sensor RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 161 of 329

13B-161

MR-372-J84-13B050$624.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

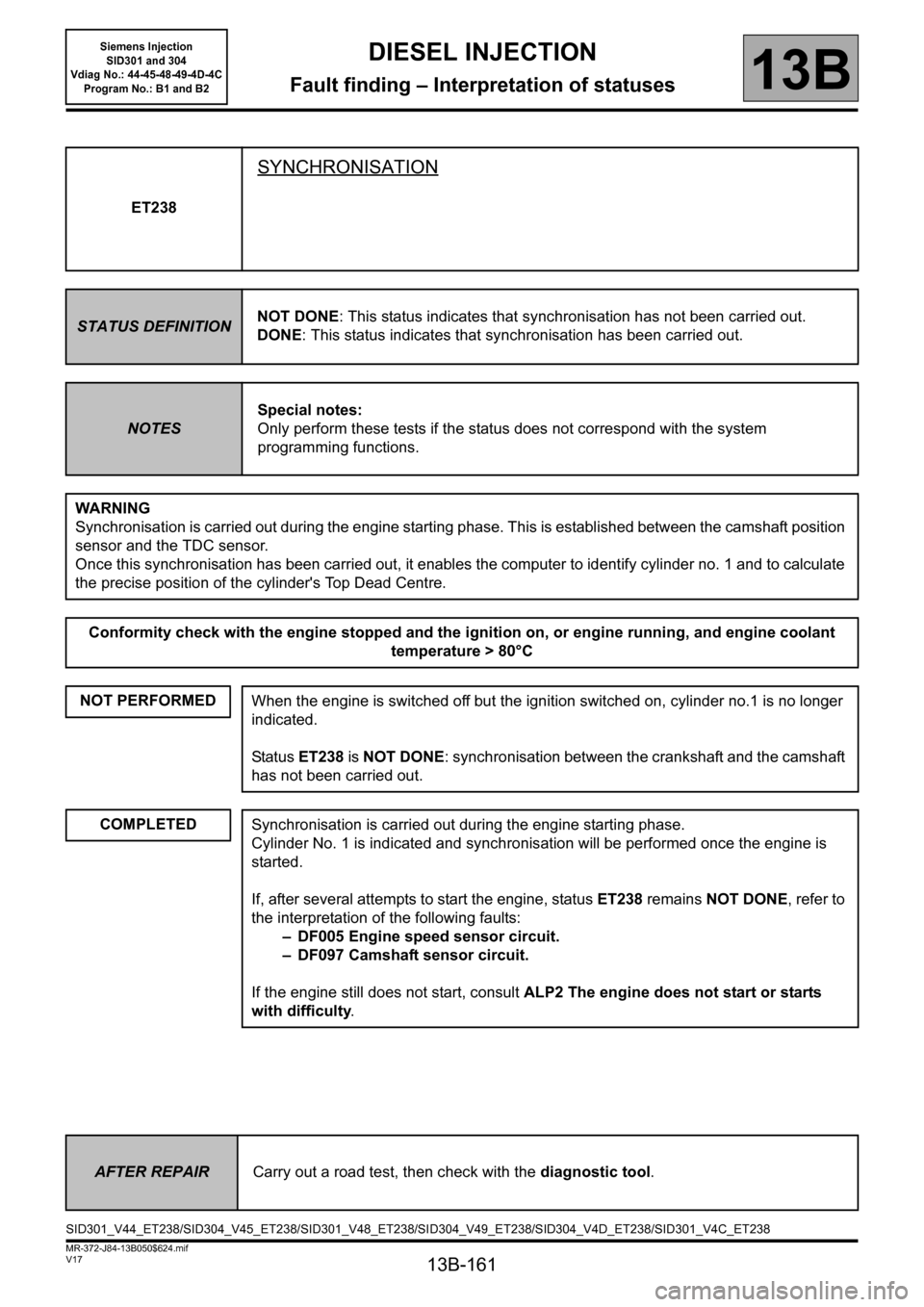

ET238

SYNCHRONISATION

STATUS DEFINITIONNOT DONE: This status indicates that synchronisation has not been carried out.

DONE: This status indicates that synchronisation has been carried out.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

WARNING

Synchronisation is carried out during the engine starting phase. This is established between the camshaft position

sensor and the TDC sensor.

Once this synchronisation has been carried out, it enables the computer to identify cylinder no. 1 and to calculate

the precise position of the cylinder's Top Dead Centre.

Conformity check with the engine stopped and the ignition on, or engine running, and engine coolant

temperature > 80°C

NOT PERFORMED

When the engine is switched off but the ignition switched on, cylinder no.1 is no longer

indicated.

Status ET238 is NOT DONE: synchronisation between the crankshaft and the camshaft

has not been carried out.

COMPLETEDSynchronisation is carried out during the engine starting phase.

Cylinder No. 1 is indicated and synchronisation will be performed once the engine is

started.

If, after several attempts to start the engine, status ET238 remains NOT DONE, refer to

the interpretation of the following faults:

– DF005 Engine speed sensor circuit.

– DF097 Camshaft sensor circuit.

