warning RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Manual PDF

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 343 of 431

13B-343V9 MR-372-J84-13B450$152.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

*reg: regeneration

PR816

PR817

PR818

PR819

PR820

PR821

PR822

PR823

PR824

PR825REGENERATION START RECORD NO. 1

REGENERATION START RECORD NO. 2

REGENERATION START RECORD NO. 3

REGENERATION START RECORD NO. 4

REGENERATION START RECORD NO. 5

REGENERATION START RECORD NO. 6

REGENERATION START RECORD NO. 7

REGENERATION START RECORD NO. 8

REGENERATION START RECORD NO. 9

REGENERATION START RECORD NO. 10

PARAMETER

DEFINITIONThese parameters are shown in Km.

NOTESSpecial notes:

For Vdiag48:

These parameters must only be interpreted using ALP11 Particle filter warning light

comes on too often.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

> 80°C, without electrical consumers

These parameters are used so that the history of the last ten regeneration starts when driving can be found.

EDC16C36_V48_PR816/EDC16C36_V48_PR817/EDC16C36_V48_PR818/EDC16C36_V48_PR819/EDC16C36_V48_PR820/

EDC16C36_V48_PR821/EDC16C36_V48_PR822/EDC16C36_V48_PR823/EDC16C36_V48_PR824/EDC16C36_V48_PR825/

EDC16C36_V50_PR816/EDC16C36_V50_PR817/EDC16C36_V50_PR818/EDC16C36_V50_PR819/EDC16C36_V50_PR820/

EDC16C36_V50_PR821/EDC16C36_V50_PR822/EDC16C36_V50_PR823/EDC16C36_V50_PR824/EDC16C36_V50_PR825/

EDC16C36_V58_PR816/EDC16C36_V58_PR817/EDC16C36_V58_PR818/EDC16C36_V58_PR819/EDC16C36_V58_PR820/

EDC16C36_V58_PR821/EDC16C36_V58_PR822/EDC16C36_V58_PR823/EDC16C36_V58_PR824/EDC16C36_V58_PR825

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 352 of 431

13B-352

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC002ENTER INJECTOR CODES

NOTESThis command is run after replacing the injectors and only if the vehicle is IMA

configured (ET104 Injector code use is YES).

If this command is not run, fault DF276 Injector code programming will be present.

Ignition on and engine stopped.

WARNING

The letters J and Q, and figures 0 and 9 are not used in IMA coding.

If these characters are used the entry will be invalid.

Cylinder no. 1 is the cylinder located at the engine flywheel end.

Procedure to be followed:

– Read the 7-character alphanumeric codes engraved on the upper section of the injector body.

– Use command SC002.

– Select the cylinder number concerned in the Desired column, then confirm.

– Enter the injector code noted for the cylinder.

– Enter the new codes for each cylinder, then confirm.

– When the command is completed, the modified codes appear in the Current column.

– Check that the codes correspond to those read earlier.

– If the codes entered appear in neither the Current column nor the Desired column, check the conformity of the

codes read, and make sure the data has been entered correctly.

The possible confusions are:

the figure "1" with the letter "I" and "L",

the figure "2" with the letter "Z",

the figure "5" with the letter "S",

the figure "6" with the letter "G",

the figure "8" with the letter "B".

– Exit fault finding mode.

– Switch off the ignition and wait for the diagnostic tool message (maximum time 8minutes) Communication

lost with computer: EDC16 C36, check the tool connection and computer power supply before switching

the ignition back on.

– Switch the ignition back on and check for faults.

–DF276 Injector code programming should be stored.

EDC16C36_V44_SC002/EDC16C36_V4C_SC002/EDC16C36_V48_SC002/EDC16C36_V50_SC002/EDC16C36_V54_SC002/

EDC16C36_V58_SC002EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 355 of 431

13B-355

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC017PARTICLE FILTER REGENERATION

NOTESOnly run this command after interpretation of the following faults:

– DF308 Clogged particle filter,

– DF311 Failed regenerations limit exceeded,

– DF312 Speed request.

WARNING

It is essential to observe the health and safety regulations (see MR364 (Megane II ph2), MR370 (Scenic II

ph2), Mechanical, 19B, Exhaust, Particle filter: Cleaning) and observe the following procedure.

SAFETY INSTRUCTIONS TO BE FOLLOWED:

The regeneration causes exhaust fumes and high temperatures.

The vehicle must be outside during regeneration.

If it is not possible to carry out regeneration outside, use an extractor fan that can withstand the very high

regeneration temperatures (400°C at the exhaust outlet).

Perform regeneration on a surface free from fire risks (oil, dry leaves, etc.). Nothing should be left in the vicinity

of the exhaust pipe.

