sensor RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 74 of 329

13B-74

MR-372-J84-13B050$429.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF195

PRESENT

OR

STOREDENGINE SPEED/CAMSHAFT SENSOR CONSISTENCY

1. DEF: Signal inconsistency

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the engine is started or following a road test.

If the fault is present:

Longer starting time, requires several attempts to start the vehicle.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Check that the camshaft sensor, component code 746, is correctly positioned and mounted.

Check the connection and condition of the camshaft sensor connector, component code 746 (see MR 417,

Mechanical, 13B, Diesel injection, Camshaft position sensor: Removal - Refitting) and the injection

computer connector, component code 120 (see MR 392, 385, 364, 370 and 417, Mechanical, 13B, Diesel

injection, Diesel injection computer: Removal - Refitting).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair) repair the connector(s); otherwise, replace the wiring.

With the ignition on, check the supply of the camshaft sensor, component code 746:

–+ 12 V after ignition on connection 3FB (or 3FB3 for Kangoo II),

–earth on connection 3FJ.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3FJ between components 746 and 120,

–3CQ between components 746 and 120,

–3FB (or 3FB3 for Kangoo II) between components 746 and 983 (or 1337 for Kangoo II).

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the condition of the camshaft target.

If these checks are correct, replace the camshaft sensor

(see MR 417, Mechanical, 13B, Diesel injection,

Camshaft position sensor: Removal - Refitting).

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF195 / SID304_V45_DF195 / SID301_V48_DF195 / SID304_V49_DF195 / SID304_V4D_DF195 / SID301_V4C_DF195

Page 77 of 329

13B-77

MR-372-J84-13B050$429.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF209

PRESENT

OR

STOREDEGR VALVE POSITION SENSOR CIRCUIT

CC.1 : Short circuit to + 12 V

CO.0:Open circuit or short circuit to earth

NOTESPriority when dealing with a number of faults:

–DF011 Sensor supply voltage no. 1.

Conditions for applying the fault finding procedure to a stored fault:

The fault becomes present after starting the engine.

If the fault is present:

EGR valve cut-off

Use the Wiring Diagram Technical Notes for CLIO III, MODUS, MEGANE II ph2,

SCENIC II ph2 and KANGOO II.

Check the connection and condition of the connector for the EGR valve, component code1460, and the

connector for the injection computer, component code120.

If the connectors are faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

With the ignition on, check for the presence of + 5 V on the connection 3GC and an earth on connection 3GD of

the EGR valve, component code 1460.

Check the continuity, insulation and the absence of interference resistance on the following connections:

–3GD between components 1460 and 120,

–3GC between components 1460 and 120,

–3EL between components 1460 and 120.

If the connection(s) are faulty and if there is a repair method (see Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF209 / SID304_V45_DF209 / SID301_V48_DF209 / SID304_V49_DF209 / SID304_V4D_DF209 / SID301_V4C_DF209

Page 85 of 329

13B-85

MR-372-J84-13B050$429.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

*diff: differential

*temp: temperatureDF308

PRESENT

OR

STORED

CLOGGED PARTICLE FILTER

1. DEF: Signal outside upper limit

NOTESPriorities when dealing with a number of faults:

Deal with faults stored in the computer first.

Ask the customer about vehicle usage: driving style, type of journey, etc.

Conditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault is present:

– particle filter regeneration is inhibited,

– the EGR function is inhibited,

– the vehicle performance is reduced,

– the level 1 warning light is lit and a warning message (or light) is displayed on the

instrument panel.

Check that there are no leaks or blockages in the exhaust pipe,

Repair if necessary.

Carry out an After-Sales regeneration (before and after each regeneration, check the oil and diesel fuel levels).

Run command SC017 Particle filter regeneration (see Interpretation of commands).

Use ALP 21: Particle filter warning light lit.

Deal with the interpretation of fault DF1003 Particle filter differential pressure sensor circuit.

Check the exhaust system.

Deal with the interpretation of fault DF1000 Particle filter upstream temperature sensor circuit.

Deal with the interpretation of fault DF1007 Catalytic converter 1 downstream temperature sensor circuit.

Deal with the interpretation of fault DF999 Particle filter downstream temperature sensor circuit.

Deal with the interpretation of fault DF652 Turbine upstream temperature sensor circuit.

Carry out Te s t 1 0: Air Chain at the level of the turbocharger.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

Explain to the customer how the particle filter system works.