If the engine still does not start, consult ALP2 The engine does not start or starts

with difficulty.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID301_V44_ET238/SID304_V45_ET238/SID301_V48_ET238/SID304_V49_ET238/SID304_V4D_ET238/SID301_V4C_ET238

Page 162 of 329

13B-162

MR-372-J84-13B050$624.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

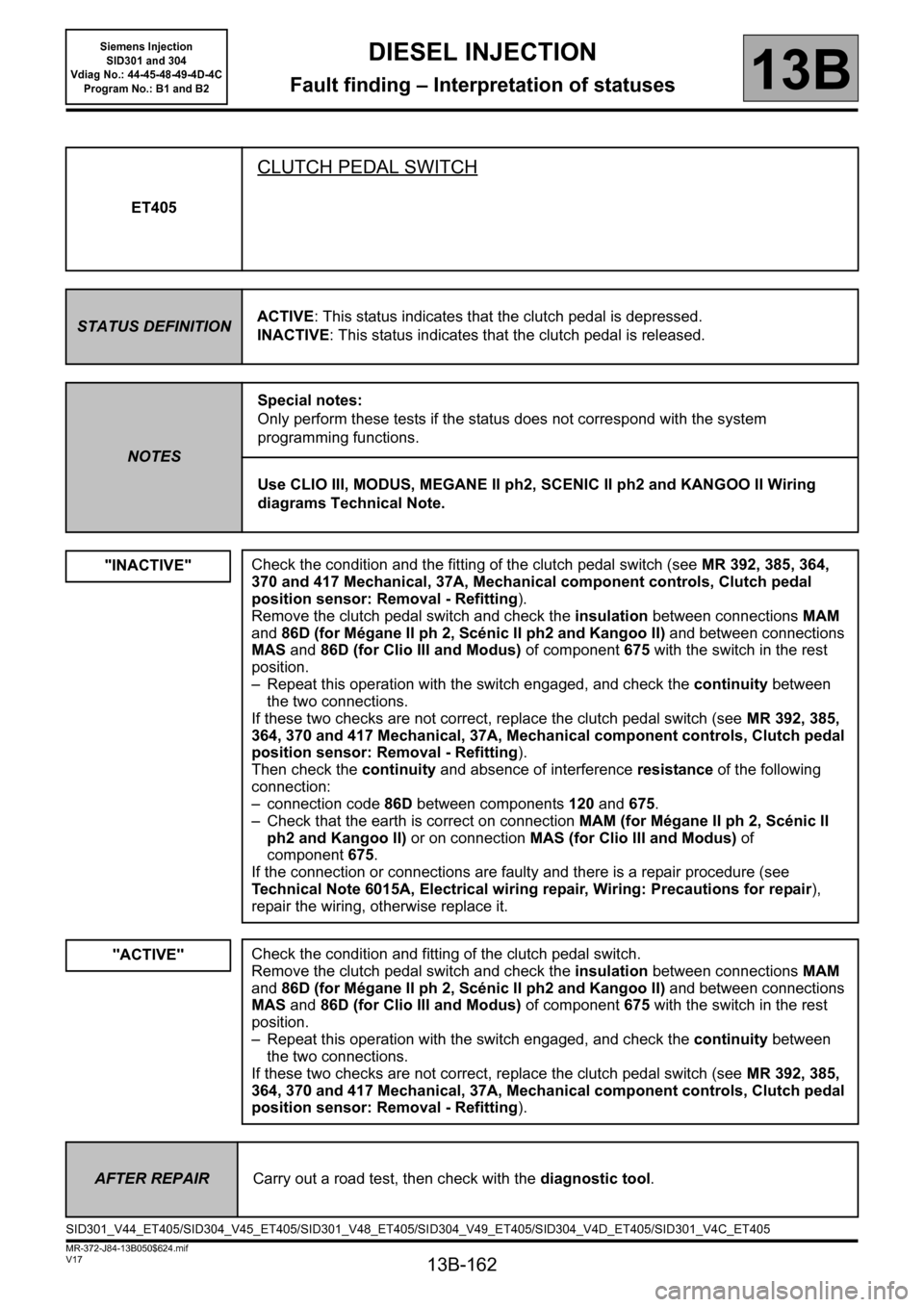

ET405

CLUTCH PEDAL SWITCH

STATUS DEFINITIONACTIVE: This status indicates that the clutch pedal is depressed.

INACTIVE: This status indicates that the clutch pedal is released.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

"INACTIVE"

Check the condition and the fitting of the clutch pedal switch (see MR 392, 385, 364,

370 and 417 Mechanical, 37A, Mechanical component controls, Clutch pedal

position sensor: Removal - Refitting).

Remove the clutch pedal switch and check the insulation between connections MAM

and 86D (for Mégane II ph 2, Scénic II ph2 and Kangoo II) and between connections

MAS and 86D (for Clio III and Modus) of component675 with the switch in the rest

position.

– Repeat this operation with the switch engaged, and check the continuity between

the two connections.

If these two checks are not correct, replace the clutch pedal switch (see MR 392, 385,

364, 370 and 417 Mechanical, 37A, Mechanical component controls, Clutch pedal

position sensor: Removal - Refitting).

Then check the continuity and absence of interference resistance of the following

connection:

– connection code 86D between components 120 and 675.

– Check that the earth is correct on connectionMAM (for Mégane II ph 2, Scénic II

ph2 and Kangoo II) or on connectionMAS (for Clio III and Modus) of

component675.

If the connection or connections are faulty and there is a repair procedure (see

Technical Note 6015A, Electrical wiring repair, Wiring: Precautions for repair),

repair the wiring, otherwise replace it.

"ACTIVE"Check the condition and fitting of the clutch pedal switch.

