relay RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 116 of 329

13B-116

MR-372-J84-13B050$468.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

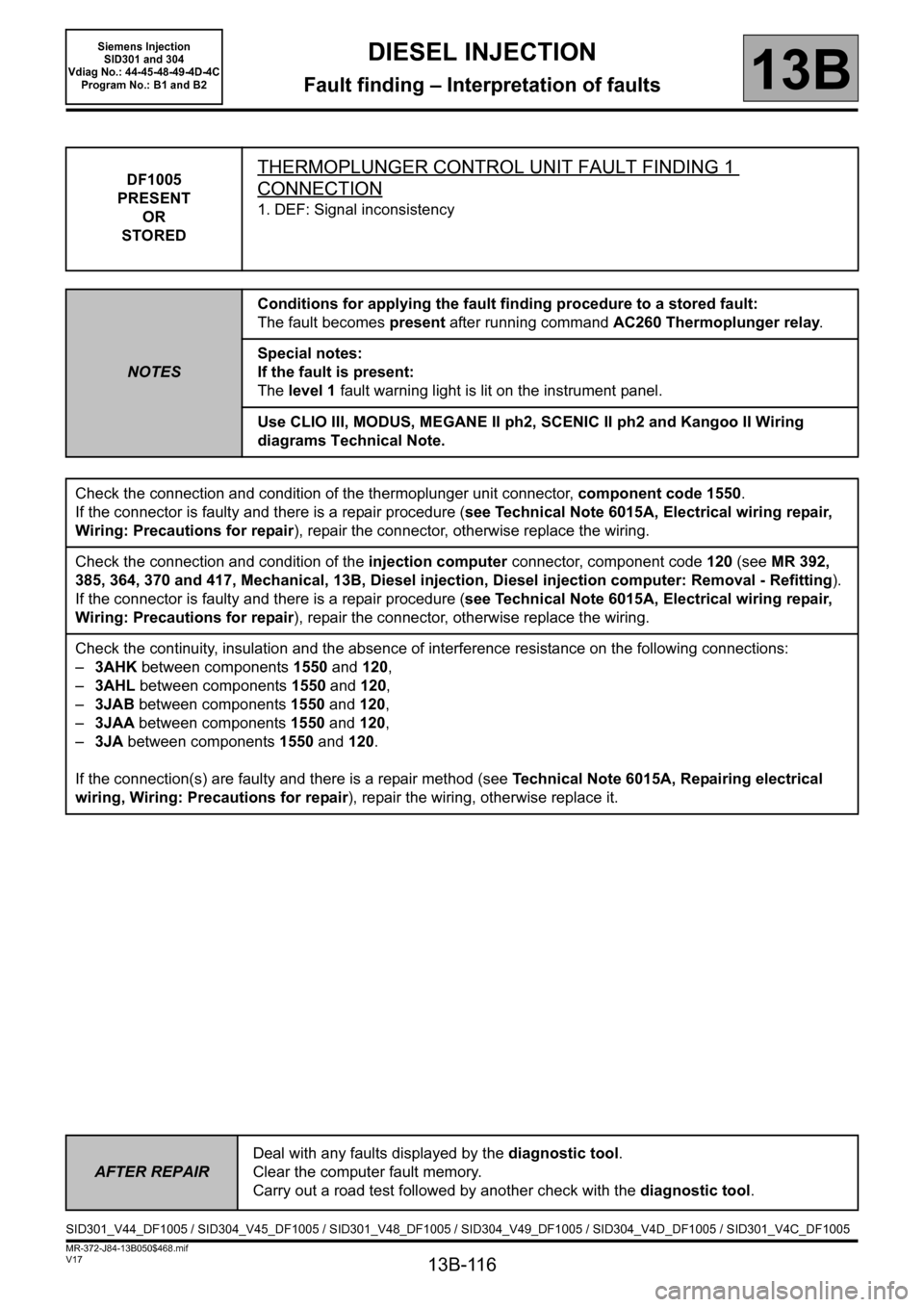

DF1005

PRESENT

OR

STOREDTHERMOPLUNGER CONTROL UNIT FAULT FINDING 1

CONNECTION

1. DEF: Signal inconsistency

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present after running command AC260 Thermoplunger relay.