SID301_V44_DF308 / SID304_V45_DF308 / SID301_V48_DF308 / SID304_V49_DF308 / SID304_V4D_DF308 / SID301_V4C_DF308

Page 89 of 329

13B-89

MR-372-J84-13B050$429.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF582

PRESENT

OR

STOREDPRESSURE CONSISTENCY

1. DEF: Signal outside lower limit

2. DEF: Signal outside upper limit

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present after starting the engine.

If the fault is present:

–The level 1 and OBD fault warning lights are lit on the instrument panel.

–The cruise control/speed limiter is inhibited.

– Loss of performance, torque setpoint restricted.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Check the condition and connection of the turbocharging pressure sensor connector, component code 1071.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the connection and condition of the injection computer connector, component code 120 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

With the ignition on, check for + 5 V on connection 3LQ and earth on connection 3LN of the turbocharging

pressure sensor.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3LQ between components 1071 and 120,

–3LN between components 1071 and 120,

–3LP between components 1071 and 120.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the consistency between the atmospheric pressure and the turbocharging pressure (PR035

Atmospheric pressure = PR041 Turbocharging pressure

).

Engine stopped (cold), the pressure read by the two sensors must be nearly the same.

If the values are very different, replace the turbocharging pressure sensor.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF582 / SID304_V45_DF582 / SID301_V48_DF582 / SID304_V49_DF582 / SID304_V4D_DF582 / SID301_V4C_DF582

Page 91 of 329

13B-91

MR-372-J84-13B050$429.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF647

PRESENT

OR

STORED

EGR VALVE POSITION REGULATION

1. DEF: Signal inconsistency

2. DEF: Signal outside lower limit

3. DEF: Signal outside upper limit

4. DEF: Values outside limits

5. DEF: Faulty sensor

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present after starting the engine.

Priority when dealing with a number of faults:

– DF011 Sensor supply voltage no. 1.

Special notes:

–The level 1 fault warning light is lit on the instrument panel.

– Engine instability, possibly even stalling.

– Difficult to start engine or even impossible when cold.

– Loss of performance.

– Possible smoke emissions.

Use the Wiring Diagram Technical Notes for CLIO III, MODUS, MEGANE II ph2,

SCENIC II ph2 and KANGOO II.

Check the connection and condition of the connector for the EGR valve, component code1460 and the

connector for the injection computer, component code 120.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

With the ignition on, check for + 5 V on connection 3GC and earth on connection 3GD of the exhaust gas

recirculation valve, component code 1460.

Check the continuity, insulation and the absence of interference resistance on the following connections:

–3GD between components 1460 and 120,

–3GC between components 1460 and 120,

–3EL between components 1460 and 120.

If the connection(s) are faulty and if there is a repair method (see Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF647 / SID304_V45_DF647 / SID301_V48_DF647 / SID304_V49_DF647 / SID304_V4D_DF647 / SID301_V4C_DF647

Page 94 of 329

13B-94

MR-372-J84-13B050$429.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF652

PRESENT

OR

STOREDTURBINE UPSTREAM TEMPERATURE SENSOR CIRCUIT

CC.0 : Short circuit to earth

CO.1 : Open circuit or short circuit to +12 V.

1. DEF: Micro-break

2. DEF: Signal inconsistency

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present if:

– ignition is on (CC.0),

– following a road test, engine warm (CO.1).

Special notes:

If the fault is present:

– the EGR function is inhibited,

– particle filter regeneration is inhibited,

– the vehicle performance is reduced,

–the level 1 warning light is lit.

IMPORTANT

The turbine upstream temperature sensor only measures temperatures above

100°C.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Run command AC029 High pressure circuit sealing check and check PR667 Turbine upstream temperature.

If the turbine upstream temperature is above 120°C, then the sensor is correct, otherwise continue the fault

finding procedure.

Check the connection and condition of the connector of the turbine upstream temperature sensor, component

code 1589 and the injection computer connector, component code 120 (see MR 392, 385, 364, 370 and 417,

Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair) repair the connector(s); otherwise, replace the wiring.

Measure the resistance of the turbine upstream temperature sensor, component code 1589 between

connections 3B and 3JQ.

If the resistance is not between 313 KΩ and 436 KΩ at 100°C, replace the turbine upstream temperature

sensor.

With the ignition on, check for + 5 V on connection 3B and earth on connection 3JQ of the turbine upstream

temperature sensor, component code 1589.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID304_V45_DF652 / SID304_V49_DF652 / SID304_V4D_DF652 / SID301_V4C_DF652

Page 101 of 329

13B-101

MR-372-J84-13B050$468.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF886

PRESENT

OR

STOREDPRESENCE OF WATER IN THE DIESEL FUEL

1. DEF: Water in diesel fuel

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present after a road test above 24 mph (40 km/h) and the engine

speed above 1000 rpm.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Check whether there is any water in the diesel filter; replace the filter if necessary.

