sensor RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 387 of 431

13B-387

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

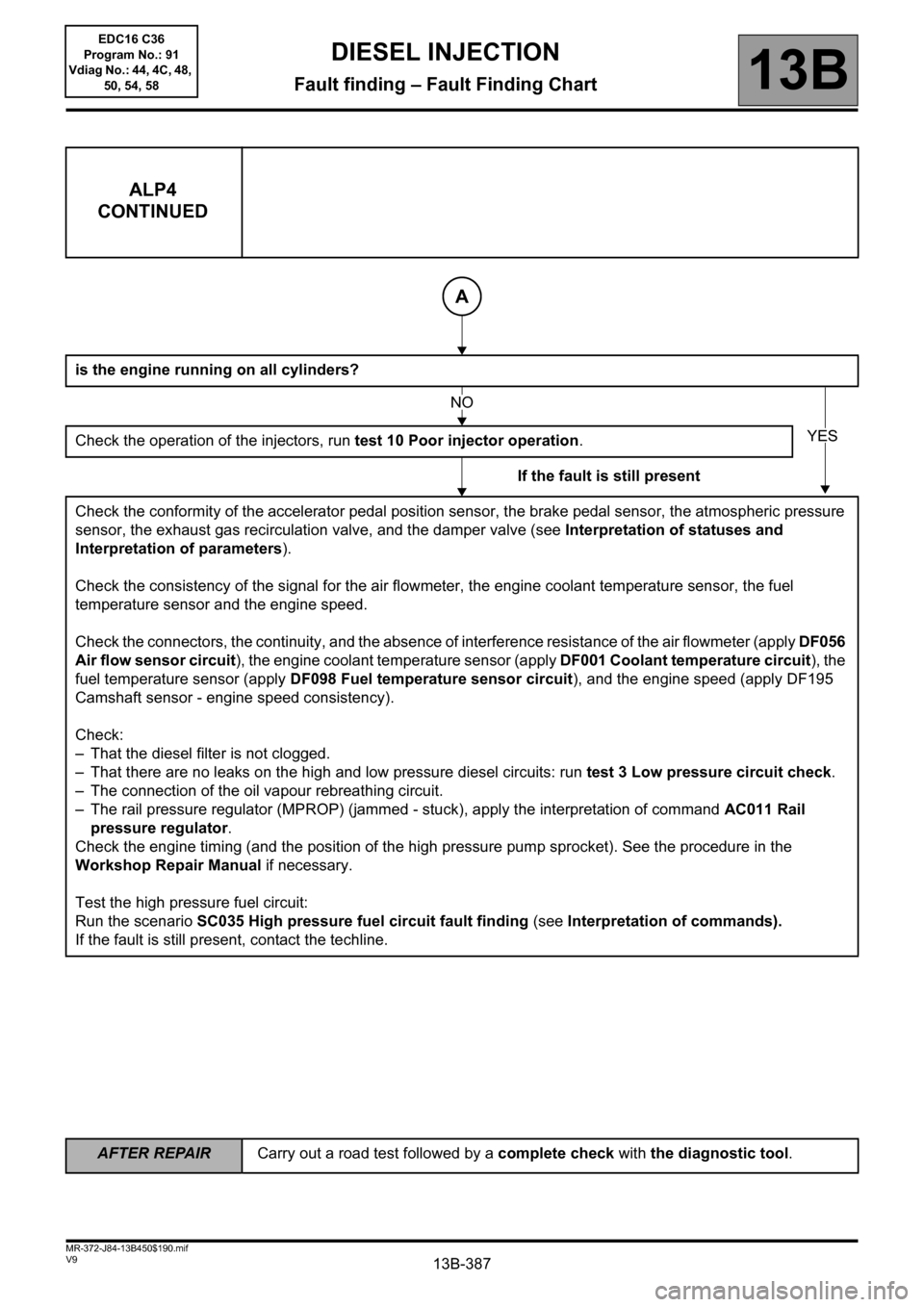

ALP4

CONTINUED

is the engine running on all cylinders?

Check the operation of the injectors, run test 10 Poor injector operation.

If the fault is still present

Check the conformity of the accelerator pedal position sensor, the brake pedal sensor, the atmospheric pressure

sensor, the exhaust gas recirculation valve, and the damper valve (see Interpretation of statuses and

Interpretation of parameters).

Check the consistency of the signal for the air flowmeter, the engine coolant temperature sensor, the fuel

temperature sensor and the engine speed.

Check the connectors, the continuity, and the absence of interference resistance of the air flowmeter (apply DF056

Air flow sensor circuit), the engine coolant temperature sensor (apply DF001 Coolant temperature circuit), the

fuel temperature sensor (apply DF098 Fuel temperature sensor circuit), and the engine speed (apply DF195

Camshaft sensor - engine speed consistency).

Check:

– That the diesel filter is not clogged.

– That there are no leaks on the high and low pressure diesel circuits: run test 3 Low pressure circuit check.

– The connection of the oil vapour rebreathing circuit.

– The rail pressure regulator (MPROP) (jammed - stuck), apply the interpretation of command AC011 Rail

pressure regulator.

Check the engine timing (and the position of the high pressure pump sprocket). See the procedure in the

Workshop Repair Manual if necessary.

Test the high pressure fuel circuit:

Run the scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

If the fault is still present, contact the techline.