IMPORTANT

– Check the engine oil level before running the command to avoid any engine racing. The oil level must

be between the minimum threshold and the middle level on the oil dipstick.

– Before performing a particle filter regeneration, it is essential to deactivate the air conditioning

compressor (risk of engine damage) and all the electrical consumers.

IF NECESSARY:

Regeneration can be stopped by briefly pressing the vehicle start button twice (less than 3 seconds).

Switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes) Communication lost

with computer: EDC16C36, check the tool connection and the computer supply. before switching on the

ignition again.

PROCEDURE TO BE FOLLOWED:

Before a particle filter regeneration, check that there are no leaks or blockages in the exhaust pipe,

Repair if necessary

To run this command, select the command mode on the diagnostic tool, and select command SC017 Particle

filter regeneration.

When regeneration is complete, a message will indicate whether regeneration was successful, and what

operations need to be carried out (filter replacement, whether an oil service is required, etc.).

EDC16C36_V48_SC017/EDC16C36_V50_SC017/EDC16C36_V58_SC017EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 378 of 431

13B-378

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

VP036INHIBIT FUEL SUPPLY

NOTESThis command enables you to disable the supply to the injectors.

This command is carried out with the engine switched off, and ignition on.

This command allows the injectors to be locked, so that starting is not possible.

Command VP036 allows the engine compressions to be checked in complete safety without disconnecting the

injector connectors or the TDC sensor.

Procedure to follow: (cylinder no. 1 is located on the flywheel end).

– Remove all the heater plugs, connect the compression gauge.

– Position the gear lever in neutral (manual gearbox) or on position P (automatic gearbox).

– Depress the brake pedal and maintain this position.

– Activate command VP036.

– Try to start the vehicle.

– Check the engine compressions.

Start the procedure again on another cylinder.

WARNING

Keep the brake pedal depressed for the length of the test.

Re-establish control of the injectors using command VP037 Stop fuel supply inhibition.

EDC16C36_V44_VP036/EDC16C36_V4C_VP036/EDC16C36_V48_VP036/EDC16C36_V50_VP036/EDC16C36_V54_VP036/

EDC16C36_V58_VP036EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 380 of 431

