relay RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 118 of 431

13B-118V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF119

CONTINUED 1

WARNING

If the fault is stored:

Visually check the condition of the surrounding area.

If, on detection of the fault, the engine speed is considerably slower than the idling speed (less than 400 rpm) and

no customer complaint is declared (warning light indicated by the customer does not come on and vehicle can be

started), the fault was detected because the engine stalled. Clear the fault and carry out a road test.

Check the sensor mounting and the conformity of the camshaft target.

Check that the camshaft sensor/camshaft sprocket air gap is 3 mm maximum.

Check the electrical specifications of the sensor:

Note:

Make sure that the resistance is measured between the tracks indicated.

1. Disconnect the sensor before measuring the resistance with an Ohmmeter or multimeter.

2. The resistance between connections 3FB and 3PL of component 746 (earth and supply) must be between

7.2 kΩ and 13.4 kΩ (10.2 kΩ nominal).

3. The resistance between connections3FB and 3CQ of component 746 (output and feed) should be above

100 kΩ.

4. The resistance between connections3PL and 3CQ of component 746 (output and earth) should be above

100 kΩ.

If the values are incorrect, replace the camshaft sensor.

Check the continuity of the following connections:

– Connection code 3PL between components 746 and 120.

– Connection code 3CQ between components 746 and 120.

Check for + 12 V after relay on connection 3FB of component 746.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

If the fault is still present, replace the camshaft sensor.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 119 of 431

13B-119V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF119

CONTINUED 2

2.DEFNOTESPriorities when dealing with a number of faults:

Deal with fault DF120 Engine speed sensor signal, 1.DEF

first if it is present or stored.

Check the condition of the camshaft sensor connector (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, component code 746).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the sensor mounting and the conformity of the camshaft target.

Check that the camshaft sensor/camshaft sprocket air gap is 3 mm maximum.

Check the continuity of the following connections:

– Connection code 3PL between components 746 and 120.

– Connection code 3CQ between components 746 and 120.

Check for + 12 V after relay on connection 3FB of component 746.

If the connector(s) is/are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

– Check the tension of the timing belt.

– Check the conformity of the camshaft sprocket/camshaft assembly.

– Check the timing adjustment.

Carry out the necessary repairs.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 122 of 431

13B-122

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF151

STOREDMAIN RELAY CIRCUIT1.DEF: Relay cut off too soon

2.DEF: Relay cut off too late

NOTESSpecial notes:

The level 1 warning light is on.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

1.DEF

NOTESNone.

Check the condition of the injection feed relay mounting connector (see Wiring Diagram Technical Note, Mégane II

ph2, Scénic II ph2, component code 983).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the tightness and the condition of the "+ " and "-" battery terminals.

Check the conformity of the main relay (relay removed):

Insulation of the contacts between the following connections:

– Connection code 3FB of component 983.

– Connection codeBP37 of component983.

Resistance of the coil between the following connections:

– Connection code 3AA of component 983.

– Connection codeBP37 of component983.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Replace the relay if the resistance is less than 6 Ωor greater than 1 kΩ.

EDC16C36_V44_DF151M/EDC16C36_V4C_DF151M/EDC16C36_V48_DF151M/EDC16C36_V50_DF151M/EDC16C36_V54_DF151M/

EDC16C36_V58_DF151MEDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 123 of 431

13B-123

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF151

CONTINUED 1

Check for + 12 V battery on the following connection:

– Connection codeBP37 of component983.

Check for + 12 V after relay feed on the following connection:

– Connection code 3FB of component 983.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check the continuity and absence of any interference resistance on the following connection:

– Connection code 3AA between components 983 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check for + 12 V after relay feed on the following connections:

– Connection code 3FB of component 120.

– Connection code AP29 of component 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check the conformity of the engine management computer earths:

– Connection code NT of component 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check the conformity of fuse FM3 in the engine fuse and relay box (crimping and condition of wires on terminals).

Check the conformity of the impact sensor: incorrect contact (depending on equipment).

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the injection supply relay.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 124 of 431

13B-124

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF151

CONTINUED 2

2.DEFNOTESNone.

Check the condition of the injection supply relay mounting connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 983).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the conformity of the main relay (relay removed):

Insulation of the contacts between the following connections:

– Connection code 3FB of component 983.

– Connection code BP37 of component 983.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Resistance of the coil between the following connections:

– Connection code 3AA of component 983.