Remove the clutch pedal switch and check the insulation between connections MAM

and 86D (for Mégane II ph 2, Scénic II ph2 and Kangoo II) and between connections

MAS and 86D (for Clio III and Modus) of component675 with the switch in the rest

position.

– Repeat this operation with the switch engaged, and check the continuity between

the two connections.

If these two checks are not correct, replace the clutch pedal switch (see MR 392, 385,

364, 370 and 417 Mechanical, 37A, Mechanical component controls, Clutch pedal

position sensor: Removal - Refitting).

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID301_V44_ET405/SID304_V45_ET405/SID301_V48_ET405/SID304_V49_ET405/SID304_V4D_ET405/SID301_V4C_ET405

Page 176 of 329

13B-176

MR-372-J84-13B050$624.mif

V17

13B

DIESEL INJECTION

Fault finding – Interpretation of statuses

*elec: electric

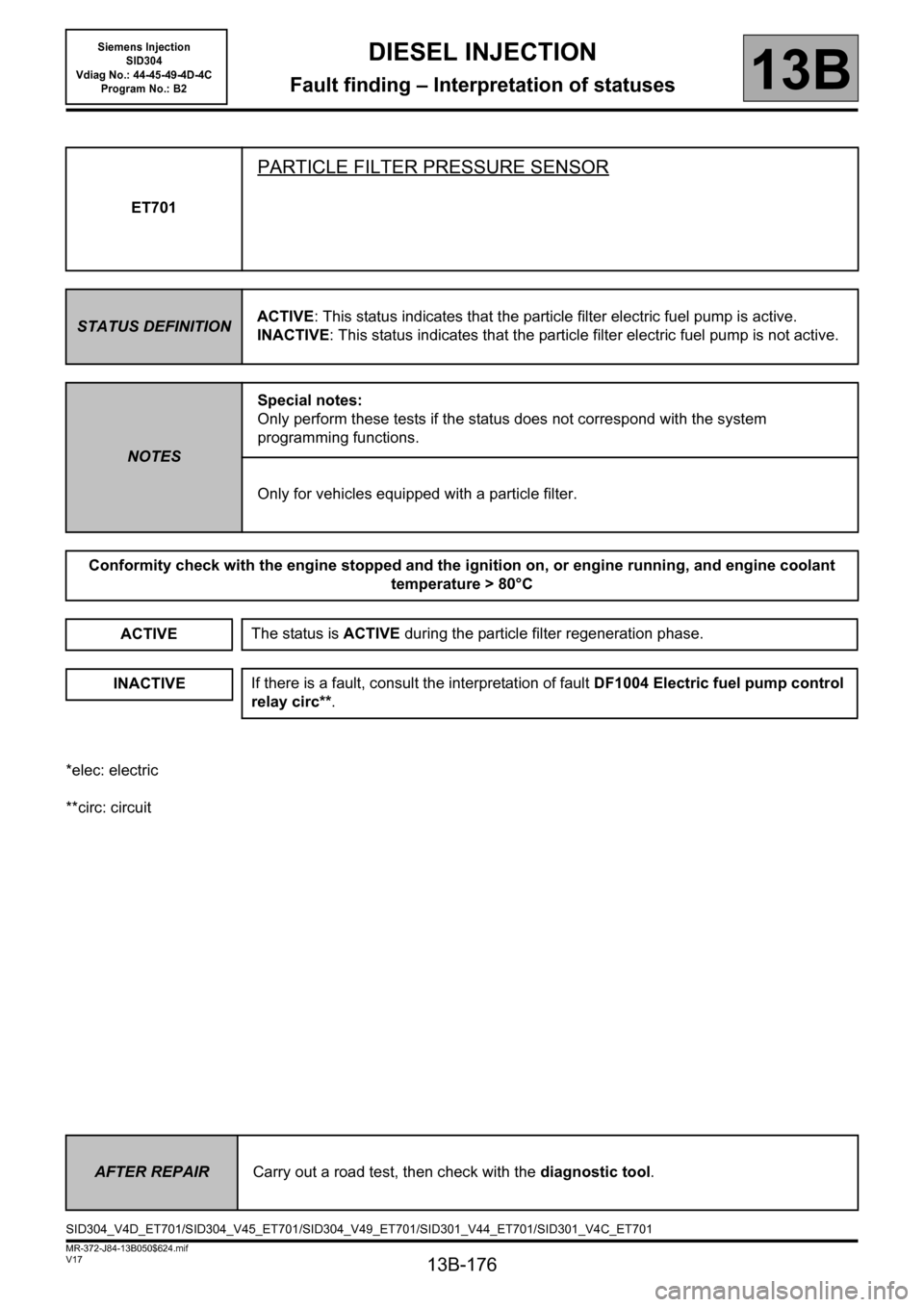

**circ: circuitET701

PARTICLE FILTER PRESSURE SENSOR

STATUS DEFINITIONACTIVE: This status indicates that the particle filter electric fuel pump is active.

INACTIVE: This status indicates that the particle filter electric fuel pump is not active.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

Only for vehicles equipped with a particle filter.

Conformity check with the engine stopped and the ignition on, or engine running, and engine coolant

temperature > 80°C

ACTIVE

INACTIVE

The status is ACTIVE during the particle filter regeneration phase.