Special notes:

If the fault is present:

The level 1 fault warning light is lit on the instrument panel.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Check the connection and condition of the thermoplunger unit connector, component code 1550.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the connection and condition of the injection computer connector, component code 120 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity, insulation and the absence of interference resistance on the following connections:

– 3AHK between components 1550 and 120,

– 3AHL between components 1550 and 120,

– 3JAB between components 1550 and 120,

– 3JAA between components 1550 and 120,

– 3JA between components 1550 and 120.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF1005 / SID304_V45_DF1005 / SID301_V48_DF1005 / SID304_V49_DF1005 / SID304_V4D_DF1005 / SID301_V4C_DF1005

Page 125 of 329

13B-125

MR-372-J84-13B050$546.mif

V17

13B

DIESEL INJECTION

Fault finding – Status summary table

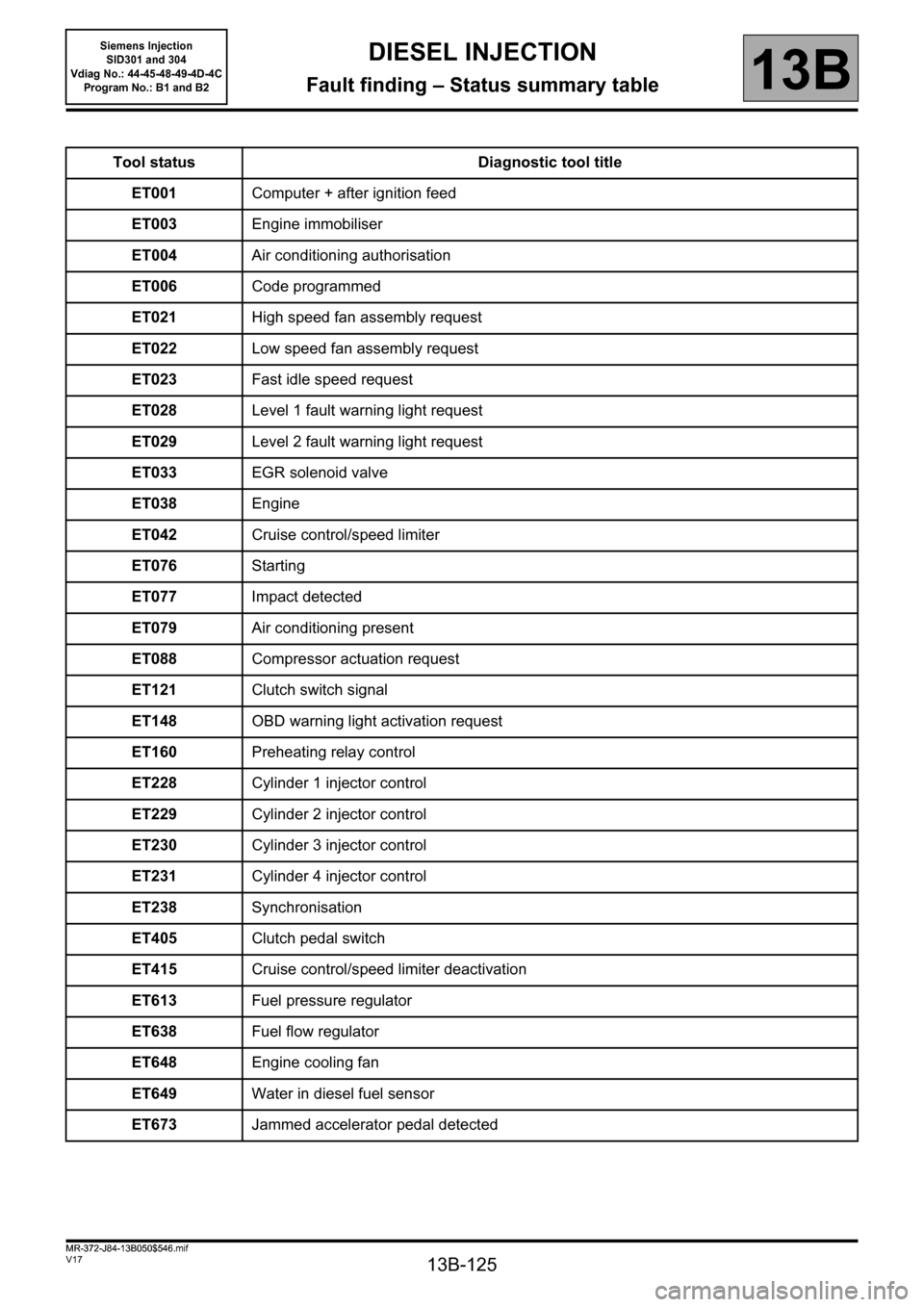

Tool status Diagnostic tool title

ET001Computer + after ignition feed

