relay RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 287 of 431

13B-287

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V9 MR-372-J84-13B450$151.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

PR058

CONTINUED

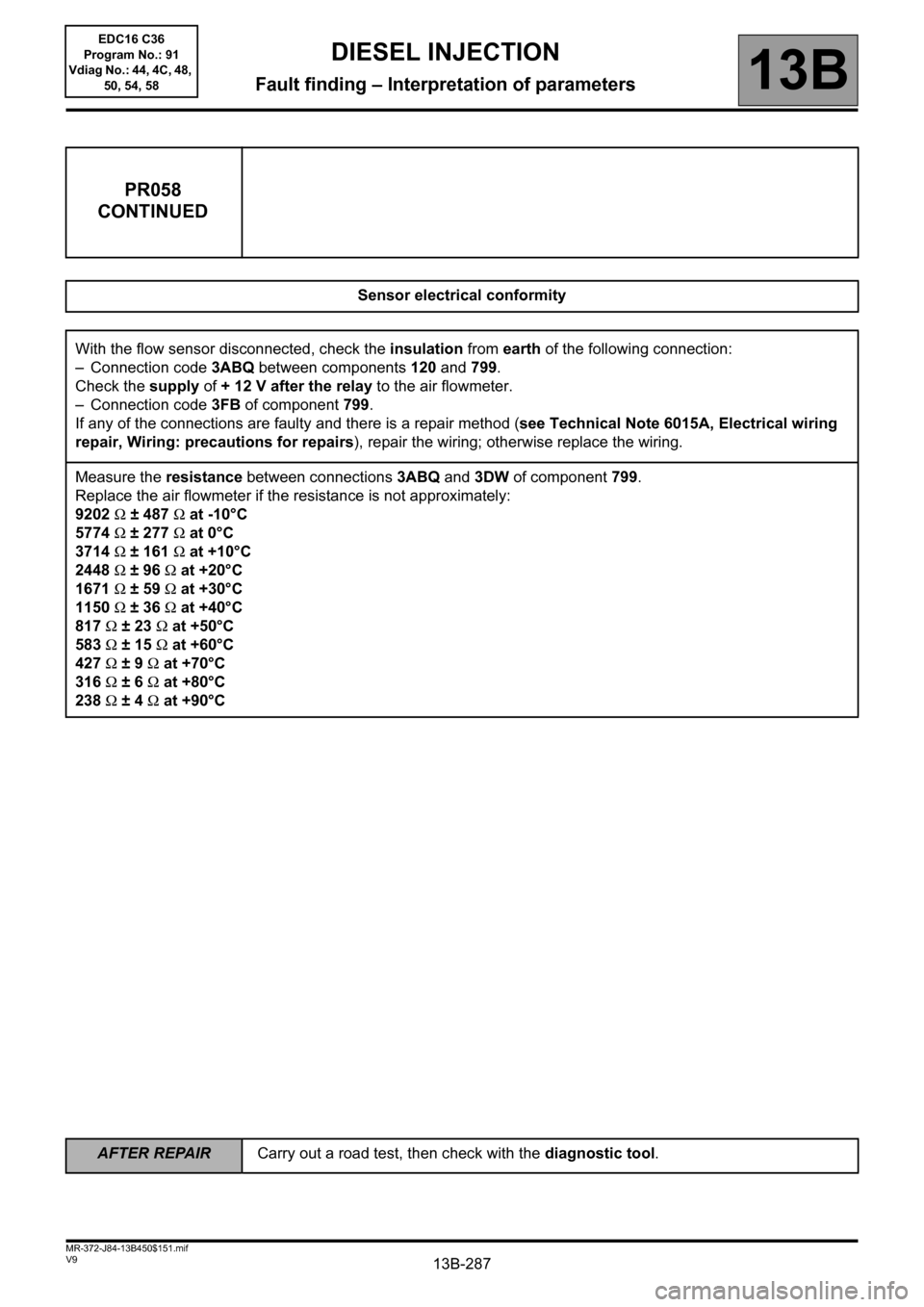

Sensor electrical conformity

With the flow sensor disconnected, check the insulation from earth of the following connection:

– Connection code 3ABQ between components 120 and 799.

Check the supply of + 12 V after the relay to the air flowmeter.

– Connection code 3FB of component 799.

If any of the connections are faulty and there is a repair method (see Technical Note 6015A, Electrical wiring

repair, Wiring: precautions for repairs), repair the wiring; otherwise replace the wiring.

Measure the resistance between connections 3ABQ and 3DW of component 799.