13B-380V9 MR-372-J84-13B450$180.mif

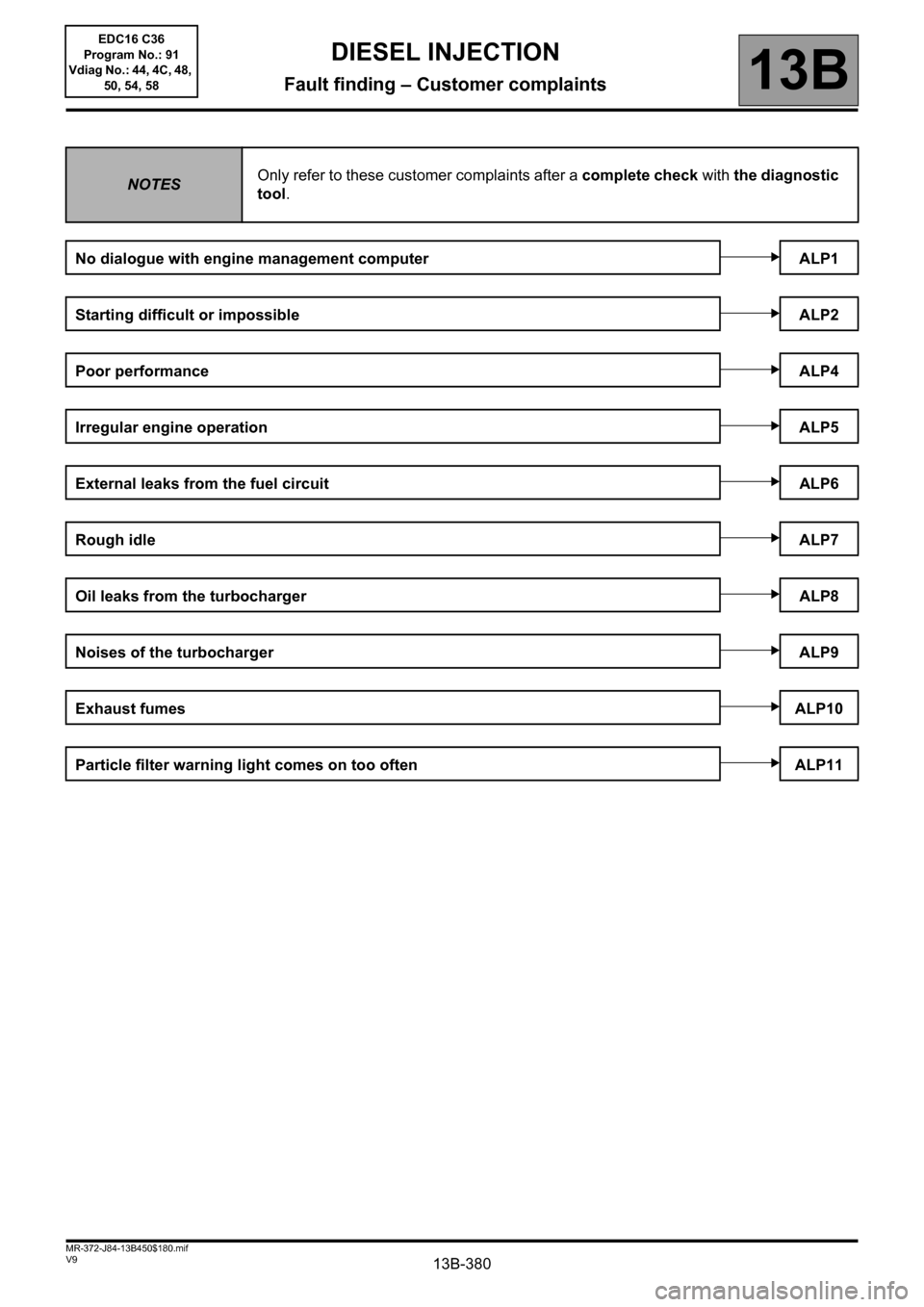

13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

NOTESOnly refer to these customer complaints after a complete check with the diagnostic

tool.