If there is a fault, consult the interpretation of fault DF1004 Electric fuel pump control

relay circ**.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID304_V4D_ET701/SID304_V45_ET701/SID304_V49_ET701/SID301_V44_ET701/SID301_V4C_ET701

Siemens Injection

SID304

Vdiag No.: 44-45-49-4D-4C

Program No.: B2

Page 186 of 329

13B-186

MR-372-J84-13B050$663.mif

V17

13B

DIESEL INJECTION

Fault finding – Parameter summary table

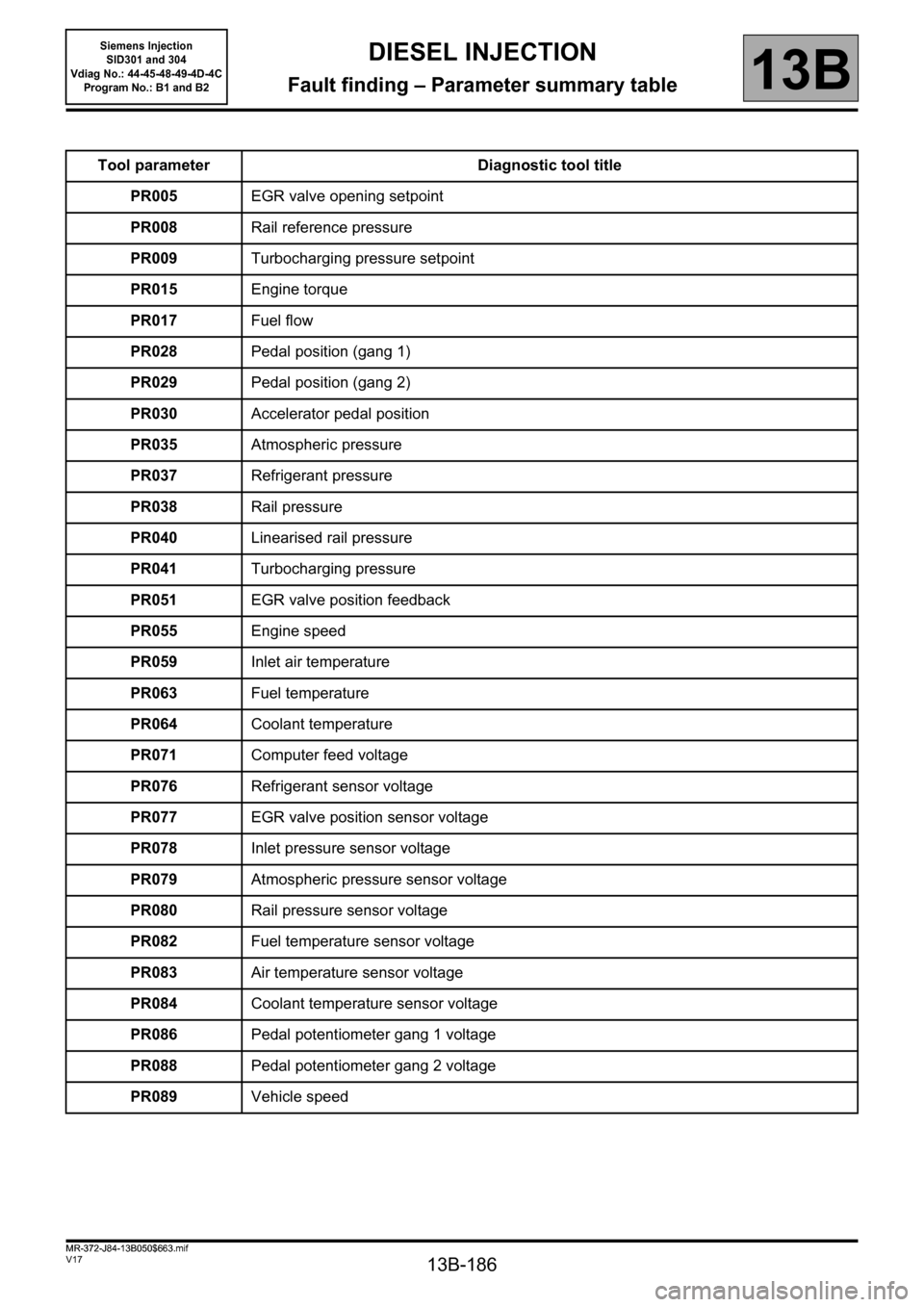

Tool parameter Diagnostic tool title

PR005EGR valve opening setpoint

PR008Rail reference pressure

PR009Turbocharging pressure setpoint

PR015Engine torque

PR017Fuel flow

PR028Pedal position (gang 1)

PR029Pedal position (gang 2)

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR040Linearised rail pressure

PR041Turbocharging pressure

PR051EGR valve position feedback

PR055Engine speed

PR059Inlet air temperature

PR063Fuel temperature

PR064Coolant temperature

PR071Computer feed voltage

PR076Refrigerant sensor voltage

PR077EGR valve position sensor voltage

PR078Inlet pressure sensor voltage

PR079Atmospheric pressure sensor voltage

PR080Rail pressure sensor voltage

PR082Fuel temperature sensor voltage

PR083Air temperature sensor voltage

PR084Coolant temperature sensor voltage

PR086Pedal potentiometer gang 1 voltage

PR088Pedal potentiometer gang 2 voltage

PR089Vehicle speed

MR-372-J84-13B050$663.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

Page 187 of 329

13B-187

MR-372-J84-13B050$663.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Parameter summary table13B