ET003Engine immobiliser

ET004 Air conditioning authorisation

ET006Code programmed

ET021High speed fan assembly request

ET022Low speed fan assembly request

ET023Fast idle speed request

ET028Level 1 fault warning light request

ET029Level 2 fault warning light request

ET033EGR solenoid valve

ET038Engine

ET042Cruise control/speed limiter

ET076Starting

ET077Impact detected

ET079Air conditioning present

ET088Compressor actuation request

ET121Clutch switch signal

ET148OBD warning light activation request

ET160Preheating relay control

ET228Cylinder 1 injector control

ET229Cylinder 2 injector control

ET230Cylinder 3 injector control

ET231Cylinder 4 injector control

ET238Synchronisation

ET405Clutch pedal switch

ET415Cruise control/speed limiter deactivation

ET613Fuel pressure regulator

ET638Fuel flow regulator

ET648Engine cooling fan

ET649Water in diesel fuel sensor

ET673Jammed accelerator pedal detected

MR-372-J84-13B050$546.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

Page 127 of 329

13B-127

MR-372-J84-13B050$585.mif

V17

13B

DIESEL INJECTION

Fault finding – Interpretation of statuses

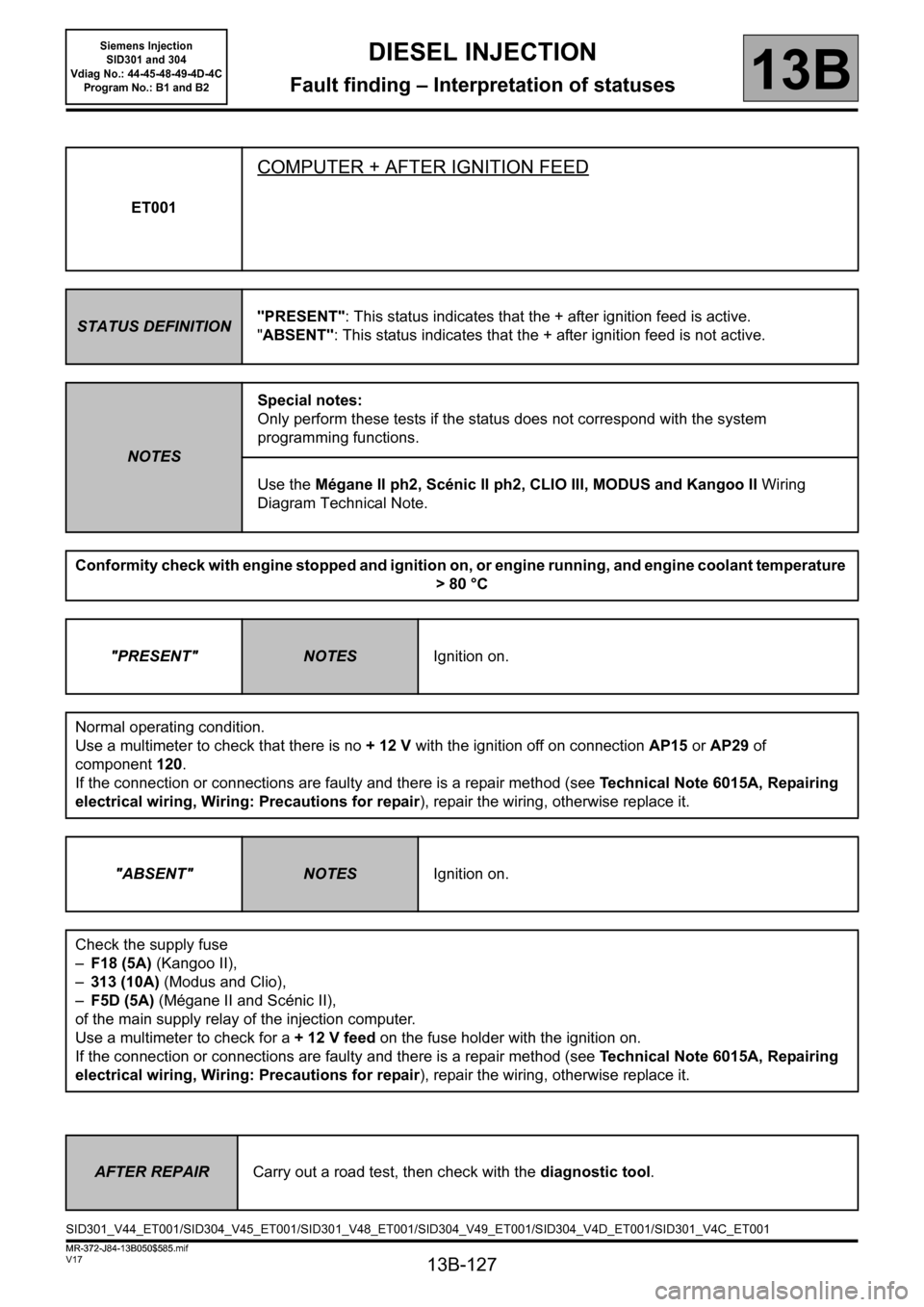

ET001

COMPUTER + AFTER IGNITION FEED

STATUS DEFINITION"PRESENT": This status indicates that the + after ignition feed is active.

"ABSENT": This status indicates that the + after ignition feed is not active.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

Use the Mégane II ph2, Scénic II ph2, CLIO III, MODUS and Kangoo II Wiring

Diagram Technical Note.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C

"PRESENT"

NOTESIgnition on.

Normal operating condition.

Use a multimeter to check that there is no +12V with the ignition off on connectionAP15 or AP29 of

component120.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

"ABSENT"

NOTESIgnition on.

Check the supply fuse

–F18 (5A) (Kangoo II),

–313 (10A) (Modus and Clio),

–F5D (5A) (Mégane II and Scénic II),

of the main supply relay of the injection computer.

Use a multimeter to check for a + 12 V feed on the fuse holder with the ignition on.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID301_V44_ET001/SID304_V45_ET001/SID301_V48_ET001/SID304_V49_ET001/SID304_V4D_ET001/SID301_V4C_ET001

