filter RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 175 of 431

13B-175

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

* diff: differential

DF315

PRESENT

OR

STOREDPARTICLE FILTER DIFF* PRESSURE SENSOR

CO: Open circuit

CC.1: Open circuit or short-circuit on + 12 volts

C0.0: Open circuit or short circuit to earth

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault is present:

–the level 1 warning light is lit,

–the OBD warning light will come on after three consecutive driving cycles (start

+ 5 seconds + switch off the ignition switched and wait 1 minute),

– the particle filter fault finding procedure is inhibited,

– particle filter regeneration is inhibited.

Priorities when dealing with a number of faults:

– DF315 if it is present.

– DF308 "Particle filter clogged" if DF315 is stored and DF308 is present.

– DF011 Sensor supply voltage no. 1 if it is present or stored.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V48_DF315/EDC16C36_V50_DF315/EDC16C36_V58_DF315EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 177 of 431

13B-177

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF315

CONTINUED 2

CO.0

CONOTESNone.

Check the condition of the connector of the differential pressure sensor (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, Component code 1290).

Check the condition of the connector of the engine management computer (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, Component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity and insulation to earth of the following connections:

– connection code3TL,

– connection code3TM,

between components 120 and 1290.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

• 3XU between components 120 and 1288,

• 3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the differential pressure sensor.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 178 of 431

13B-178

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

* diff: differential

DF316

PRESENT

OR

STOREDPARTICLE FILTER DIFF* PRESSURE

1.DEF: Signal incoherent

2.DEF: Below minimum threshold

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on.

– the engine is started.

Special notes:

If the fault is present:

– the particle filter fault finding procedure is inhibited,

–the Level 1 and OBD warning lights are lit.

Use bornier Ele. 1681 for all operations on the engine management computer

connector.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Check the condition of the pressure pipes on the differential pressure sensor.

Check that they are sealed and in the correct position.

Replace if necessary.

Check the condition of the connectors on the differential pressure sensor and the injection computer.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check the continuity, insulation and the absence of interference resistance on the following connections:

– Connection code3AAQ,

– Connection code3TM,

– Connection code 3TL,

between components 1290 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

EDC16C36_V48_DF316/EDC16C36_V50_DF316/EDC16C36_V58_DF316EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 185 of 431

13B-185

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF652

PRESENT

OR

STOREDTURBINE UPSTREAM TEMPERATURE SENSOR CIRCUIT

CC.O: Short circuit to earth

CO.1: Open circuit or short-circuit on +12 V.

NOTESConditions for applying fault finding procedures to stored faults:

The fault becomes present with the ignition on (CC.0) or after a road test, with the

engine warm (CO.1).

Special notes:

If the fault is present:

– particle filter regeneration is inhibited,

– the vehicle performance is reduced,

– temperature regulation before the particle filter is inhibited.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

CC.0

NOTESNone.

Check the condition of the turbine upstream temperature sensor connector.

Check the condition of the engine management computer connector.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation from earth of the following connections:

– connection code 3ABS,

– connection code3ABT,

between components 120 and 1589.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the turbine upstream temperature sensor.

EDC16C36_V48_DF652/EDC16C36_V50_DF652/EDC16C36_V58_DF652EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 189 of 431

13B-189

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF890

PRESENT

OR

STOREDMOVEMENT DURING REGENERATION PRESSURE SENSOR

NOTESConditions for applying fault finding procedures to stored faults:

The fault becomes present during an After-Sales regeneration carried out using the

diagnostic tool at a speed above zero.

Special notes:

If the fault is present:

– regeneration in progress is stopped.

IMPORTANT

The fault is present because the vehicle was driven while the After-Sales regeneration was in progress.

The vehicle must remain stationary throughout regeneration.

DO NOT DRIVE THE VEHICLE DURING AFTER-SALES REGENERATION.

CHECK THAT THE VEHICLE IS CORRECTLY IMMOBILISED.

– switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes): Communication

lost with computer: EDC16C36, check the tool connection and computer supply.

– switch on the ignition,

– establish dialogue with the injection computer,

– clear the faults from the computer memory.

Check that there are no leaks or blockages in the exhaust pipe,

– Repair if necessary

– carry out another After-Sales regeneration,

– run command SC017 Particle filter regeneration and follow the procedure (see Interpretation of commands).

If the fault is still present, contact the Techline.

EDC16C36_V48_DF890/EDC16C36_V50_DF890/EDC16C36_V58_DF890EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 194 of 431

13B-194

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF899

PRESENT

OR

STOREDREGENERATION TEMPERATURE LIMIT EXCEEDED

1.DEF: Above maximum threshold

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present during an After-Sales regeneration, if the temperature

threshold is exceeded.