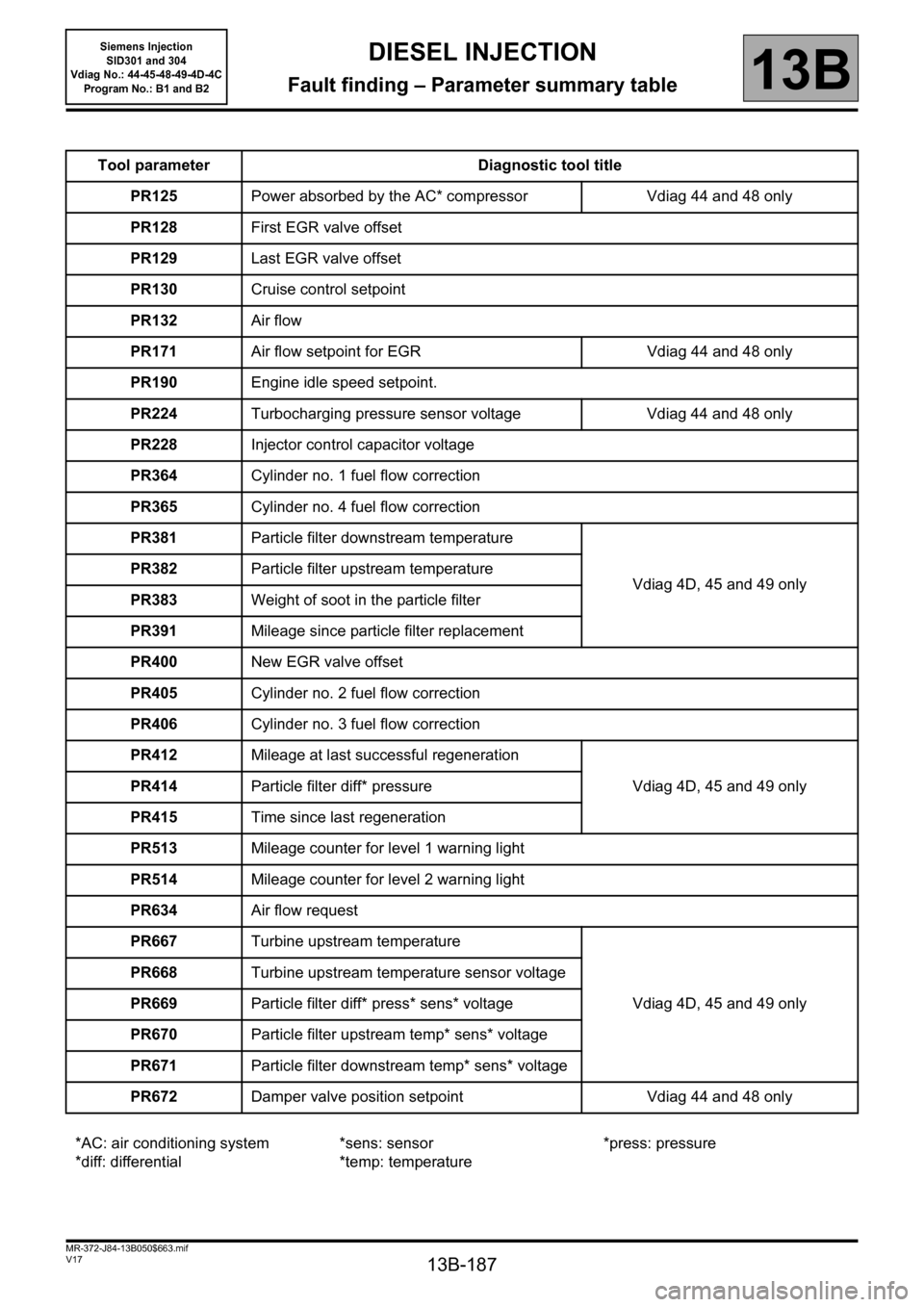

Tool parameter Diagnostic tool title

PR125Power absorbed by the AC* compressor Vdiag 44 and 48 only

PR128First EGR valve offset

PR129Last EGR valve offset

PR130Cruise control setpoint

PR132Air flow

PR171Air flow setpoint for EGR Vdiag 44 and 48 only

PR190Engine idle speed setpoint.

PR224Turbocharging pressure sensor voltage Vdiag 44 and 48 only

PR228Injector control capacitor voltage

PR364Cylinder no. 1 fuel flow correction

PR365Cylinder no. 4 fuel flow correction

PR381Particle filter downstream temperature

Vdiag 4D, 45 and 49 only PR382Particle filter upstream temperature

PR383Weight of soot in the particle filter

PR391Mileage since particle filter replacement

PR400New EGR valve offset

PR405Cylinder no. 2 fuel flow correction

PR406Cylinder no. 3 fuel flow correction

PR412Mileage at last successful regeneration

Vdiag 4D, 45 and 49 only PR414Particle filter diff* pressure

PR415Time since last regeneration

PR513Mileage counter for level 1 warning light

PR514Mileage counter for level 2 warning light

PR634Air flow request

PR667Turbine upstream temperature

Vdiag 4D, 45 and 49 only PR668Turbine upstream temperature sensor voltage

PR669Particle filter diff* press* sens* voltage

PR670Particle filter upstream temp* sens* voltage

PR671Particle filter downstream temp* sens* voltage

PR672Damper valve position setpoint Vdiag 44 and 48 only

*AC: air conditioning system

*diff: differential*sens: sensor

*temp: temperature*press: pressure

Page 188 of 329

13B-188

MR-372-J84-13B050$663.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Parameter summary table13B