MR-372-J84-13B050$585.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

Page 156 of 329

13B-156

MR-372-J84-13B050$585.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

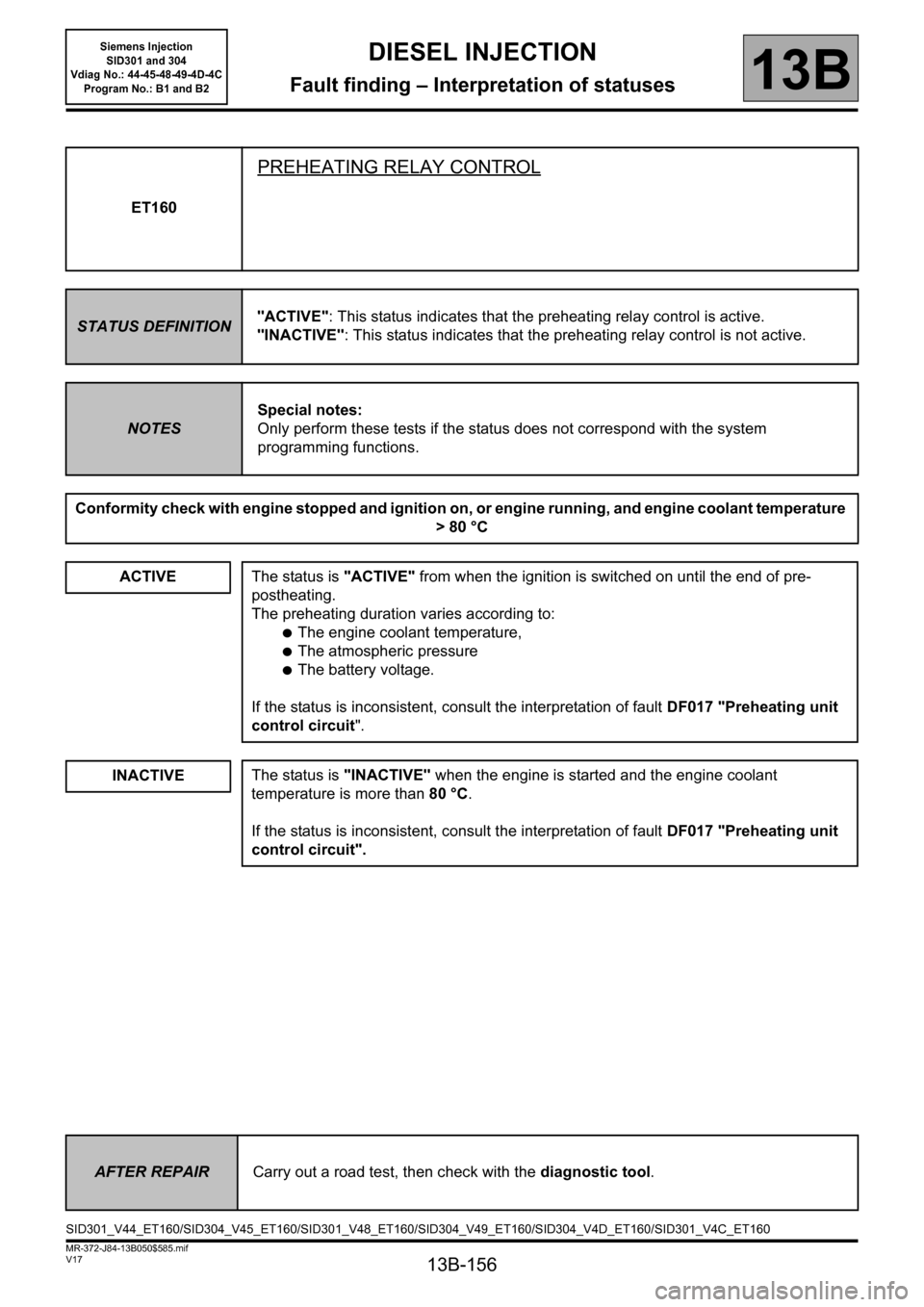

ET160

PREHEATING RELAY CONTROL

STATUS DEFINITION"ACTIVE": This status indicates that the preheating relay control is active.

"INACTIVE": This status indicates that the preheating relay control is not active.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C

ACTIVE

The status is "ACTIVE" from when the ignition is switched on until the end of pre-

postheating.

The preheating duration varies according to:

●The engine coolant temperature,

●The atmospheric pressure

●The battery voltage.

If the status is inconsistent, consult the interpretation of fault DF017 "Preheating unit

control circuit".

INACTIVEThe status is "INACTIVE" when the engine is started and the engine coolant

temperature is more than 80 °C.

If the status is inconsistent, consult the interpretation of fault DF017 "Preheating unit

control circuit".