A

NO

YES

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 388 of 431

13B-388

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

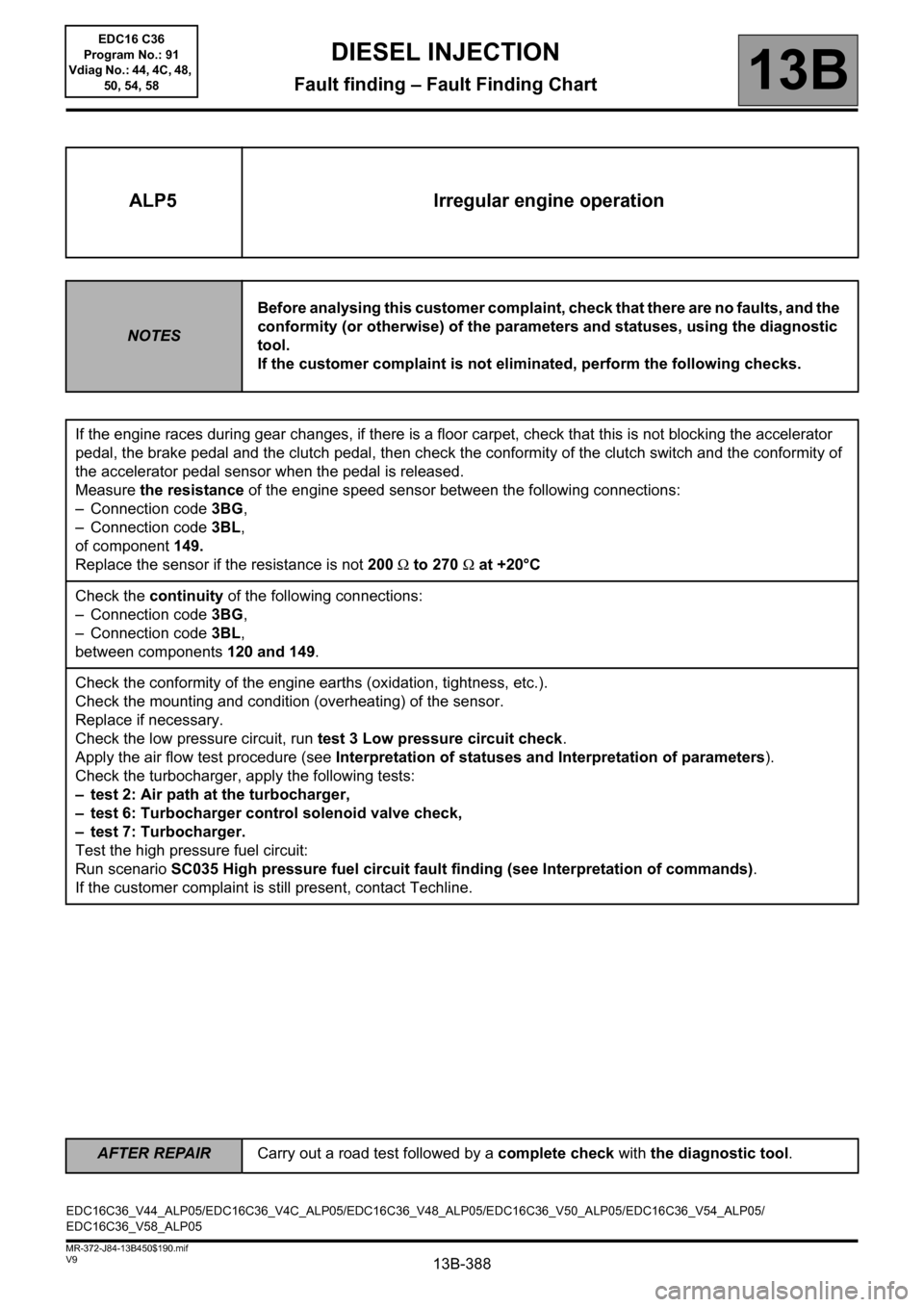

ALP5 Irregular engine operation

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

If the engine races during gear changes, if there is a floor carpet, check that this is not blocking the accelerator

pedal, the brake pedal and the clutch pedal, then check the conformity of the clutch switch and the conformity of

the accelerator pedal sensor when the pedal is released.

Measure the resistance of the engine speed sensor between the following connections:

– Connection code 3BG,

– Connection code 3BL,

of component 149.

Replace the sensor if the resistance is not 200 Ω to 270 Ω at +20°C

Check the continuity of the following connections:

– Connection code 3BG,

– Connection code 3BL,

between components120 and 149.

Check the conformity of the engine earths (oxidation, tightness, etc.).

Check the mounting and condition (overheating) of the sensor.

Replace if necessary.

Check the low pressure circuit, run test 3 Low pressure circuit check.

Apply the air flow test procedure (see Interpretation of statuses and Interpretation of parameters).

Check the turbocharger, apply the following tests:

– test 2: Air path at the turbocharger,

– test 6: Turbocharger control solenoid valve check,

– test 7: Turbocharger.

Test the high pressure fuel circuit:

Run scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

If the customer complaint is still present, contact Techline.

EDC16C36_V44_ALP05/EDC16C36_V4C_ALP05/EDC16C36_V48_ALP05/EDC16C36_V50_ALP05/EDC16C36_V54_ALP05/

EDC16C36_V58_ALP05EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 391 of 431