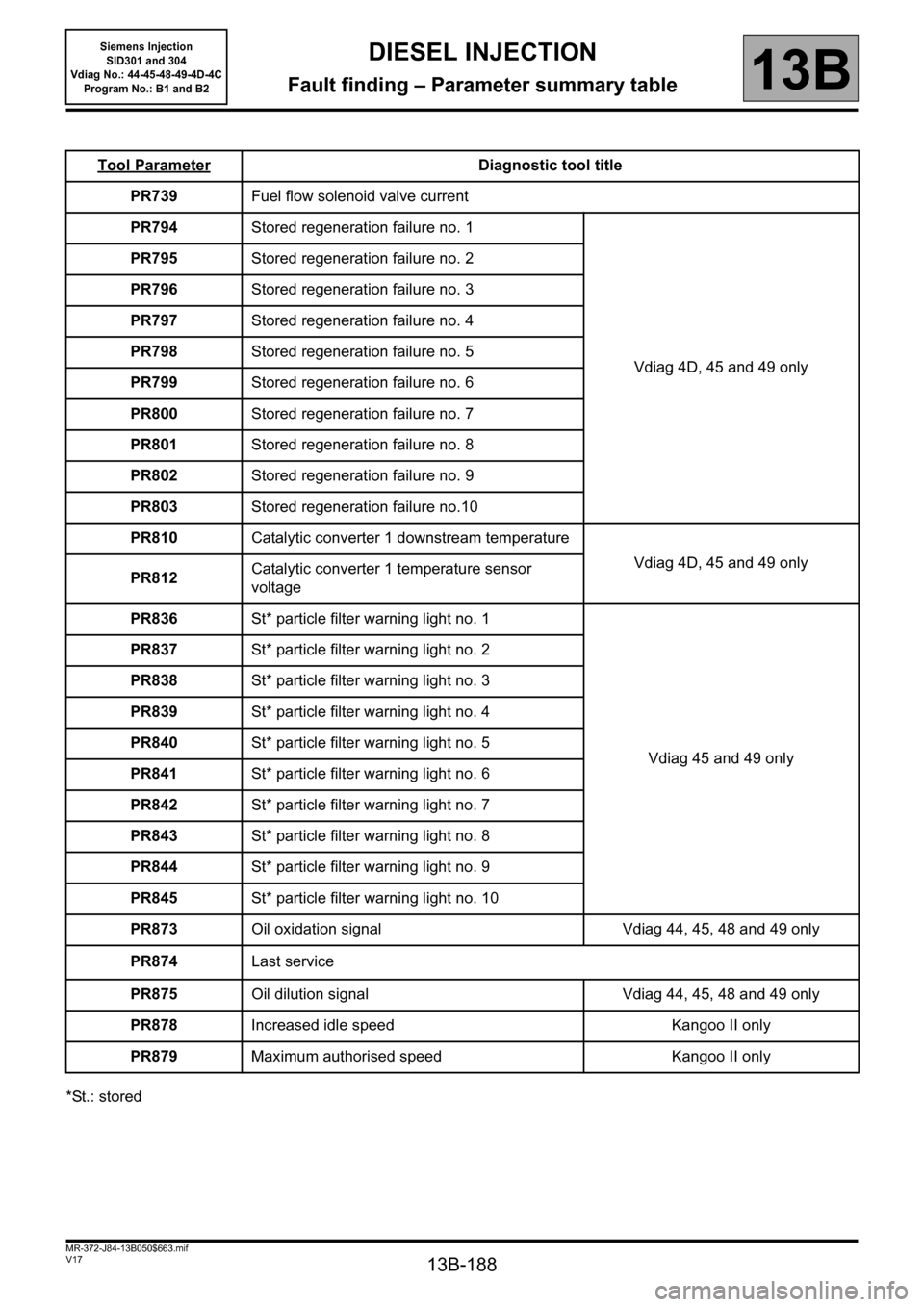

*St.: storedTool Parameter

Diagnostic tool title

PR739Fuel flow solenoid valve current

PR794Stored regeneration failure no. 1

Vdiag 4D, 45 and 49 only PR795Stored regeneration failure no. 2

PR796Stored regeneration failure no. 3

PR797Stored regeneration failure no. 4

PR798Stored regeneration failure no. 5

PR799Stored regeneration failure no. 6

PR800Stored regeneration failure no. 7

PR801Stored regeneration failure no. 8

PR802Stored regeneration failure no. 9

PR803Stored regeneration failure no.10

PR810Catalytic converter 1 downstream temperature

Vdiag 4D, 45 and 49 only

PR812Catalytic converter 1 temperature sensor

voltage

PR836St* particle filter warning light no. 1

Vdiag 45 and 49 only PR837St* particle filter warning light no. 2

PR838St* particle filter warning light no. 3

PR839St* particle filter warning light no. 4

PR840St* particle filter warning light no. 5

PR841St* particle filter warning light no. 6

PR842St* particle filter warning light no. 7

PR843St* particle filter warning light no. 8

PR844St* particle filter warning light no. 9

PR845St* particle filter warning light no. 10

PR873Oil oxidation signal Vdiag 44, 45, 48 and 49 only

PR874Last service

PR875Oil dilution signal Vdiag 44, 45, 48 and 49 only

PR878Increased idle speed Kangoo II only

PR879Maximum authorised speed Kangoo II only

Page 194 of 329

13B-194

MR-372-J84-13B050$702.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of parameters