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID301_V44_ET160/SID304_V45_ET160/SID301_V48_ET160/SID304_V49_ET160/SID304_V4D_ET160/SID301_V4C_ET160

Page 176 of 329

13B-176

MR-372-J84-13B050$624.mif

V17

13B

DIESEL INJECTION

Fault finding – Interpretation of statuses

*elec: electric

**circ: circuitET701

PARTICLE FILTER PRESSURE SENSOR

STATUS DEFINITIONACTIVE: This status indicates that the particle filter electric fuel pump is active.

INACTIVE: This status indicates that the particle filter electric fuel pump is not active.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

Only for vehicles equipped with a particle filter.

Conformity check with the engine stopped and the ignition on, or engine running, and engine coolant

temperature > 80°C

ACTIVE

INACTIVE

The status is ACTIVE during the particle filter regeneration phase.

If there is a fault, consult the interpretation of fault DF1004 Electric fuel pump control

relay circ**.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID304_V4D_ET701/SID304_V45_ET701/SID304_V49_ET701/SID301_V44_ET701/SID301_V4C_ET701

Siemens Injection

SID304

Vdiag No.: 44-45-49-4D-4C

Program No.: B2

Page 225 of 329

13B-225

MR-372-J84-13B050$741.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of parameters

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

PR132

CONTINUED

Check the + 12 V after relay supply to the air flowmeter.

– connection 3FB (3FB3 for Kangoo II) of component 799.

Check for continuity and absence of interference resistance of the following connections:

– connection code3DV,

– connection code3DW,

between components 120 and 799.

With the flow sensor connected, the vehicle ignition on and engine stopped:

Measure the voltage between connections 3DW and 3DV of component 799.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

– If the voltage is not between 0.3 V and 0.7 V, replace the air flowmeter (see MR 392, 385, 364, 370 and 417,

Mechanical, 12A, Fuel mixture, Air flowmeter: Removal - Refitting).

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 259 of 329

13B-259

MR-372-J84-13B050$819.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of commands

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

AC037: Preheating relay.

Activating this lets you listen to the operation of the preheating relay and enables the warning light in the

instrument panel to be illuminated.

AC079: Static actuator test.

Activating this allows you to activate the injection system actuators (simultaneously runs commands

AC003, AC005 to AC008, AC012, AC037, AC213, and AC214).

Run this command with the engine stopped and the engine coolant temperature below 40°C.

AC099: Inhibition of electrical consumers.

AC100: Cancel inhibition of electrical consumers.

AC213: Fuel flow solenoid valve.

AC214: Turbocharger control solenoid valve.

Activating this allows you to listen to the operation of the turbocharger control solenoid valve.

AC233: Thermoplungers no. 1 and no. 2 (Vdiag 45, 49 and 4D only).

AC234: Thermoplunger no. 3 (Vdiag 45, 49 and 4D only).

AC235: Thermoplunger no. 4 (Vdiag 45, 49 and 4D only).

AC236: Coolant pump relay (only for vehicles equipped with a particle filter, except KANGOO II).

AC237: Fuel pump relay (only for vehicles equipped with a particle filter).

Activating this allows you to check the sealing on the 5

th particle filter injector circuit.

AC238: Particle filter injector (Only for vehicles equipped with a particle filter).

AC239: Particle filter temperature sensor fault finding (only for vehicles equipped with a particle filter).

Run this command with the engine stopped and the engine coolant temperature below 40°C.

AC260: Thermoplunger relay.

Activating this allows you to check the three thermoplunger relays.

Page 262 of 329

13B-262

MR-372-J84-13B050$819.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of commands

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

SC017

PARTICLE FILTER REGENERATION

NOTESCarry out this command only under the following conditions:

– DF308 Clogged particle filter present.

Ignition on and engine stopped.

Vdiag 45, 49 and 4D only.

WARNING:

–It is essential to carry out the next procedure in accordance with the safety and cleanliness guidelines,

(see MR 364 (Mégane II), 370 (Scénic II), 417 (Kangoo II), 385 (Modus), 392 (Clio III), Mechanical, 19B,

Exhaust, Particle filter: Cleaning).