Replace the air flowmeter if the resistance is not approximately:

9202 Ω ± 487 Ω at -10°C

5774 Ω ± 277 Ω at 0°C

3714 Ω ± 161 Ω at +10°C

2448 Ω ± 96 Ω at +20°C

1671 Ω ± 59 Ω at +30°C

1150 Ω ± 36 Ω at +40°C

817 Ω ± 23 Ω at +50°C

583 Ω ± 15 Ω at +60°C

427 Ω ± 9 Ω at +70°C

316 Ω ± 6 Ω at +80°C

238 Ω ± 4 Ω at +90°C

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 309 of 431

13B-309V9 MR-372-J84-13B450$152.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

PR132

CONTINUED

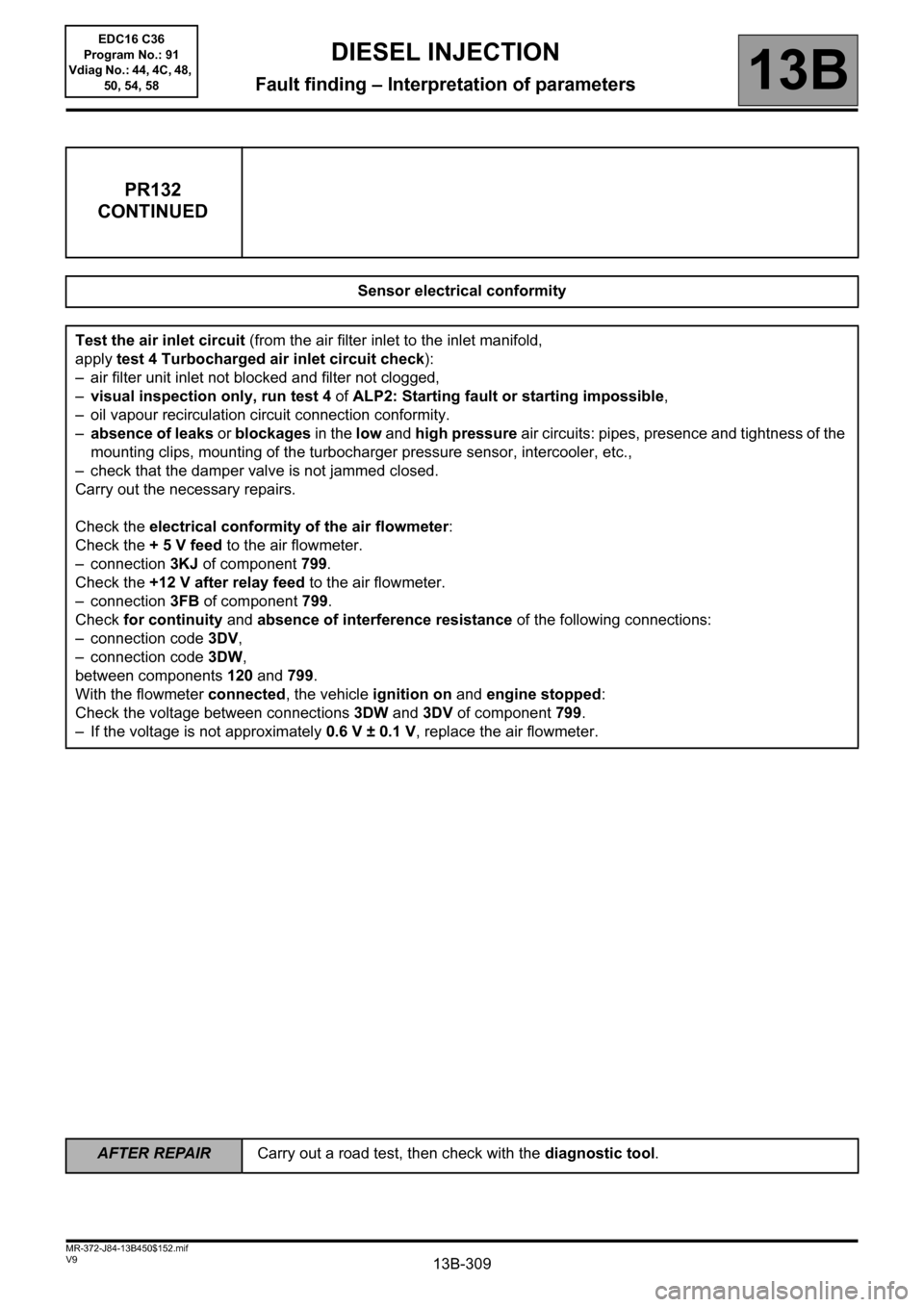

Sensor electrical conformity

Test the air inlet circuit (from the air filter inlet to the inlet manifold,

apply test 4 Turbocharged air inlet circuit check):

– air filter unit inlet not blocked and filter not clogged,

–visual inspection only, run test 4 of ALP2: Starting fault or starting impossible,

– oil vapour recirculation circuit connection conformity.