Drain the fuel filter.

Check the connection and condition of the connector of the water in diesel fuel sensor, component code 414.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the connection and condition of the injection computer connector, component code 120 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance of the water in diesel fuel sensor, component code 414 between connections 3FB and

M.

If the resistance is not:

2140Ω

With the ignition on, check for + 12 V after ignition on connection 3FB (or AP15 for Kangoo II) and earth on

connection M (MH or MW for Kangoo II) of the water in diesel fuel sensor, component code 414.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the continuity, insulation and the absence of interference resistance on the following connections:

–3FB (or AP15 for Kangoo II) between components 414 and 120,

–M (MH or MW for Kangoo II) between components 414 and 120,

–3WT between components

414 and 120.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Replace the water in diesel fuel sensor.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF886 / SID304_V45_DF886 / SID301_V48_DF886 / SID304_V49_DF886 / SID304_V4D_DF886 / SID301_V4C_DF886

Page 105 of 329

13B-105

MR-372-J84-13B050$468.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF953

PRESENT

OR

STOREDPARTICLE FILTER ABSENT

1. DEF: Signal outside lower limit

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the engine is started or following a road test.

Priorities when dealing with a number of faults:

Deal with the following faults first: DF1003 Particle filter differential pressure

sensor circuit.

If the fault is present:

– smoke is emitted,

– the OBD warning light is lit.

Visually check the particle filter.

Check that the particle filter is in good condition.

Check that the exhaust is not broken or damaged.

Apply the interpretation of fault DF1003 Particle filter differential pressure sensor circuit.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF953 / SID304_V45_DF953 / SID301_V48_DF953 / SID304_V49_DF953 / SID304_V4D_DF953 / SID301_V4C_DF953

Page 107 of 329

13B-107

MR-372-J84-13B050$468.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF999

PRESENT

OR

STORED

PARTICLE FILTER DOWNSTREAM TEMPERATURE SENSOR

CIRCUIT

CC.0 : Short circuit to earth

CO.1 : Open circuit or short circuit to +12 V.

1. DEF: Micro-breaks

2. DEF: Signal outside lower limit

3. DEF: Signal inconsistency

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present:

– with the ignition on (for status CC.0),

– after a road test with a warm engine (for status CO. 1).

Special notes:

If the fault is present:

–The level 1 fault warning light is lit on the instrument panel.

IMPORTANT

The particle filter downstream temperature sensor only measures temperatures

above 50°C.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Run command AC029 High pressure circuit sealing test and check PR381 Particle filter downstream

temperature.

If the particle filter downstream temperature is above 50°C, then the sensor is correct, otherwise continue the fault

finding procedure.

Check the connection and condition of the connector of the particle filter downstream temperature sensor,

component code 1288 (see MR 392, 385, 364, 370 and 417, Mechanical, 19B, Exhaust, Particle filter

temperature sensors: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the connection and condition of the injection computer connector, component code 120 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance of the particle filter downstream temperature sensor, component code 1288 between

connections 3TG and 3XU.

If the resistance is not:

106170Ω

6886Ω < X < 6906Ω at 200°C,

2565Ω < X < 2585Ω at 300°C,1192Ω

663Ω

temperature sensors: Removal - Refitting).

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF999 / SID304_V45_DF999 / SID301_V48_DF999 / SID304_V49_DF999 / SID304_V4D_DF999 / SID301_V4C_DF999

