greater than 36 mph (60 km/h) for 1 minute to trigger the

regeneration procedure.

2. Keep driving at an average speed of 36 mph (60 Km/h), until the particle filter message or warning light on

the instrument panel goes out. In order for the procedure to succeed, it is necessary to drive without stopping

the engine or leaving the engine running at idle speed for an extended period of time. The regeneration time

depends on the vehicle and driving conditions but should last for 20 minutes maximum.

3. If regeneration when driving fails (the warning light has not switched off or the service warning light has come

on), carry out a particle filter regeneration in the Renault dealership. Run command SC017 Particle filter

regeneration (see interpretation of commands).

Check that there are no leaks or blockages in the exhaust pipe.

Repair if necessary

If the fault is still present, contact the Techline.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 175 of 431

13B-175

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

* diff: differential

DF315

PRESENT

OR

STOREDPARTICLE FILTER DIFF* PRESSURE SENSOR

CO: Open circuit

CC.1: Open circuit or short-circuit on + 12 volts

C0.0: Open circuit or short circuit to earth

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault is present:

–the level 1 warning light is lit,

–the OBD warning light will come on after three consecutive driving cycles (start

+ 5 seconds + switch off the ignition switched and wait 1 minute),

– the particle filter fault finding procedure is inhibited,

– particle filter regeneration is inhibited.

Priorities when dealing with a number of faults:

– DF315 if it is present.

– DF308 "Particle filter clogged" if DF315 is stored and DF308 is present.

– DF011 Sensor supply voltage no. 1 if it is present or stored.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V48_DF315/EDC16C36_V50_DF315/EDC16C36_V58_DF315EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 176 of 431

13B-176

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF315

CONTINUED 1

CC.1NOTESNone.

Check the condition of the connector of the differential pressure sensor.

Check the condition of the connector of the engine management computer.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation in relation to + 12 V on the following connections:

– connection code3TL,

– connection code3TM,

between components 120 and 1290.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the differential pressure sensor.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 177 of 431

13B-177

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF315

CONTINUED 2

CO.0

CONOTESNone.

Check the condition of the connector of the differential pressure sensor (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, Component code 1290).

Check the condition of the connector of the engine management computer (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, Component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity and insulation to earth of the following connections:

– connection code3TL,

– connection code3TM,

between components 120 and 1290.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

• 3XU between components 120 and 1288,

• 3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the differential pressure sensor.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 178 of 431

13B-178

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

* diff: differential

DF316

PRESENT

OR

STOREDPARTICLE FILTER DIFF* PRESSURE

1.DEF: Signal incoherent

2.DEF: Below minimum threshold

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on.

– the engine is started.

Special notes:

If the fault is present:

– the particle filter fault finding procedure is inhibited,

–the Level 1 and OBD warning lights are lit.

Use bornier Ele. 1681 for all operations on the engine management computer

connector.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Check the condition of the pressure pipes on the differential pressure sensor.

Check that they are sealed and in the correct position.

Replace if necessary.

Check the condition of the connectors on the differential pressure sensor and the injection computer.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check the continuity, insulation and the absence of interference resistance on the following connections:

– Connection code3AAQ,

– Connection code3TM,

– Connection code 3TL,

between components 1290 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

EDC16C36_V48_DF316/EDC16C36_V50_DF316/EDC16C36_V58_DF316EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 179 of 431