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

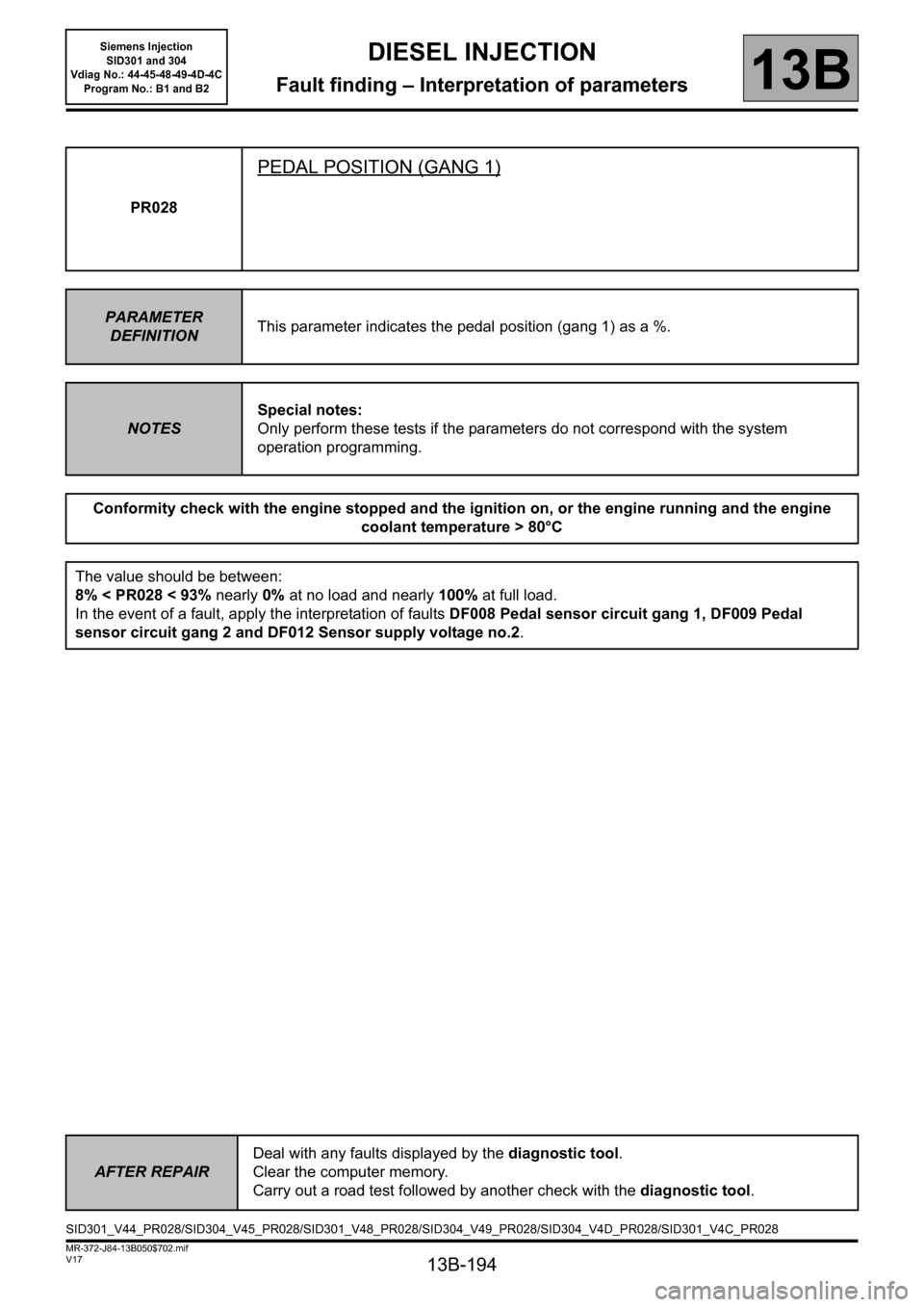

PR028

PEDAL POSITION (GANG 1)

PARAMETER

DEFINITIONThis parameter indicates the pedal position (gang 1) as a %.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

Conformity check with the engine stopped and the ignition on, or the engine running and the engine

coolant temperature > 80°C

The value should be between:

8% < PR028 < 93% nearly 0% at no load and nearly 100% at full load.

In the event of a fault, apply the interpretation of faults DF008 Pedal sensor circuit gang 1, DF009 Pedal

sensor circuit gang 2 and DF012 Sensor supply voltage no.2.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_PR028/SID304_V45_PR028/SID301_V48_PR028/SID304_V49_PR028/SID304_V4D_PR028/SID301_V4C_PR028

Page 195 of 329

13B-195

MR-372-J84-13B050$702.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of parameters