–absence of leaks or blockages in the low and high pressure air circuits: pipes, presence and tightness of the

mounting clips, mounting of the turbocharger pressure sensor, intercooler, etc.,

– check that the damper valve is not jammed closed.

Carry out the necessary repairs.

Check the electrical conformity of the air flowmeter:

Check the + 5 V feed to the air flowmeter.

– connection 3KJ of component 799.

Check the +12 V after relay feed to the air flowmeter.

– connection 3FB of component 799.

Check for continuity and absence of interference resistance of the following connections:

– connection code3DV,

– connection code3DW,

between components 120 and 799.

With the flowmeter connected, the vehicle ignition on and engine stopped:

Check the voltage between connections 3DW and 3DV of component 799.

– If the voltage is not approximately 0.6 V ± 0.1 V, replace the air flowmeter.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 350 of 431

13B-350V9 MR-372-J84-13B450$160.mif

13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

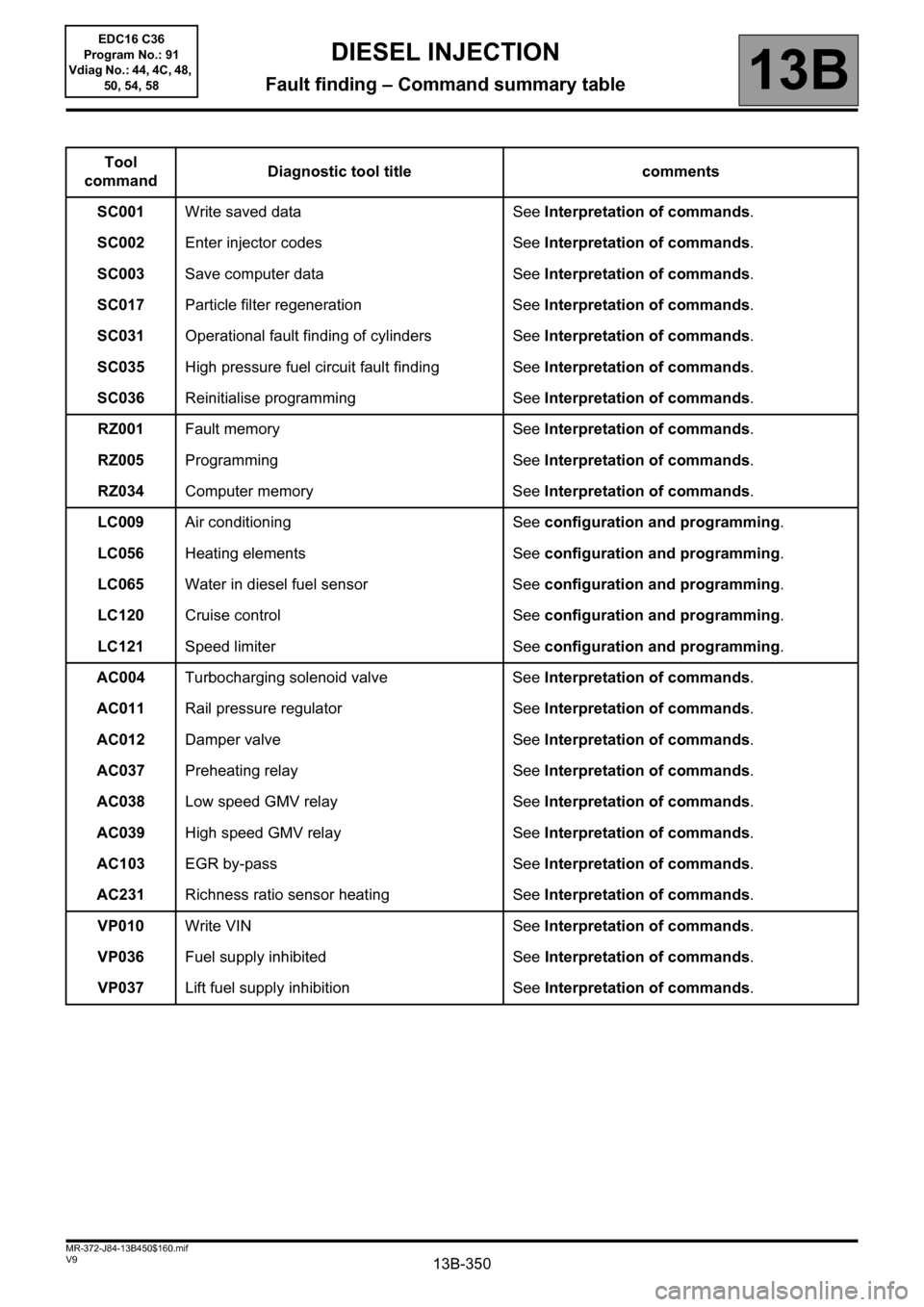

Tool

commandDiagnostic tool title comments

SC001Write saved data See Interpretation of commands.

SC002Enter injector codes See Interpretation of commands.

SC003Save computer data See Interpretation of commands.

SC017Particle filter regeneration See Interpretation of commands.

SC031Operational fault finding of cylinders See Interpretation of commands.

SC035High pressure fuel circuit fault finding See Interpretation of commands.

SC036Reinitialise programming See Interpretation of commands.

RZ001Fault memory See Interpretation of commands.

RZ005Programming See Interpretation of commands.

RZ034Computer memory See Interpretation of commands.

LC009Air conditioning See configuration and programming.

LC056Heating elements See configuration and programming.

LC065Water in diesel fuel sensor See configuration and programming.

LC120Cruise control See configuration and programming.

LC121Speed limiter See configuration and programming.

AC004Turbocharging solenoid valve See Interpretation of commands.

AC011Rail pressure regulator See Interpretation of commands.