No dialogue with engine management computer ALP1

Starting difficult or impossibleALP2

Poor performanceALP4

Irregular engine operationALP5

External leaks from the fuel circuit ALP6

Rough idleALP7

Oil leaks from the turbocharger ALP8

Noises of the turbochargerALP9

Exhaust fumesALP10

Particle filter warning light comes on too often ALP11

DIESEL INJECTION

Fault finding – Customer complaints

Page 385 of 431

13B-385

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

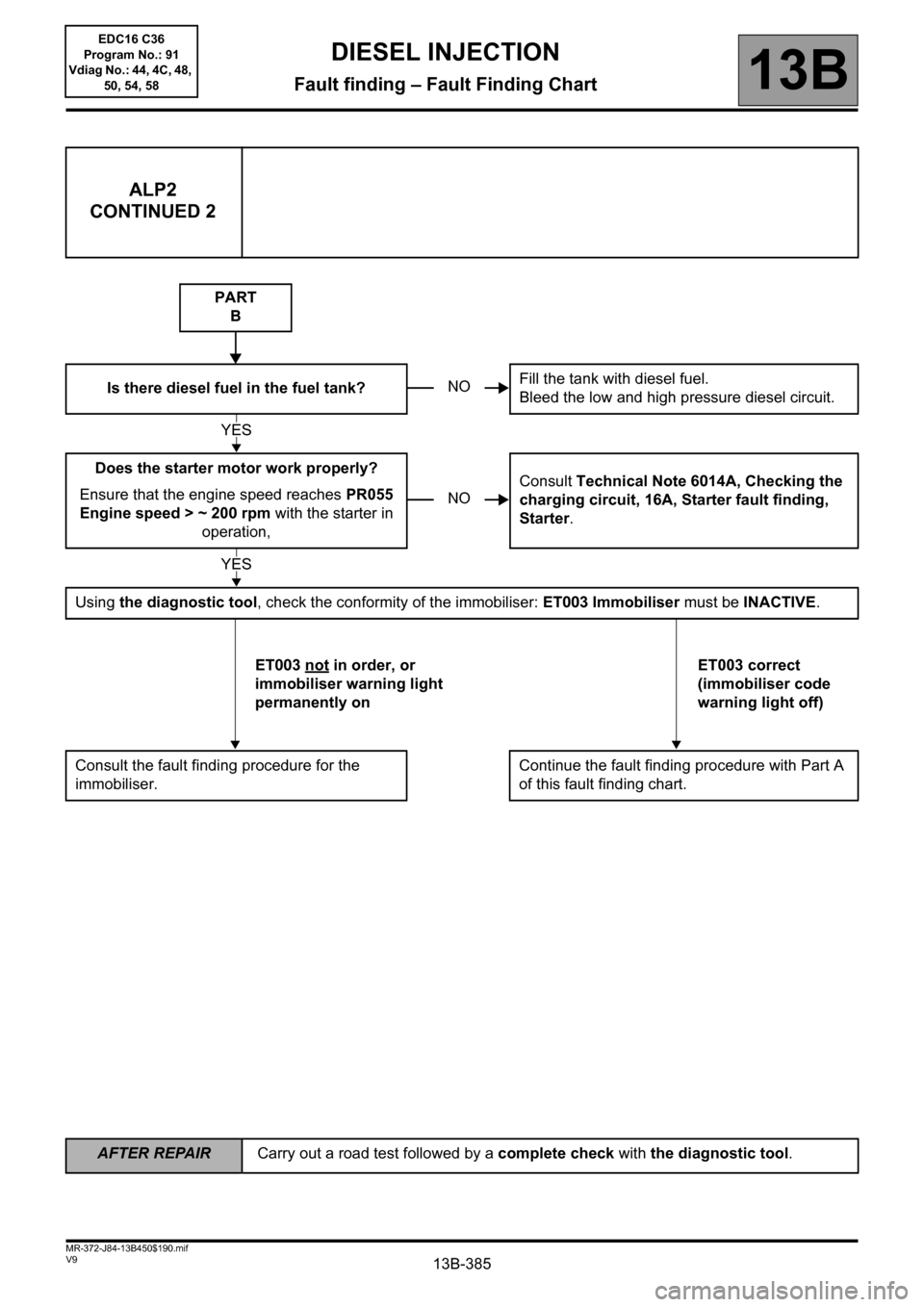

ALP2

CONTINUED 2

Is there diesel fuel in the fuel tank?Fill the tank with diesel fuel.

Bleed the low and high pressure diesel circuit.

Does the starter motor work properly?

Ensure that the engine speed reaches PR055

Engine speed > ~ 200 rpm with the starter in

operation, Consult Technical Note 6014A, Checking the

charging circuit, 16A, Starter fault finding,

Starter.

Using the diagnostic tool, check the conformity of the immobiliser: ET003 Immobiliser must be INACTIVE.

ET003 not

in order, or

immobiliser warning light

permanently onET003 correct

(immobiliser code

warning light off)

Consult the fault finding procedure for the

immobiliser.Continue the fault finding procedure with Part A

of this fault finding chart.