– do not run command AC029 High pressure circuit seal test until regeneration has finished.

– before each regeneration, check the fuel level,

– before and after each regeneration, check the oil level.

With the engine running and the vehicle stopped, this function allows the particle filter to be regenerated.

Safety instructions to be followed:

The regeneration causes exhaust fumes and high temperatures.

The vehicle must be outside during regeneration.

If it is not possible to carry out regeneration outside, check that the extractor fan can withstand the very high

regeneration temperatures.

Perform regeneration on a surface free from fire risks (oil, dry leaves, etc.).

Nothing should be left in the vicinity of the exhaust pipe.

Before regeneration:

– Respect After-Sales recommendations for particle filter regeneration.

– Check the oil level to prevent the engine from racing.

– Check the fuel level.

– Check the sealing on the 5th particle filter injector circuit using actuator AC237 Fuel pump relay.

– Check that there are no leaks or blockages in the exhaust pipe,

To perform regeneration:

– Vehicle stopped and in neutral.

– Engine running and warm.

– No pedal depressed (accelerator and clutch).

– No faults present preventing regeneration from being carried out on the system.

– No leak in the 5th particle filter injector circuit.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID304_V45_SC017 / SID304_V49_SC017 / SID304_V4D_SC017 / SID301_V4C_SC017

Page 269 of 329

13B-269

MR-372-J84-13B050$819.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of commands

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

AC236

COOLANT PUMP RELAY

NOTESThis command is used to check the operation of the electric coolant pump relay.

Use the CLIO III, MODUS, MEGANE II ph2 and SCENIC II ph2 Wiring Diagrams

Technical Note.

Vdiag 45, 49 and 4D only. (except Kangoo II).

Check the connection and condition of the coolant pump relay connector, component code 573 and injection

computer connector B, component code 120.

If the connector(s) are faulty and there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector(s), otherwise replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3VG between components 573 and 120,

–3V between components 573 and 369,

–3FB between components 573 and 983,

–3FB1 between components 573 and 983.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

SID304_V45_AC236 / SID304_V49_AC236 / SID304_V4D_AC236 / SID301_V4C_AC236

Page 274 of 329

13B-274

MR-372-J84-13B050$897.mif

V17

DIESEL INJECTION

Fault finding – Fault Finding Chart

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

ALP 2 The engine does not start or starts with difficulty

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Check the presence and conformity of the fuel by running Test 13 Diesel fuel conformity check.

Carry out fault finding on the charge circuit (See Technical Note 6014A, Checking the charging circuit or 87G,

Engine compartment connection unit).

Check the starter and the starter relay (see Technical Note 3632A, Starter fault finding).

Check the injection computer main relay (refer to the interpretation of fault DF015 Main relay control circuit).

Check the injection computer: that the connections and wiring are in good condition, that earths and feeds are

present.

If the wiring is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Check the camshaft sensor and TDC sensor, as well as their wiring (refer to the interpretation of faults DF005

Engine speed sensor circuit and DF097 Camshaft sensor circuit).

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, if not replace it.

Check the air inlet circuit (refer to the interpretation of fault DF301 Air inlet circuit).

Check that the damper valve operates correctly (refer to the interpretation of fault DF641 Damper valve circuit).

Check the low pressure fuel supply system by performing test 1 Low pressure supply check and test 2

Internal fuel transfer pump (ITP) check.

Check the high pressure fuel supply system by performing test 3 High pressure fuel pressure solenoid valve

check, test 4 High pressure pump (HPP) and fuel flow solenoid valve check and test 5 Rail high pressure

regulation circuit check.

Check the injectors by performing test 6 Major leak in injectors/injectors open and test 7 Incorrect injection

amount.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_ALP2 / SID304_V45_ALP2 / SID301_V48_ALP2 / SID304_V49_ALP2 / SID304_V4D_ALP2 / SID301_V4C_ALP2