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

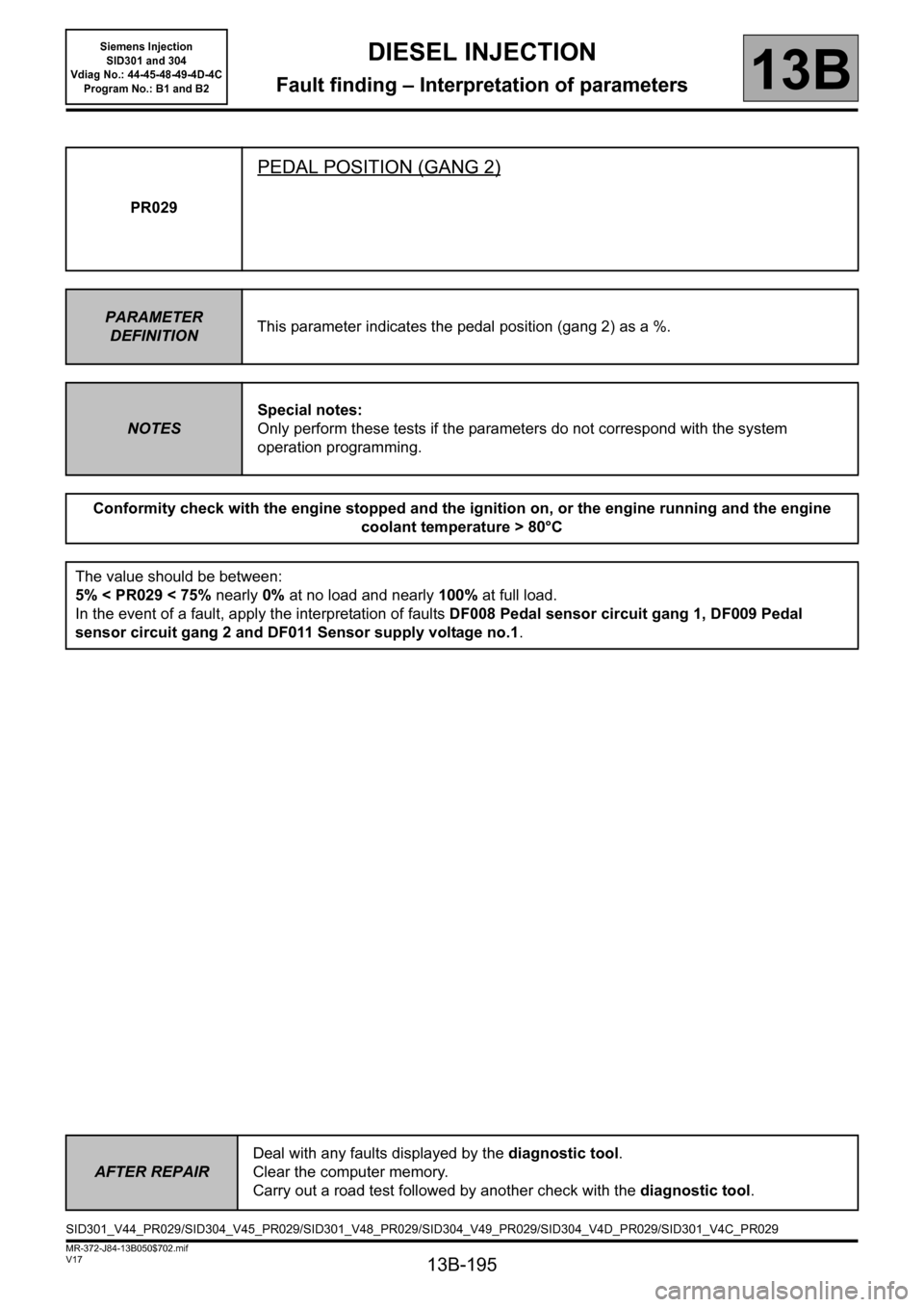

PR029

PEDAL POSITION (GANG 2)

PARAMETER

DEFINITIONThis parameter indicates the pedal position (gang 2) as a %.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

Conformity check with the engine stopped and the ignition on, or the engine running and the engine

coolant temperature > 80°C

The value should be between:

5% < PR029 < 75% nearly 0% at no load and nearly 100% at full load.

In the event of a fault, apply the interpretation of faults DF008 Pedal sensor circuit gang 1, DF009 Pedal

sensor circuit gang 2 and DF011 Sensor supply voltage no.1.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_PR029/SID304_V45_PR029/SID301_V48_PR029/SID304_V49_PR029/SID304_V4D_PR029/SID301_V4C_PR029

Page 196 of 329

13B-196

MR-372-J84-13B050$702.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of parameters

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

PR030

ACCELERATOR PEDAL POSITION

PARAMETER

DEFINITIONThis parameter indicates the accelerator pedal position in %.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

There must be no present or stored faults.

Perform this fault finding procedure:

– after finding an inconsistency in the parameter,

– after a customer complaint (e.g. lack of power).

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

Diagrams Technical Notes.

Conformity check with the engine stopped and the ignition on, or the engine running and the engine

coolant temperature > 80°C

If no pressure is exerted on the pedal PR030 = 0%.

In the event of a fault, refer to the interpretation of fault DF008 Pedal potentiometer circuit gang 1 or

DF009 Pedal potentiometer circuit gang 2.

Sensor electrical conformity

Check the continuity and absence of interference resistance of the following connections:

– connection code3LR,

– connection code3LS,

– connection code3LT,

– connection code3LU,

– connection code3LW,

– connection code3LV,

between components 120 and 921.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_PR030/SID304_V45_PR030/SID301_V48_PR030/SID304_V49_PR030/SID304_V4D_PR030/SID301_V4C_PR030

Page 197 of 329

13B-197

MR-372-J84-13B050$702.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of parameters

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

PR030

CONTINUED

Pedal sensor connected, vehicle ignition on and engine stopped:

– check that the value of PR030 Accelerator pedal position:

0% no load,

100% full load,

138% full load after pedal kickdown point.

– If the value is not correct, replace the accelerator pedal sensor (see MR 392, 385, 364, 370

and 417

Mechanical, 37A, Mechanical component controls, Accelerator pedal: Removal - Refitting).

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.