13B-179

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

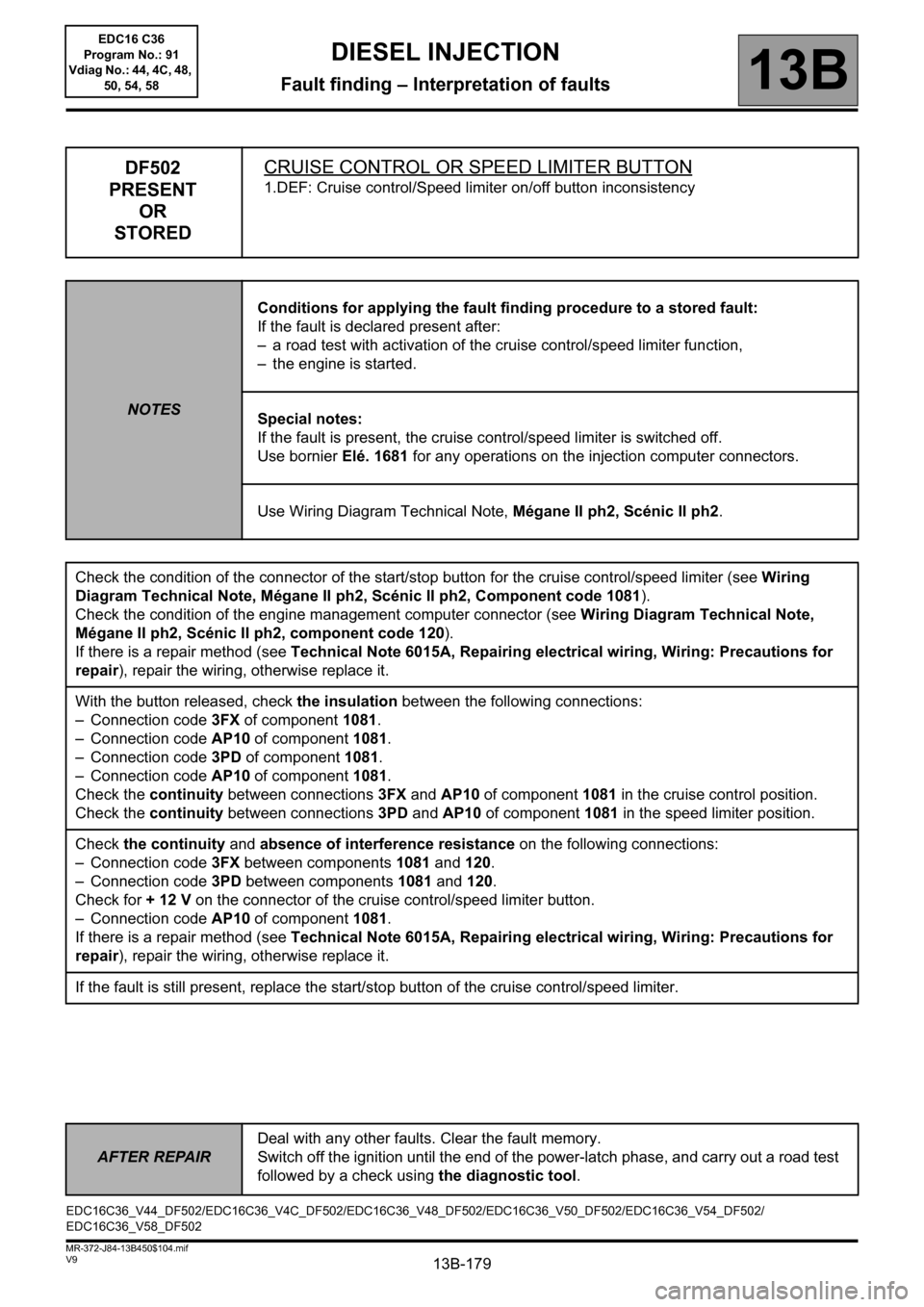

DF502

PRESENT

OR

STOREDCRUISE CONTROL OR SPEED LIMITER BUTTON

1.DEF: Cruise control/Speed limiter on/off button inconsistency

NOTESConditions for applying the fault finding procedure to a stored fault:

If the fault is declared present after:

– a road test with activation of the cruise control/speed limiter function,

– the engine is started.

Special notes:

If the fault is present, the cruise control/speed limiter is switched off.

Use bornier Elé. 1681 for any operations on the injection computer connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Check the condition of the connector of the start/stop button for the cruise control/speed limiter (see Wiring

Diagram Technical Note, Mégane II ph2, Scénic II ph2, Component code 1081).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

With the button released, check the insulation between the following connections:

– Connection code 3FX of component 1081.

– Connection code AP10 of component 1081.

– Connection code 3PD of component 1081.

– Connection code AP10 of component 1081.

Check the continuity between connections 3FX and AP10 of component 1081 in the cruise control position.

Check the continuity between connections 3PD and AP10 of component 1081 in the speed limiter position.

Check the continuity and absence of interference resistance on the following connections:

– Connection code 3FX between components 1081 and 120.

– Connection code 3PD between components 1081 and 120.

Check for + 12 V on the connector of the cruise control/speed limiter button.

– Connection code AP10 of component 1081.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair

), repair the wiring, otherwise replace it.

If the fault is still present, replace the start/stop button of the cruise control/speed limiter.

EDC16C36_V44_DF502/EDC16C36_V4C_DF502/EDC16C36_V48_DF502/EDC16C36_V50_DF502/EDC16C36_V54_DF502/

EDC16C36_V58_DF502EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 180 of 431

13B-180

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF530

PRESENT

OR

STOREDEGR ADAPTIVES

1.DEF: Offset invalid

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on.

– the engine is started,

– a road test.

Special notes:

If the fault is present the EGR function is disabled.

Use bornier Ele. 1681 for all operations on the engine management computer

connector.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

1.DEF

NOTESNone.

Check the condition of the connector of the EGR valve (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, Code organe1460).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector(s) is/are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run command SC036 Reinitialise the programming and select EGR valve to reinitialise the EGR valve offsets.

(see Interpretation of commands).

If the fault is still present, contact the Techline.

EDC16C36_V44_DF530/EDC16C36_V4C_DF530/EDC16C36_V48_DF530/EDC16C36_V50_DF530/EDC16C36_V54_DF530/

EDC16C36_V58_DF530EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58