AC012Damper valve See Interpretation of commands.

AC037Preheating relay See Interpretation of commands.

AC038Low speed GMV relay See Interpretation of commands.

AC039High speed GMV relay See Interpretation of commands.

AC103EGR by-pass See Interpretation of commands.

AC231Richness ratio sensor heating See Interpretation of commands.

VP010Write VIN See Interpretation of commands.

VP036Fuel supply inhibited See

Interpretation of commands.

VP037Lift fuel supply inhibition See Interpretation of commands.

DIESEL INJECTION

Fault finding – Command summary table

Page 372 of 431

13B-372

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC037PREHEATING RELAY

NOTESThis command is only run if fault DF025 Preheating unit diagnostic connection or

DF017 Preheating unit control circuit is present or stored and if no other fault is

present.

Ignition on and engine stopped.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Before applying the following fault finding procedure, check that the battery voltage is not below 12 V.

Otherwise, recharge the battery.

Check the connections on the preheating unit, heater plugs and injection computer.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Measure the resistance of the heater plugs. If this resistance is > 2 Ω, replace the defective plug(s).

Check the continuity and the absence of interference resistance on the following connections:

– Connection code 37AA between components257 and 681.

– Connection code 37AB between components 257 and 682.

– Connection code 37AC between components 257 and 683.

– Connection code 37AZ between components 257 and 680.

Check the condition of fuse FM12 (70 A) of the preheating unit supply. Replace it if necessary.

Then check for +12 V on connection BP35 of component 257.

Check the continuity, insulation, and the absence of interference resistance of the following connections:

– Connection code 3FF,

– Connection code 3FY,

Between components 257 and 120.

If the fault is still present, replace the pre-postheating unit.

EDC16C36_V44_AC037/EDC16C36_V4C_AC037/EDC16C36_V48_AC037/EDC16C36_V50_AC037/EDC16C36_V54_AC037/

EDC16C36_V58_AC037EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 373 of 431