13B-391

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

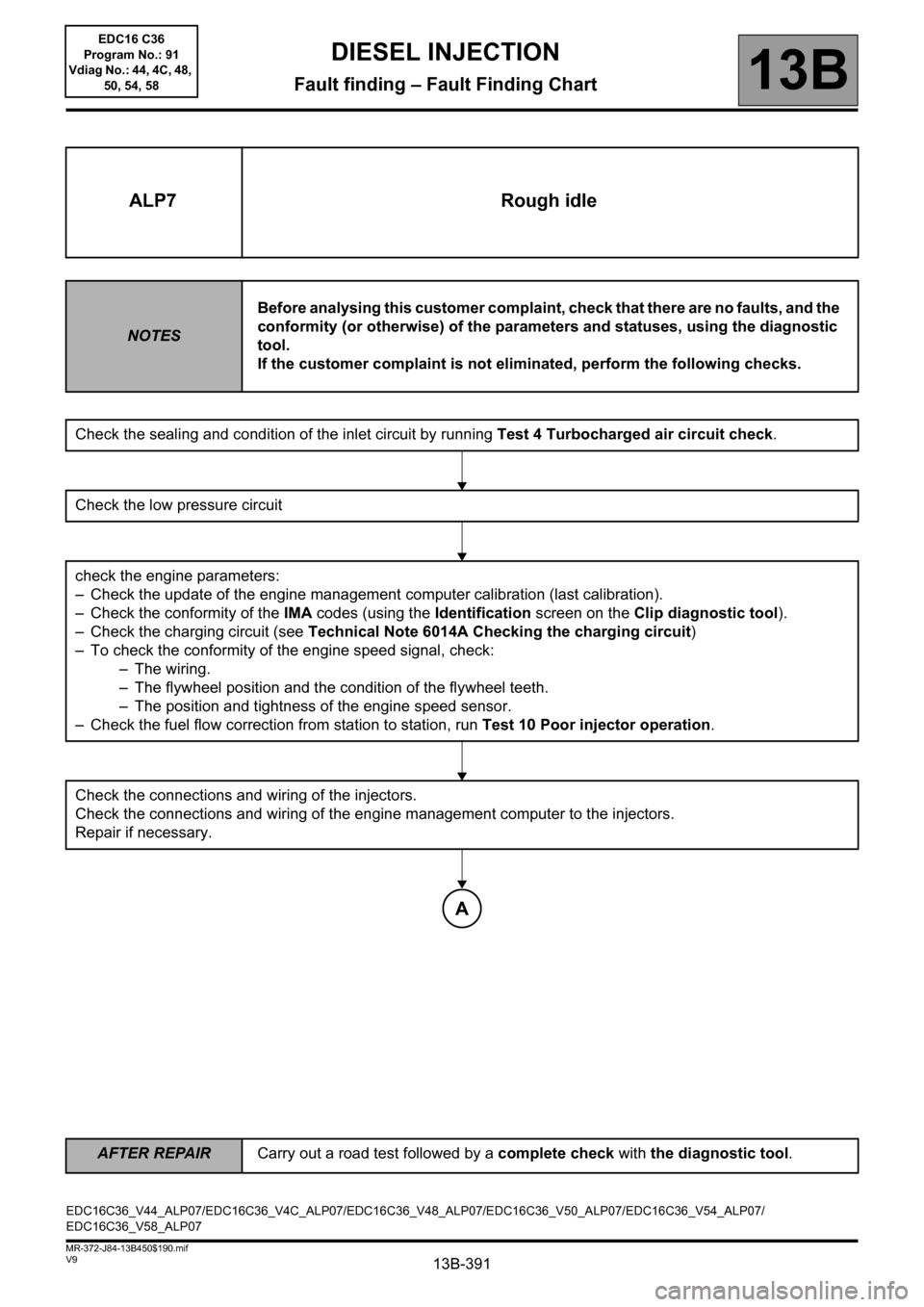

ALP7 Rough idle

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

Check the sealing and condition of the inlet circuit by running Test 4 Turbocharged air circuit check.

Check the low pressure circuit

check the engine parameters:

– Check the update of the engine management computer calibration (last calibration).

– Check the conformity of the IMA codes (using the Identification screen on the Clip diagnostic tool).

– Check the charging circuit (see Technical Note 6014A Checking the charging circuit)

– To check the conformity of the engine speed signal, check:

– The wiring.

– The flywheel position and the condition of the flywheel teeth.

– The position and tightness of the engine speed sensor.

– Check the fuel flow correction from station to station, run Test 10 Poor injector operation.

Check the connections and wiring of the injectors.

Check the connections and wiring of the engine management computer to the injectors.

Repair if necessary.

A

EDC16C36_V44_ALP07/EDC16C36_V4C_ALP07/EDC16C36_V48_ALP07/EDC16C36_V50_ALP07/EDC16C36_V54_ALP07/

EDC16C36_V58_ALP07EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 402 of 431

13B-402

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

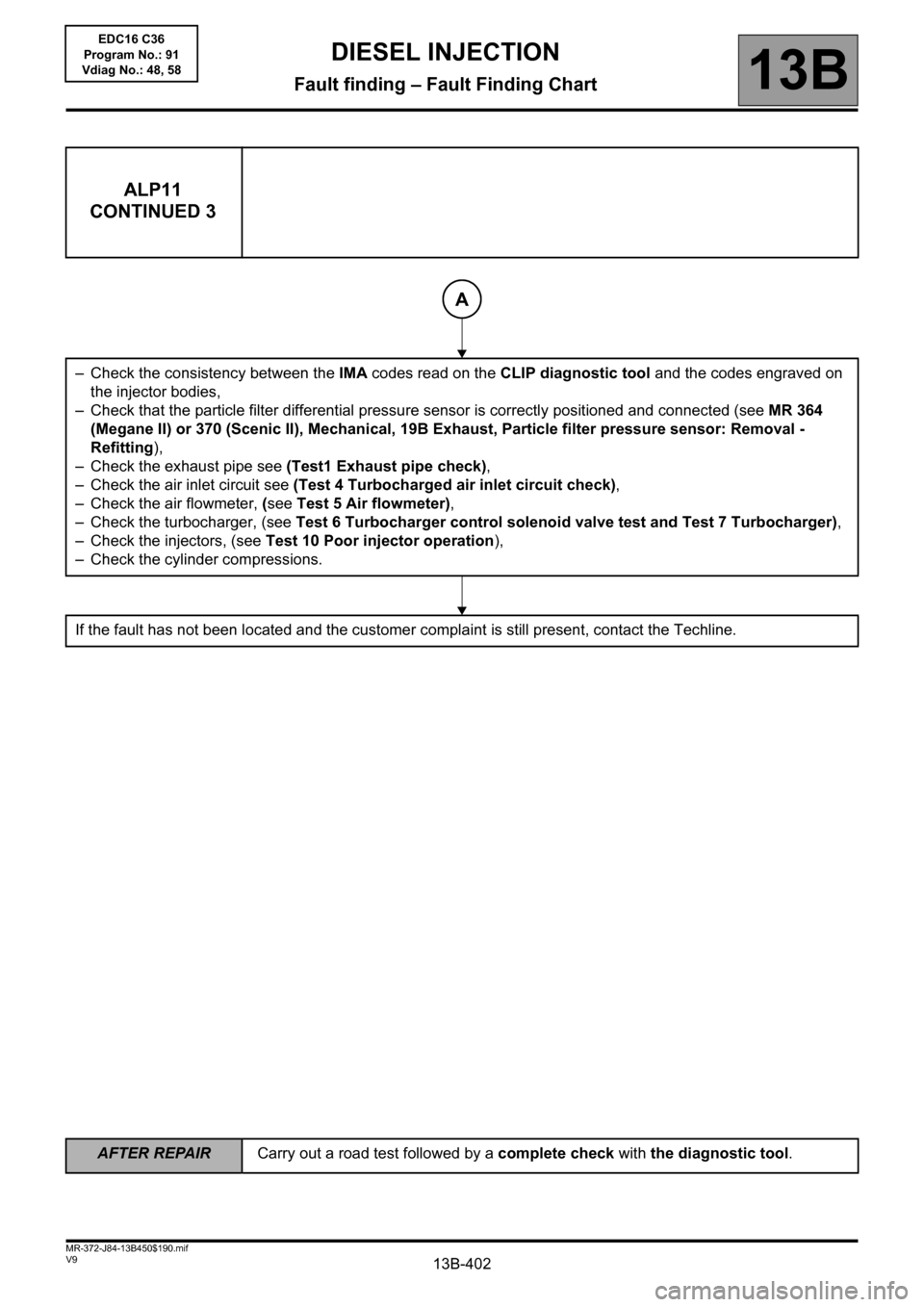

ALP11

CONTINUED 3

– Check the consistency between the IMA codes read on the CLIP diagnostic tool and the codes engraved on

the injector bodies,

– Check that the particle filter differential pressure sensor is correctly positioned and connected (see MR 364