– Connection codeBP37 of component983.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Replace the relay if the resistance is less than 6 Ωor greater than 1 kΩ.

Check the continuity and absence of any interference resistance on the following connection:

– Connection code 3AA between components 983 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the injection supply relay.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 160 of 431

13B-160

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF293

CONTINUED

Make sure that there is no water in the diesel filter.

Bleed the diesel filter and the low and high pressure diesel circuits, if necessary (see MR 364 (Mégane) or 370

(Scénic), Mechanical, 13A, Fuel supply, and 13B, Diesel injection).

If the diesel filter contains a large amount of water, apply the first part of the Test 11: Diesel fuel conformity check

(Is the fuel cloudy or does it separate into 2 parts?)

Start the engine and wait at least 1 minute to confirm the repair.

If the fault was stored but not present, carry out a road test (see Note).

If the fault does not reappear, end of fault finding procedure.

Check the continuity, insulation and the absence of interference resistance of the following connection:

– Connection code 3WT between components 414 and 120.

Check the +12 V after relay feed of the water detection sensor:

– Connection code3FB of component414.

Check the earth of the water detection sensor:

– Connection code NT of component 414.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

– Start the engine and wait at least 1 minute to confirm the repair.

Check the conformity of the fuel used by running test 11 Diesel fuel conformity check.

If none of these checks reveal any faults:

– Replace the water detection sensor,

– clear the fault,

– start the engine and wait at least 1 minute to confirm the repair.

Note:

When the water level in the fuel filter unit is below the sensor's electrodes, some driving conditions (cornering,

gradients) may result in water being detected (in fact, the sensor's off-centre position in the fuel filter unit, combined

with the driving conditions, causes water to be detected).

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 182 of 431

13B-182

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF643

CONTINUED

Check the continuity and insulation against earth and against +12 V on the following connection:

– Connection code 3HI between components 1105 and 120.

Also check for + 12 V after relay feed on the pressure regulator connector.

– Connection code 3FB of component 1105.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Measure the resistance of the pressure regulator between the following connections:

– Connection code 3FB of component 1105.

– Connection code 3HI of component 1105.

If the resistance value of the regulator is not 3 ± 0.1 Ω at 20°C, replace the pressure regulator.

If the fault is still present, contact the Techline.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 198 of 431

13B-198

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF970

PRESENT

OR

STOREDRICHNESS RATIO SENSOR HEATING CIRCUITCC.0: Short circuit to earth

CC.1: Short-circuit on +12 volts.

CO: Open circuit

1.DEF: Internal electrical fault

2.DEF: Below minimum threshold

3.DEF: Above maximum threshold

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on,

– a road test,

– the relay is actuated by command AC231 Richness ratio sensor heating.

Special notes:

Use the bornier Elé. 1681 for all operations on the connectors of the injection

computer.

The richness ratio sensor is only present on certain F9Q818 engines. Check that the

vehicle is correctly equipped with this sensor.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF970/EDC16C36_V4C_DF970/EDC16C36_V48_DF970EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48