PART

B

NO

YES

NO

YES

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 386 of 431

13B-386

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

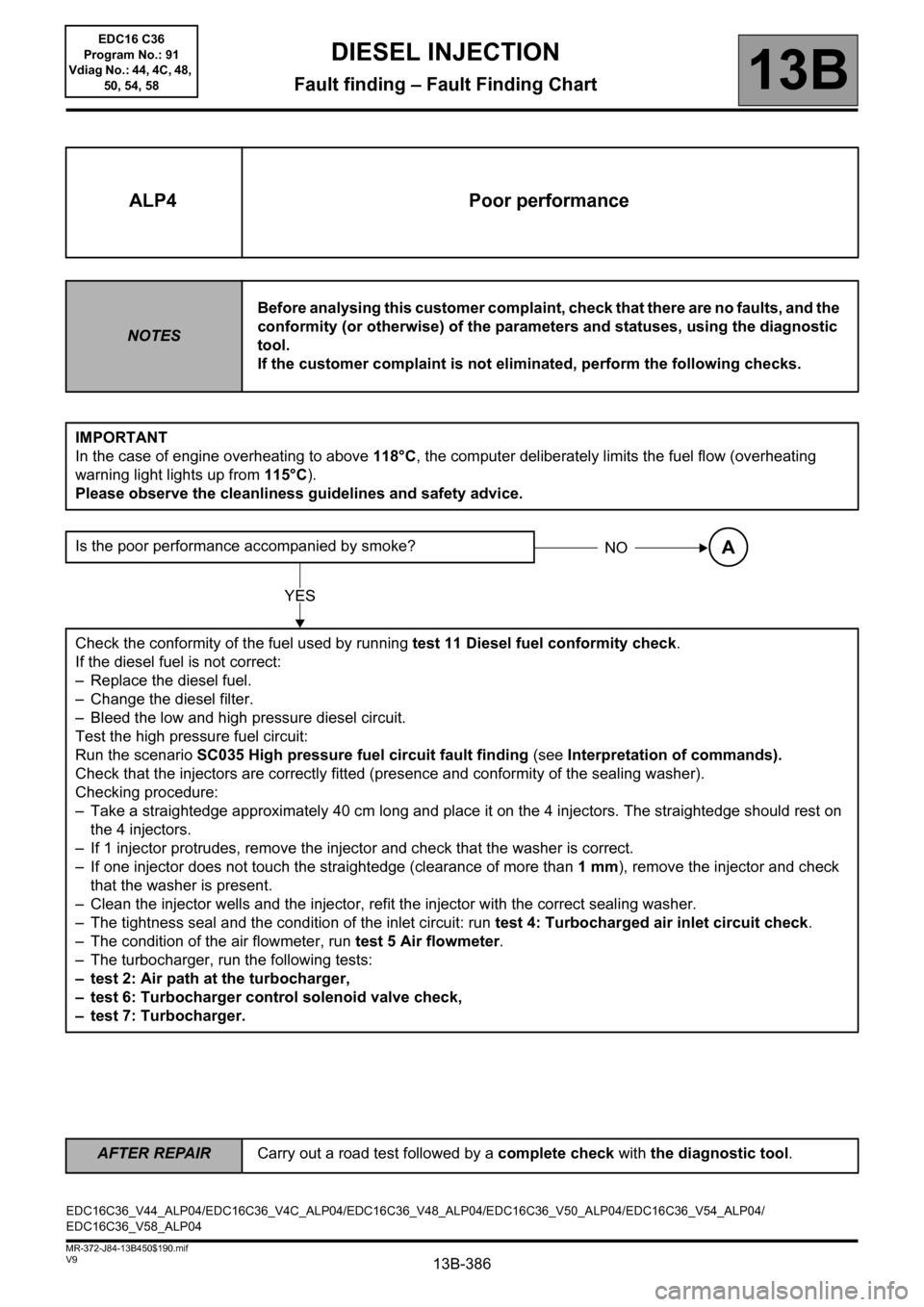

ALP4 Poor performance

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT

In the case of engine overheating to above 118°C, the computer deliberately limits the fuel flow (overheating

warning light lights up from 115°C).

Please observe the cleanliness guidelines and safety advice.

Is the poor performance accompanied by smoke?

Check the conformity of the fuel used by running test 11 Diesel fuel conformity check.

If the diesel fuel is not correct:

– Replace the diesel fuel.

– Change the diesel filter.

– Bleed the low and high pressure diesel circuit.

Test the high pressure fuel circuit:

Run the scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

Check that the injectors are correctly fitted (presence and conformity of the sealing washer).

Checking procedure:

– Take a straightedge approximately 40 cm long and place it on the 4 injectors. The straightedge should rest on

the 4 injectors.

– If 1 injector protrudes, remove the injector and check that the washer is correct.

– If one injector does not touch the straightedge (clearance of more than 1 mm), remove the injector and check

that the washer is present.

– Clean the injector wells and the injector, refit the injector with the correct sealing washer.

– The tightness seal and the condition of the inlet circuit: run test 4: Turbocharged air inlet circuit check.

– The condition of the air flowmeter, run test 5 Air flowmeter.

– The turbocharger, run the following tests:

– test 2: Air path at the turbocharger,

– test 6: Turbocharger control solenoid valve check,

– test 7: Turbocharger.

NOA

YES

EDC16C36_V44_ALP04/EDC16C36_V4C_ALP04/EDC16C36_V48_ALP04/EDC16C36_V50_ALP04/EDC16C36_V54_ALP04/

EDC16C36_V58_ALP04EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 399 of 431