13B-373

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

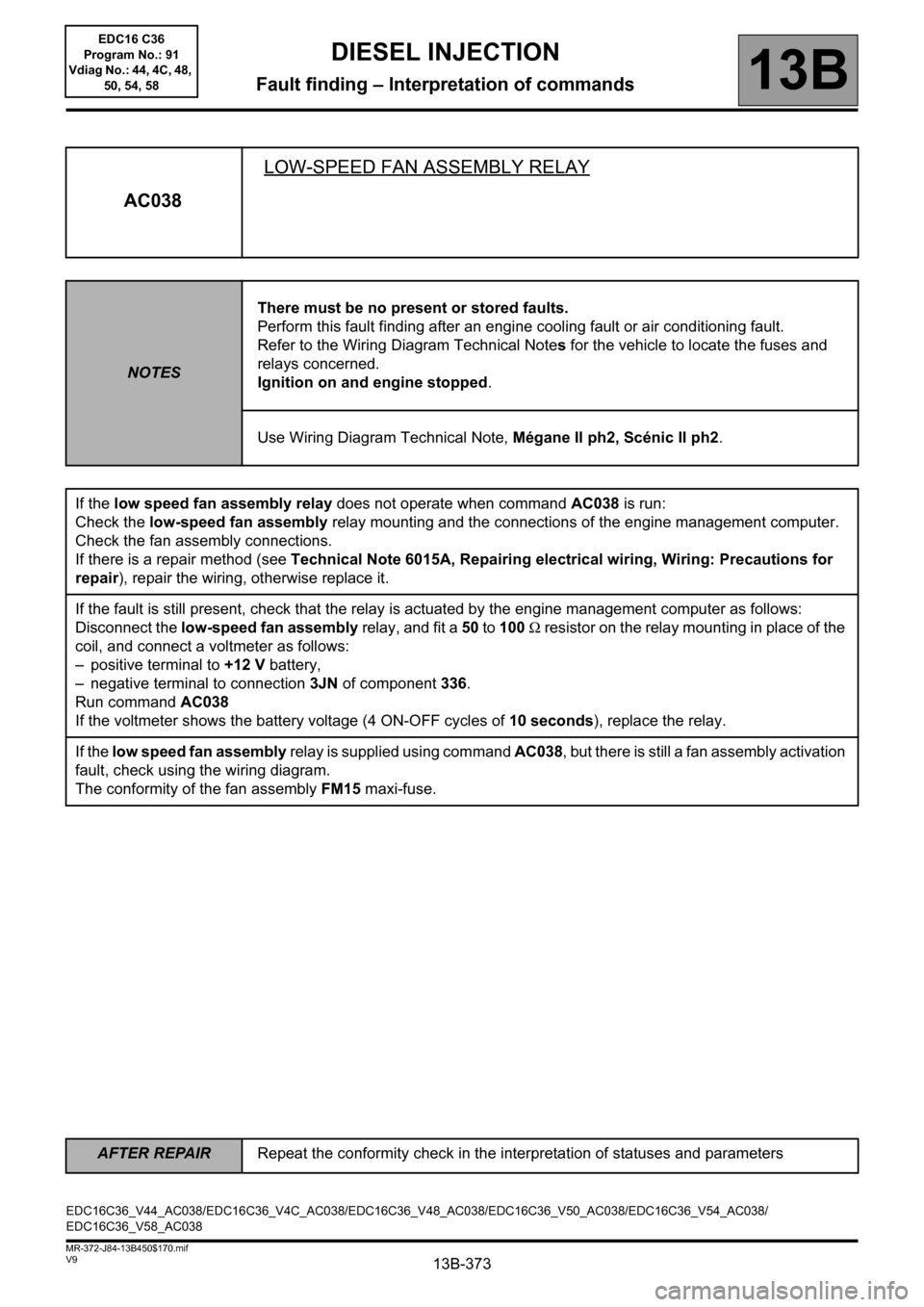

AC038LOW-SPEED FAN ASSEMBLY RELAY

NOTESThere must be no present or stored faults.

Perform this fault finding after an engine cooling fault or air conditioning fault.

Refer to the Wiring Diagram Technical Notes for the vehicle to locate the fuses and

relays concerned.

Ignition on and engine stopped.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

If the low speed fan assembly relay does not operate when command AC038 is run:

Check the low-speed fan assembly relay mounting and the connections of the engine management computer.

Check the fan assembly connections.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

If the fault is still present, check that the relay is actuated by the engine management computer as follows:

Disconnect the low-speed fan assembly relay, and fit a 50 to 100 Ω resistor on the relay mounting in place of the

coil, and connect a voltmeter as follows:

– positive terminal to +12 V battery,

– negative terminal to connection 3JN of component 336.

Run command AC038

If the voltmeter shows the battery voltage (4 ON-OFF cycles of 10 seconds), replace the relay.

If the low speed fan assembly relay is supplied using command AC038, but there is still a fan assembly activation

fault, check using the wiring diagram.

The conformity of the fan assembly FM15 maxi-fuse.

EDC16C36_V44_AC038/EDC16C36_V4C_AC038/EDC16C36_V48_AC038/EDC16C36_V50_AC038/EDC16C36_V54_AC038/

EDC16C36_V58_AC038EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 375 of 431

13B-375

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC039HIGH SPEED FAN ASSEMBLY

NOTESThere must be no present or stored faults:

Perform this fault finding after an engine cooling fault.