Page 203 of 431

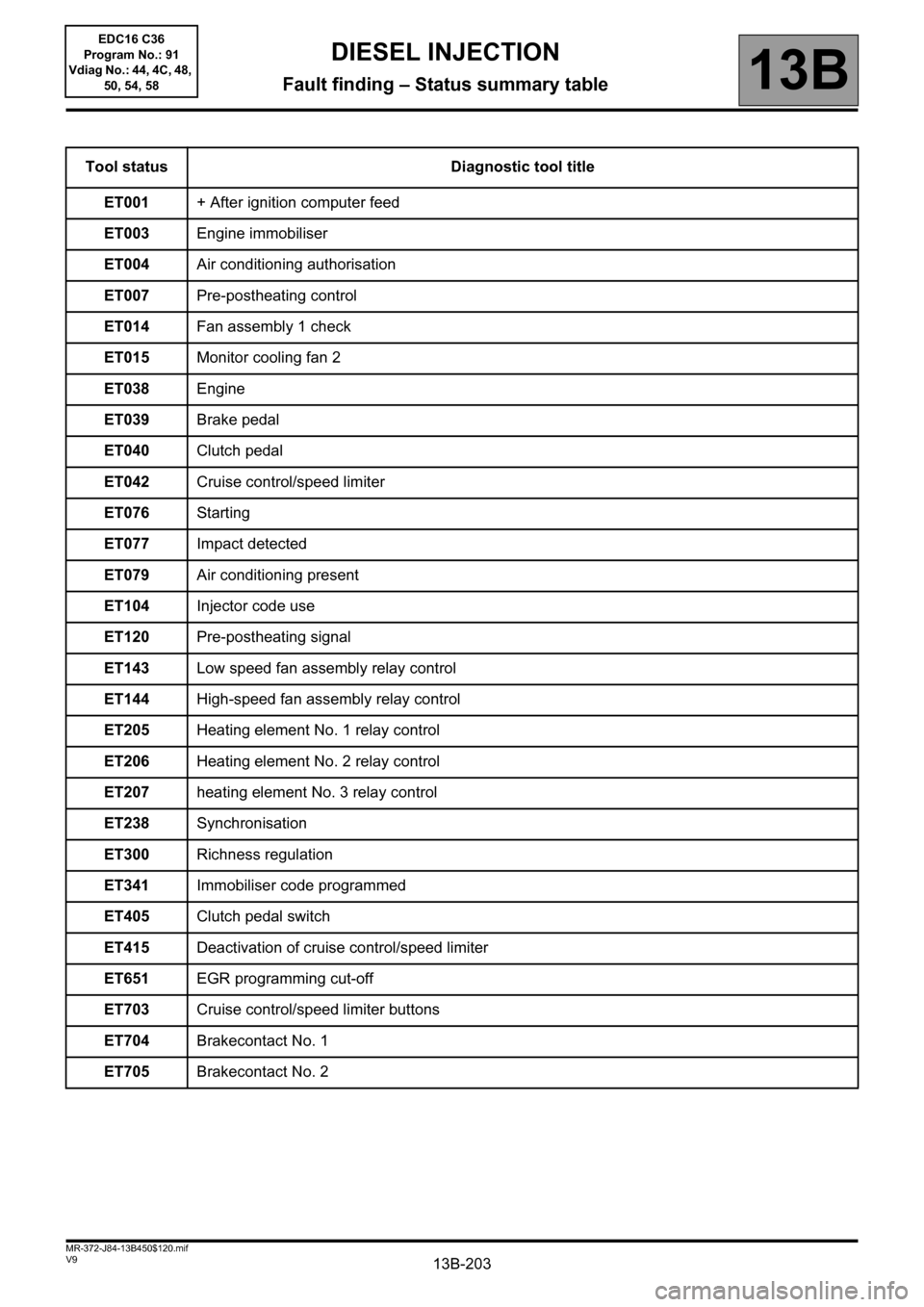

13B-203V9 MR-372-J84-13B450$120.mif

13B

Tool status Diagnostic tool title

ET001+ After ignition computer feed

ET003Engine immobiliser

ET004Air conditioning authorisation

ET007Pre-postheating control

ET014Fan assembly 1 check

ET015Monitor cooling fan 2

ET038Engine

ET039Brake pedal

ET040Clutch pedal

ET042Cruise control/speed limiter

ET076Starting

ET077Impact detected

ET079Air conditioning present

ET104Injector code use

ET120Pre-postheating signal

ET143Low speed fan assembly relay control

ET144High-speed fan assembly relay control

ET205Heating element No. 1 relay control

ET206Heating element No. 2 relay control

ET207heating element No. 3 relay control

ET238Synchronisation

ET300Richness regulation

ET341Immobiliser code programmed

ET405Clutch pedal switch

ET415Deactivation of cruise control/speed limiter

ET651EGR programming cut-off

ET703Cruise control/speed limiter buttons

ET704Brakecontact No. 1

ET705Brakecontact No. 2

DIESEL INJECTION

Fault finding – Status summary table