13B-399

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

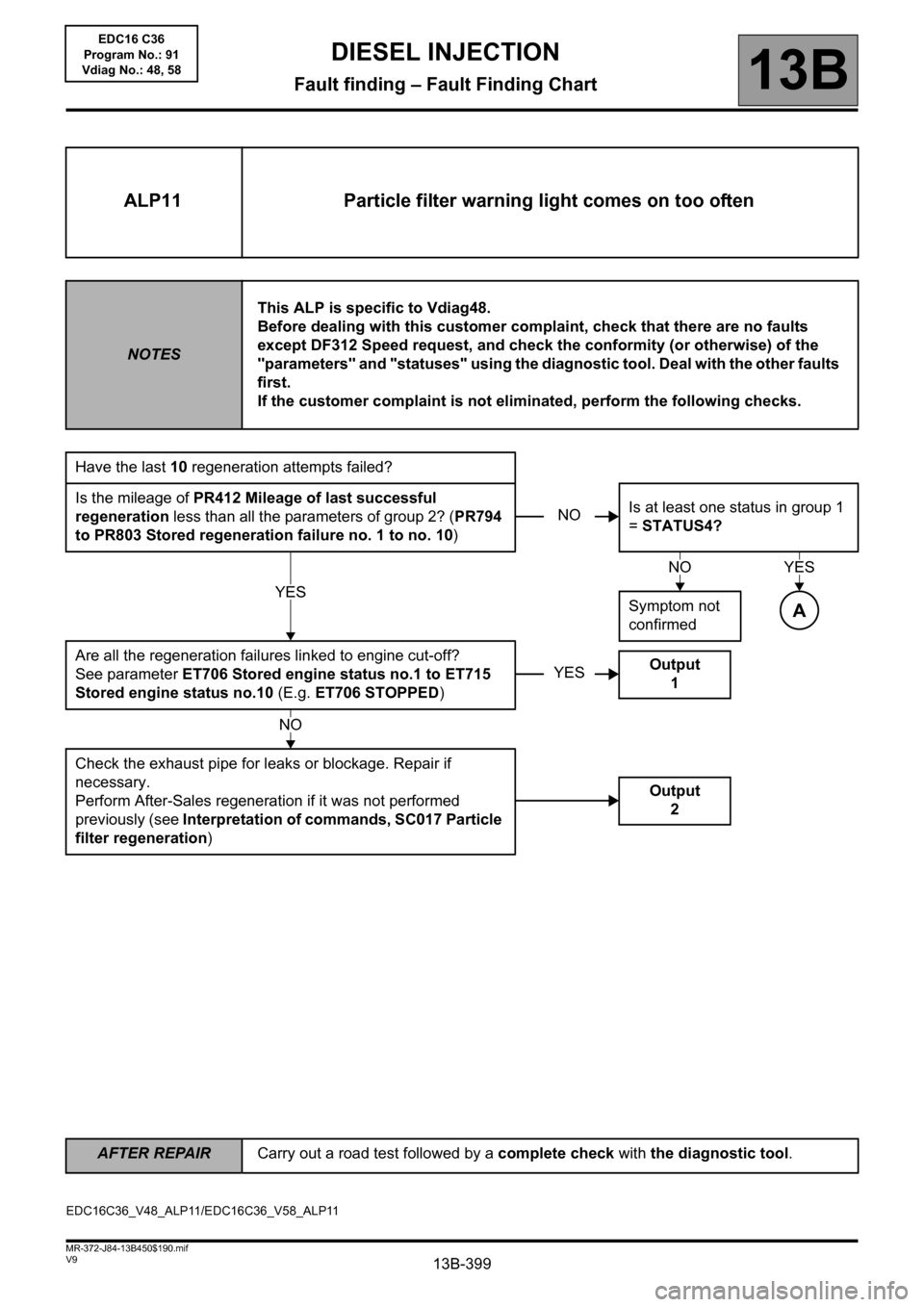

ALP11 Particle filter warning light comes on too often

NOTESThis ALP is specific to Vdiag48.

Before dealing with this customer complaint, check that there are no faults

except DF312 Speed request, and check the conformity (or otherwise) of the

"parameters" and "statuses" using the diagnostic tool. Deal with the other faults

first.

If the customer complaint is not eliminated, perform the following checks.

Have the last 10 regeneration attempts failed?

Is the mileage of PR412 Mileage of last successful

regeneration less than all the parameters of group 2? (PR794

to PR803 Stored regeneration failure no. 1 to no. 10)Is at least one status in group 1

= STATUS4?

Symptom not

confirmed

Are all the regeneration failures linked to engine cut-off?

See parameter ET706 Stored engine status no.1 to ET715

Stored engine status no.10 (E.g. ET706 STOPPED)

Check the exhaust pipe for leaks or blockage. Repair if

necessary.

Perform After-Sales regeneration if it was not performed

previously (see Interpretation of commands, SC017 Particle

filter regeneration)

NO

YES

NOYES

A

YESOutput

1

NO

Output

2

EDC16C36_V48_ALP11/EDC16C36_V58_ALP11EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 403 of 431