Refer to the Wiring Diagram Technical Notes for the vehicle to locate the fuses and

relays concerned.

Ignition on and engine stopped.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

If, when running command AC039, the high-speed fan assembly relay is not activated:

Check the high-speed fan assembly relay mounting and the connections of the engine management computer.

Check the fan assembly connections.

Repair if necessary.

If the fault is still present, check that the relay is actuated by the engine management computer as follows:

Disconnect the high speed fan assembly relay 335, fit a 50 to 100 Ω resistor on its mounting in place of the coil,

and connect a voltmeter as follows:

- positive terminal to +12 V battery,

- negative terminal to connection 3JP of component 335.

Run command AC039.

If the voltmeter shows the battery voltage (4 ON-OFF cycles of 10 seconds), replace the relay.

Disconnect the high speed fan assembly relay 337, fit a 50 to 100 Ω resistor on its mounting in place of the coil,

and connect a voltmeter as follows:

- positive terminal to +12 V battery,

- negative terminal to connection 3JP of component 337.

Run command AC039.

If the voltmeter shows the battery voltage (4 ON-OFF cycles of 10 seconds), replace the relay.

If the high-speed fan assembly relays are fed using command AC153, but there is still a fan activation fault, check

using the wiring diagram:

The conformity of the fan assembly FM15 maxi-fuse.

EDC16C36_V44_AC039/EDC16C36_V4C_AC039/EDC16C36_V48_AC039/EDC16C36_V50_AC039/EDC16C36_V54_AC039/

EDC16C36_V58_AC039EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 381 of 431

13B-381

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

13B

ALP1 No dialogue with engine management computer

STEP 1

Check the conformity of the vehicle type and the domain selected on the tool.

Check that the tool is not faulty by trying to establish dialogue with a computer on another vehicle.

Check the supply to the diagnostic socket:

+ Before ignition.

+ After ignition.

Earth.

Check (according to wiring diagram and equipment):

– The conformity of the after ignition fuse.

– The conformity of the injection relay mounting.

The conformity of the injection relay:

65 Ω ± 5 between the following connections:

– Connection code BP37 of component 983.

– Connection code 3AA of component 983.

infinite resistance between connections (open contact):

– Connection code BP37 of component 983.

– Connection code 3FB of component 983.

resistance < 0.2 Ω between the following connections (contact closed):

– Connection code BP37 of component 983.

– Connection code3FB of component983.

Disconnect the engine management computer and check that there are no conducting parts on the computer

studs. If this reveals any kind of impurity, rectify it and try to establish dialogue.

If the fault is still present, place the bornier Elé. 1681 on the engine harness:

Check for continuity and absence of interference resistance on the following multiplex connections:

– Connection code 133B between components 120 and 225.

– Connection code 133C between components 120 and 225.

Check for + 12 V on connections 3FB and AP29 of component 120.

Check for earth on connections NT of component 120.

A

EDC16C36_V44_ALP01/EDC16C36_V4C_ALP01/EDC16C36_V48_ALP01/EDC16C36_V50_ALP01/EDC16C36_V54_ALP01/

EDC16C36_V58_ALP01

DIESEL INJECTION

Fault finding – Fault Finding Chart

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 382 of 431

13B-382

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP1

CONTINUED

If there is no + 12 V, carry out the following operations:

Shunt the normally open contact of the central injection unit supply relay, i.e. connections BP37 and 3FB of

component 983.

Check for + 12 V on connections 3FB and AP29 of component 120.

Check the continuity of the connection between:

– Connection code 3AA between components 120 and 983.

Try to establish dialogue with another computer on the same vehicle.

If dialogue is established with another computer on the same vehicle, go to step 2.

If dialogue cannot be established with any other computer on the same vehicle (see 88B, Multiplexing, ALP).

STEP 2

Contact the Techline.

A

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 384 of 431

13B-384

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP2

CONTINUED 1

Test the high pressure fuel circuit:

Run the scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

Check that the heater plugs are actuated using the AC037 Preheating relay command.

Check the tightness and the condition of the inlet circuit: run test 4: Turbocharged air inlet circuit check and

follow the procedure.

Check that the exhaust is not blocked, run test 1 Exhaust system check and follow the procedure.

Check the consistency of the signal from the engine coolant temperature sensor.

Check the operation of the rail pressure regulator (DRV) using command AC011 Rail pressure regulator.

Check the timing setting.

End of part A

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58