(Megane II) or 370 (Scenic II), Mechanical, 19B Exhaust, Particle filter pressure sensor: Removal -

Refitting),

– Check the exhaust pipe see (Test1 Exhaust pipe check),

– Check the air inlet circuit see (Test 4 Turbocharged air inlet circuit check),

– Check the air flowmeter, (see Test 5 Air flowmeter),

– Check the turbocharger, (see Test 6 Turbocharger control solenoid valve test and Test 7 Turbocharger),

– Check the injectors, (see Test 10 Poor injector operation),

– Check the cylinder compressions.

If the fault has not been located and the customer complaint is still present, contact the Techline.

A

EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 404 of 431

13B-404V9 MR-372-J84-13B450$200.mif

13B

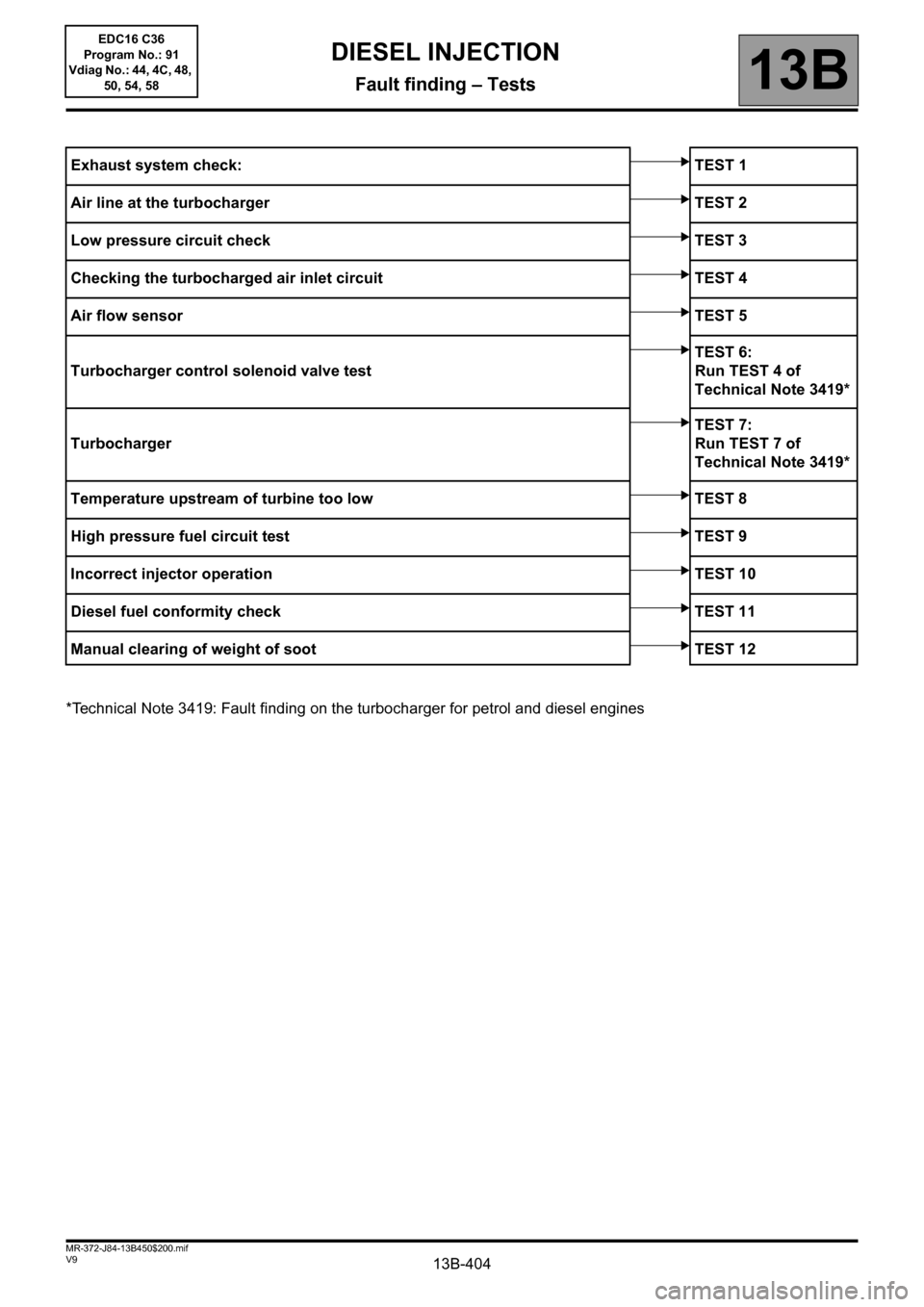

*Technical Note 3419: Fault finding on the turbocharger for petrol and diesel enginesExhaust system check: TEST 1

Air line at the turbocharger TEST 2

Low pressure circuit check TEST 3

Checking the turbocharged air inlet circuit TEST 4

Air flow sensorTEST 5

Turbocharger control solenoid valve testTEST 6:

Run TEST 4 of

Technical Note 3419*

TurbochargerTEST 7:

Run TEST 7 of

Technical Note 3419*

Temperature upstream of turbine too low TEST 8

High pressure fuel circuit test TEST 9

Incorrect injector operation TEST 10

Diesel fuel conformity check TEST 11

Manual clearing of weight of soot TEST 12

DIESEL INJECTION

Fault finding – Tests

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 407 of 431

13B-407V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

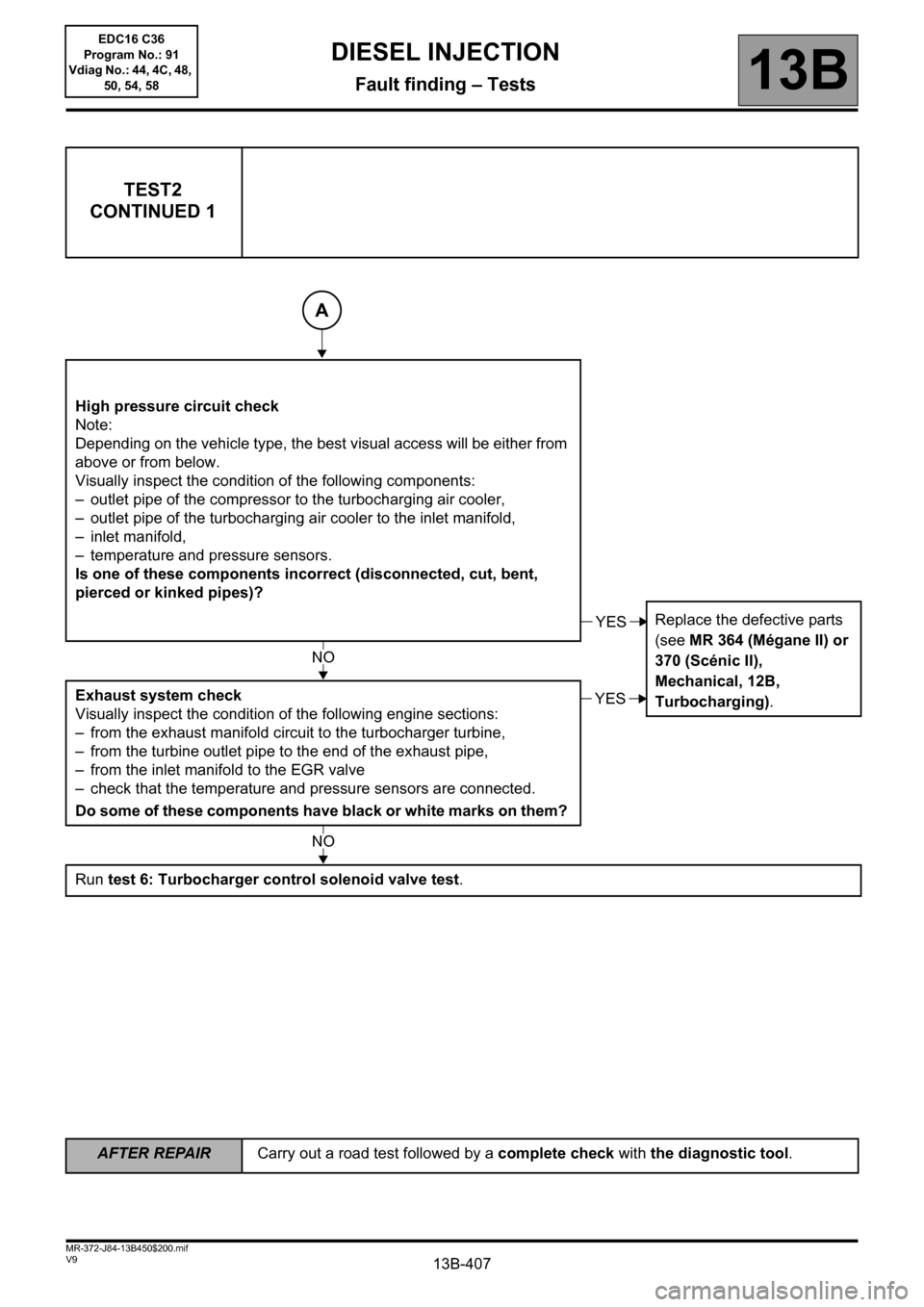

TEST2

CONTINUED 1

High pressure circuit check

Note:

Depending on the vehicle type, the best visual access will be either from

above or from below.

Visually inspect the condition of the following components:

– outlet pipe of the compressor to the turbocharging air cooler,

– outlet pipe of the turbocharging air cooler to the inlet manifold,

– inlet manifold,

– temperature and pressure sensors.

Is one of these components incorrect (disconnected, cut, bent,

pierced or kinked pipes)?

Replace the defective parts

(see MR 364 (Mégane II) or

370 (Scénic II),

Mechanical, 12B,

Turbocharging). Exhaust system check

Visually inspect the condition of the following engine sections:

– from the exhaust manifold circuit to the turbocharger turbine,

– from the turbine outlet pipe to the end of the exhaust pipe,

– from the inlet manifold to the EGR valve

– check that the temperature and pressure sensors are connected.

Do some of these components have black or white marks on them?

Run test 6: Turbocharger control solenoid valve test.