13B-403

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

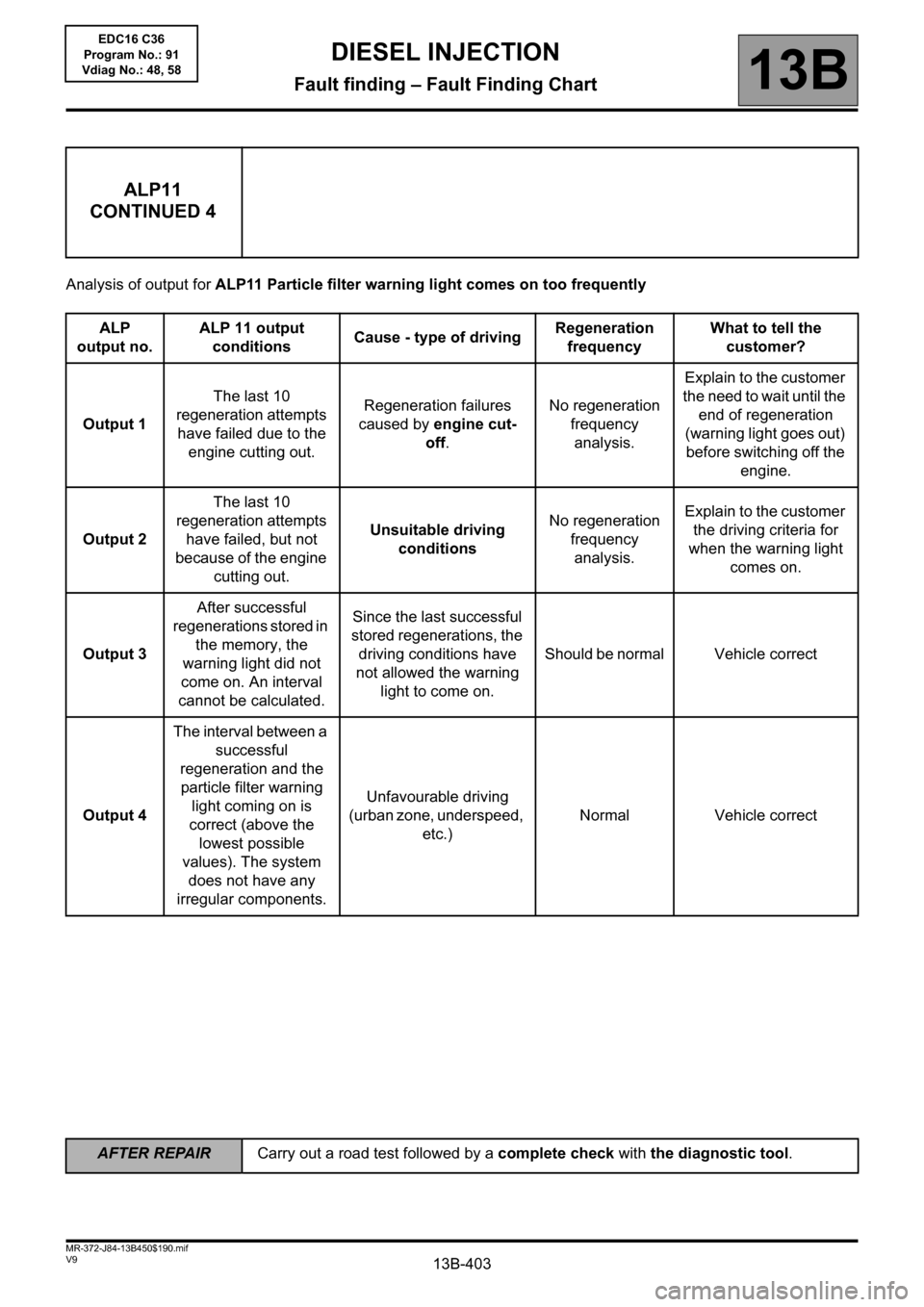

Analysis of output for ALP11 Particle filter warning light comes on too frequently

ALP11

CONTINUED 4

ALP

output no.ALP 11 output

conditionsCause - type of drivingRegeneration

frequencyWhat to tell the

customer?

Output 1The last 10

regeneration attempts

have failed due to the

engine cutting out.Regeneration failures

caused by engine cut-

off.No regeneration

frequency

analysis.Explain to the customer

the need to wait until the

end of regeneration

(warning light goes out)

before switching off the

engine.

Output 2The last 10

regeneration attempts

have failed, but not

because of the engine

cutting out.Unsuitable driving

conditionsNo regeneration

frequency

analysis.Explain to the customer

the driving criteria for

when the warning light

comes on.