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 205 of 431

13B-205V9 MR-372-J84-13B450$131.mif

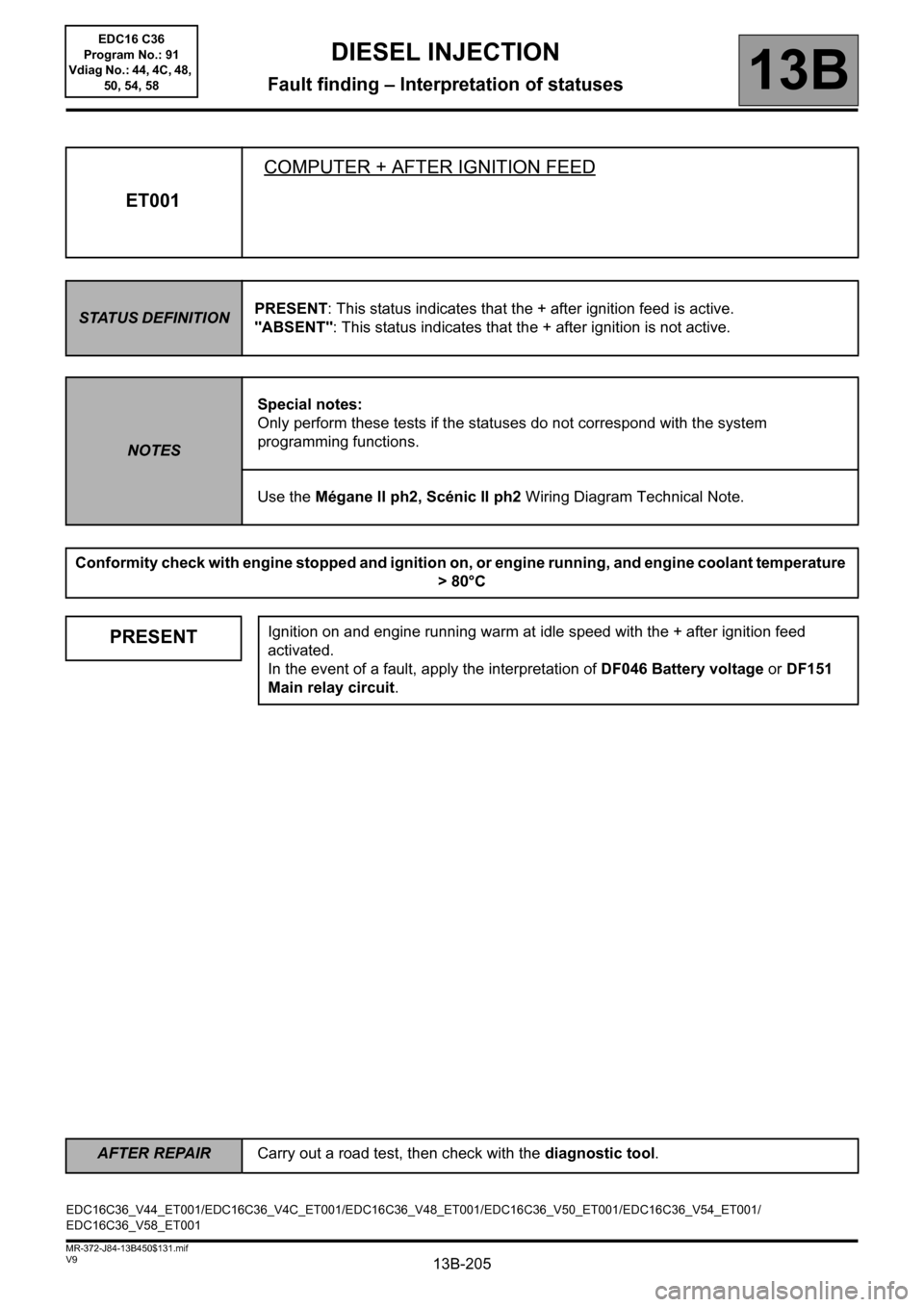

13B

ET001COMPUTER + AFTER IGNITION FEED

STATUS DEFINITIONPRESENT: This status indicates that the + after ignition feed is active.

"ABSENT": This status indicates that the + after ignition is not active.

NOTESSpecial notes:

Only perform these tests if the statuses do not correspond with the system

programming functions.

Use the Mégane II ph2, Scénic II ph2 Wiring Diagram Technical Note.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

> 80°C

PRESENTIgnition on and engine running warm at idle speed with the + after ignition feed

activated.

In the event of a fault, apply the interpretation of DF046 Battery voltage or DF151

Main relay circuit.

EDC16C36_V44_ET001/EDC16C36_V4C_ET001/EDC16C36_V48_ET001/EDC16C36_V50_ET001/EDC16C36_V54_ET001/

EDC16C36_V58_ET001

DIESEL INJECTION

Fault finding – Interpretation of statuses

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58