A

YES

NO

YES

NO

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 408 of 431

13B-408V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

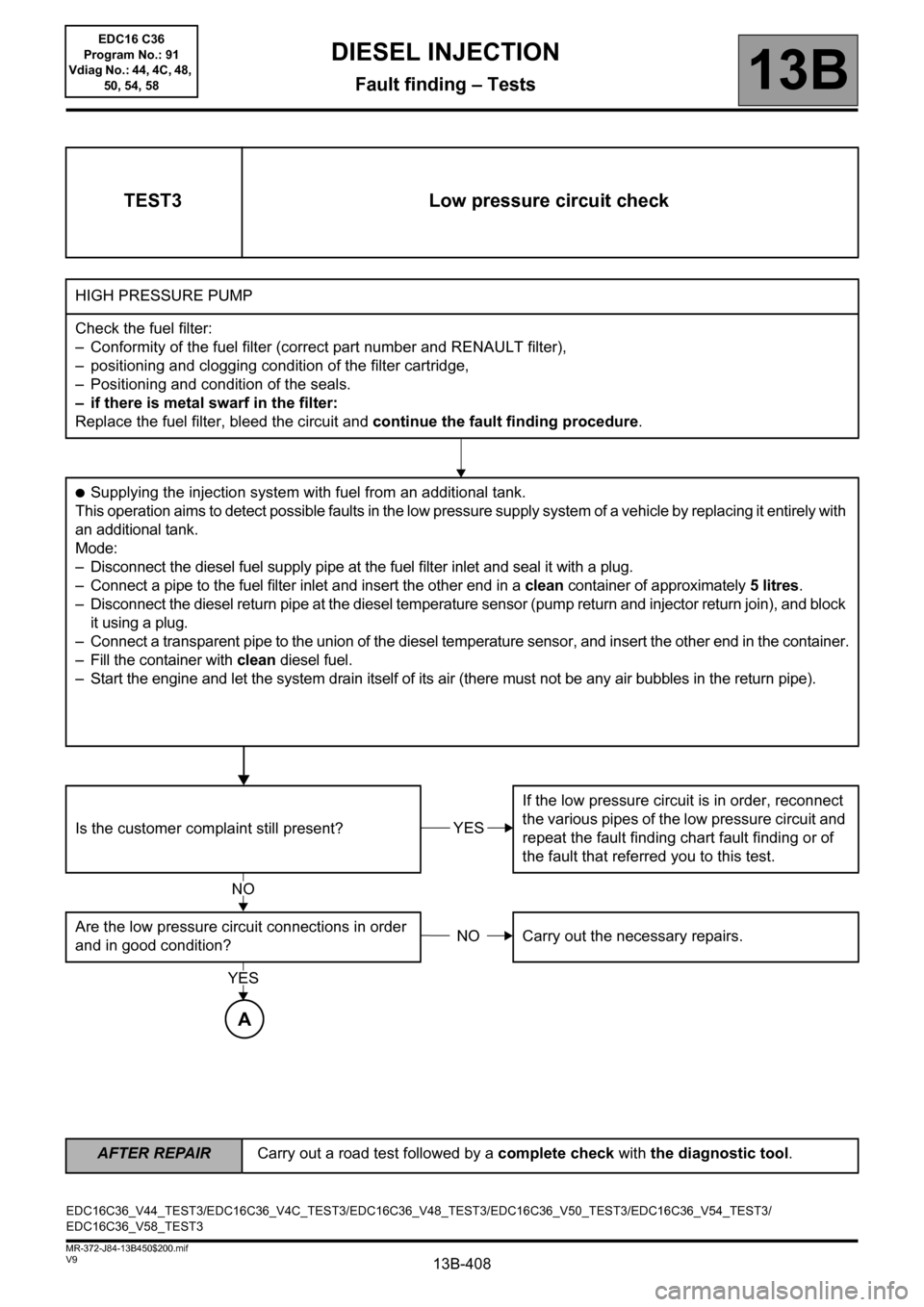

TEST3 Low pressure circuit check

HIGH PRESSURE PUMP

Check the fuel filter:

– Conformity of the fuel filter (correct part number and RENAULT filter),

– positioning and clogging condition of the filter cartridge,

– Positioning and condition of the seals.

– if there is metal swarf in the filter:

Replace the fuel filter, bleed the circuit and continue the fault finding procedure.

●Supplying the injection system with fuel from an additional tank.

This operation aims to detect possible faults in the low pressure supply system of a vehicle by replacing it entirely with

an additional tank.

Mode:

– Disconnect the diesel fuel supply pipe at the fuel filter inlet and seal it with a plug.

– Connect a pipe to the fuel filter inlet and insert the other end in a clean container of approximately 5litres.

– Disconnect the diesel return pipe at the diesel temperature sensor (pump return and injector return join), and block

it using a plug.

– Connect a transparent pipe to the union of the diesel temperature sensor, and insert the other end in the container.

– Fill the container with clean diesel fuel.

– Start the engine and let the system drain itself of its air (there must not be any air bubbles in the return pipe).

Is the customer complaint still present?If the low pressure circuit is in order, reconnect

the various pipes of the low pressure circuit and

repeat the fault finding chart fault finding or of

the fault that referred you to this test.

Are the low pressure circuit connections in order

and in good condition?Carry out the necessary repairs.