Special notes:

If the fault is present:

– regeneration in progress is stopped.

Carry out particle filter replacement:

– Switch on the ignition.

– establish dialogue with the injection computer,

– run command SC036 Reinitialise programming,

–select After particle filter replacement as the operation type, then follow the instructions given by the

diagnostic tool,

–switch off the ignition,

– wait for the diagnostic tool message (maximum time 8 minutes) Communication lost with computer:

EDC16C36, check the tool connection and the computer supply before switching the ignition back on,

– clear the faults from the computer memory (this operation must be carried out within 3 minutes of the ignition

being switched on).

– Check the weight of soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply the procedure of test 12 Manual clearing of the weight of soot.

If the fault is still present, contact the Techline.

EDC16C36_V48_DF899/EDC16C36_V50_DF899/EDC16C36_V58_DF899EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 195 of 431

13B-195

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

* diff: differential

DF953

PRESENT

OR

STOREDPARTICLE FILTER ABSENT

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault is present:

– particle filter regeneration is inhibited,

– blue/white smoke and black particles coming from the exhaust,

the OBD warning light will illuminate after three consecutive driving cycles (start + 5

seconds, switch off the ignition and wait 40 seconds).

Priorities when dealing with a number of faults:

– DF315 Particle filter diff.* pressure sensor if present or stored

IMPORTANT

In the long term, this fault may lead to premature wear and a greater risk of

turbocharger failure.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V48_DF953/EDC16C36_V50_DF953/EDC16C36_V58_DF953EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 196 of 431

13B-196

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF953

CONTINUED

Check the status of the differential pressure sensor connector and engine management computer.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the particle filter is present.

If it is present,

Visually check that the particle filter is in good condition by positioning the vehicle on a lift:

– not damaged (no abnormal welds, if necessary compare it with another vehicle fitted with particle filter),

– if there are After-Sales sleeves, as a result of a previous operation, check that the particle filter's contents were

not emptied out when it was removed.

If the particle filter is not in good condition or is absent:

– Replace the particle filter.

– Switch on the ignition.

– establish dialogue with the injection computer,

– run command SC036 Reinitialise programming,

–select After particle filter replacement as the operation type, then follow the instructions given by the

diagnostic tool,

– switch off the ignition,

– wait for the diagnostic tool message (maximum time 8 minutes): Communication lost with computer:

EDC16C36, check the tool connection and computer supply before switching the ignition back on.

– clear the faults from the computer memory (this operation must be carried out within 3 minutes of the ignition

being switched on).

– Check the weight of soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply the procedure of test 12 Manual clearing of the weight of soot.

If the fault is still present, contact the Techline.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 201 of 431

13B-201

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

*ADAC: Trip Computer

DF1020

PRESENT

OR

STOREDENGINE OIL DILUTION

1. DEF: Above maximum threshold

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the engine is started.

– a road test.

Special notes:

If the fault is present:

– particle filter regeneration is inhibited.

Use bornier Elé. 1681 for any operations on the injection computer connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Note:

This fault is activated in case of considerable oil dilution due to a significant number of particle filter regenerations.

Carry out the following:

– An oil change (see MR 364 (Mégane II) or MR 370 (Scénic II), Mechanical, 10A Engine and peripherals,

Engine oil: Draining – Filling),

– reset the oil wear meter,

– clear the faults.

Reset the oil wear meter after the oil change:

It will be necessary to reinitialise the display of the trip computer.

With the ignition on:

– hold down the TC* button for 5 s.

Re-initialisation has worked when the on-board computer no longer displays the key.

If this is not the case, restart the procedure.

Specific case:

If an oil change is performed before the oil service interval warning is exceeded, reinitialise the display.

EDC16C36_V50_DF1020/EDC16C36_V58_DF1020EDC16 C36

Program No.: 91

Vdiag No.: 50, 58

Page 234 of 431

13B-234V9 MR-372-J84-13B450$131.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