Page 109 of 329

13B-109

MR-372-J84-13B050$468.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

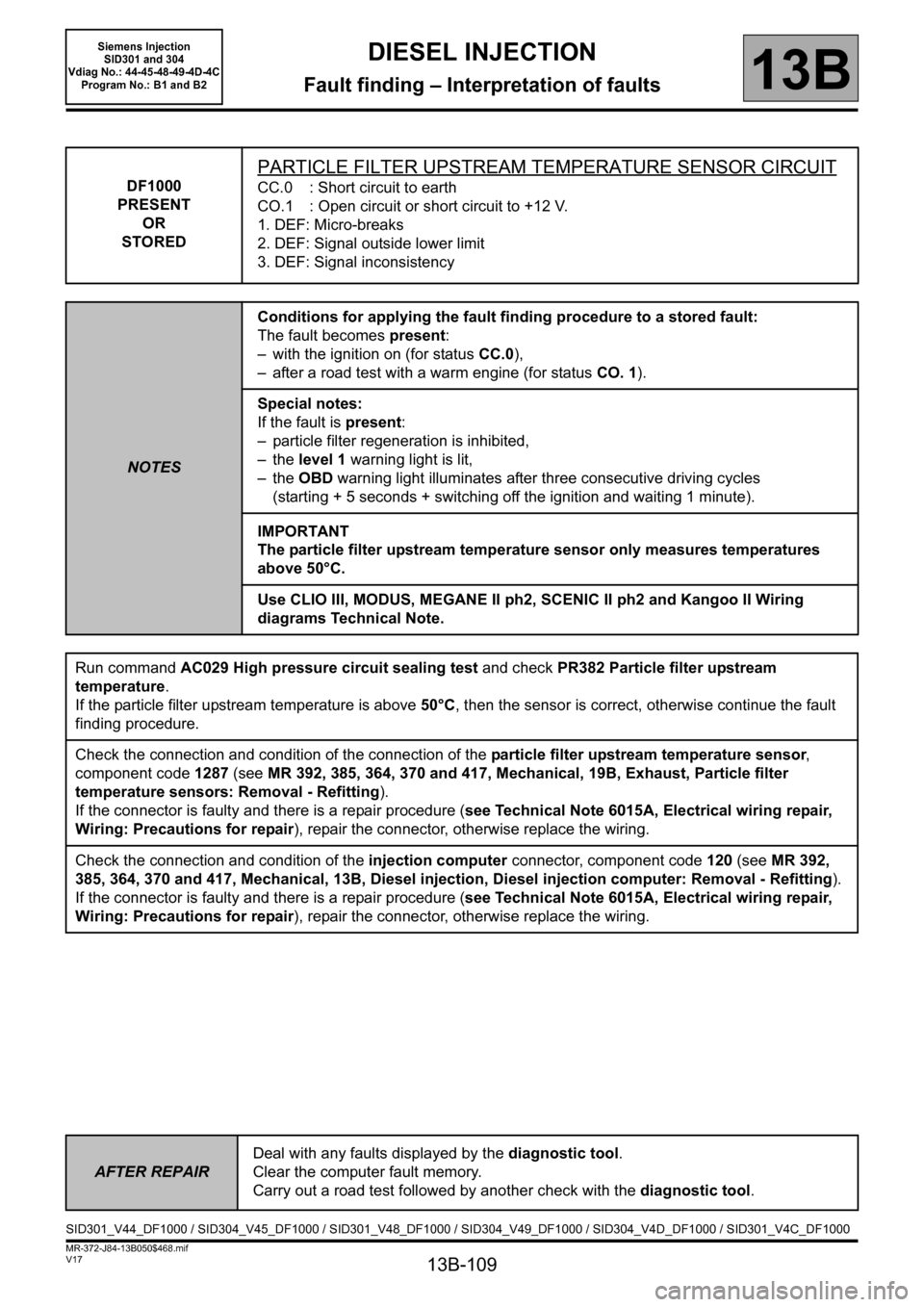

DF1000

PRESENT

OR

STORED

PARTICLE FILTER UPSTREAM TEMPERATURE SENSOR CIRCUIT

CC.0 : Short circuit to earth

CO.1 : Open circuit or short circuit to +12 V.

1. DEF: Micro-breaks

2. DEF: Signal outside lower limit

3. DEF: Signal inconsistency

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present:

– with the ignition on (for status CC.0),

– after a road test with a warm engine (for status CO. 1).

Special notes:

If the fault is present:

– particle filter regeneration is inhibited,

– the level 1 warning light is lit,

– the OBD warning light illuminates after three consecutive driving cycles

(starting + 5 seconds + switching off the ignition and waiting 1 minute).

IMPORTANT

The particle filter upstream temperature sensor only measures temperatures

above 50°C.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Run command AC029 High pressure circuit sealing test and check PR382 Particle filter upstream

temperature.

If the particle filter upstream temperature is above 50°C, then the sensor is correct, otherwise continue the fault

finding procedure.

Check the connection and condition of the connection of the particle filter upstream temperature sensor,

component code 1287 (see MR 392, 385, 364, 370 and 417, Mechanical, 19B, Exhaust, Particle filter

temperature sensors: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the connection and condition of the injection computer connector, component code 120 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF1000 / SID304_V45_DF1000 / SID301_V48_DF1000 / SID304_V49_DF1000 / SID304_V4D_DF1000 / SID301_V4C_DF1000