YES

NO

NO

YES

A

EDC16C36_V44_TEST3/EDC16C36_V4C_TEST3/EDC16C36_V48_TEST3/EDC16C36_V50_TEST3/EDC16C36_V54_TEST3/

EDC16C36_V58_TEST3

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 410 of 431

13B-410V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

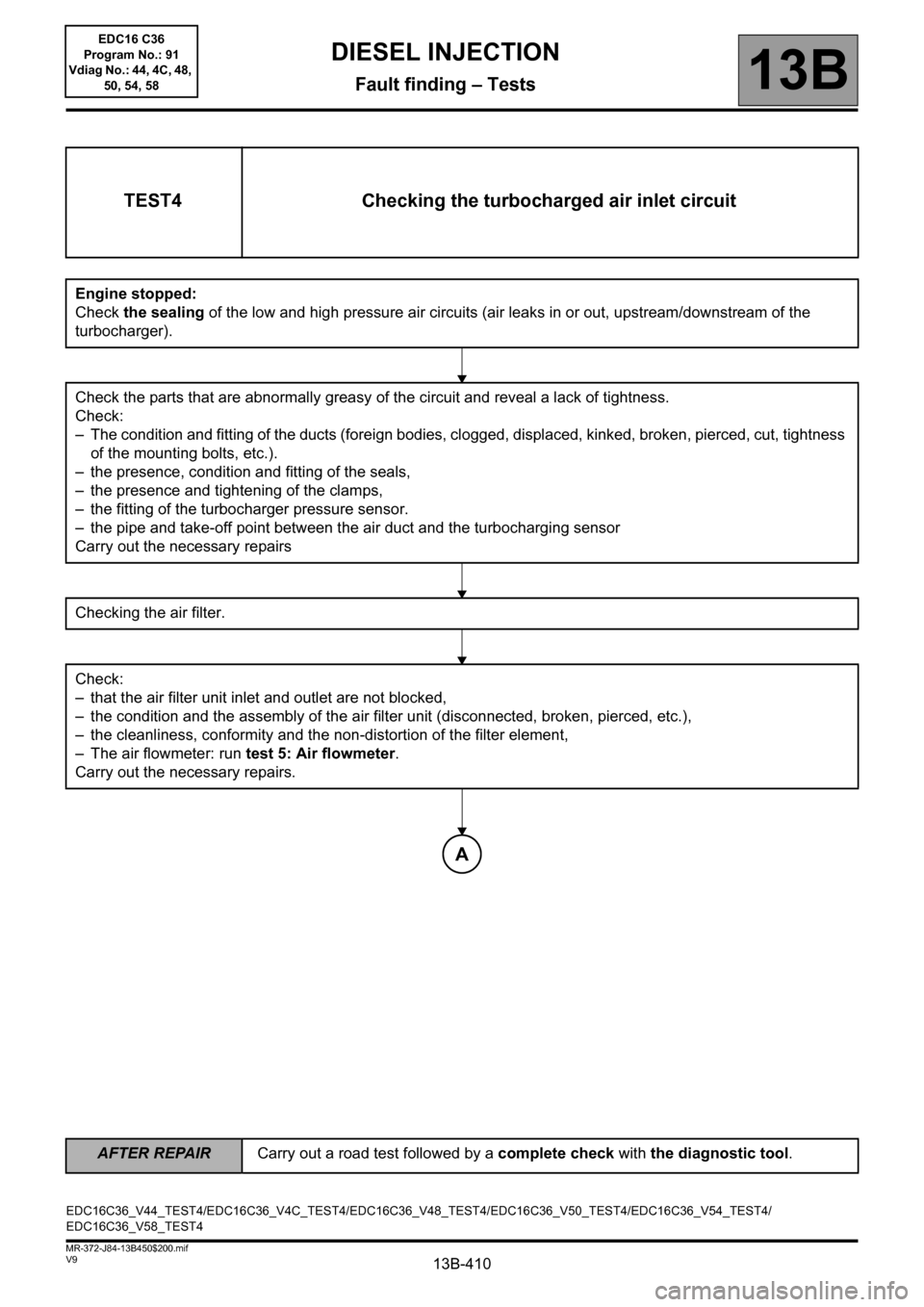

TEST4 Checking the turbocharged air inlet circuit

Engine stopped:

Check the sealing of the low and high pressure air circuits (air leaks in or out, upstream/downstream of the

turbocharger).

Check the parts that are abnormally greasy of the circuit and reveal a lack of tightness.

Check:

– The condition and fitting of the ducts (foreign bodies, clogged, displaced, kinked, broken, pierced, cut, tightness

of the mounting bolts, etc.).

– the presence, condition and fitting of the seals,

– the presence and tightening of the clamps,

– the fitting of the turbocharger pressure sensor.

– the pipe and take-off point between the air duct and the turbocharging sensor

Carry out the necessary repairs

Checking the air filter.

Check:

– that the air filter unit inlet and outlet are not blocked,

– the condition and the assembly of the air filter unit (disconnected, broken, pierced, etc.),

– the cleanliness, conformity and the non-distortion of the filter element,

– The air flowmeter: run test 5: Air flowmeter.

Carry out the necessary repairs.

A

EDC16C36_V44_TEST4/EDC16C36_V4C_TEST4/EDC16C36_V48_TEST4/EDC16C36_V50_TEST4/EDC16C36_V54_TEST4/

EDC16C36_V58_TEST4

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 411 of 431

13B-411V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

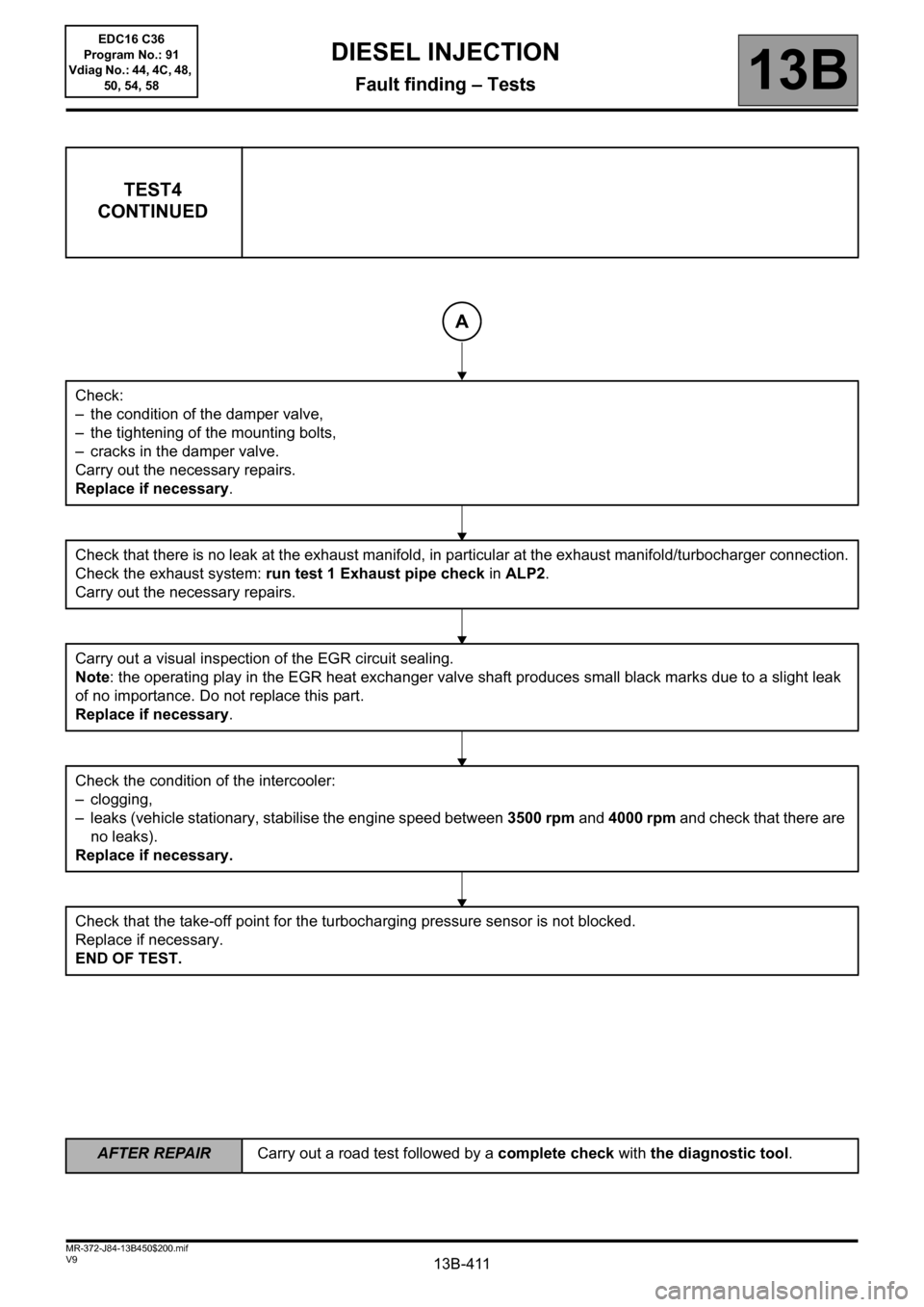

TEST4

CONTINUED

Check:

– the condition of the damper valve,

– the tightening of the mounting bolts,

– cracks in the damper valve.