Output 3After successful

regenerations stored in

the memory, the

warning light did not

come on. An interval

cannot be calculated.Since the last successful

stored regenerations, the

driving conditions have

not allowed the warning

light to come on.Should be normal Vehicle correct

Output 4The interval between a

successful

regeneration and the

particle filter warning

light coming on is

correct (above the

lowest possible

values). The system

does not have any

irregular components.Unfavourable driving

(urban zone, underspeed,

etc.)Normal Vehicle correct

EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 426 of 431

13B-426V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

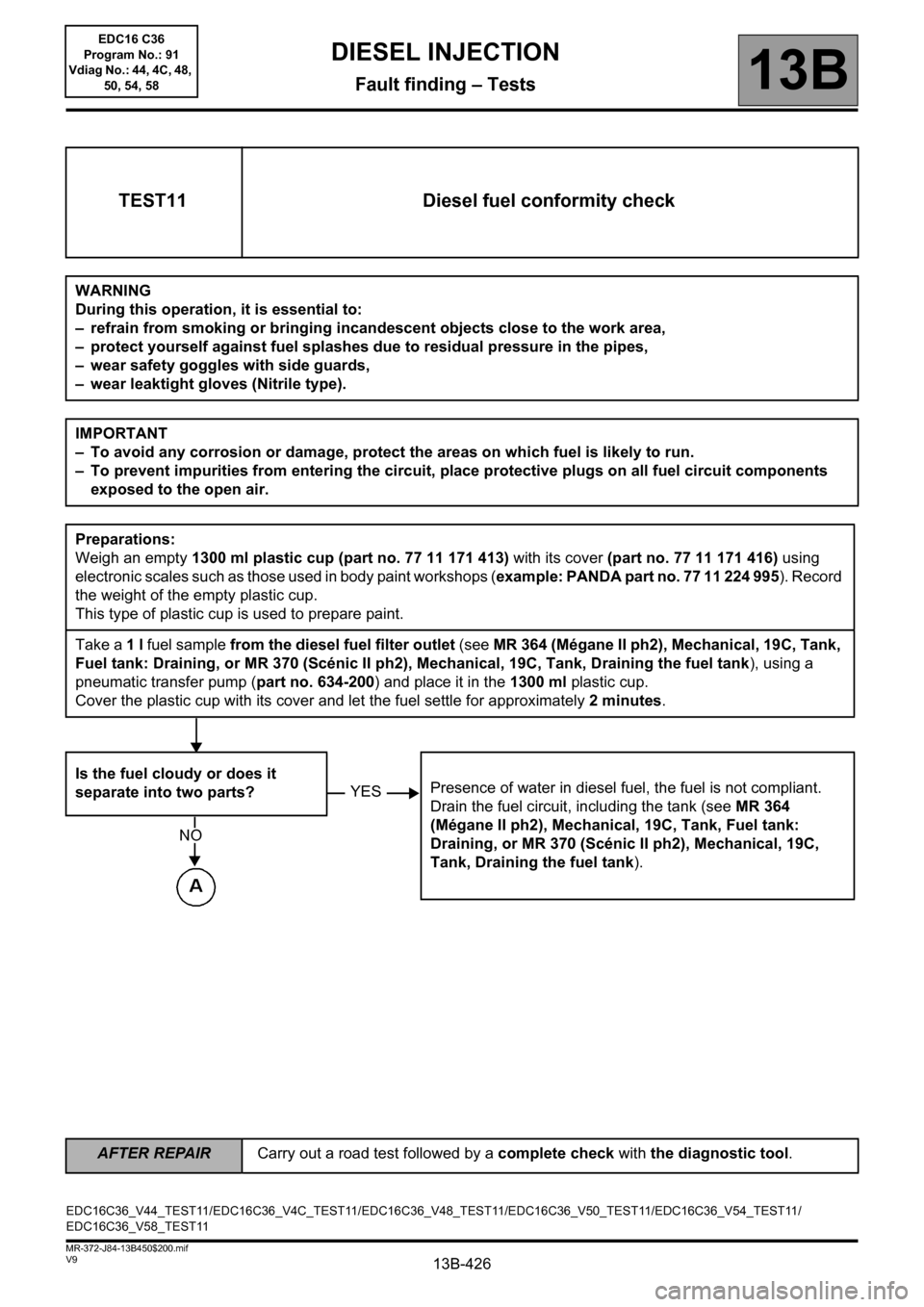

TEST11 Diesel fuel conformity check

WARNING

During this operation, it is essential to:

– refrain from smoking or bringing incandescent objects close to the work area,

– protect yourself against fuel splashes due to residual pressure in the pipes,

– wear safety goggles with side guards,

– wear leaktight gloves (Nitrile type).

IMPORTANT

– To avoid any corrosion or damage, protect the areas on which fuel is likely to run.

– To prevent impurities from entering the circuit, place protective plugs on all fuel circuit components

exposed to the open air.

Preparations:

Weigh an empty 1300 ml plastic cup (part no. 77 11 171 413) with its cover (part no. 77 11 171 416) using

electronic scales such as those used in body paint workshops (example: PANDA part no. 77 11 224 995). Record

the weight of the empty plastic cup.

This type of plastic cup is used to prepare paint.

Take a 1 l fuel sample from the diesel fuel filter outlet (see MR 364 (Mégane II ph2), Mechanical, 19C, Tank,

Fuel tank: Draining, or MR 370 (Scénic II ph2), Mechanical, 19C, Tank, Draining the fuel tank), using a

pneumatic transfer pump (part no. 634-200) and place it in the 1300 ml plastic cup.

Cover the plastic cup with its cover and let the fuel settle for approximately 2 minutes.

Is the fuel cloudy or does it

separate into two parts?Presence of water in diesel fuel, the fuel is not compliant.

Drain the fuel circuit, including the tank (see MR 364

(Mégane II ph2), Mechanical, 19C, Tank, Fuel tank:

Draining, or MR 370 (Scénic II ph2), Mechanical, 19C,

Tank, Draining the fuel tank).

YES

NO

EDC16C36_V44_TEST11/EDC16C36_V4C_TEST11/EDC16C36_V48_TEST11/EDC16C36_V50_TEST11/EDC16C36_V54_TEST11/

EDC16C36_V58_TEST11EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.