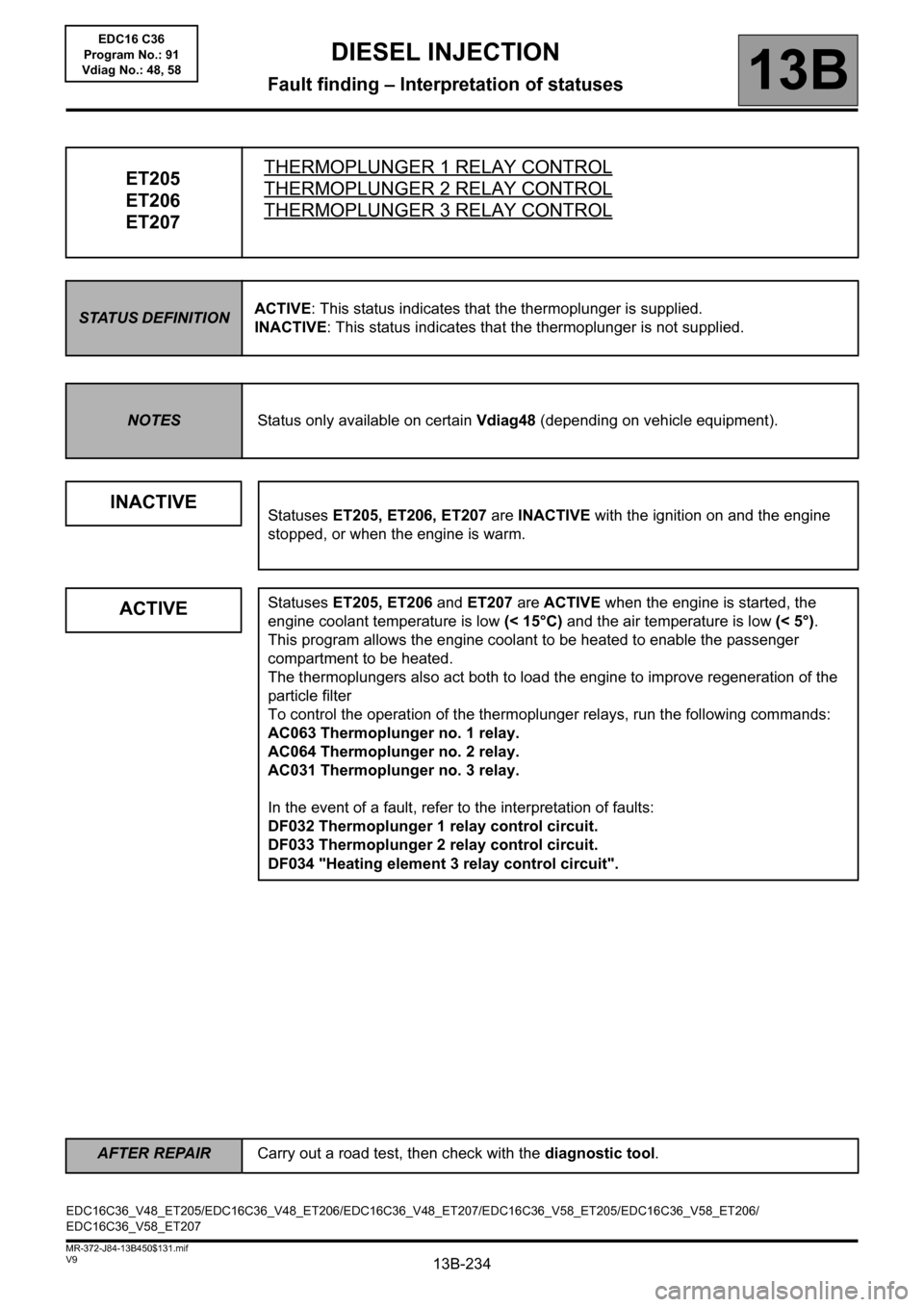

ET205

ET206

ET207THERMOPLUNGER 1 RELAY CONTROLTHERMOPLUNGER 2 RELAY CONTROL

THERMOPLUNGER 3 RELAY CONTROL

STATUS DEFINITIONACTIVE: This status indicates that the thermoplunger is supplied.

INACTIVE: This status indicates that the thermoplunger is not supplied.

NOTESStatus only available on certain Vdiag48 (depending on vehicle equipment).

INACTIVEStatuses ET205, ET206, ET207 are INACTIVE with the ignition on and the engine

stopped, or when the engine is warm.

ACTIVEStatuses ET205, ET206 and ET207 are ACTIVE when the engine is started, the

engine coolant temperature is low (< 15°C) and the air temperature is low (< 5°).

This program allows the engine coolant to be heated to enable the passenger

compartment to be heated.

The thermoplungers also act both to load the engine to improve regeneration of the

particle filter

To control the operation of the thermoplunger relays, run the following commands:

AC063 Thermoplunger no. 1 relay.

AC064 Thermoplunger no. 2 relay.

AC031 Thermoplunger no. 3 relay.

In the event of a fault, refer to the interpretation of faults:

DF032 Thermoplunger 1 relay control circuit.

DF033 Thermoplunger 2 relay control circuit.

DF034 "Heating element 3 relay control circuit".

EDC16C36_V48_ET205/EDC16C36_V48_ET206/EDC16C36_V48_ET207/EDC16C36_V58_ET205/EDC16C36_V58_ET206/

EDC16C36_V58_ET207

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 58