Carry out the necessary repairs.

Replace if necessary.

Check that there is no leak at the exhaust manifold, in particular at the exhaust manifold/turbocharger connection.

Check the exhaust system: run test 1 Exhaust pipe check in ALP2.

Carry out the necessary repairs.

Carry out a visual inspection of the EGR circuit sealing.

Note: the operating play in the EGR heat exchanger valve shaft produces small black marks due to a slight leak

of no importance. Do not replace this part.

Replace if necessary.

Check the condition of the intercooler:

– clogging,

– leaks (vehicle stationary, stabilise the engine speed between 3500 rpm and 4000 rpm and check that there are

no leaks).

Replace if necessary.

Check that the take-off point for the turbocharging pressure sensor is not blocked.

Replace if necessary.

END OF TEST.

A

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 412 of 431

13B-412V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

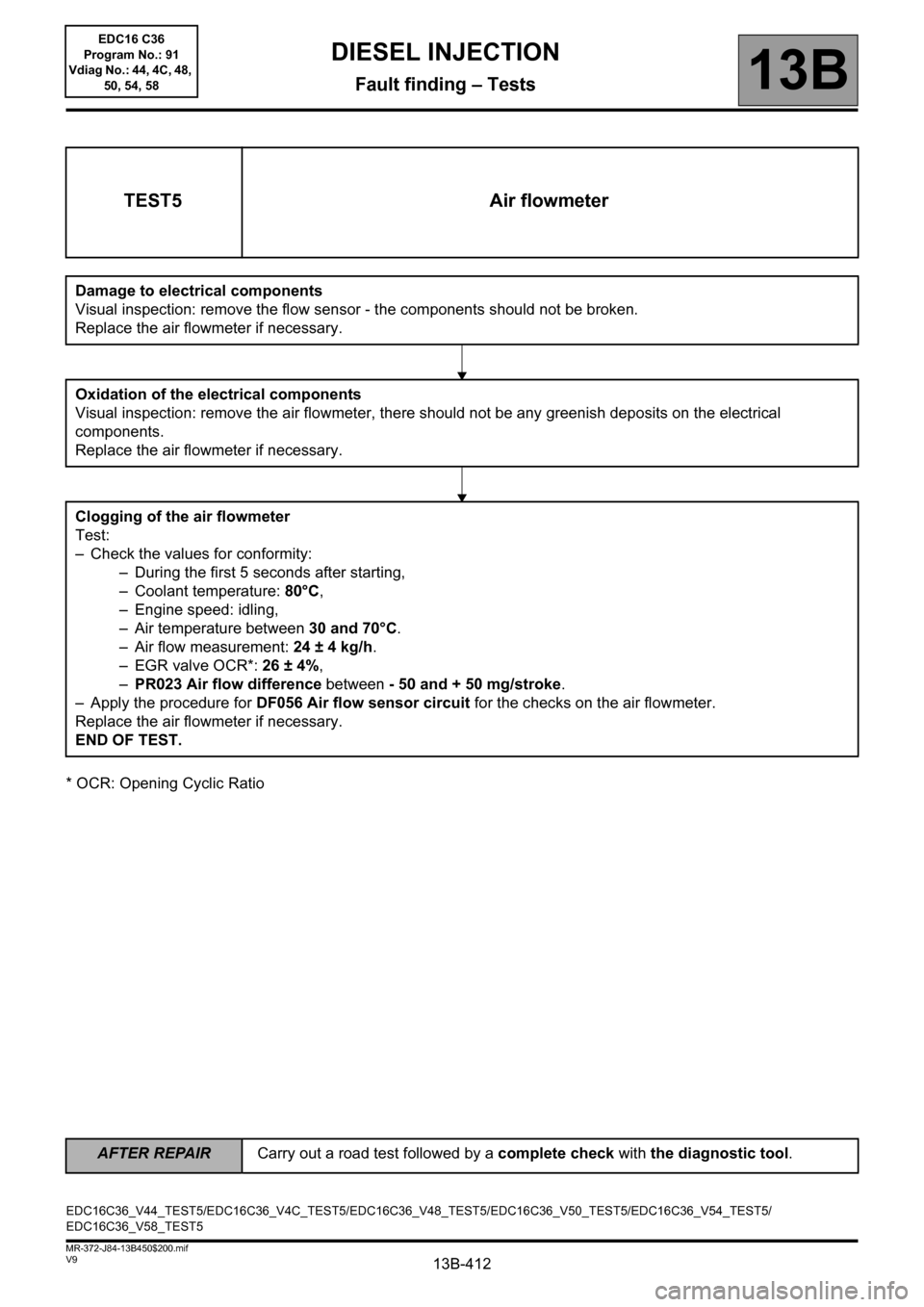

* OCR: Opening Cyclic Ratio

TEST5 Air flowmeter

Damage to electrical components

Visual inspection: remove the flow sensor - the components should not be broken.

Replace the air flowmeter if necessary.

Oxidation of the electrical components

Visual inspection: remove the air flowmeter, there should not be any greenish deposits on the electrical

components.

Replace the air flowmeter if necessary.

Clogging of the air flowmeter

Test:

– Check the values for conformity:

– During the first 5 seconds after starting,

– Coolant temperature: 80°C,

– Engine speed: idling,

– Air temperature between 30 and 70°C.

– Air flow measurement: 24 ± 4 kg/h.

– EGR valve OCR*: 26 ± 4%,

–PR023 Air flow difference between - 50 and + 50 mg/stroke.

– Apply the procedure for DF056 Air flow sensor circuit for the checks on the air flowmeter.

Replace the air flowmeter if necessary.

END OF TEST.

EDC16C36_V44_TEST5/EDC16C36_V4C_TEST5/EDC16C36_V48_TEST5/EDC16C36_V50_TEST5/EDC16C36_V54_TEST5/

EDC16C36_V58_TEST5

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58